This site contains details of what I do – it does not mean that it is safe or legal for you to do the same, and I accept no responsibility if you do. You are responsible for ensuring that what you do is within your capabilities and is safe and legal in your country. Guns, even antiques, can be dangerous and if you don’t know what you are doing get expert help. Many antique guns are of historic and/or financial value, and its your responsibility to find out if what you want to do will damage their value. Remember, leaving them as they are won’t diminish their value but inappropriate repair might well make them worth less, maybe much less! If in doubt don’t do it.

______________________________________________________

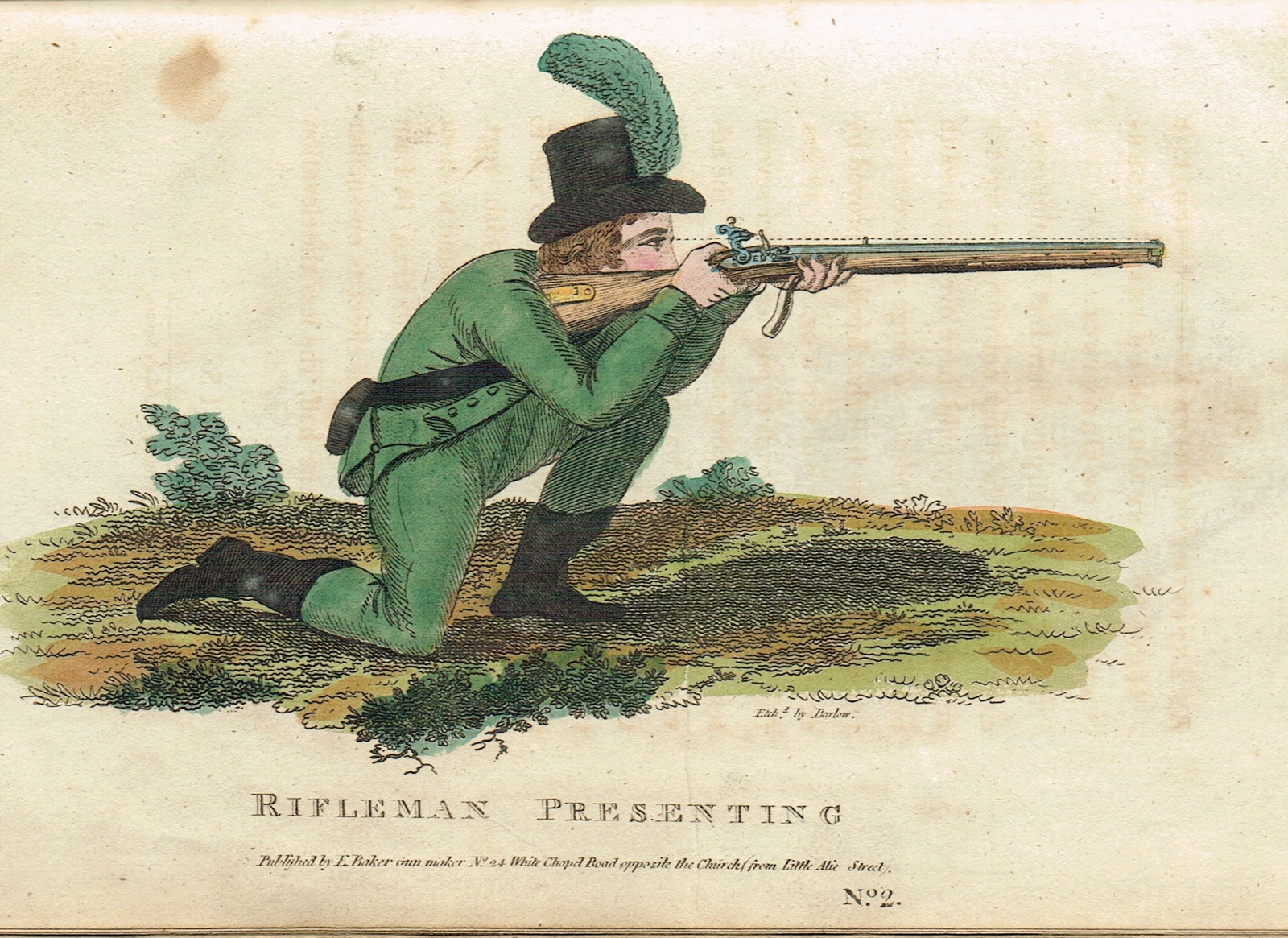

I assume he is holding the sling out of the way with his left hand? from Ezakial Baker’s Practice etc..

Find your way around – There is a MENU of PAGES used for fixed items along the top of the screen.

All the regular POSTS are in the HOME page – use the menus on the right to jump to whichever POST you want, or the MENU below the header will show you POSTS that are relevant to the given subject and the top menu on the right will keep you up to date with changes…

Welcome to my site – you’ll find this post is a sort of diary where I put things I’m doing that are (almost) relevant to the subject – they ‘fall off the bottom’ after a few weeks – bits from the diary may get put into existing or new posts when they fall off. Please feel free to contact me via the comments box in each post or by my email as per the CONTACT tab at the top. If I can I will respond – email will usually get a quicker response. I am fond of obscure English sayings which are marked* – you can look them up on Google if you need to interpret them.

(Photos on this site are copyright unless attributed)

___________________ DIARY ______________________

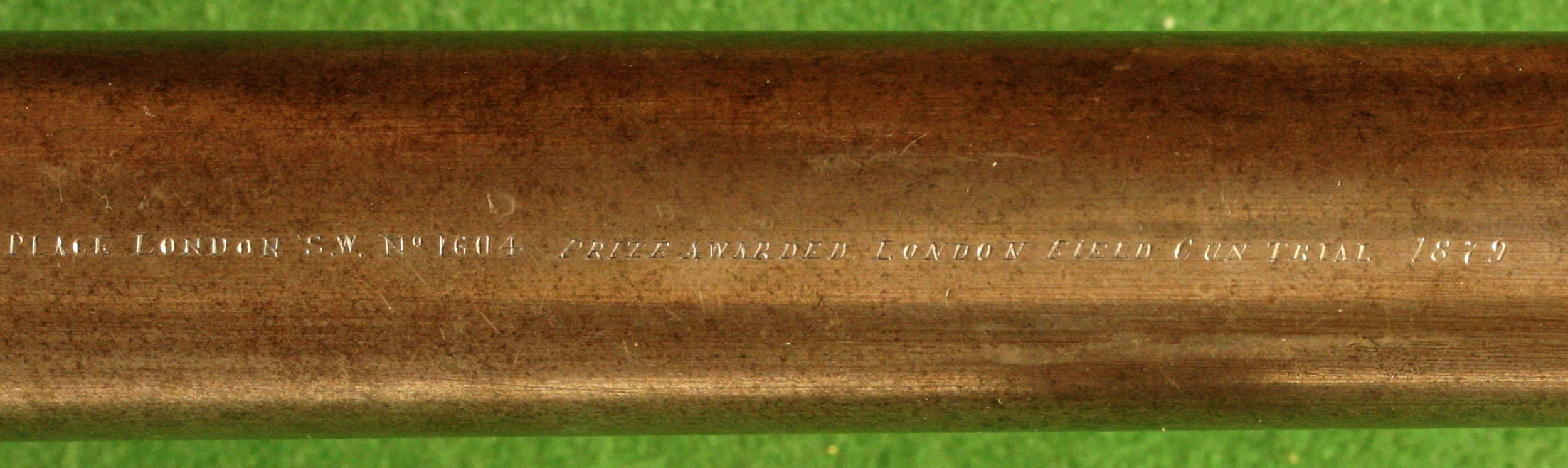

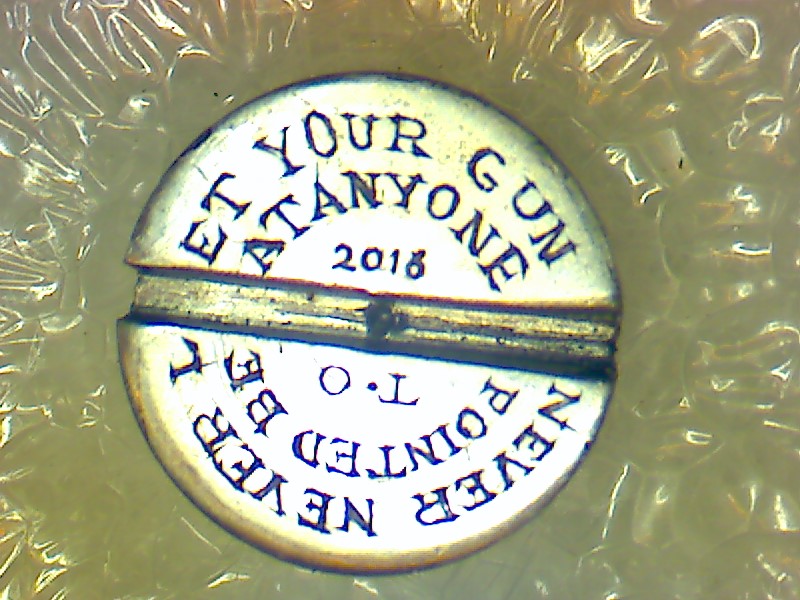

9th May – I’m back now, so can get back to keeping the blog up to date and doing a bit of gun play! Sunday at the Northern Shooting Show is more of a family day out – Saturday is for the serious shooters, so I had a steady stream of spectators but no so much involvement, although I did run out of screws to engrave and give away! It was mighty chilly again, but I snook off to a hotel for Sunday night before going to visit the Royal Armouries at Leeds at the invitation of an Emeritus curator who had come across this blog. I had a tour of the incredible museum with my expert guide, but the highlight was a visit to the store room where the full collection is held, where my host highlighted some incredible guns – the collection has everything, but is a bit light on the purely presentational stuff, which suits me as I prefer antiques that were made for use. It really made me revise my ideas about the standard of workmanship possible – some of the fine engraving and steel carving of the European gunmakers is staggering, and made me realise how crude most of the stuff I do is. Being able to handle some of them (with cotton gloves!) was awsome. I would love to put together a book on gun engraving, which would in reality have to be a picture book with fantastic photos – its been a long term ambition of mine to do it – I had better learn to take better photographs and chat up the armouries and a few museums! Anyway I’m inspired to try harder with my engraving – I hadn’t done much in the months before the show, and it took me all Saturday to get back into the swing of it – when I haven’t done any for a while I always end up breaking the tips off gravers – on Saturday morning I had a dump of half a dozen broken tips by half way through the morning, and it wasn’t until Sunday morning that I had the knack of sharpening the gravers to cut sweetly. One interesting aspect of engraving I shared with a couple of engravers who visited the stand was that they too found that a freshly sharpened graver needed to wear down a little before it was cutting at its best, which explains why I don’t often use my very hard Glensteel gravers as they don’t seem to get to the sweet spot. I think they are much more popular with the GRS and Lindsay users where the feel of the cut is masked by the powered cutting – another point that was made to me was how different the engraving from these machines, and from chasing, look compared to that done by simple push engraving – as readers of this blog will be aware, it’s a point I feel strongly about. I can tell at a glance which technique was used to cut a design.

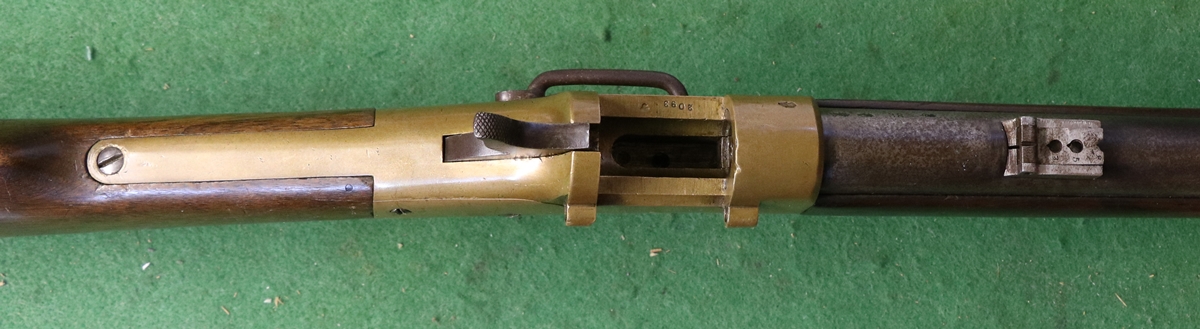

Along with my visit to the Royal Armouries I got to visit the National Firearms Collection which is near the Armouries – its the formal national collection of arms, particularly military arms, including modern arms from all nations, and arms kept for forensic purposes – as at the Armouries, most of the military stuff is in quantities that would arm a platoon or two, so its a massive warehouse. I was very privileged to visit as its normally out of bounds through three sets of security doors – but I was able to handle the 1864 Warner Carbine, and see how the breech block was configured so I can think about making one for mine – unfortunately I had to hand over my phone at the entrance so couldn’t photograph it. I’d thoroughly recommend a visit to the Armouries – entrance is free and its awsome – go before trendy new museum folk get rid of all the guns from the displays because its not politically correct!

6th May – Very busy day at the Northern Shooting Show with lots of interest in gun engraving. I gave away lots of engraved screws to children and several to adults. I had visits from several people who have visited this website, which was very satisfying, including a couple of engravers who were also re-enactors – one who even knew what ‘narlbending’ was! (It’s the Viking answer to knitting and is how they made their socks – don’t say this website doesn’t educate you in directions you never thought possible). Anyway its pretty chilly here but we are looking forward to another busy day tomorrow. The popularity of the show is put down to the reasonable entrance price compared to many (£10). Anyway, I’m looking forward to welcoming more website visitors tomorrow.

4th May – I went with Dick to see a firearms dealer in the south of England, and saw amongst his many hundreds of old guns one that would qualify for my collection of curious firearms inventions. It was a percussion double shotgun with back action locks, well made and signed Firearms Manufactory (?) on the barrel, the locks unsigned. Its special feature was a framework pivoted either side on the front lower corner of the lockplates that carried a bridge that in the backward position introduced 2 pads in the way of the cocks to prevent them hitting the nipples. The bridge was moved by a spring loaded sliding member under the fore end with a trigger shaped frame sticking down at the front of the fore end. To fire the gun the ‘trigger’ had to be pulled back by the left hand while it was supporting the gun, against the fairly strong spring, in order to swing the pads out of the path of the cocks. It seemed a very difficult maneuver to operate the trigger at the same time as shooting the gun. It was quite a decently made gun but totally impractical – a relic of a short period when percussion guns were thought more dangerous than flintlocks and some odd safety devices were patented. I am sorry to say I didn’t get a photo, but I did express an interest and I will follow it up. I’m more or less ready to set off for Harrogate – my contact at the Royal Armories tells me the good news that there are one or more Warner’s patent carbines to view. If you are at the Northern Shooting show be sure to visit the Artisans and Classics pavilion opposite Hall 1 and introduce yourself to me – I’ll be behind my microscope!

3rd May – The number of attacks on this site dropped quite dramatically a few days ago – from about 100 a day to about 25 – there seem to have been a network of ‘bots’ installed on hacked computers that was actively targeting all WordPress sites (this one uses wordpress) under the control a a hacker controlled computer that stayed hidden. It looks as if the network has more or less stopped its activities – we hope permanently but who knows? Maybe one of the security services has taken it out? There is a whole dirty world out there!

3rd May – Still sorting out what to take of interest to display at the show this w/e. I’ll gather all the military flint and percussion pistols I can lay hands on as they are popular. One of my objectives in visiting the Royal Armouries is to see the Warner’s Patent carbine I believe they have. I have one that is missing its breech block, and if I could get a really good look at a similar one, I’d have a go at making a new one – I have a piece of brass that is about the right colour that I rough cast into a block some time ago – I think its enough for two goes… The Warner carbine was one of many carbine designs rushed out for the American Civil war in 1864 – like many of the other designs, the military was so desperate that they ordered some of each, and about 4001 Warners were made by Warner and later by Greene Rifle Works in Worcester mass. Most of these were never issue and were sold off in 1866 at the end of hostilities – many ending up in France. Some appear to have ended up in England and have London proof marks – they are .50 calibre, although many were made for 56-56 Spencer cartridges. The breech mechanism is similar to the Snider, except that it has a separate slider in front of the trigger to move the extractor claw. Presumably the gun then had to be turned over to drop the case out as it would be too hot to handle for a minute or so. It will go to the show, and I’ll take my rough old Snider 1853 carbine conversion as a comparison.

2nd May – It being Giles’s birthday we went out for a meal instead of concentrating on this blog – disgraceful! Today I began to sort out stuff to take up to Harrogate for the Northern Shooting Show, and making labels for the guns and pistols I’ll take. I’m looking forward to going to the Royal Armouries after the show – somehow York seems miles away, whereas its only about 3 hours drive, so I should have gone ages ago! I had a battle with the printer trying to get it to print a batch of business cards to take – sometimes I think technology is taking its revenge for the 40 odd years I spent pushing it around to achieve my evil ways (or something like that)! If anyone reading this wants to see any particular guns at Harrogate, let me know!

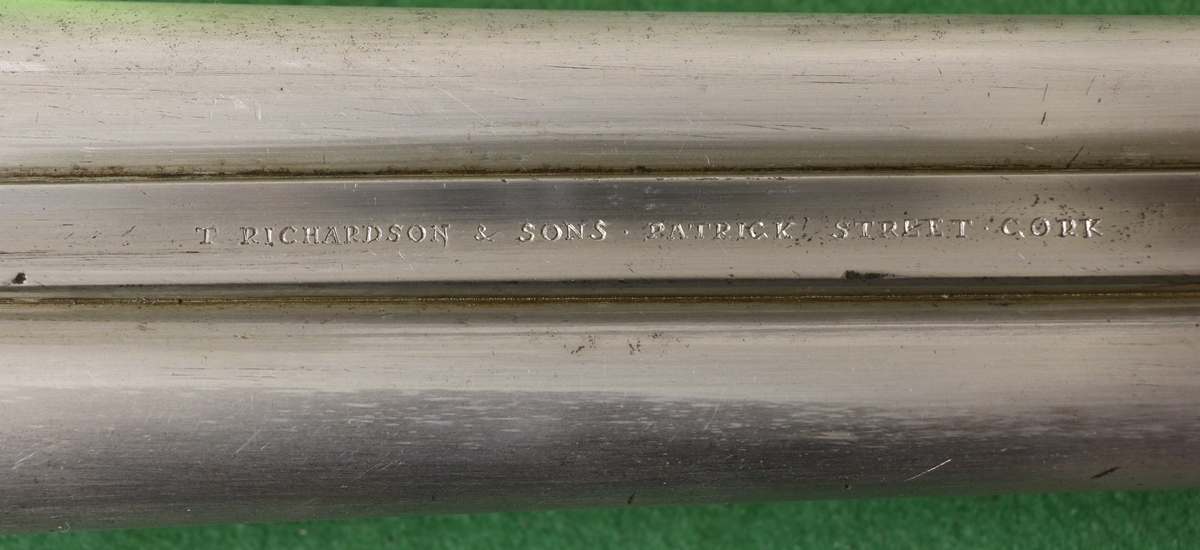

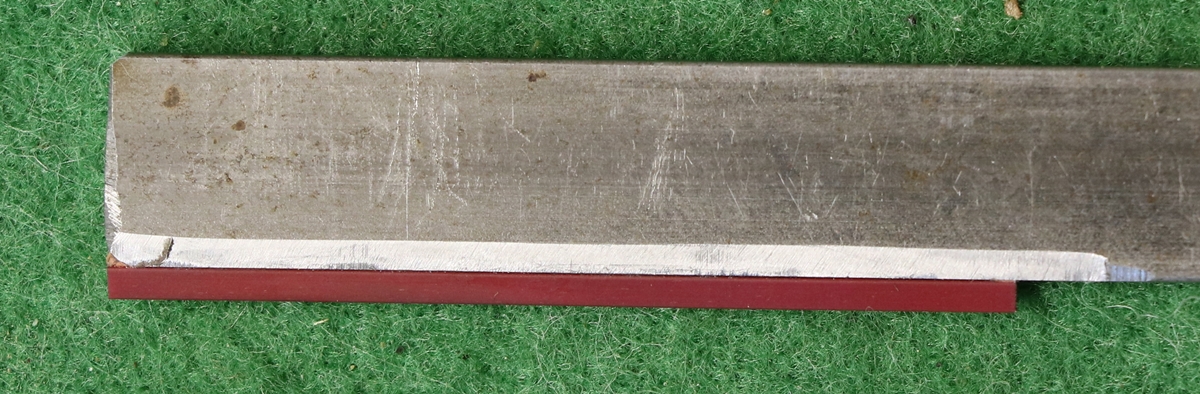

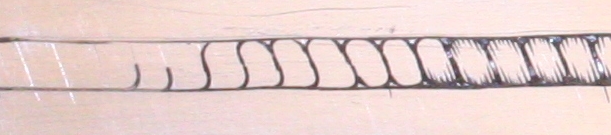

1st May I decided to clean out some of the workshop to celebrate the bank holiday, but didn’t get far. I did sharpen about 20 gravers, but then blunted or chipped half a dozen engraving a barrel for Martin – engraving barrels is always difficult because you can’t rotate the workpiece to do curves – you have to do it all with the tool and as I am limited as to where I can point the barrel some cuts are quite awkward and you end up cutting curves the ‘un-natural’ way – clockwise is more difficult for a right handed person. This barrel still had a fairly crisp coating of rust/browning that made it more difficult still as the metal underneath was softer than the surface layer – anyway its got done! I wiped it over with G96 gun blue that turned it dark and made it look as if it had always been there….

30th April – Went to North Norfolk for lunch with friends followed by a long walk so nothing much to report. As often happens the number of visitors to this site goes down at weekends, but only by a little – it now gets over 200 visitors a day on average, and each visitor looks at an average of from 5 to 15 different posts. Add to that around 60 visitors a day who get stopped from visiting the site because they are up to no good, and it makes the site quite popular, given its specialist nature! It is difficult to ascertain exactly how many of those visits are from regulars, but it looks as if up to half of the visitors have visited the site before. Around 20 visits to the site come from searches, almost all through Google. Most of the visits come from the UK and the US, but the list of countries that have visited since the site went live a couple of years ago totaled 182 when I last looked – I didn’t know there were that many countries! I suppose that almost all the visits from obscure countries like Papua New Guinea and Ulan Bator are actually the hackers in other countries using hacked computers in those countries to attempt logins, and all of those will have been blocked by the software. I have some difficulty in knowing which statistics include the blocked visits, and which exclude them. There is a long blacklist of visitors who have tried to hack into the site, and they are permanently blocked from any access to the site. Keeping the site interesting and safe is quite a labour, but its gratifying when I get appreciative emails and comments, which I do quite often, usually tied to questions about guns they have recently acquired and want to know what they are and if we will repair them – I’ve made a number of interesting acquaintances that way!

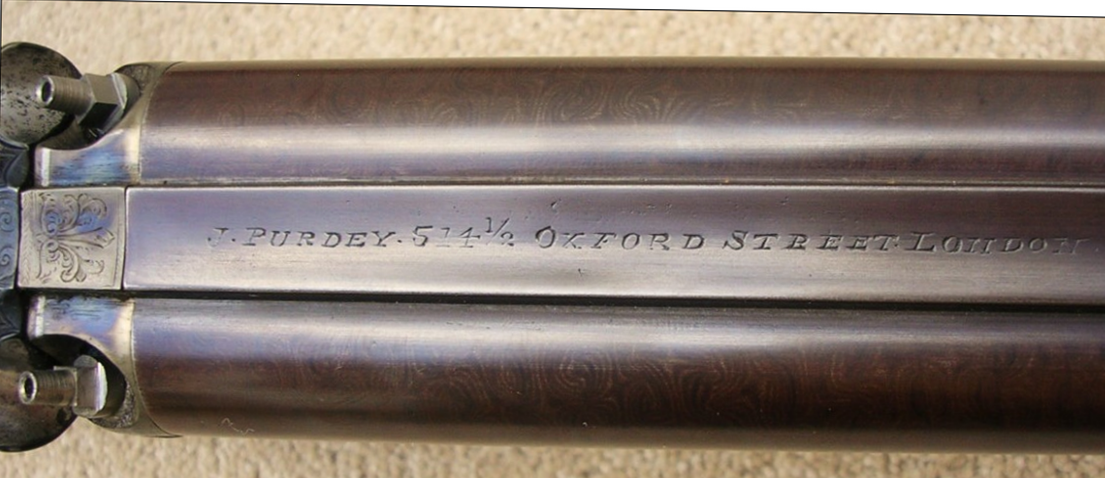

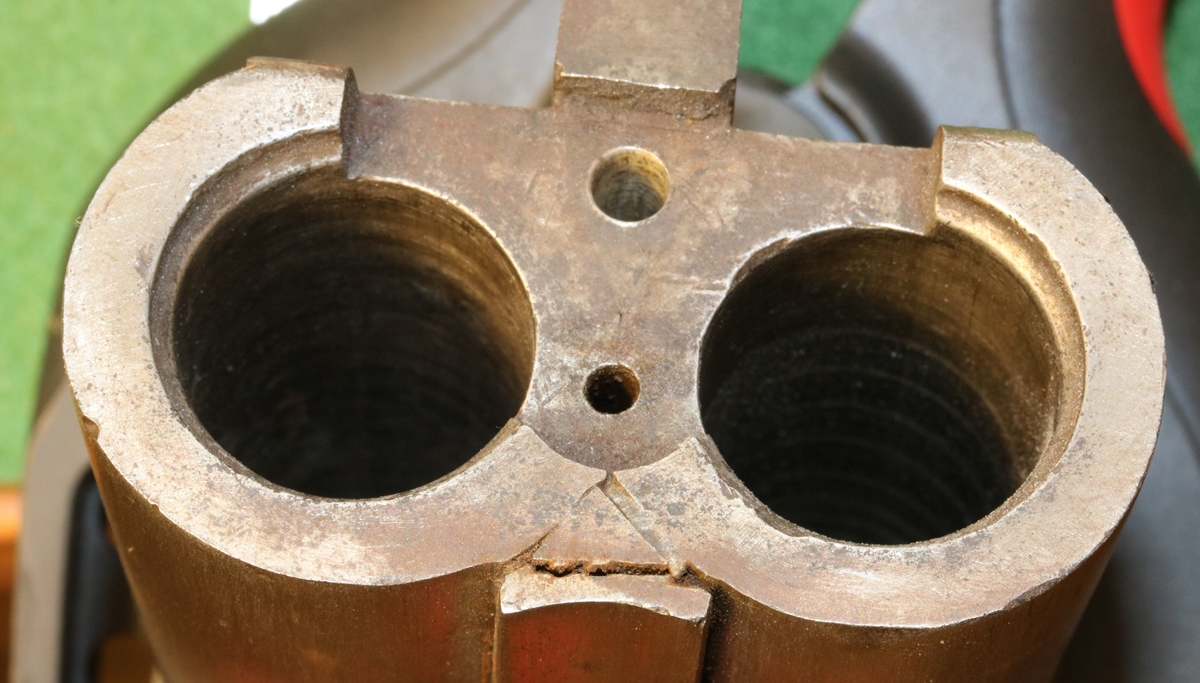

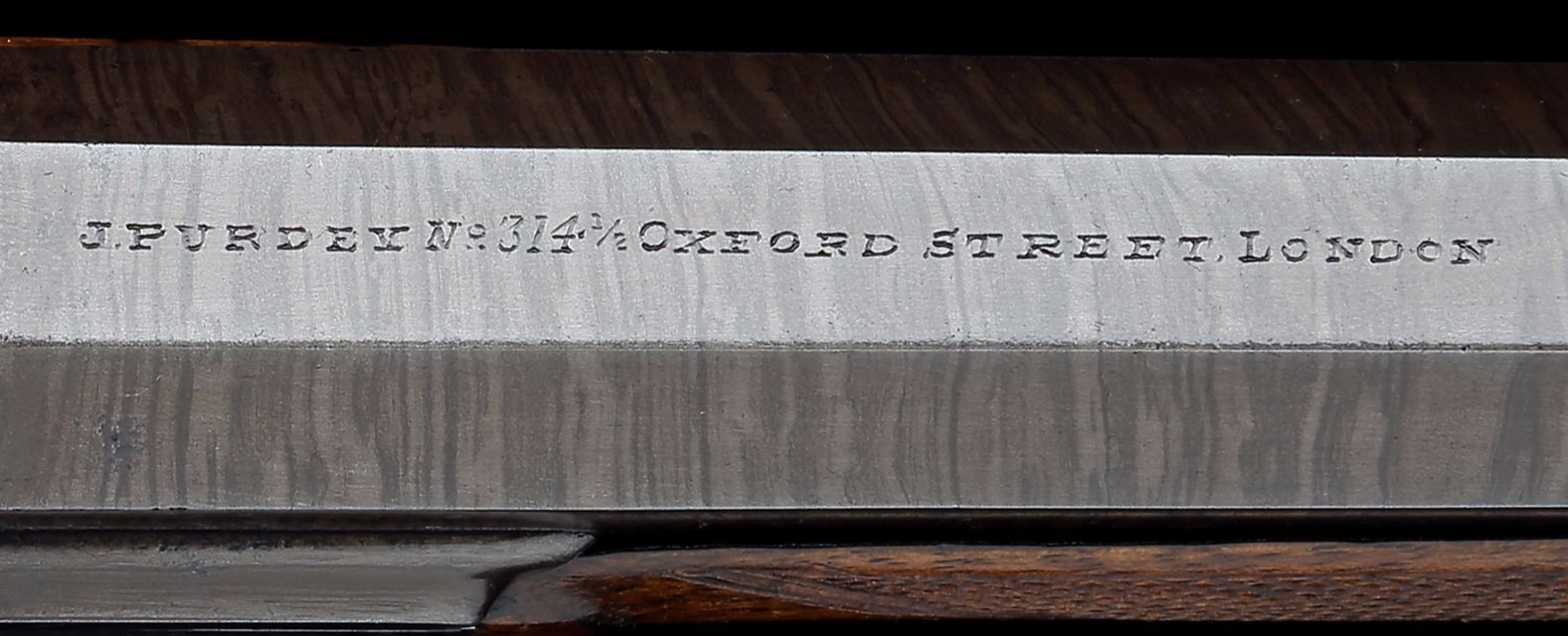

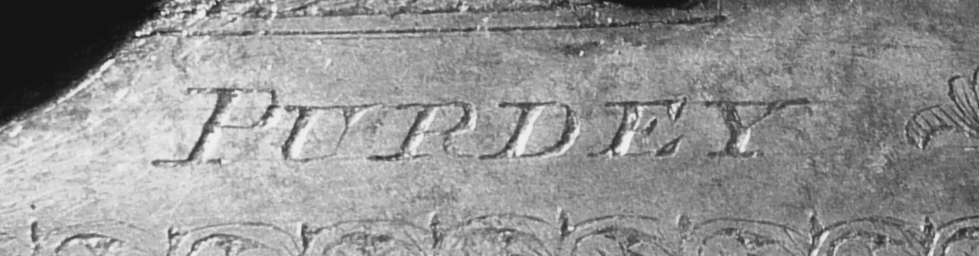

29 April – Derusted Dick’s bits and pieces – I had to clean out the old washing-up bowl I use for electrolysis as it was getting a bit full of rust – the process effectively takes the rust off the objects and puts it on the piece of scrap steel that is used as the other (+ve) electrode – if course it doesn’t actually do that, its just looks like that! In fact the electric current splits water molecules into hydrogen that is released at the object, and oxygen at the scrap electrode. The hydrogen and oxygen are in a very reactive state (nascent) so the oxygen rusts the electrode and the hydrogen reduces the rust (iron oxide) on the object to a different form that doesn’t adhere and becomes a dark powder that is easily removed. The caustic soda in the solution is just so that current will flow through the water, but it has the added advantage that it attacks any oil and grease on the parts. See the article in ARTICLES page for how to do it. The parts of the Witton and Daw (see photo below) were done in two batches, each for about an hour, at a constant current of about 2.5 Amps with the voltage around 10 volts. Doing all the small parts is tedious, but I have a number of wires with miniature crocodile clips to hold screws etc They were then dried and fine wire brushed and lightly sprayed with Napier cleaner that contains a vapour phase inhibitor VP 90. When I went up to look at the Sandringham gun collection Purdey’s were there checking the guns, they didn’t oil any of the guns – just put a fresh VP 90 sachet or two in each display case – I keep a sachet in each gun cabinet or cupboard – if its good enough for Purdey and the Royal guns, its good enough for me!.

Fine scroll engraving, the finial on the triggerplate is particularly fine and in perfect condition. There are some deep corrosion pits in the flash guards – it might be worth welding and reshaping the inner surfaces as the rest of it is perfect.

The escutcheon of the bolt is unusually good – it is a substantial steel piece with the head of the bolt recessed flush and a slot under the head for a screwdriver to get it out.

28th April – Dick brought over the furniture of the Witton & Daw to be derusted – its not in bad shape but the caustic gets rid of all the old grease and muck and the electrolysis gets rid of the rust, leaving it much easier to see what needs doing, and means that the fit to the wood is not spoilt by rust.

Emails have started to arrive about preparations for the Northern Shooting Show at Harrogate next weekend – I started to sort out a few bits to engrave while I talk to people – its no good trying to do a ‘proper’ job as I can’t keep up enough concentration and still interact. I have made a batch of Percussion decapping tools that I can engrave in my sleep, more or less, and also the usual supply of blank screw heads so that I can engrave flowers and give them to the young children – the girls in particular love small, intricate things and take a lot of interest in engraving, it must be boring for them being dragged round a gun show so I make a point of engaging with them. I might take my electric hone this time as there is power and I ran out of gravers last time – sharpening them by hand is tedious when you are used to a motor driven hone! If you are coming to the show be sure to introduce yourself! I’ll bring the New Land Hussar’s pistol and the Heavy Dragoon with me in case anyone wants to have a look at them.

Parts of the Witton and Daw to derust – not in bad condition!

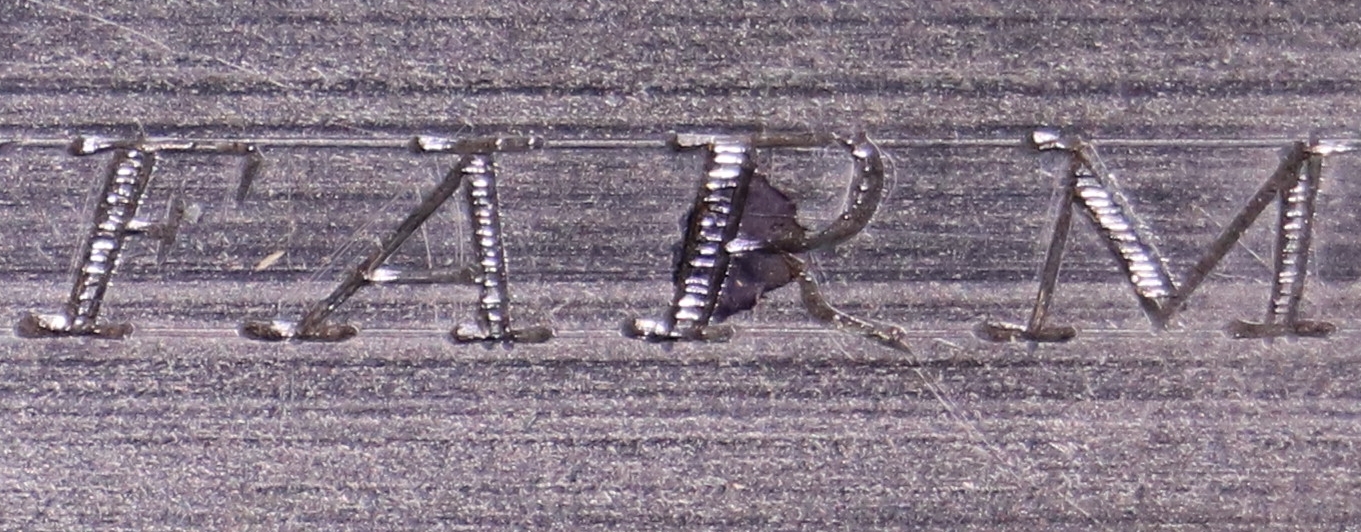

28th April – I’ve put post on Giles’s woodturning Shou Sugi Ban …… see it on recent posts menu to the right….

27th April – I went to Dick’s and took a couple of nice military pistols he has fettled to put on this site for sale – there is a very nice New Land pattern Officer’s Pistol signed to the 1 st Hussars and a nice Heavy Dragoon pistol by Henry Nock with the number 14 on the trigger guard – presumably one of a number issued to a privately raised unit. I have to say both look stunning and the New Land is particularly fine because of its provenance. See GUNS FOR SALE for photos. We sat down and had a discussion about prices – we want to avoid the excesses of some well known dealers and offer guns that people will want to own at sensible prices so that they are a reasonable option for those beginning a collection. They have all been expertly restored and mostly any serious work is recorded on this website so there should be no hidden nasties ! – we will always consider offers but be warned that we have already tried to keep them low. I will be adding a post on a bowl that Giles turned at the weekend as its a trendy and interesting technique, if not immensly practical – not that that ever bothered Giles……. (the technique is called Shou Sugi Ban – japanese burnt wood)

New Land Pistol of 1st Hussars ( Kings German Legion) with bolted Paget pattern lock – see for sale page…

Henry Nock private Heavy Dragoon pistol – see for sale page….

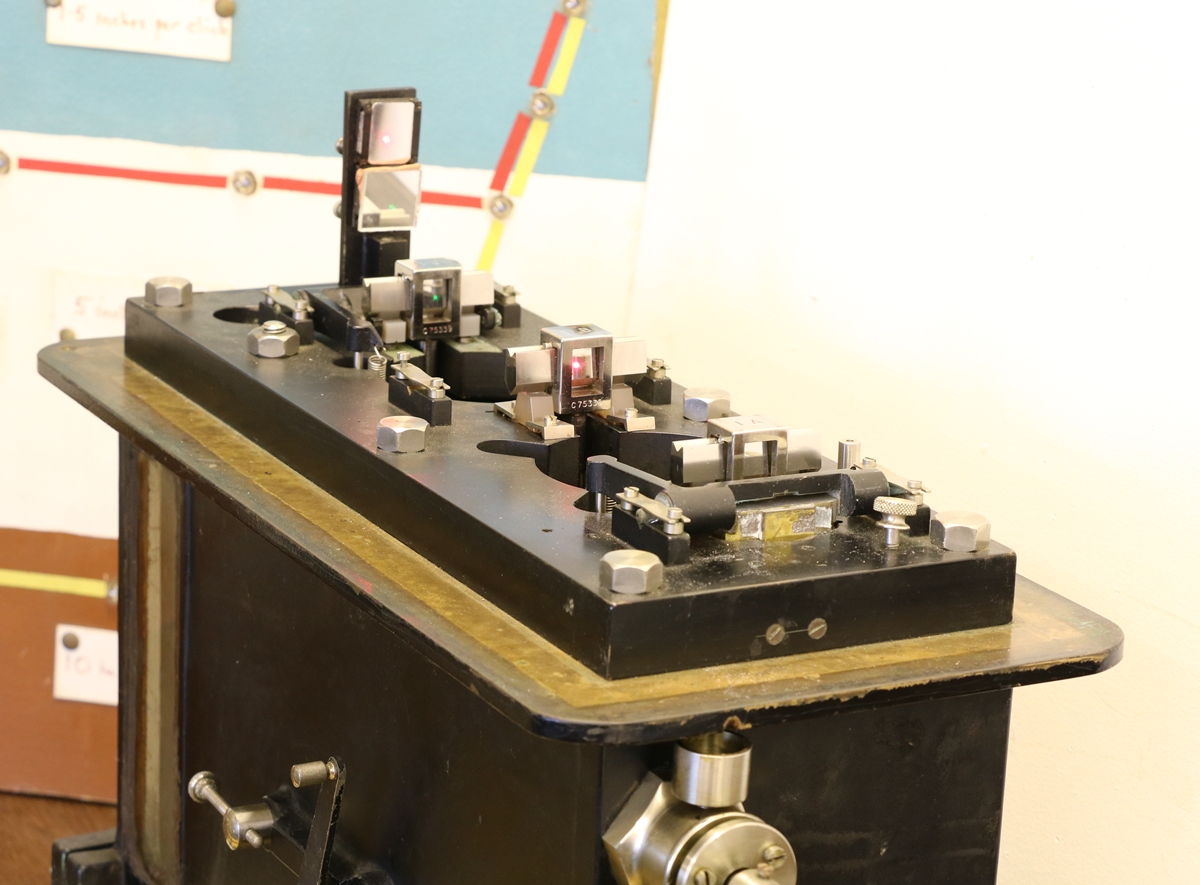

26th April – My battles with technology continued unabated! I struggled to get my powerpoint stuff working for my talk to the children at the Bill Tutte club and as soon as I had it working the projector went so dim that none of the slides could be read anyway – so I had to do it all on a whiteboard, which I really prefer anyway, being a bit of a Luddite. Now I just have to get the Microbit computer program running for tomorrow at 9, so I’m sorry, no gun waffle tonight……. Except reading Lister’s book I noticed that he thought guns with a false breech or a lock fixed with one screw and a hook on the front were unusual – he must have mainly dealt with flinlocks.

25th April Computers really bug me! I spent an hour sorting out a powerpoint presentation when my Windows 10 computer decided to shut down to install upgrades and lost the work – Microsoft decided to include uncontrolled upgrades in Windows 10 and made it almost impossible to circumvent them. Grrrrr…….. By the evening I was in need of a little soothing so got out my all time favourite book “Antique Firearms – their care repair and restoration” by Ronald Lister which is a wonderful example of a 1960’s ‘gun restoration for dummies’. Among others, there is a chapter on the ideal workshop and one on tools – the workshop chapter has a full paragraph describing his cupboard, with all the dimensions and what it was made of and what you can put in it! Oh for the days of a simple life…. My second favourite book is called ‘Foundry Irons’ by Kirk and lists all the types of iron a 1911 American foundry might make, complete with recipes – even in the face of terrible insomnia it is guaranteed to send me to sleep within minutes – I’ve never got past the first chapter….. Serious guns are going to have to wait until Friday as I was reminded that I said I would go into school on Thursday and help the children with some new Microbit computers – I did play with them once for half an hour, so I suppose that makes me an expert! I hope the children are on the ball! Children and computers is turning into a bit of a thing… taking over life…. I did manage to derust the Witton and Daw locks today (see below), and Dick and I had a further discussion about the 4 barreled pistol – We have been puzzled as to how it can hold together when fired as the single powder chamber is large enough to hold around 5 drams of powder, but the screw threads don’t fit very securely and the barrels are just soldered in, plus the barrel alignment finishes up rather out of line. I did think that maybe the thread and alignment were because the barrels got swapped for another similar pistol, but now we think that actually the barrels are an inferior Indian? replacement and not at all of the quality of the action body – we have doubts as to whether they would stand anything other than a minute charge, and would also explain the very poor fit of the thread, and the misalignment. If you shot the pistol as it is, the barrels would become the projectile! Probably the original barrels would be cast brass in one piece?

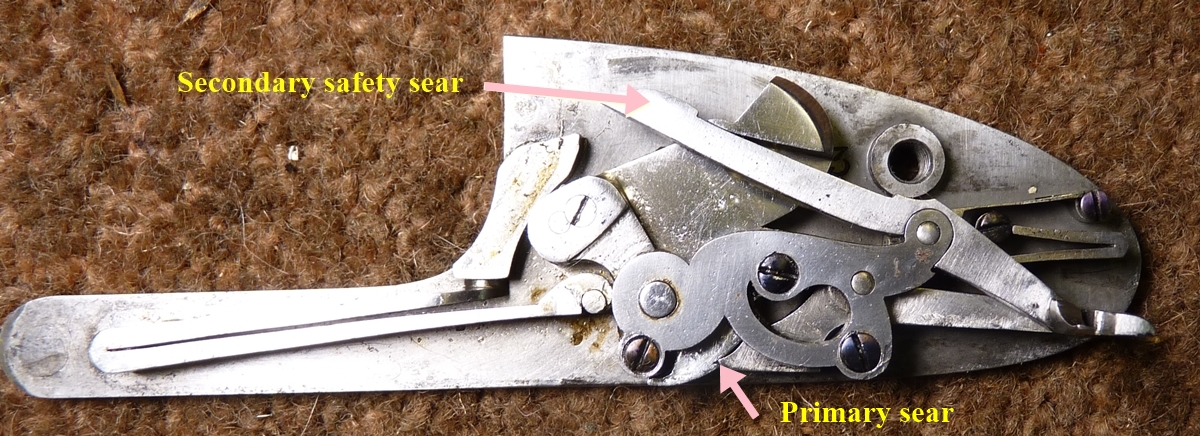

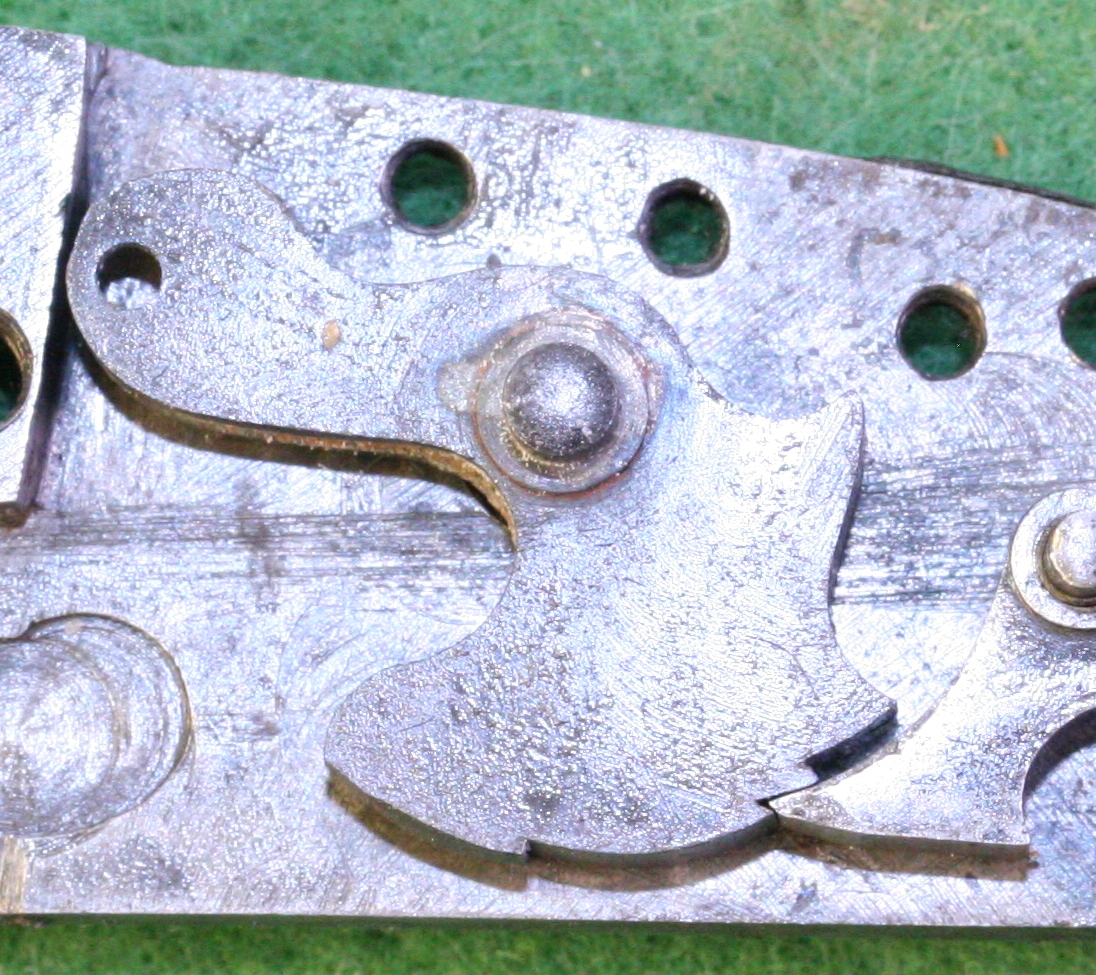

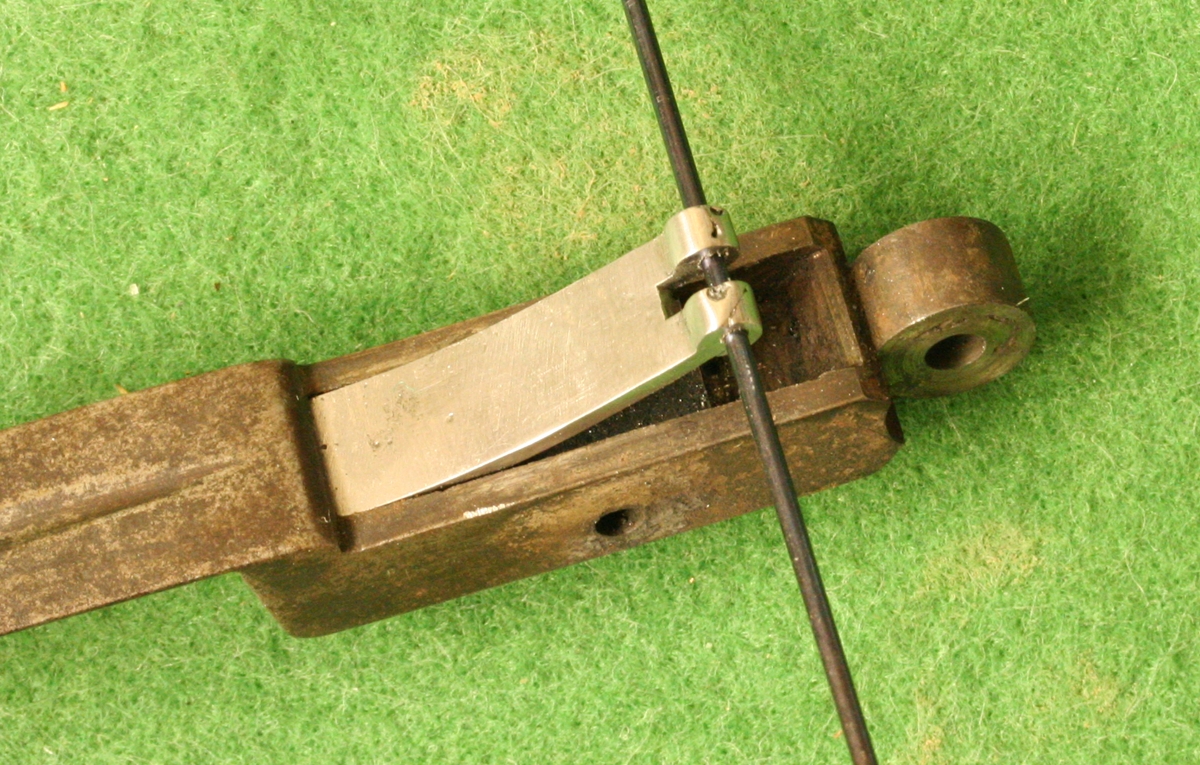

The Witton and Daw locks (here derusted) are unusual in that they fit a percussion round bodied gun – the bottom edge of the locks is rounded, although it doesn’t show in this photo. Its a good quality gun – its a shame that the barrels are not better or I would have bought it myself to shoot. The plain cock screw is wrong – I don’t think I’ve ever seen a highly engraved lock and cocks with a dead plain screw! No doubt ithey will come under my graver at some point.

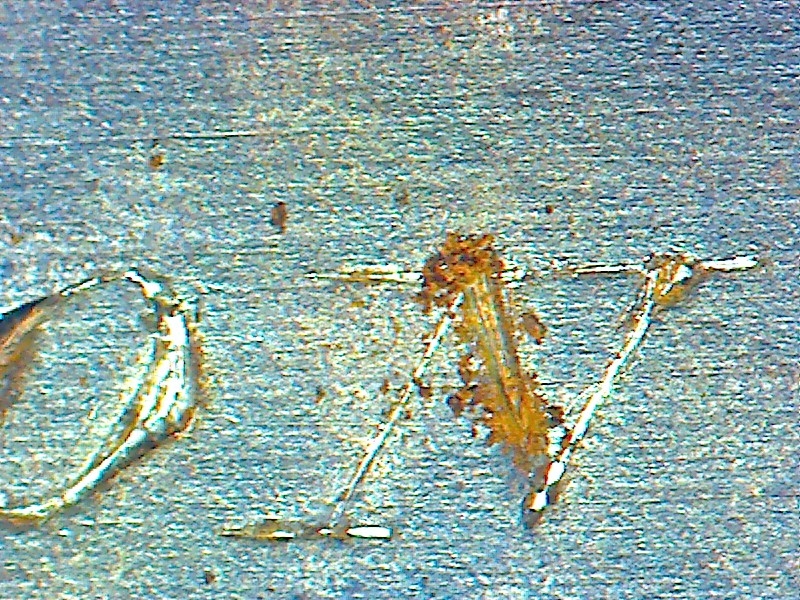

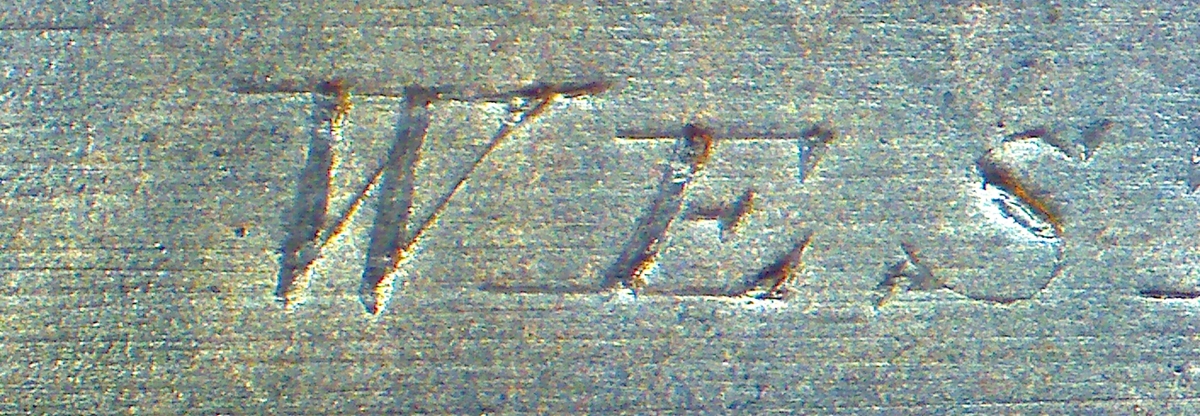

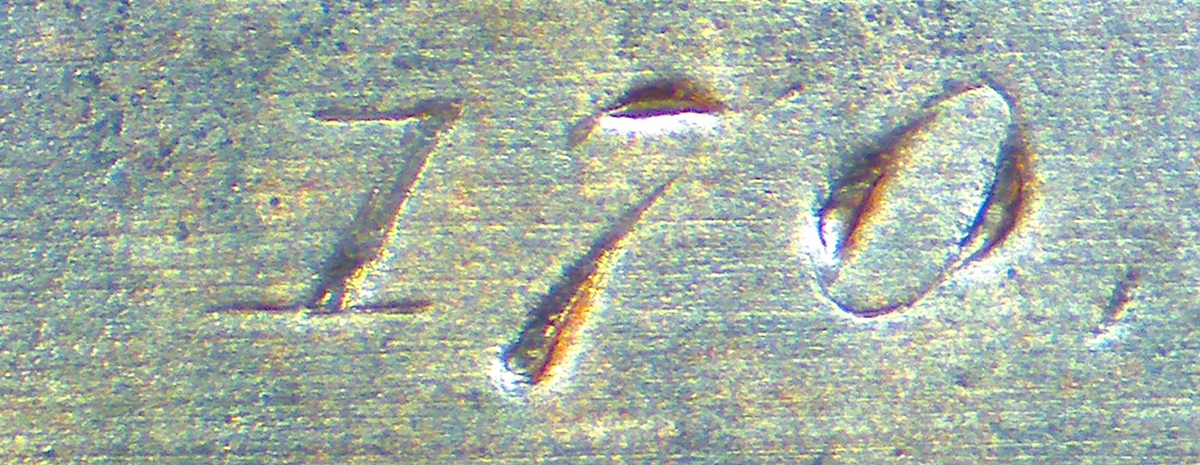

24th April – Busy sorting out my talk to the children at the Bill Tutte club on Wednesday – I was trying to scan some slides into a powerpoint but the scanner would not connect to any of my computers, even the old XP one that is contemporary with the scanner – technology marches on , mostly leaving me in its wake…… Dick came over to collect the stuff I did last night and brought the pistols to which the cock belonged – but I forgot to photograph them. They are pretty interesting – a pair of smallish bore long barreled pistols with very tapered barrels engraved TOW and GRIFFIN LONDON with diagonal silver cross at the foresight but, apart from the barrels they look very French in the locks, cocks, highly carved stock with wavy silver wire decoration and continental style furniture – they are percussion, which of course isn’t right for Tow and Griffin who used the joint name for a few years before Griffin gave way to Tow, who was originally Griffin’s barrel maker ( G & T was approx 177x – 1778 ). In fact the usual naming had the two names the other way round. Anyway I’m not sure what was going on – I suspect that the pistols were made as percussion pistols in France using a pair of old T & G barrels, and that none of the rest of the original flintlock was incorporated. It could I suppose be that they were made in France as flintlocks and converted there.I have a French Long gun with almost identical cocks and similar locks made in Lyon, so I’m pretty sure that it was made in France, at least in its final incarnation. I’ll try to get a photo before they disappear…….Dick is anxious to get his hands on the Andrews lock and finish it off as he doesn’t think much of my filing on the final shaping (in that I think he is quite justified!). Anyway its a swap for my engraving and welding – I had better touch up a few welding faults on the lock before I hand it over. He bought me a pair of locks from the Witton and Daw from Holts last sale that need the derusting treatment – maybe I’ll do that tomorrow, although I have STEM club in the afternoon to sort out….. How do I come to have so many things to do? (answers on a postcard please!)

23rd April – The weather got pleasant to be outside so the boat got all the attention until evening! I got a call from Dick asking when I was intending to do the welding and engraving so I figured I had better do it there and then, which I did. I put a little extra weld on the spur of the cock as it was a bit thin compared to its mate on the other gun of the pair – I will leave it to Dick to file up, I did a rough shaping just to make sure I had put on enough metal. I also engraved the false breech – a 10 minute job.

22nd April – Back from the Arms Fair, which was not exactly teeming with buyers! I formed the conclusion that the volume of sales is not high and that dealers are keeping their turnover up by increasing their prices – but then I am known to be a a cynic! A few very nice guns were on show – including the inevitable cased pairs of Manton flintlock duelling pistols – but now they carry price tickets of £40,000 or so. There is a lot of overpriced mediocre stuff and I was a bit surprised at the price labels on Colt percussion revolvers – but I guess the main market is set by prices in the US and the fall in the pound pushes our prices up. I did see a few choice pieces on the Bonham’s stand that will be in the auction on 17th May – I had a look at the online catalogue and it struck me that Bonham’s estimates are about 50% less than Holt’s estimates for similar lots – but I bet that isn’t reflected in the actual hammer prices! Having said that, my rule of thumb is buy at Bonhams, sell at Holts! Anyway I’ll be viewing the Bonhams sale in due course. The C & T auction tomorrow has a few guns at very low estimates – I questioned this and was told that it was deliberate and they were expected to fetch at least twice or 3 times the top estimate – you have been warned. I did find the usual rogue guns – my old unknown friend had been busy with his graver on his trademark ‘Twigg’ signature….. One thing I noticed is that as the supply of good flintlocks at reasonable prices has dried up, the price of percussion pistols and long guns has climbed, and good cased percussion duelling and target pistols are well into 5 figures. All good fun, but I didn’t buy anything – I do, however, meet an increasing number of people I know as I get more into the hobby. One last observation – the average age of those at this and similar events is going up a year for each passing year….. that just isn’t sustainable ……………………………………………….

21st April – I started on the Andrew’s frizzen spring today – first turning up the boss for the end and tapping it 9 B.A. then welding it to a thinned down piece if spring steel, then bending it, then I got distracted! I got a phone call asking if I was going to the London Antique Arms fair tomorrow as if so I could collect a case I’d left with a friend to see if it fitted his pistols. I’d forgotten that it was this weekend, but I do need to go, if for no other reason than to try and get a handle on current prices. My ideas of prices seem way out when compared with a lot of dealer’s ideas, so I’ll try to ‘recalibrate’ myself! Also I like to play ‘ spot the fake’ – there is usually enough to keep me amused, although there are a couple of dealers who sheepishly close the boxes on one or two cased pistols if they see me coming – can’t think why! I went over to Dicks to have a look at the very impressive collection of pistols he has been playing with, and brought away a couple of small jobs – a gouge in a cock to be welded over, and a bit of border engraving on a false breech from a Nock pistol where it had been rebuilt as part of a re-conversion to flintlock. So I didn’t get far with the spring……

The turned boss in position on the spring blank – a small piece of Plasticine (modelling clay), not yet in place, held the boss in place while I tack welded it – it really does work very well , unlikely as it may seem!

Bit more filing up required, then weld a pip on the side for the location and possibly a ramp for the tail of the frizzen. It really pays to leave a ‘handle’ on the part for as long as possible!

Nock False Breech to have the border carried round the new surface.

Damaged cock – it really needs some reshaping too as it looks a bit mean!

20th April – Very chilly and uninviting today so I didn’t feel drawn to boat fiddling! I determined to make some progress with the Andrews lock as its bugging me- I did some more welding to put the cam that contacts the ramp on the frizzen spring into a better place and widened the bearing surfaces into a smoother shape and made a shaft for a pivot – at the moment I can’t see how the original was fixed as the bearings both have clear holes through them the same size – I guess i may be horribly non traditional and just peen an axle in place – otherwise I will have to weld up the outside bearing hole and tap it M3 – but that risks loosing the alignment, which is critical. One problem that arises from the frizzen not really matching the pan section is that it is a bit tricky positioning the frizzen spring and the matching cam on the frizzen – the shape of the pan section limits the pan opening angle as the cam can’t go forward much because it hits the bearing arm…. Anyway I think I have just about got a compromise – it seems to open enough to clear the cock, so the next step is probably to make a frizzen spring – I have a couple of castings but neither has a short enough arm to fit the nose of the lockplate. I feel at the end of this rather frustrating process I might have a working lock (after a fashion) but I should have a much better understanding of the geometry of frizzens and pans! So the next problem is to make a frizzen spring – I will probably cut a blank from spring steel, then build up a boss to take the fixing screw with weld, and also build up the peg on the back then shape and bend the spring and finally weld on the top of the spring for the lump on the frizzen to engage with. I’ll post some pics while I do it. Here is today’s work;-

The outer hole for the frizzen bearing is a bit oval – it has been welded at some time in the past. Maybe I should weld and tap it M3 – the shaft is 3.3 mm diameter The pretty purple colour comes from putting it in the top oven of the Aga to weaken the Araldite.

At the moment this is as far as the frizzen will open, but I’m reluctant to take any more off until I get a frizzen spring working and can see how it functions.

19th April – Another lovely day but a bit chilly. Sat in the sun and planned my session at the Bill Tutte club with a group of would-be scientists aged 9 to 14 next week. I need to assemble a number of props as I have to keep their attention for 2 hours! I did a bit more on the Andrew’s lock – I’ll put up some photos shortly but it is shaping up – I drilled the frizzen pivot and filed up the frizzen to a first approximation. It is going to be difficult to position the frizzen spring so that it opens the frizzen fully – I think I’ll have to do a bit more welding to shift the lump into a better place to catch on the spring. I don’t think this one will have a roller on either the frizzen or the spring. I get a lot of visitors to this site who are looking for information on a couple of the spurious posts on the site – both ‘ putting a foot pedal on a welder’ & ‘ land cruiser steering lock problem’ get found quite often – When I was trying desperately to make a bit of room in my shed I came across a box of parts for the steering lock – since Toyota screwed up the repair I have a full set of parts to fix any problems that I no longer need. I think my patent finder at the British Library is back from holiday so I will try to get the next couple of J R Cooper patents to try and track down the covered lock gun.

18th April – Beautiful morning – I just had to be outside playing with the boat! I got back to the Andrews lock in the afternoon when it got decidedly chilly outside and put the lock in the Aga top oven to break down the epoxy bond, then had to clean it up before welding the bearing face to make it a bit wider. The main reason I’m playing around with the lock in spite of the difficulty of getting the pan section and frizzen to mate is that I need the practice in TIG welding, and this job is certainly giving me plenty of that. Anyway I made a decent fist of this bit of welding so that when I filed it flat for the bearing surface there were no voids and it all fitted. I’ll now drill through for the frizzen pivot and file up the frizzen and see if I need any weld ‘patches’. I’m also gearing up to engrave Martin’s barrel – I need a bit of practice as I haven’t engraved for weeks (actually months).

17th April – I was all set to share some really interesting pearls of gun wisdom on the blog last night at 10:30 when all the power failed and my computer and the internet with it…. It still hadn’t been restored by midnight, so I went to bed early for a change and now that the power is back ( it came on around 1 in the morning) I have completely forgotten what the pearls of wisdom were, and it is as if my brain has been wiped in some sort of computer crash! Anyway I spent much of yesterday and this morning sorting out bits of the boat so that when the weather warms up we can sail it. ( for those not in the UK, the last few days have seen winds from the North and daytime air temperatures around 13 degrees C., although some nice sunshine appeared from time to time. The rudder was horribly chewed up as it hits the propeller of the outboard if one isn’t careful, and whoever worked on the boat during its previous life clearly didn’t know the difference between stainless steel screws and the rusting sort – which in the way of things are now so rusted in that they can’t be removed. Some car body filler and a bit of work on the lathe turning reinforcing sleeves for the pivot and a couple of coats of white one-pot polyurethane paint will see a marked improvement. Normal gun related service should be resumed tomorrow…..

15th April – Catching up on shopping and rampant nature in the garden today, but I did manage a little engraving tonight. I have now fudged my wordpress files so I can download all the IP addresses of visitors and over time see how many regular visitors there are and which country they come from – I don’t get any identification of individuals, so your privacy isn’t compromised! Of the 200 odd visitors a day I think about 50 seem to come back on more than one day, and often visit more than once in a day, but so far I’ve only looked at 3 days of data. Most of the remaining visitors are casual visitors, although probably 20 or 30 are hackers trying to get into the site – many of the hackers try almost every day although they are blocked from actually getting onto the server. The worst countries for hackers are Ukraine and the US, with some from China and Russia, but a lot of hacking attempts use ‘bots’ on computers in many small, obscure places like Ulan Bator.

14th April – I went over to Dicks to look at the 4 barreled pistol he is restocking – it is around 1760 ish so I took Keith Neil & Back’s book on Great British Gunmakers 1740 – 1790 to check out the butt shape. Looking at examples in the book I suggested slight reshaping of the butt to better fit the period of the pistol –

The line is not quite right, but the outer edge needs to come in a bit and the ‘beak’ to go!

We then had a discussion about the alignment of the barrels when screwed home – at the moment they end up at an odd angle – its neither a single barrel or a pair of barrels on top, but an intermediate angle with about 30 degrees to go before a single barrel is uppermost. The screw thread is intact and nothing seems to have been altered (the barrels were made separate and soldered to the ring piece that screws to the action). We thought that a pair of barrels ought to be uppermost but sighting along the pistol we realised that the barrels were slightly inclined to one side. At this point we noticed that the ring with the barrels attached had a noticeable built-in angle – which must have added significantly to the manufacturing difficulty. Based on the assumption that the angle must have been intended to incline the barrels either upward or downward but not sideways we concluded that the alignment must be with a single barrel uppermost and the barrel group slightly downwardly inclined – since pistols usually kick up on firing. This means that the barrel assembly was designed to be screwed a further 30 degrees round from its current tight position. Another one of life’s little mysteries! Here is a picture of teh underside that shows the taper on the ring ;-

The red arrow shows the narrowest point of the ring – it should align with the middle of the bottom of the action.

The writing at the breech end is apparently in Hindi and is thought to be 3 initials – R.K.K

13th April – An extra days shoot at Eriswell for a small subset of AML – very informal and pleasant. I started with my ‘Twigg’ flintlock to see if lightening the trigger pull had improved my hit rate, but unfortunately I didn’t have any very fine Swiss OB for priming the pan due to an oversight, and so it was going off very slowly – so I didn’t have much luck. I then went back to my old D Egg back action percussion standby and managed around 50% hits with that, so about par for the course for me. After lunch I used my Miruku 12 Bore O/U that I hadn’t shot for a while. I needed more cartridges and without thinking bought 21 gram X Comps instead of the 28 gram I normally use, but I still did pretty well (for me!) . I swapped 4 for 28 gram loads for a couple of distant clays – which I missed – and was surprised at the extra recoil. By the end of the afternoon and after 50 cartridges I was glad I’d shot the lighter load – some of my companions looked a bit beaten up! Apropos of the Andrews lock – I realised that it was stupid to try to reposition the outer bracket for the frizzen pivot to reduce the width – much better just to thicken up the hub of the frizzen to fit – so I’ll have to unglue it (heat it up) and weld the hub and file it to fit the slot and then re glue it and drill for the pivot…….

Off to Dick’s tomorrow as he is wondering what to do to the butt of the 4 barreled pistol – I vetoed the idea of a plain oval silver escutcheon as being far to modern for a 1760 pistol – it should be a cast silver or brass one with relief decoration or none at all – or possibly a ‘grotesque’ – I’ll stick a couple of books in the car so we can look up an appropriate shape for the butt etc. One problem is that we can’t find a suitable brass casting for a butt plate………

12 April later – I steeled myself to tackle the Andrews lock – the frizzen is beginning to get into shape, but was offset rather a lot to the outside of the lock – the face of the lockplate was raised into a platform about 1.5 mm high in the contact area with the frizzen bearing – on most locks it would be flush, and so I decided to file the platform off to move the frizzen over by enough to put it in the correct alignment with the cock. This of course means that the gap for the frizzen is too wide, and the outside bracket will have to be shifted over – i.e. cut off and rewelded. It is all getting to be a bit of a saga. and by this stage I’m only doing it because its a good exercise in fudging! Each time I file a new bit of the pan section or frizzen I discover that it’s been badly welded and reshaped before – so it is really just a mess – which makes me glad that I made a new lockplate to start with – I’d be feeling pretty desperate if it was the original I was messing about with! Anyway here are some photos – I got to the stage of fitting the frizzen into the correct place and Aralditing it so that I can drill the pivot before I redo the outside bracket. We are hoping to sail the boat we bought last year over Easter so I’ve got to sort that out over the next couple of days…. and then it looks as if I will have a kitchen and bathroom to refit for Giles over the summer….. and I still need to get on top of programming the Mindstorms…. and the engraving jobs I picked up at the last AML shoot are waiting… and I need to get a slightly bigger ball mould for the Nock……. no peace for the wicked then……….

The frizzen as it was offset

The raised platform to be filed off – much easier to work on if you screw it to a block of wood!

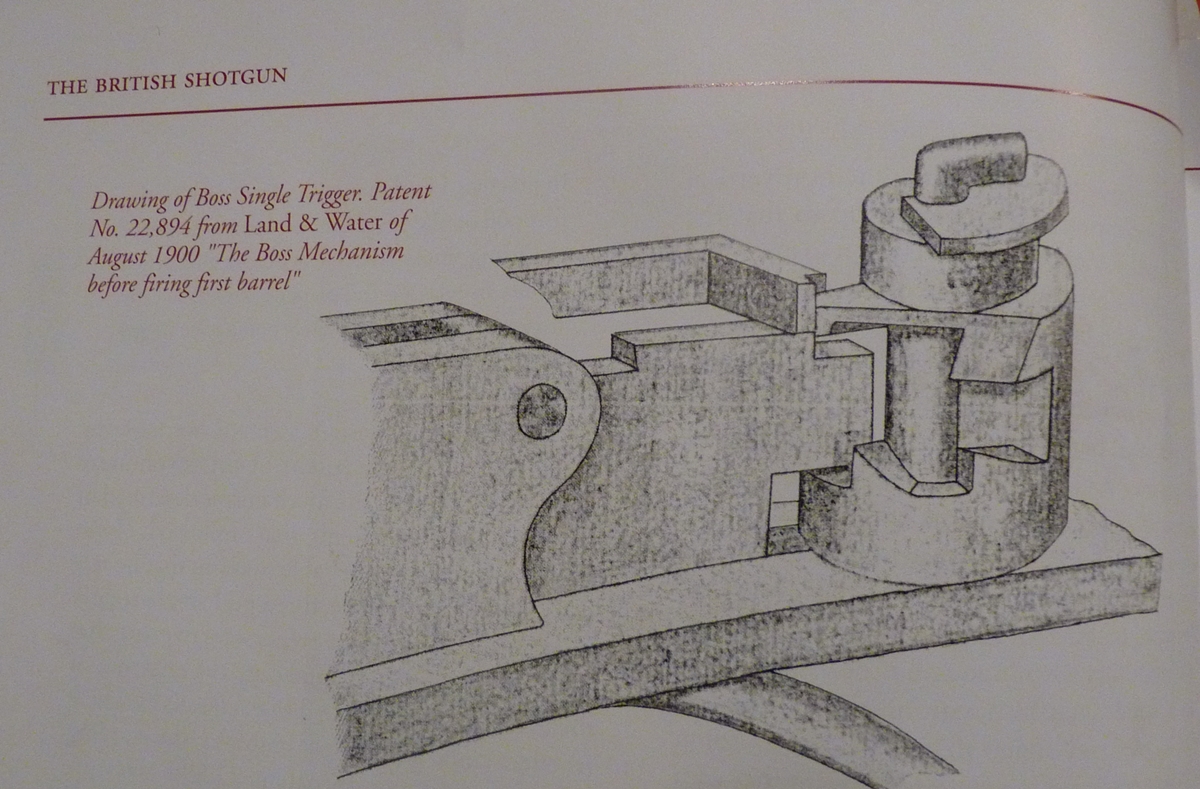

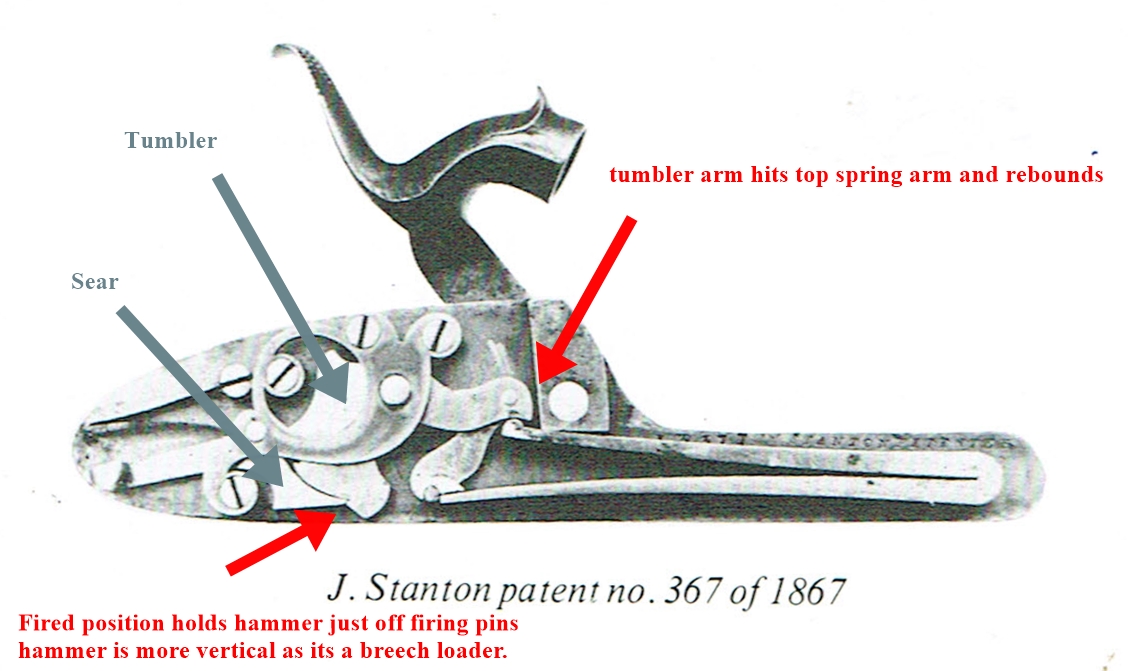

Glued and ready to drill – the outer bracket will need moving!

12th April I did a bit more on the Andrews lock, but it is going to be a bit of a fudge as the frizzen isn’t really right – I may have to do major surgery on it again! I got a couple more J R Cooper patents from the British Library, but nothing that matches my gun – there are a couple more I could get but I’ll have to wait til next week. It got me interested in the beginnings of the percussion/pinfire/centrefire revolution – It begins to look as if Cooper was desperate to adapt the percussion cap to the breech loader in any way possible. The development of percussion ignition in England was severely constrained by Forsyth’s 1807 patent that was held at law to be a master patent and effectively stopped almost all development in England during its life. France had been ahead of England in gun development in the middle and early 18th century and French gunmakers took advantage of the fact that Forsyth didn’t patent percussion ignition abroad to recover the initiative. By the time Forsyth’s patent expired in 1823, just after he won a case against Joseph Manton over the Manton Tubelock patent, Pauly in France had effectively invented the cartridge as we know it today and the stage was set for the development of many of the features we are familiar with when we pick up a modern shotgun. It took a few years for the new inventions to ‘shake down’ – for instance all cartridges now depend on the ability of the case to expand on firing and provide the gas seal to prevent gas escape at the breech but the metallurgy involved took time to be developed. Similarly the placing of a pellet of fulminate in the exposed head of the cartridge in Pauly’s design created possible dangers and escape of gas on firing, so the pinfire cartridge was an interim solution until the copper cap was used to avoid the problem. All this time, and even as late as the 1860’s Cooper was busy patenting breech loading mechanisms using conventional percussion caps. It all makes for an interesting study – its the most febrile period of gun development of all time, the flintlock era dragged on for several hundred years, but from Forsyth’s patent to a gun that we would feel at home with was a mere 50 years or so – or maybe a few more if you want to include hammerless boxlocks with single triggers – most of it in little more than the working life of a gunmaker! It is a fascinating time to study – while there is a lot of published material on the early breechloading cartridge guns ( e.g. Cruddington & Baker ‘The British Shotgun’ Vol 1), there doesn’t seem to be much covering the ‘dinosaurs’ like JR Cooper who seem to have been struggling to keep the old ignition system going while loading from the breech, for whatever reason. Room for more study here!

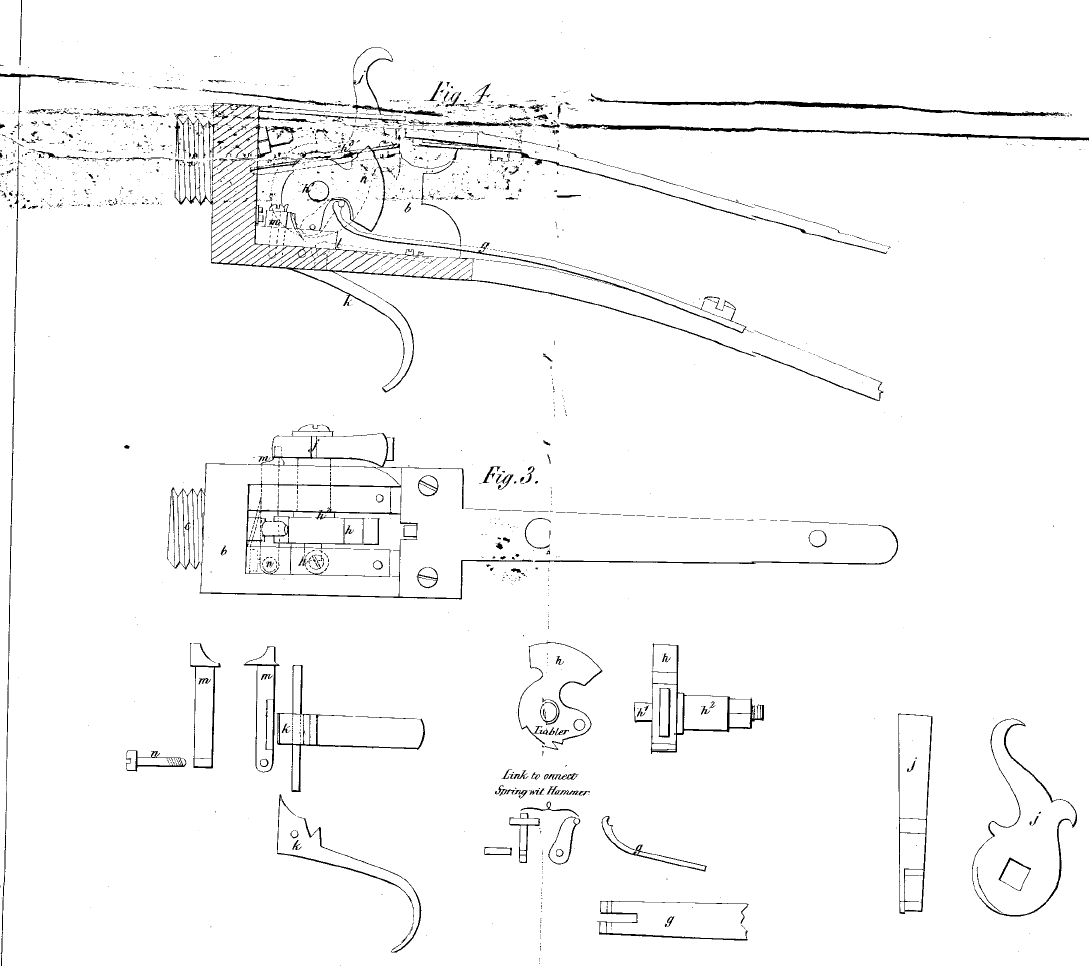

11th April – back in the land of the living. I followed up a reference in De Witt Baileys and Douglas Nye’s book on English gunmakers that said J R Cooper had a patent No 7610 dated 1838 for an enclosed percussion lock so I got a copy from the British Library – fantastic service, it took less than an hour! It is a breechloader, but still has an external ‘hammer’ for cocking it and no magazine. So the book lists a few more possible patents he took out – I’ll get those too – I’m not sure how many I can get from the British Library on my Reader’s ticket – I have put a link to the .pdf of the patent on the J R Cooper post – you can see the beginnings of the idea – so it will be interesting to follow it up and see how far he patented things……..

J R Cooper’s patent 7610 of 1838 – part of the way to my gun….he had obviously started thinking about it in 1838

There is another drawing on the 1838 patent that is a boxlock percussion shotgun.

9th April Last of the fixing – vents for the double glazed windows in the kitchen and bathroom to increase ventilation levels which have never been quite adequate for the Cornish weather. Then a bit of hacking in the garden – not the internet kind, so now just tidy up and load the car and off home tomorrow. Paid our visit to ‘The Gurnard’s Head’ restaurant tonight – still good but I was a bit underwhelmed by my main dish – Ray wing with a very tasty heap of lardrons, lentils and hazel nuts as the poor ray wing was tiny and overwhelmed by the heap on top of it. Anyway we always enjoy going there, and the large picture of an old couple having a meal by Kells (?) has returned and keeps us guessing about what is going on…..

8th April Still in Cornwall and still fixing things – a bunker to hold logs, a new curtain rail, fixed a fire guard and made a heat resistant area to protect the worktop. Almost time to go home so I can resume playing with restoration. I’ve had an email about a pinfire gun and was wondering what the market for shootable double pinfire shotguns was? I do know a couple of people who shoot them, including a 28 bore, and they make quite convincing black powder cartridges based on breech loading cartridge cases with a standard percussion cap as the detonator. You need to swage out the rim of the case as pinfire cartridges were rimless, and insert a pin that strikes the detonating compound in the cap.

We had a short trip out to Penzance and Lamorna Cove this afternoon and called in at Scarlets in Lelant near Hayle (one of our favourite eating places – handy while the kitchen was in chaos) – they have a display of pictures by local artists including a series of ‘collographs’ of birds. I’m still not sure what the technique involves, but it is a form of print making – anyway we bought one of a buzzard that was rather fine. We currently have 3 favourite eating places – Salts in Hayle, a restaurant cum pub, Scarlets in Lelant – a restaurant/cafe and delicatessen and wine shop that has the great advantage that you can buy a bottle of wine from their vast selection and have it with your meal at the wine shop price, and take the remains (if any) home. Our third and poshest place is ‘The Gurnard’s Head’ in Zennor – special treat once per holiday meal for many years!

7th April I put a new top on the other worksurface in the kitchen, fixed the bathroom fan and put a new security light outside – the old type with a halogen tube bulb last about 2 years and the bulb blows and they are by then so rusty and horrible that its not worth replacing the bulb – anyway I replaced it with an LED security light in the hope that it might survive – this one appears to have stainless steel screws so I’m hoping it will do for 4 or 5 years. The wire to the old light was not long enough to reach the cable gland on the new one, so the whole wire had to be removed back to the switch- I didn’t have any more 1 mm t&e cable so used a gash piece of 3 core 13A flexible power cord which is probably better of the final connection anyway, but 13A is overkill – its just what I had – perpetually going out to Screwfix or B&Q or wherever eats into work time as either involve at least an hour.

This blog is now getting around 200 visitors a day – not counting the 50 or 60 idiots per day who try to log on to the site by guessing both the user name and password – since not one of them has even found the correct login page its rather pathetic = but I assume it all done by bots running on computers controlled by a small number of hackers. As the site is set up at the moment you have three tries at the password before you get blocked for a day, and anyway I check and permanently block anyone who tries to log on. Most of the attacks come from the Ukraine, followed by the US. Some of the attackers have been doing it for months and clock up hundreds of blocked attacks – all these things are logged on the site and I check them regularly so keep an eye on what is going on.

6th April Finished installing the washing machine and rebuilding the kitchen units around it. I realised how much the design of kitchens had changed since I did this on e originally – then the normal sink unit took the place of the worktop, now they are all designed to be inset into the worktop. I bought a cheap new worktop from B&Q – its OK but when cut it looks just like the ‘logs’ made of compressed woodchips that we are burning on the woodburning stove at the mohent – £3 a bag from Poundland -we are big spenders. Come to think of it, the ‘logs’ are probably about one third of the price of the melamine coated worktop weight for weight! I’ll post a picture of the kitchen and then settle down to read Keith Neil and Backs book on gun cases etc..

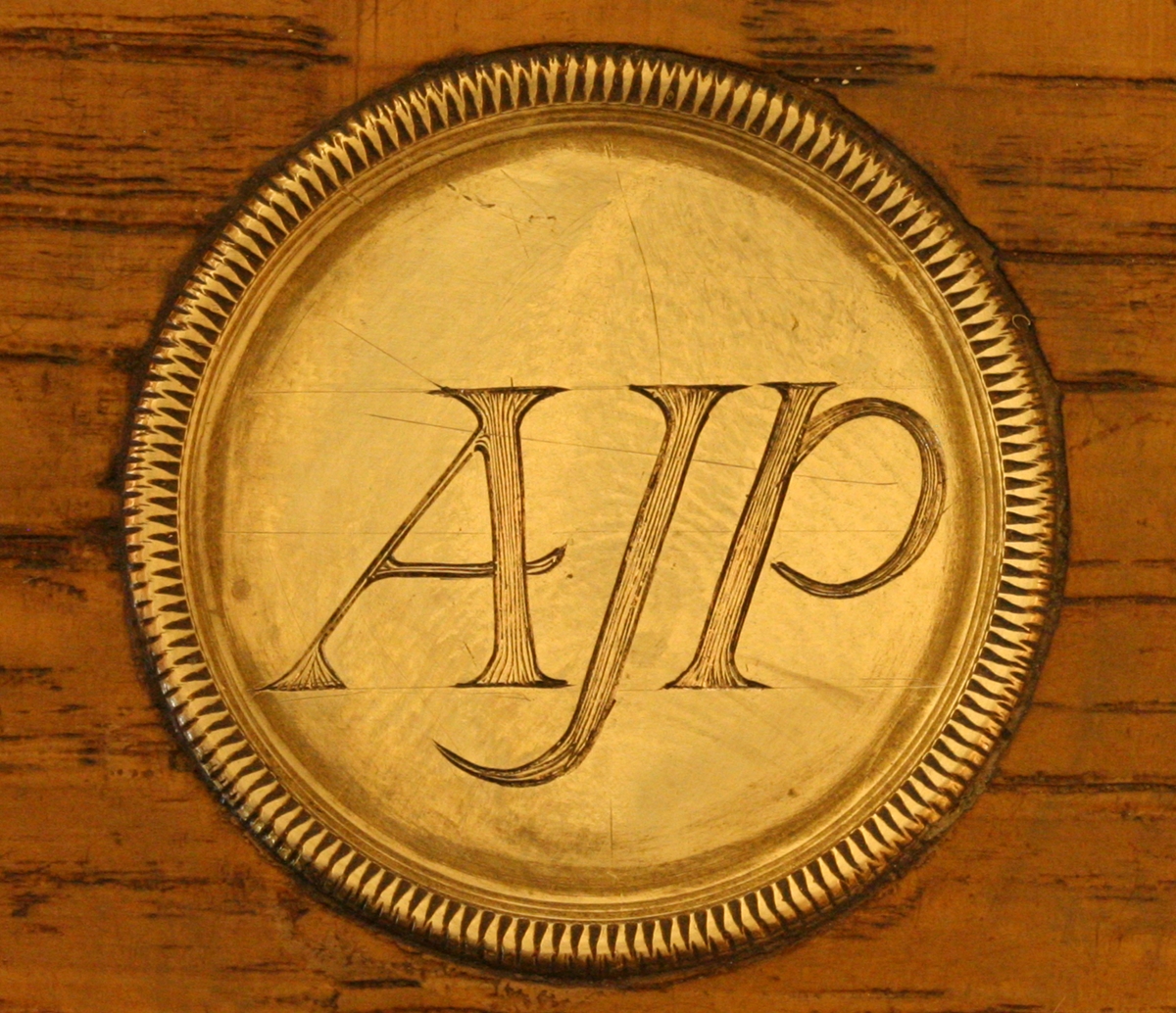

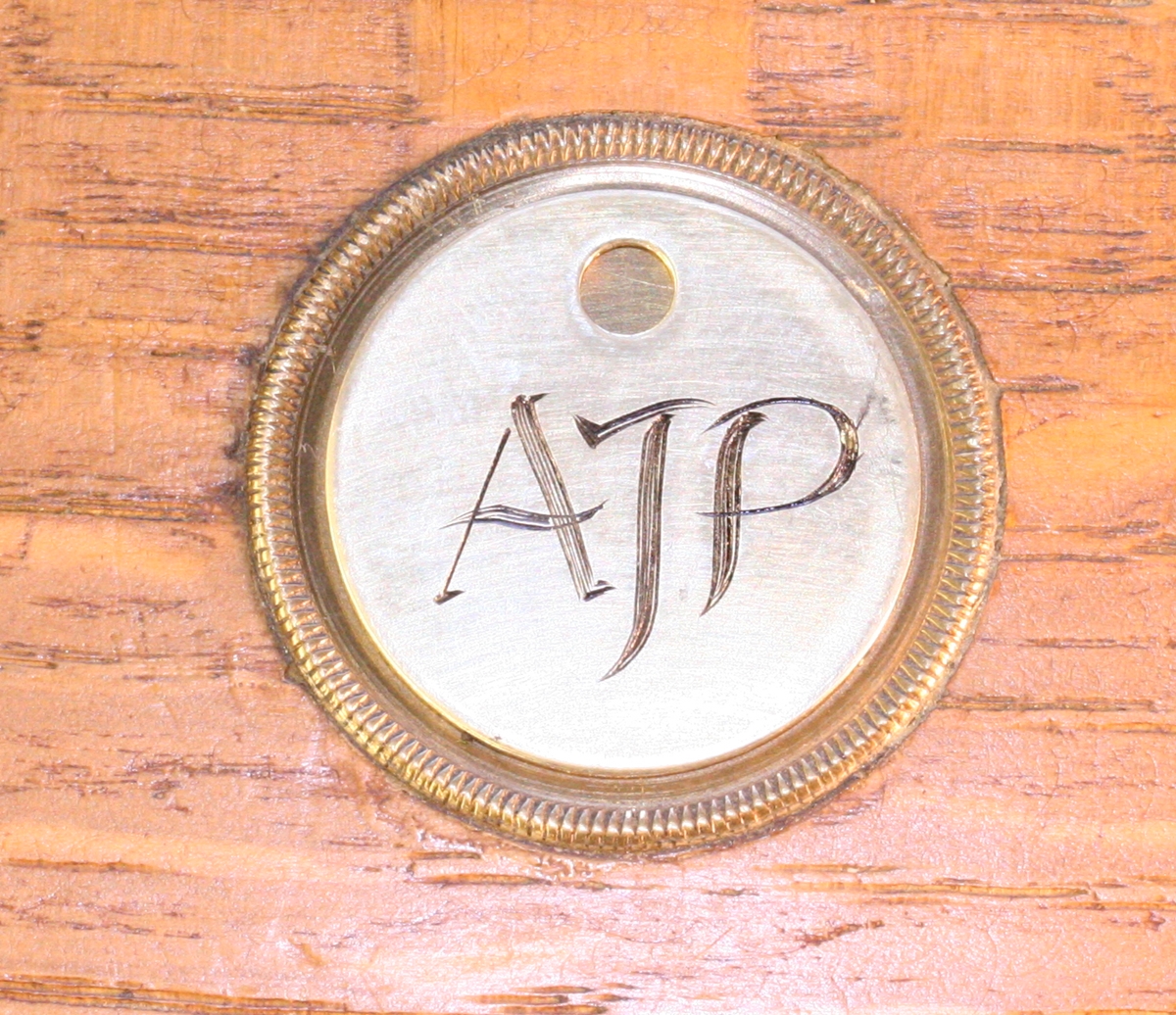

5th April. The book on cases is fascinating – I’m surprised how late the ‘normal’ gun and pistol case arrived. The first fitted cases – as distinct from utilitarian packing cases – seemed to have appeared around 1763 and were made of tinplate (produced from about 1723), follow by oak around 10 years later, with mahogany coming on the scene about 5 years after that. Early cases would have had a simple ‘rectangular’ brass handle planted on the lid. Around 1795 the inset circular handle began to appear – initially with the centre filled with a brass plate, and later with the ‘classic’ round handle showing wood in the centre. More tomorrow – and some pictures of progress on the kitchen – I got everything sorted today – the waste fittings are a pain to sort out as there are about half a dozen different types of pipe and fitting, and they are not interchangeable. I have a sack of fittings left over from previous jobs but couldn’t find what I wanted so had to buy more.. I started fitted the new worktop but found that the standard top I bought is half an inch narrower than the standard top bought 30 years ago, which meant a bit of bodging to fill a gap – its also a couple of mm thinner, but I can cope with that.

4th Mar. My gun related activity today was limited to reading Keith Neal and Back’s book ‘British Gunmakers Their Trade Cards, Cases and Equipment’ which was published in 1980 and is difficult to come by – I had to fork out £130 for a mint copy – luckily it was more of a swap as I traded a set of 19th century books on insects that I had inherited but had no interest in. I wish I had had a copy before I started casing guns and pistols! Like every book published by the pair it is THE definitive work on the subject. My main activity was stripping o ut the kitchen sink and re-doing a bit of plumbing to accommodate a washing machine and put in a few shut off valves – the cottage was converted in the 1950s and when mains water was installed it was done with NO stopcocks or shut off valves – not even a stopcock on the incoming main which is buried under the bath and its impossible to fit one now! To shut off the water I have to go into the road and dig up the external stopcock from under the dirt.

Just for fun, here are a couple of photos;

As it was, minus the cupboard doors (I think cupboard is such a medieval word)!

Destruction phase: A couple of flexible tap connectors/shut offs added. I don’t know what happened but it must be the first time I’ve done half a dozen compression joints and not had a single drop of water!

3rd April. Now in Cornwall contemplating destroying the kitchen to make space for the washing machine. I had an email from my friend serving in Sinai who has asked an Iranian about the script on the 4 barreled pistol and established that its not Farsi, or, probably Arabic, and that its most likely Sanscrit or Hindi which aligns with my thoughts. He thinks that he can get a translation, which would be great, and might throw some light on whether the silver wire inlay is likely to be foreign or from Birmingham like the brassware.

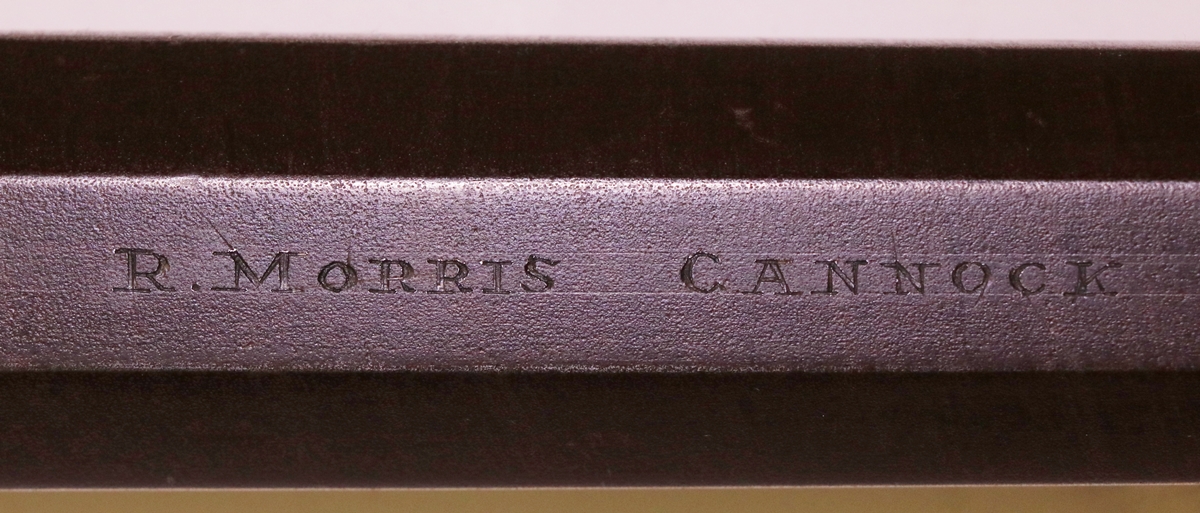

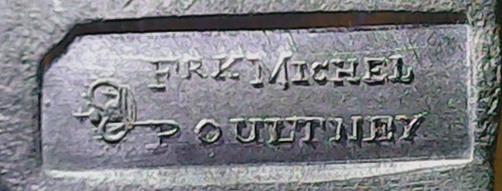

1 April Fate’s April fools joke on me was to make me miss the first 10 clays on the AML shoot in a row! Thereafter I was back to normal – miss one, hit one. My feeling that muzzle loading shooting is getting more popular is amply demonstrated in the number of people turning out for our monthly shoots – we now have 3 squads – around 30 shooters – we’ll soon be swamped by our own success. I shot the Jackson Improved Central Fire 14 bore percussion double – it is a nice gun, and the breech is very neat and slim as the cocks are in about the position they are in a hammer gun, but there is nothing ‘improved’ about my shooting today. I finished the afternoon shoot with my Beretta o/u and got about the same result – but I did hit more of the ‘driven’ clays. I realised today at the shoot that one of the weird things about this blog is that some people know more about what I’ve been up to than I do, on account of the fact that I hardly have any memory for past events! I picked up a couple of jobs – both fairly low key – an old lock to see if I could decipher the name and the recut it – its a fairly cheap lock so no problems. The other job is to recut the name on a lock by Morris that is in Olde English script, and engrave the name on the barrel. (Actually, having looked at the lock, I realise that the name on it is different and I am to erase it and start over, so no need for the Olde English). The jobs will have to wait until I get back from Cornwall where we are going to sort out the holiday cottage for the season – this includes fitting a washing machine in place of part of a kitchen cupboard – apparently necessary in order to let it successfully on airbnb & www.tinminerscottage.co.uk. I will take some gun books so I can at least put some snippets of information here. My evening activity is to do my homework on the Lego Mindstorms computers so I can keep one step ahead of my STEM club children – school and STEM (Science Technology Engineering and Maths) seem to be taking up increasing amounts of my time as I am getting roped in to help in daytime school activities – I can’t say I mind as its very rewarding – see www.kettlefields.club . I’ve also got to prepare 2 hours of talk and fun for the children of the Bill Tutte club in Newmarket – I’m not sure what the work ‘retirement’ means, but life was a lot more peaceful when I only worked about 50 hours a week! Our treat in Cornwall will be to slope off to The Gurnard’s Head at Zennor for a meal – one of the nicest places we know in Cornwall. At least this time we don’t have to find someone to chicken sit as Giles will still be living in the house – getting in a full time chicken sitter at the new living wage would be a bit expensive – cheaper just to eat the chickens and replace them when we got back!

31 March Another month gone! I went to Dick’s today to photograph a few guns that are coming up for sale soon – and the odd 4 barrelled pistol by Walsingham of about 1763 – here is a photo, the rest are in the post 4-BARRELLED PISTOL. I took some more photos of the Griffin as Dick has tidied up the stock under the lock aperture – its now looking fantastic. There is also a nice flintlock pistol by Henry Nock – probably an officer’s pistol, and a military issue pistol. They will eventually appear on the for-sale page when we have an idea of a sensible price.

See 4 BARRELLED PISTOL Post for more pictures

See Griffin Pistol Post for more…

30th Mar. I had to finish and test a couple of electronic temperature regulator boards for a client who wanted them urgently – I wasted half an hour because I’d swapped two resistors in assembling one of them and finding the fault took time. I came back to the Andrews lock/frizzen problem – the frizzen is not the right shape for the pan section and I’m struggling to build it up enough to reshape it so it fits – at the moment it just looks a mess but I hope with a lot of filing and another iteration of welding it will come together. Visitors who leave this sort of mess to people like me can feel smug!

At least if I can’t get it to work I can revert to the original percussion setup and nothing of the original gun will be lost or damaged – the advantage of making a new lockplate!

29th Mar I went to Dick’s today and had a look at a little flintlock pistol he has for restoration. I’ll get some photos of it later – its by Wm Walsingham of Birmingham, about 1760. A 4 brass barreled volley pistol with all the barrels opening into a single chamber that connects to the pan – the barrels unscrew as a group (they are made as a single casting) and powder is put in the chamber – it looks as if it would hold quite a lot – and the barrels screwed back on. Its worn but nicely engraved all over the brass. The stock is badly damaged – partly eaten away and the butt cap gone with it – the rest appears to have been filed down – it was clearly originally inlaid with silver wire in a very elaborate way – all that remains are marks where the silver was before it was all filed off. I don’t know how unusual it is as a design, but I treat anything of that vintage as a bit special – pre 1780 stuff doesn’t grow on trees! I think there is no option but to make a new stock and a new buttcap but I don’t think it is going to be possible to make a convincing reproduction of the original, and I certainly don’t think it would be economical – anyway I think it would be wrong – so I would make a plain butt and cap. The rest of the pistol only needs careful cleaning – I would resist any temptation to recut the engraving – it is perfectly readable as it is and the untouched nature of the pistol metalwork shows clearly. Once you start recutting it makes people wonder just how much is genuine!

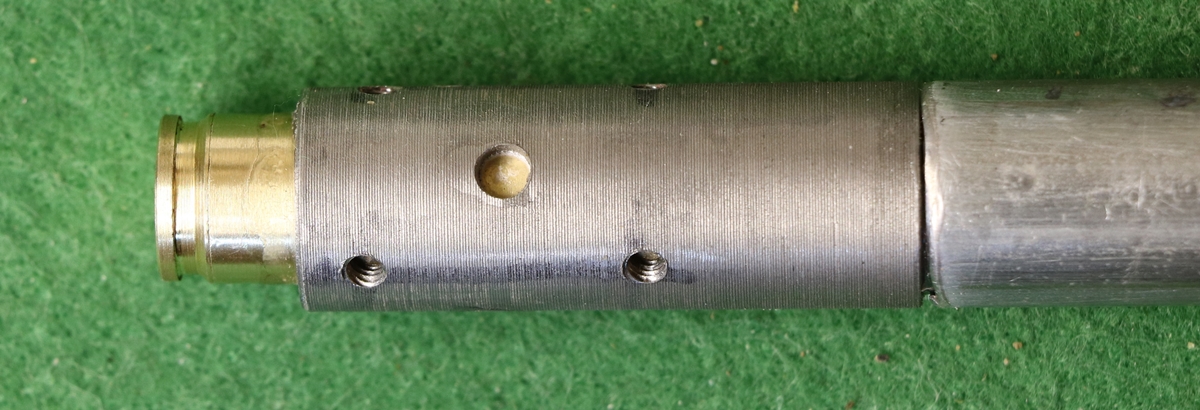

8th Mar. A VERY frustrating morning at the range! The sights I put on the Nock are good and I am confident that I can aim quite well with them – certainly well enough to get a sub 4 inch group at 25 yards without too much effort – but try as I could, I failed to get a group of any reasonable size – I had a sheet of A3 paper as a target and I even had a few shots off both sides of it. I tried several combinations of patch, and also tried both 1.7 drams and 2.25 drams of Swiss No 4, all to no avail – I just could not get any consistency in the shots – I think I could have done better with a shotgun firing ball! The 12 groove rifled bore is good, with lands narrower than the deep grooves, and I was using two 10 thou patches or one ten and one fifteen to give a tighter fit – I guess that it still wasn’t enough to grip the ball and maybe the ball sheds the patches and rattles around? Anyway I need to consult the experts! As an interim measure I’ll get the ball mould reworked to about 20 or 25 thou bigger diameter so I can go back to using 1 patch. I had a couple of misfires – but always it went on the second cap – I think I’ll have to change the nipple – its currently narrow at the top, wide at the bottom but I find the opposite is much more reliable, so I’ll make a new nipple – I hope the thread is one I have a die for! I took the .17 HMR just to convince myself that I am not completely useless and got some reasonable groups. Frustration apart it was a nice morning with a small but friendly gathering at the ITSC range. To my STEM club this afternoon – the children were so excited by the weather being good enough to be outside that it took a while to get them to concentrate – so I over-ran as usual…. The school has unearthed another 3 of an older generation of Lego computers so there will be enough to move to more, smaller groups with less friction!

Clay shooting sequence – range about 25 m

the top frame probably coincides with pulling the trigger, the second the sound of the shot, the third shows the shot as it misses the clay!

The entire sequence is 0.2 of a second. In the second frame you can see a faint trail heading for the impact point – I guess that is the shot column – the shot travels at near the speed of sound and the microphone was about 8 – 10 feet from the muzzle. Using the audio trace this frame is when the sound arrived at the camera.

It shows how far ahead you need to aim if you are snap shooting, and shows the slight changes in direction due to bounces.

(I think this sequence was shot with a .410 with a 2 1/2 inch cartridge, which would account for the fact that the shot cloud looks a bit small?)

27th Mar. In Cambridge running a historical reconstruction of gravity measurement with pendula – using a video recorder and lasers – not very authentic but effective. I did have a few moments to contemplate the Andrews pistol and drill the hole and cut the slot for the mainspring – I have gone back to thinking the smaller cock is right as, with a flint in the jaws, the top will end up aligned with the middle of the pan – I had to do my STEM club programs so that was all I managed, apart from getting out a few bits for shooting the Nock rifle tomorrow with the aperture rear sight and the enclosed foresight. Last time I got to the range after everyone had left, so tomorrow I will try to hit the ground running! I might take the .17 HML to sight it in, but I’m running out of ammo. I tried looking at a video I had taken of shooting a ‘rabbit’ clay with a muzzle loading shotgun in frame by frame mode at 50 f.p.s. Its quite interesting as you can see when the gun fired, then 4 frames later the shot is just visible in front of the clay and in the next frame hits the ground immediately in front of the clay but exactly aligned. Its amazing (to me anyway) how far the ‘rabbit’ travelled between the smoke appearing in the video and the shot hitting the ground – probably a good 6 feet, and that is without allowing for the time delay between brain and finger, and trigger and ignition. It was a very near miss in front! I’ll take the camera next Saturday when the AML shoots a Cambridge Gun Club, and try to get some more film……….. You would think retirement would be relaxing, but its far more hectic than working for a living – although I suppose I do get to choose – at least to some extent!

26th Mar. I made new screws to hold the bridle etc – 4 UNF threads, and the side nail, 6 UNC and cut the slot for the tab on the sear spring with a flat graver. The cock I was going to use is a bit too small I think, so I found a slightly larger one – I might go and take advice from Dick as he has done a lot more of these jobs than I. I did get the grass cut and the apple trees pruned, so it wasn’t a bad day, considering that we lost an hour due to the clocks changing to BST – we’ll have to wait ’til autumn to get it back. Robbery! I’ve got to write some programs for my STEM club some time before Tuesday, and I find I carelessly agree to talk to another children’s Science and Maths club in Newmarket in April, which will need quite a lot of preparation if I am to do them justice.

I’m not sure how to tackle the hole for the frizzen axle as it is bored out both ends and so won’t take a screw thread without more welding – its already been welded and moved once – the pan section is a bit of a mess, which is why its giving me more problems to get it in place than I would normally expect.- the same goes for the frizzen! I’ll finish the back of the lock where it touches the barrel when I do the final fitting with the touchhole in place.

25th Mar. I’m still struggling to get the pan casting into the lockplate neatly! So frustrated did I become that I resorted to cleaning the house for a couple of hours! So I’m afraid there is little progress worth showing ( except in respect of our domestic environment!)… I will make a few nails/screws tomorrow and try to get the frizzen into shape – I don’t know where it came from, but it seems to have been welded in a number of places, as was the pan section.

24th Mar. Went to Jason’s to get the lock welded and have spent most of the rest of the day struggling to get it filed up in a reasonable way – unfortunately it seems to need files of a shape as yet uninvented! I was very glad its only a lock I made myself as its taking a bit of a bashing – I’d be worried if it was the original. I found a better frizzen – the problem with the pan section is that the pivot for the frizzen is very high compared to most others – anyway I had to weld up and reposition the pivot on the frizzen and will have to reshape the tail with weld and add the tab to catch on the roller. The configuation of pan and frizzen pivot is odd, and it will need a very short frizzen spring – I’m not sure if it would have had a roller for that pan section or not.

23rd Mar. Progress on the Andrews – a bit slow as I had a meeting about computing in schools – I was in the middle of welding the hook when my lift rang the doorbell – miles away….! Anyway I plucked up the courage to do the script engraving – not my best effort, and tacked the pan section in place so that tomorrow I can get Jason to weld it in – I don’t trust my welding. I did manage to weld the hook on the front of the lock that holds it in although I did get the front of the lock rather hot and oxidised it rather more than I wanted – I just built up the hook with filler rod – I got a good approximation to the shape with weld then filed it – I need to do the final lock fitting but I’ll wait til the pan is fully welded as the lock plate may need flattening.

The script is not perfect, but will tone in when the plate is case hardened with Blackley’s stuff at the end.

The mess around the pan is modelling clay I used to hold the pan in the correct position while I tack welded it. It works long enough to hold until the tacking is done, and doesn’t tend to run or move at all. I use it often – its just firm enough and stays in the position you put it. I think the heat just drives the petroleum jelly out of it and leaves the clay!

22nd Mar. The Andrews pistol is coming along – I cut the aperture to fit the pan but haven’t welded it in place yet. I filed the chamfer round the lock – it’s not at 45 degrees, but around 35 to the flat surface, then had the excitement of engraving lines at the top and bottom of the chamfer surface which was quite tricky, particularly round the curves – that done I then engraved a running leaf motif down the middle of the remaining surface – the whole chamfer surface is about 2 1/2 mm wide, so by the time the two lines are engraved the leaf motif is probably less than 1.5 mm wide. Anyway, it looks better than I expected. I’ve done some of the decoration and foliage work – so now I only have to tackle the script name, which is a terrifying prospect – I’ll have to have a few goes on a scrap of metal. Doing the chamfer and the pattern across the tail got through all my gravers again, so I had another sharpening session before I could tackle the foliage.

A few differences, but recognisably the same pattern! I couldn’t decide if I wanted the ‘leaves’ round the sear spring screw.

21st Mar. – proper day playing with the Andrews pistol – I copied the holes from the original lock plate by fixing the old on top of the new, with suitable hardboard spacer, using superglue – one of my ‘must have’ items is a small pump of Locktite 7455 Activator that takes all the uncertainty out of using superglue, even if there are gaps. I then used my little Seig mill as a drill, locating each hole in the original plate with a sharpened rod of the appropriate diameter ( make sure it runs true) and then substituting a drill and drilling right through the new plate. I think with care I can get to about 0.1 mm. I drilled a series of 1.5 mm holes through the middle of the safety slot and cut out the slot with a fine fretsaw and filed it with a No 6 file, and milled the 4 mm slot with a 3 mm cutter. I’ve now tapped all the holes – I couldn’t find a taps that replicated the original threads so I used No 4 UNF for the bridle screws and No 6 UNC for the side nail – that means I’ll have to make new screws etc. UNC & F are my favourite threads – probably because I have the best selection of taps and dies and it matches more often than not. Next job is to file the bevel on the outer edge of the lock so that it can be engraved – Putting the engraved bevel around a lock is a first for me, so I hope it works out! I’m not sure how easy it will be to file a constant width bevel – I don’t have the filing skills of a classic gunmaker! I’ll run round with dividers first to mark a line to file to, and just try to keep a constant angle – fingers crossed. At some point I also have to fix on the hook that secures the front of the lock in place – in the past I have just built it up with weld, including the hook bit – so I’ll try that as its quick……………. And I had my STEM club this afternoon, and a School Governing Body meeting in the evening and a meeting at the school at 8.00 a.m. tomorrow…………….

The hole for the mainspring peg can wait until I am ready to put the frizzen spring on.

20th Mar – The browning is coming along nicely but slow – its called Blackley’s Slow Brown, so I suppose I should expect it! anyway I think 1 or two more goes and it will be OK. Tomorrow I need to tackle the problem of transferring the positions of the holes from the old lockplate to the new, complicated by the fact that both have bits on the back and can’t be put close together, plus there are no straight edges to measure from. I think I’ll have to clamp them together with spacers and mark with points of the right size to fit each hole using the miller to push the points in vertically. I figure that the holes need to be right to within about .1 of a mm – particularly the alignment of the bridle fixing holes with the tumbler hole – I have got that slightly wrong before and the tumbler is slightly misaligned and jams, and the only solution is to make a bigger tumbler hole, which is not a good thing. The other way is to mark and drill the tumbler hole, then use the tumbler to position the bridle and mark that, but its quite tricky to do that. Once I have the holes drilled I will cut out for the pan section so that I finish with the ‘heavy’ metalwork, and get on with engraving the lock to match the original, except that the foliage on the nose of the lockplate was put on for the conversion. After that is a matter of welding the pan section and cleaning up and case hardening the lock and fettling the cock and frizzen – not much then?

The lighting wasn’t very even, but the browning is. The twist stands out very well but not artificially so.

1 9th Mar I decided that I couldn’t bring myself to cut up the nice original lock to re-convert it to flint -its against my principles ( I do have a few!) to do that to good guns, OK for junk or if a lot of the pistol is missing. Anyway that meant I had to make a new lock plate from scratch and put the pan in that – I will reuse all the internals of the lock because they can be put back if necessary. It took me most of today to mill up a strip of 6 x 50 mm mild steel as a blank and then cut it out and fit it to the lock pocket – it is a bit slimmer than the original plate as I really needed 1/4 inch (6.4 mm) plate but don’t have any. I am also browning the barrel – first go with Blackleys didn’t touch the metal, I thought I’d try immersing it in copper sulphate to etch the barrel a bit, but that just copper plated most of it and I had to clean it all off. Blackley’s still didn’t touch most of the metal so I reverted to my used printed circuit board etchant and that got it going. Making a new lock means I’ll have to make a new side nail as I can’t match up the thread – its halfway between 6 UNC and 8 UNC, but I’ll do a 6 UNC nail as the hole in the lock is a bit near the edge of the bolster. I’ll probably have to make a couple of screws to hold the bridle as I don’t expect I’ll find a tap that works with the existing threads. I lined up the barrel and lock plate to find where the touch-hole will go and it seems to go together perfectly – the pan section is just right – I don’t know where it came from, it doesn’t look like a casting, more like an original cut out. I put the step on the back of the lock, and couldn’t resist engraving it – which meant spending over an hour sharpening 15 gravers that had piled up blunt or chipped. I usually leave them til I run out, then do them all together as its quicker that way.

I’ll have to mill out the slot for the safety,,. which will be fiddly, and then square off the end – even more tricky. I did it for the Lancaster (twice) so I guess I can do it again! My milling machine is pretty crude and has backlash in the leadscrews and vibrates so it is always exciting using small cutters!

18th Mar – The restoration of the Andrews pistol continues – I’ll make a separate post as I have a lot of photos. I have stripped it down, so I’ll include a few notes on what you need to know to take antique flint and percussion guns apart. I have all the parts to do a back conversion – and I think I’ll probably do one using the original lock plate as it will make a good demonstration of what to look out for in deciding if a flintlock is a re-conversion, and the percussion conversion is not a particularly nice one. So – see the beginnings of the ANDREWS RESTORATION post.

Selection of castings for Andews re-conversion – the cocks and frizzen spring will need to be sorted when the rest is in place.

I am temped to make a new lockplate!

17th Mar – I had a visit this morning from a chap who had a couple of antique guns – one he thought might be a shooter, but I’m afraid I didn’t think that was a good idea as it was too far gone to be worth teh considerable work in restoring it, and anyway I suspect the barrel was not recoverable. Anyway he is keen on taking up muzzle loading shooting and will come along to the Anglian Muzzle Loaders shoot on 1st April and join teh growing number of people shooting muzzle loaders. i suggested that if he likes it he might find a modern reproduction a good way in as they are still affordable at auction. I did a bit of work on the Andrews Pistol – running the bits through the de-rusting – its in pretty fair condition. I had a look at a couple of photos on Andrews pistols on the web – Google images – Andrews pistols, and found two different flint lock designs in use – an older version with a stepped,rounded tail to the lock and a traditional English serpentine cock and a semi rainproof pan, and later design with a square tail to the lock and a French cock and a full rainproof pan. The former matches the lock shape on my pistol. I went to Dicks and we hunted around for bits to make a flintlock for it – I had found most of the bits but we found a frizzen spring casting that is (probably) the right size – it won’t be clear until the lockplate and pan section are in place. I now need to decide whether to use the original lock plate or make a new one…… difficult! The Griffin pistol I showed earlier before repair is now finished and Dick has been asked by a friend living abroad to sell it for him, and I offered to put it on this site. You can see the photos in the Post Griffin Pistol and some in the GUNS & BITS FOR SALE page at the top – here is a preview;

This is a Griffin Officer’s pistol from around 1760 – a number are found in America from English officers fighting in the French and Indian wars – see post Griffin Officer’s Pistol for more pics – click on the photo for more details. It is No. 1 of a pair, no longer together.

16th Mar – It was interesting to watch, from time to time during the day, how the Holts Auction was going – there was so much stuff that it ran from 10 oclock to about 7 p.m. Many of the lots struggled to make the reserves – but there were so many guns that were much of a muchness that you wonder who was buying it – most of the lots went to either bidders in the room or on the telephone, a few lots went to internet sales (it costs an additional 3% to bid via the internet!). The percussion guns I picked as being worth buying – the Bond (1800 hammer price) and the Greener (3900 hammer price) shotguns – made good money and the ones I thought were a bit rough, like the Nock 7 barreled gun that I thought rather rough and the Witton and Daw just scraped over the bottom reserve (700) as did the horribly badly ‘restored’/abused Manton breech loading flintlock. Mostly I thought the bottom estimates were on the high side – Holts seldom sell below the bottom estimate . By the time you add the buyer’s premium and VAT to the hammer price, the Greener was a shade under £5000 – I would have happily paid £4000 for it, but 5K is a bit inflationary. There will inevitably be some inflation in antique and modern gun prices because a fair number end up in the US and the dollar now buys more gun in England than before, or put another way, it means that Americans can afford to bid higher. The Witton and Daw was a reasonable buy at the selling price as it was unusual – it was bought by a friend and will probably pass through Dick and my hands on its way to its eventual home. I look forward to including it in the blog. I was sorry to see that the East India Company rampart gun lock had been taken out of the sale as I have one that has been converted to percussion that I’d like to return to flintlock – I am chasing the lock via my contacts………. I was hoping that it would form my next project as I’ve finished all the jobs on hand, but I found a pistol by Andrews buried under the junk on my bench (yes, really! – its been there for months and months…) that definitely needs a bit of TLC – It would make a good target for re-conversion to flint s I could make a new lock and remove the drum and nipple conversion, but I have no confidence at the moment that I can get the necessary castings, and although I do have some odd castings in stock, I don’t think I have a pan section, a frizzen and a cock that will go together – maybe I can get something from Dick….. Anyway I will start by cleaning it all up and see where we go from there…….. the obvious first step is to dump the whole lot in the de-rusting tank for an hour or so and then lightly brush off the soft black powder that hard brown rust gets turned into when it goes from ferrous to ferric oxide………magic!

Its all a bit sad, nothing serious but a bit of surface rust and worn woodwork – the percussion conversion is rather poor quality but the basic pistol was good – one reason to want to convert it back to flintlock.

The safety catch is broken – a fiddly part to repair and a lot of the lock plate has been filed away in the conversion and would need to be built up if it is re-converted and we didn’t make a new lock.

A reasonably good quality lock on the inside – not top quality but perfectly good, and it will clean up just fine.

The barrel is not too bad – it hasn’t had a lot of wear, only a bit of patchy rust – teh ‘London’ is clearly visible and not unduly worn.