___________________ DIARY _____________ _________

7th April – Gave up on Parcelforce after another ‘I’m very sorry but there is nothing I can do…’ so went and bought another basin and fittings for another £150. Now I suppose there will be a fight to get the money back on the original order from Better Bathrooms! I heard today that E.J. Blackley, the founder of the eponymous company has died. A great guy and a great inventive genius – the business continues to be run by his son Kevin. I had a look at diamond sharpening stones, and was pleasantly surprised that the prices were considerably less than the last time I tried to buy one. From www.buybettertools.com a 6 inch DMT (reliable brand) stone in 1200, 600 or 325 grit costs 29.99 including VAT. My very fine diamond stone is a DMT extra extra fine at 8000 grit, but I didn’t feel it was worth the cost (£101.99) as it didn’t give a very good surface finish. A half decent 6 inch x 2 inch Arkansas stone is going to cost at least £50, but with care you could make do with a slip of 1 inch x 3 inches. (disclaimer – I have no connection with ‘buy better tools’ and have never used them, but the stones are branded so shop around for DMT diamond stones…) I looked at optical visors before I got a microscope, and borrowed an expensive Optivisor, but it didn’t really do anything special for me that a cheap one didn’t do perfectly well. As explained elsewhere, with simple optics there is a direct relationship between magnification and working distance – the higher the magnification the shorter the working distance. A magnification of 3.5 is about right to give you enough room to engrave without sticking the graver in your nose. A number of professional engravers use a single loupe or eyeglass in one eye, and engrave with their face very close to the work, but I find it very difficult. I now rely entirely on my microscope which gives me magnifications from about 5 up to x 25, but a decent stereo microscope that is suitable for engraving will cost you several hundred pounds secondhand, or about £600 or more for a Chinese version. I found a very good second hand Wilde ( later Leica) with stand for the price of a new Chinese model. I was lucky that the microscope I found had almost suitable magnifications for engraving, and I found an add on lens that made it perfect for my work. The big advantage of a microscope is that the more complex optics breaks the relationship between magnification and working distance, so that I can have about 120mm of working distance at all magnifications I can use. Don’t buy a microscope until you have checked out the magnifications available and the working distance- you need a low mag. of x5 or less, and are unlikely to need much above x25 even for very fine work. A working distance of around 120mm is good – much more and you can’t get your hands and eye into comfortable relative positions, much lee and there isn’t room for your hands between the objective lens and the workpiece.

6th April – Still tearing my hair out over my missing parcel which hasn’t materialised. Hours trying to phone just gets people who say ‘ terribly sorry, but there is nothing we can do’ – Its still in Birmingham as far as I can see, but in the digital pipeline and inaccessible to mere humans – it it doesn’t materialise tomorrow I’ll have to find a substitute. The missing item is a bathroom basin that I need to replace one I have already taken to the dump, and I need the room finished soon as it will be used next week. It’s supposed to be delivered tomorrow, but I’m loosing hope………………… Thinking about starting engraving, I realise there is quite a threshold to cross, because, althought it seems that it is a fairly simple process, you can’t really see well enough with the naked eye so you need an optical aid of some sort, which you won’t at first be used to using. You also need some means of holding the workpiece, and since the force you need to exert for engraving steel is quite high, the holding needs to be secure but you need to be able to move it with your other (left) hand and to use it to oppose the force of the engraving hand. All this bearing in mind that in the beginning your graver will occasionally come out of the metal suddenly and fly off and impale your other hand – all that without the complication of actually engraving. Plus there is the problem of what you are going to engrave! I haven’t managed to find a source of suitable soft, uniform steel with a fine or polished surface in pieces that are handy for engraving. I usually buy cold rolled mild steel bar in 6 or 8 x 50 mm in 3m lengths and get it cut into 150mm lengths by the supplier ( I need to check who is best) and then get a local firm to surface grind it, but I haven’t found anyone who will produce a suitable surface, so I have to do a lot of work to get the surfacc fit for engraving with a fine file and then wet and dry down to 1000 grit. I have bought cheap little engineers squares and engraved those for practice – check out Tracy Tools on the web, great service and very very cheap for what seems like perfectly good stuff – I get blanks for gravers from them, plus drills, taps and dies. I must investigate getting steel with a decent finish and add it to my shop. Having got that far with our beginning engraving, we then meet the next little problem – within a few minutes you will either have blunted your graver or more probably broken off the tip as you tried to finish off a cut without impaling yourself – so you need to sharpen it – whole new can of worms! As a beginner you CANNOT sharpen a graver without a jig, you can get a proprietory one or get one of mine. Then you need a ‘stone’ to sharpen it on, and since gravers are hard and the surface to be sharpened is small they will quickly wear the surface of anything but the hardest ‘stone’ into an uneven shape that won’t sharpen true. If you break the tip off your graver you’ll need to remove quite a lot of metal, perhaps 1/4 mm or more to get the point back, so you need a fairly coarse ‘stone’, but that won’t give you a very good finish so you need a finer ‘stone’ for finishing. Even that stone will be a bit fierce for putting the tiny heel faces on the back of the point ( maybe a triengle of 1/4mm side). So you need 3 ‘stones’, preferably the coarse and the finishing will be diamond ‘stones’, and the heel stone an Arcansas stone – about the hardest, finest stone in use – you can’t get proper black Arkansas any more, but the white is OK. I use 260 and a 1200 diamond, and a white Arkansas stone, plus I have an old 10000 grit diamond that I just use for starting the heels so that I don’t score the Arkansas ( the 10000 grit diamond was a disappointment for sharpening as it didn’t give a particularly good surface and was very expensive). You can’t shirk the sharpening palaver especially when beginning as you’ll spend around 1/4 to 1/3 of your time doing it, and you won’t get much joy out of your engraving until you have mastered it. BUT it is perfectly possible to master it all in time – I did, and I didn’t have any hints on steel engraving, just an old graver that I used rather primatively on brass 50 years ago…………… If all that sounds a bit daunting you can always cheat and start with copper, which you can buy with a good finish and won’t require so much force, or be so destructive of your tools, so less sharpening time, then when you have made some progress you can make the transition to steel. I wouldn’t recommend brass as it is difficult to get a soft grade that engraves easily – most brass is a pain to engrave as it requires quite a bit of force to cut but will then suddenly yield and your tool will skid off making a nasty unintended cut across the surface and into the side of your thumb! I have found rifle cartridge cases engrave well but the curved surface is not easy for beginners……

5th April – Spent hours chasing a parcel that had gone astray and that I needed urgently. The , I bought it off had given it to Parcelforce in time, but Parcelforce had ‘ sent it to the wrong depot’ – how you can do that with everything computerised with bar codes is beyond me. Anyway I spent hours waiting in queues to talk to the supplier and getting no-where – the phone number they gave me for Parcelforce also got nowhere In the end I googled ‘Parcelforce Birmingham phone number’ (the latest depot it had been sent to) and in 30 seconds got sense and a promise that it would be prioritised and arrive tomorrow morning – we shall see! Anyway I got so frustrated that I took a chainsaw to a massive Budlia tree/bush and reduced it to a mangled stump, which left me with a very large heap of tangled branches to get rid of – still, I felt better for it. Still having some issues with my over enthusiastic Rottweiler blocking my visitor, but I’m working on it. And so, unfortunately the Gun Case Blog is again neglected. I had an email asking about what was needed to start engraving, so I might see if I can come up with a simple list. I get a few emails every week from visitors to the site and I’m always pleased to hear from interested enthusiasts, so if you have any questions you think I might be able to answer, or constructive comments for that matter, email me as per CONTACTS………….

4th April – My Rottweiler (named Wordfence – see below if you are not a follower of my blog) bit me, presumably for interfering in his choice of who to block from this blog, and blocked me! That is more difficult to deal with than his blocking of other people, as I can’t get onto the site to unblock myself! Fortunately I have a ‘get out of jail’ card, otherwise I wouldn’t be on the blog now. I’m sure it blocked me for some transgression that I hadn’t committed – If you get blocked from the site email me and I’ll sort it! These tribulations are sent to try us……….

3rd April – Internet came back last night, probably somewhere flooded, there was a lot of water about and the phone was on the blink too. I managed to re-instate a regular visitor to this blog who had somehow got blocked by my pet Rotweiler – Wordfence – that guards my blog against the (literally) hundreds of attacks every day. Anyway I managed to catch it blocking his IP address and duly admonished it. Peace is now restored! I was prompted by his recommendation to a watch ‘The Repair Shop’ on BBC2 that I’d recently been invited to apply to take part in a TV show being produced that wanted real ‘nutters’ who were prepared to go to any lengths to find parts etc to restore the object of their passion, the nuttier the better. I did give them a brief intro to the world of muzzle loading shooting and restoration, but I must, unusually, have sounded too sane for their plans, and they went off in search of more interesting nutters – perhaps like the 40 odd families I met at a lock on the Thames this summer who were each driving some form of amphibious vehicle on a rally on the river – ex army DUKW’s, amphibious 1940’s Jeeps, converted estate cars and whatever the little amphibious car of the 1970’s was – 40 of them in total – what a sight. The extraordinary thing was that they had come from all over Europe, as far as Poland, driving the bigger vehicles or trailing the smaller ones – talking to them, I realised that I and my muzzle loading friend are indeed sadly far far too sane to qualify!

2nd April – My internet is playing up and its almost impossible to do anything – try again tomorrow!

1 st April Too late for April fool’s jokes, that has to be before noon. I have been reading Keith Neal and Back’s book on gun cases and trade cards. Its a very useful guide to dating cases and also for anyone who wants to case antique guns, either in an antique case or a adapted box. While the best course of acction for anyone contemplating doing that would be to buy a copy of the book, they are hard to come by and expensive, so one gun may not justify the trouble and expense – I thought I’d extract some essential information from the book and put it in a Post, and add a table of dating features to my GUN DATES page – so that is the intention. I also need to do the promised Post on duelling pistols…..

30th march – Almost another month gone… I put all the furniture back on the 8 bore, where I know the fit is bad I put a bit of hard black wax on the edge using my tiny hot air gun (1/4 inch nozzle) to take up the gap, and melt more into any remaining gaps. The butt plate needed the bottom edge trimmed slightly – they often stick out a bit and catch, anyway it all went together reasonably well, and I got the screw heads aligned perfectly. So its beginning to come together – at the moment its all covered with sticky slacum ( boiled linseed, beeswax and terbene driers) waiting for it to go jelly like so I can wipe/rub it all off again. This process will be repeated until the finish is good enough, although it is always possible after a few coats to change to wax furniture polish and cheat! I was checking Brownell’s website for honing stones – I might just buy a few bits to make up a hone – the regular ones go up to 10 bore but I’m sure I can fudge things – the extension rod to make the hones long enough to go down the barrel are much more expensive than the rest of the kit and definitely won’t work with 8 bore barrels, so again I’ll resort to making something. I wish I had access to a Delapina lap, but never mind! I am not sure I have the perfect recipe for Slacum – I did a series of trials and came up with a maximum of 5% beeswax and around 1% terbene driers – but it didn’t seem that critical, apart from keeping the beeswax content at 5% or less. On the last lot I made the terbene went into short strings when I added it to the oil – not sure what happened there……….. My hard wax is made up of beeswax and carbon black, but it is possible to buy very hard coloured wax for repairing scratches in furniture that would be better – trouble is it costs £100 for a kit and has mostly colours we wouldn’t use. I was wondering today what essential kit one would advise someone starting out in restoration to buy initially – If I think what I would not like to be without, apart from the obvious collection of screwdrivers (turnscrews in gun speak) I guess I’d say a simple derusting setup, if necessary using an old phone charger or similar, and a cheap grinder with a very fine wire brush (probably as expensive as cheap grinder!). If I were mostly dealing with guns in better condition than I normally restore, I’d probably come up with a different list. Whichever you tackle, the need to be able to make screws will come up sooner or later if you can’t outsource that work, which takes you into the realms of a small lathe and taps and dies. And so it goes on………& on……………..& on………………………………………………….

The steel cup is a bit thick (limited by size of available end mill!) and I didn’t get rid of all the defects around it, but its meant as a functional restoration. Steaming has taken most of the dings out – minimal sanding was done – it is very effective.

The finial is quite badly rusted round the edges, which makes the fit rather poor, but improved! It no linger looks like a tired old gun that has been neglected and I hope one day it will see use again when the barrel is done.

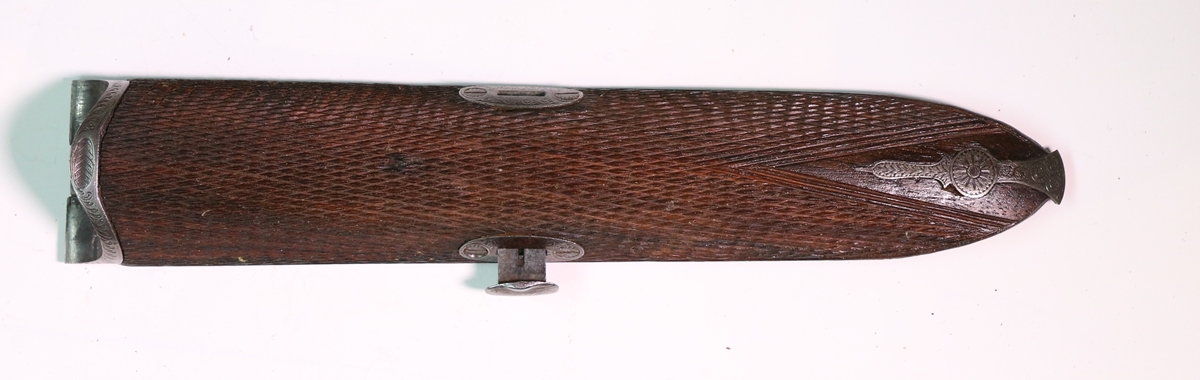

29th March – More 8 bore… I forgot to mention when discussing removing screws that one of the problems with fitted screws in old guns is that the heads are contoured to fit the furniture and as you unscrew them you need to keep the screwdriver aligned with the slot, which often means tilting it as you turn it, otherwise you partially come out of the slot. Anyway having stripped and cleaned all the furniture I escalated the job to include gently refinishing the stock as it had plenty of dings etc. I inlet a small piece of wood where a bit had come out round the finial of the trigger plate and cut the surface flush and refitted the finial temporarily, then set about steaming out the dings in the spout of a kettle on the AGA – difficult to do if you are using an electric kettle, but a wallpaper steamer would work. That got out or reduced a lot of the dings and destroyed some of the finish so I removed most of the rest on the butt with 320 grit sandpaper and methylated spirits (wood alcohol) as it was varnished with shellac. I cleaned the chequering using an old toothbrush and meths, enough to show the chequering reasonably clearly. Several goes over the stock with medium grade steel wool and meths got it to a reasonable finish – I didn’t want a complete strip to bare wood, just a somewhat better finish. There were a number of black stains – probably iron stains, so I very carefully applied oxalic acid with an artist’s paint brush to soften the stains – you need to be very careful or it will bleach the unstained wood very pale – if that happens you will need to colour it down with Van Dyke crystals in water or a spirit stain, applied carefully. When you apply oxalic acid or stain using an artist’s brush, apply it streakily along the grain of the wood – that way you hide any edges amongst the grain markings. Having got the wood to a fair finish and acceptable colour I wipe over it all with a piece of kitchen roll dipped in shellac dissolved in meths – button polish is one name for it – this seals the grain. Applying a second coat messes up the finish because it leaves smear marks, so at that point I’ll go to using ‘slacum’ to give an English oil finish, which will require several dozen coats, but before that I’ll remount all the furniture. At the moment I’m waiting for the butt plate screws and the sling mount to derust….. I also need to fit the steel cup for the side nail. The next big job will be to sort the barrel, but that may have to wait a while as I need to make/buy a tool for lapping the barrel before I rebrown it. lapping the barerl will have to wait while I clear out the outside workshop as I can’t move in there at the moment for stuff bought back from the flat – I have just about cut up all the wood from the window surrounds and fittings but all the tools, plumbing bits and electrical wiring parts are scattered around – if you don’t get much gun stuff on the blog for a bit it will be because I’m trying to have a massive sortout – there is a certain amount of domestic pressure for de-cluttering etc in addition to the workshop……………….. Happy Easter!

28th March – Continued with the 8 Bore restoration today with a visit to Dick to use his vice and torch to shift the breechblock, which we did successfully – its a strange fact that breech plugs almost always come out with perfect threads without a trace of rust. Any rust is usually confined to a tiny bit around the joint at the barrel and on the edge facing into the powder chamber. I don’t know what they used to lubricate the thread, but it certainly lasted 200 years or so! This one was no different, once heated almost to wood charring temperature and held very very securely in the vice it yielded to a 2 ft lever and came out easily thereafter. The passage from nipple to main chamber contained a lot of hard blackish powder, but as it was slightly damped with cleaner or whatever I couldn’t get it to flare like black powder although I think it may have had some in it – by the way, I DID carefully probe the barrel with a screw rod to check it wasn’t loaded before heating it! Anyway a trip to the electrolytic bath and a bit more picking out the passages with bits of bent wire and I’m sure its clear now. Now the breech plug is out I can see that the barrel is pretty reasonable, certainly shootable. I may have a go at lapping it if I can make a suitable tool. The side screw hole was a mess so I dropped a 16mm cutter into it and made a plug and glued it in, but I then made a steel cup for the head of the side nail so I might put that in instead. I initially thought that I would leave the butt plate as they are usually horrible to get out, but the rest of the furniture looked so much better than it did, so I took it off. The two screws holding the butt plate are almost guaranteed to be rusted around the heads and stuck fast. The threads are often rusty and stuck in the wood too, often pulling most of the threaded wood out with them. The technique to get them out is to very carefully pick out the slot in the head of the screws down to the metal, and put some release ‘oil’ on the joint – I put a small drop of gun oil and then take a brush of Acetone and brush it around the edge of the screws – it penetrates better than proprietary penetrating oils. You need to hold the butt very securely and have a screwdriver that is a perfect fit and try carefully. The top one is usually the worst – if it doesn’t budge fairly easily play a fine torch flame onto the screw head ( it does need to be a very fine flame) and try again. The 8 bore butt plate screws came out fairly easily, the top one with heat, and once started the screws themselves were as clean as a whistle. There was quite a bit of flake rust on the inside of the buttplate and on the wood and it took about 3 hours at 2.8Amps to derust the buttplate fully. Having derusted the furniture and thoroughly wire wheel brushed them ( .03mm wire brush) I generally coat the hidden surfaces with ‘Metalguard’ which leaves a thin anti-corrosion film over the surface of the metal as its in a fairly active state after derusting and will rust easily. I’m generally happy to put the furniture back with just the Metalguard as protection, sometimes putting on another coat if the part has been handled much since first coating. Most oils and greases soak into the wood so be sparing if you use any behind the fittings.

You know how it is? Having got so far with the restoration (actually more of a tidy-up) I can see that the woodwork could be a bit better, so for completeness I might just steam out the dings, and possibly refinish it – in for a penny, in for a pound……

Yes, I know its not quite centered!

The buttplate is held on by two screws and the tab along the top. After removing the screws the whole buttplate must be moved backwards by 6 mm to disengage the tab. As you can see, there was quite a lot of rust under the plate- its surprising that the two screws were in perfect condition in the wood.

27th March – I think I have identified a couple of cocks from E J Blackley & Son for the Post Office pistol and the Mortimer, so I rang Kevin B up and had a nice long chat – Kevin asked if the P.O. pistols would have had a French style cock ( either a spur cock or a true French cock ) or an old style cock. The French style use their ‘chin’ as a stop on the edge of the flash guard, rather than a step on the back of the cock hitting the edge of the lock. Kevin pointed out that the stock needs a small cut-away section for the stop of the ‘English’ cock, whereas the ‘chin stop’ doesn’t have the cut-out. We decided that they had had English cocks and possibly his pattern FC91 would fit so I’ll order a couple. The ‘Mortimer’ of course hasn’t yet got a stock so I can’t use that guide to the cock style, but the locks were made for a mainspring without a link, bearing directly on the tumbler as of old, so I guess that its an old style lock and would suit an ‘English’ cock – I guess it probably didn’t have a roller or link on the tail of the frizzen or the frizzen spring either. I reckon Blackleys cocks FC90 would fill the bill – I’ll have a look for frizzzen spring castings for the ‘Mortimer’, but I’ll probably make the mainsprings as I enjoy that. I’ll see Kevin at the Birmingham Antique Arms fair in June so I hope they will be cast by then – Kevin says he is doing fairly frequent castings now. I stripped the furniture from the 8 bore and put it through the electrolytic derusting. It was quite pitted and the engraving is quite worn and pitted so it won’t restore to anything like original state, and as most of the bits are hardened, I can’t easily recut them. I did try on the finial of the trigger plate by annealing it, but its too far pitted to make any difference so I’ll leave it. The wood around the furniture is badly stained black, and on one side of the finial is missing – I think the staining is a combination of rust and too much oil on the wood – my father, who owned the 8 bore before me, used to slosh oil about on guns and several of ‘his’ guns suffered from staining, although in this case there is also quite a lot of rust under the furniture that I have now scraped away carefully. I’ll go down to Dicks tomorrow and we’ll remove the 8 bore breech plug (with luck) – I ran out of gas for my Butane torch today, and my vice is not really man enough. I also need to take back the engraving I did for himon the Fowler duelling pistols. I will start a new post on both the PO pistols and the 8 bore.

Looking at the insurance certificate that came after transferring my insurance to the new Land Cruiser I spotted an exclusion – apparently I was allowed to carry up to 2000 cartridges but no explosives – now of course black powder is an explosive so I was a bit concerned that my insurance would be invalid if I carried a flask of BP to Cambridge Gun Club, let alone brought a couple of Kg back from purchase from our group. Anyway not wanting to find my insurance void I rang my broker and explained how I used black powder in a muzzle loader instead of cartridges. They very helpfully said that’s OK, you can have BP up to the equivalent of 2000 cartridges – now at 2.5 drams per shot and 1.77 grams per dram that amounts to round about 10Kg. of BP ! Anyway I said thank you very much, and they made a note on my insurance that they have authorised it. Result! But you had better check your own insurance if you carry BP in your car.

A selection of cocks from stock, on the left ? for the good PO pistol, the rest are ? for the ‘Mortimer’, FC 90 is on the right.

Furniture as was – click on pictures to see in detail.

After an hour each in the electrolytic derusting bath and a fine wire wheel.

26th March – the year marches on… I managed to sell my old Land Cruiser Amazon for the asking price and it was away within 8 hours of it being bought so that makes the new one a bit less of a shock to the finances. I drove the old one to get it out, not having driven it since I got the new one, and immediately realised just how much more solid and hefty it was – a lot more tank-like to drive too. But I did really like it and it didn’t let me down once in 10 years, so goodbye…… I took a photo of the two Post Office issue pistols I bought in Bonhams for a ridiculous price some time ago – I still can’t work out why as there is a lot of work in restoring them. They were listed as rare so I guess I was taken in in an absent minded moment!

What a mess!

By Harding, some of the lock parts are missing, and one cock is completely wrong, the other is possibly OK but a replacement. It will be a very good exercise in restoration for this blog! I now need to source a pair of cocks for these pistols and a pair for the ‘Mortimer’ repros.

25th March – busy day – has the feel of the first day of spring which I define as being able to leave the back door wide open while you potter about outside without worrying about the kitchen getting cold. I sorted the kit to go in the new Land Cruiser – it is the same position in the range as the old one but doesn’t have quite the solid feel of the last and while most gadgets are identical it has lost the programmable driver’s seat positions and the steering column now adjusts manually instead of by motors. I guess the weight has been cut down a bit to improve fuel consumption – I can now carry the (removable) back row seats with one hand where I used to struggle to lift them. But it does have a camera to view the tow hitch while reversing! My old one is getting lots of offers on Ebay, but so far not quite high enough to temp me.

Looking round for guns to sell to make some space ( pistols don’t really take much room) I came across an 8 bore percussion wildfowling gun – its reasonably nice – wildfowl guns were never very fancy as they were strictly working tools for rough conditions, – I can’t read the name as the lock is a bit worn and pitted. The barrel is pretty heavy and fine on the outside but had patches of rust inside so I set about cleaning it by running 320 grade paper up and down by hand and in a drill . This generated a lot of messy rust as I’d squirted Napier cleaner down the barrel. Anyway after a long session including getting bits of 320 grit paper stuck in the barrel, and then ‘loosing’ a couple of tissues that I was using to clean out the mess I did get it clean enough to look at the bore – probably OK is the interim verdict. I took out the flattened nipple with some difficulty but there is no passage through to the barrel. The next stage is to remove the breech block – its a round barrel with a scalloped ‘flat’ on top so I’ll have to be very careful not to damage things. I had a try with the breech cold but I was in my indoor workshop and the vice is not really man enough for the job and you do more damage that way, so I need to migrate to the outside workshop which I haven’t used since the Autumn and is full of junk – nothing is simple……. Anyway when I’ve had a good look at it I will tidy it up and put it up for sale on this website – I suspect that it will again make a fine wildfowling gun…. but I’ll sell it as an antique anyway.

8 Bore single wildfowling gun – a typical functional working gun – it will clean up very nicely

24th March I had a look at a typical Irish Duelling pistol from the height of the duelling craze in Ireland

Features of note are;-

- Octagonal barrel – after about 1770 – Spanish form before then.

- Round butt section – most early English duellers had flats down the sides, wider at first. Post 1790? The ‘hatching with 4 dots in each diamond resembles that used by Durs Egg in the early days of the genre.

- Roller on frizzen spring (also known as ‘feather spring’) This is probably post 1780 ish.

- Bolts secure barrel – replaced pins around 1775, later style pistols had silver ovals round bolts for protection.

- non rainproof pan – not necessarily a good dating guide as many old style pans were made long after the rainproof pan was patented.

- Running leaf (feather) engraved border to lock – this came into use in English guns around the turn of the century(?), along with little bits of engraving such as that on the cock of this gun – I’d rate this a strong pointer to a date.

- No set trigger – the best duellers usually had a set trigger, but some customers probably didn’t want them on teh guns they ordered.

- Tip of cock rolls forward – early or old fashioned feature.

By Comparison here is a duelling pistol by Hutchinson of Dublin.

It has;

- No hatching, small flats on butt – probably earlier than the above

- A link from the tail of the frizzen to the frizzen spring – probably an early feature, maybe 1770s. (later – roller on frizzen tail, then on spring.)

- Similarly plain lock – the cock is a replacement, copied from another Dublin dueller by Edwards of about the same date(?).

- Tip of cock rolled forwards .

- More pronounced ‘swamp’ on barrel. (i.e. a more pronounced ‘waist’)

I’d probably put the top one at around 1800 or a bit later, mainly on account of the lock border engraving – other features support a date of 1790 or later. The Hutchinson may be a bit earlier – possibly around 1780 to 1790. Estimates like this are always approximate unless you have something more concrete to go on, like an patent, or the introduction of platinum (John Manton 1805 ish) but in this case the link on the frizzen is an unusual feature and suggests an earlier rather than a later date, unless it was a speciality of Hutchinson. Of the two, I’d say the Hutchinson is the more elegant pistol.

22nd March Had a look at the result of Holts Auction – quite a lot of guns sold at the low estimate and I noticed a couple that sold below the bottom estimate, which is almost unheard of in Holts, although fairly normal in Bonhams and other auctions. A couple of guns went well above estimates, but its a difficult job picking out what will appeal to collectors and I guess its easy when you are pricing hundreds of guns to miss the occasional special. There were a number of unsold lots too. It’s impossible to tell how much the price achieved is more or less set by the estimates, or its just that the estimates are accurate – for expensive stuff the price is determined externally to a large extent, but for the run of the mill stuff I suspect that the estimates are important in setting the price achieved. Difficult to make a judgement about my area as there were not many decent muzzle loading shotguns, although I think it would have been possible to pick up something shootable at a reasonable price. The Nock 7 barreled gun made £20,000 but it was very fine. Unfortunately I couldn’t find any suitable restoration projects for the blog, so I’ll have to do one of the many that I already have. Went to test drive a car for a friend but had to wait while the salesman sold a £50000 10 year old Aston Martin to a youngish looking chap – I can’t imagine what the insurance must have been – but not my cup of tea even if I had the cash. Off tomorrow to pickup my ”new’ 9 year old Land Cruiser – come to think of it, by comparison maybe the Aston Martin wasn’t such a bad buy! Dick has a pair of duelling pistols by Hawker of Dublin for light restoration – Hewker was second only to Rigby as an Irish gunmaker of the late 18th century. ( ……Usual for breakfast)

21st March – busy day – off to Holts at their new location in Blackheath, S.E. London. I drove because I had the Alex. Henry and the Theo. Richards to return, and I also wanted to go to Cricklewood to look at a replacement Land Cruiser so it involved a journey across London – not only did I have to pay the congestion charge but an additional ‘naughty boy’ charge for having an old diesel vehicle – around £21 in all. But it is quicker than the previous journey by train to Hammersmith. Anyway I meet increasing numbers of ‘old friends’ at the auctions as my circle of contacts widens, which is nice although it cuts down the time available for looking at guns. I did check out a few percussion shotguns and had a quick look for good restoration projects (none) and checked out a gun that Martin fancied. One friend I met said apropos of this blog that I included everything except what I had for breakfast! Well, just to complete the picture, the answer is toast. No more details will be revealed. On to Cricklewood where I crawled under and over an ’09 Land Cruiser that was starting to corrode underneath – shame as the price was good, then onward to another on the way home which was the same age but much better and lower mileage but more expensive than my target – but I bought it nevertheless after a bit of a haggle, so now have to get rid of mine on ebay as the part exchange price didn’t excite me. Now I will have a smart, undented vehicle for the first time in ages, have to try to keep it that way! I’m pleased to report that our work on the Alex Henry met with much admiration – it was a good example of our ‘less is more’ approach – do the least that you can get away with to achieve the truly authentic result, and make your improvements incrementally – only resort to major surgery when a bit of simple cleaning and refurbishing leaves obvious problems. Had a discussion about making ramrods – one suggestion was a section of an old greenheart fishing rod, optionally ‘ebonised’ with a blowtorch. We all went away determined to have a try with out preferred method, so I’ll have to finish the ebony squares I have cut – I will try and make a jig to plane them octagonal, or possibly 16 sided, and then experiment with a form of ‘cenreless grinding’ with a belt sander, or possibly turning in a lathe by advancing in short sections – we shall see, I’ll report here…..

19th march – I sold the pair of pocket pistols by Abbey of Long Sutton – it was a beautiful little set and quite a bargain – I am not sure why I sell my small stuff and keep all the big guns, they take up too much room! now I’ll have to find a few more from my collection to put on the website – its time to go hunting for some restoration bargains, although I can’t pretend that there is any profit in it, (except to my wife, who fortunately doesn’t read this blog!). I do have a little pair of flintlock pocket pistols made for the Post Office – at least it is two almost identical pistols. They are in very bad condition and missing the proper cocks. I bought them at auction for a ridiculously high price – they were catalogued as ‘rare’ and I fell for it, more fool me, although I suppose someone else must have bid one offer down from me so I’m not entirely alone in the idiot stakes. Anyway I ought to fix them up, which involves getting cocks for at least the one that has a very home made cock. The one with the almost right cock has 1969 and some initials stamped tidily on the back of the cock, so that is hardly original! I also have to get a pair of cocks for the ‘Mortimer’ pistols so I’ll have to hunt around. I’ll do some photos of the Post Office pistols some time. I discovered this morning that my little CNC machine had managed to bend its spindle a bit so the cutter doesn’t run true – must have happened when it drove the cutter into the work in a mad moment – the only solution is a new DC motor at £40 or a nice brushless 500 watt motor at £90. Unfortunately neither have substantial bearings, but maybe I’m expecting too much. Tomorrow is a day for car hunting if I can find any to look at – I also have a couple of meetings at the school which promise to be ‘interesting’……… c’est la vie. Wednesday is Holts viewing and Thursday and Friday might wrap up the vehicle saga, who knows…………….

18th March. I got into trouble from one of the regular readers of this blog for my tardiness in keeping him entertained! Apologies! I will do better in future…. Yesterday we had an Anglian Muzzle loaders shoot at Cambridge Gun Club in the freezing cold – I had lost my capper on the last game shoot of the season and hadn’t replaced it so by the end of the morning standing around for 2 hours in a biting wind I could only fit a cap on the nipple by a sort of random process of tries since I couldn’t feel anything. Unusually we shot the ‘driven’ stand as part of the competition, which helped (almost) everyone’s scores – I can shoot those clays well when they are coming more or less overhead but the few that come lower to the side I miss. I think the ones I can hit are the ones where the muzzle of the gun blanks out the clay as you try to get a lead on it, so you are effectively shooting ‘Churchill’ style ( follow, accelerate, fire as you pass the clay and keep going) rather than maintained lead where you get in front and try to judge how far ahead you need to be as you wave the gun about. I also manage to hit a few that are so fast I don’t think I stand a cat in hell’s chance of hitting them so there is no chance of a considered maintained lead – I obviously need to train myself a bit better. Anyway I had a reasonable result by my standards! Apropos of the parts for the Mortimer duellers, I looked through my bookcase for inspiration and came across a book that I didn’t remember – The British Duelling Pistol by John A Atkinson published in UK and Canada in or before 1978 which is a very thorough summary of the development of the type from 1770 to 1850 or so with particular reference to the key makers – Griffin (&Tow), Twigg, Wogden, Durs Egg, Staudenmayer and the Mantons. It has lots of dating information and lots of typical 1970’s black and white photographs that are almost entirely useless as the only details visible are things that show up in outline! In spite of that it is a very good reference, although how accurate it is I am not sure – I say that because its section on Forsyth seems not to agree with things I have read elsewhere – for instance claiming that his initial work was with chlorate mixtures rather than the fulminates as mentioned in his patent. There is also no mention of Purdy who was involved in his business as far as I understand – I had better read Keith Neal’s book on Forsyth next….. One detail that interested me was the observation that the gold poinsons set in the breech blocks of guns were stamped with a gold foil facing, rather than being solid gold pressings – bit like UK copper coins nowadays! That might explain why those in my Manton double flintlock have lost their gold, and make it more acceptable for me to gold plate them. This week I’m off to view Holts sale on Wednesday in Blackheath – first time since move from Hammersmith – its quite convenient as its an hour and twenty minutes away and plenty of parking – I just need to remember to book the Dartmouth crossing on the web before I go or I’ll be in trouble. I’m not planning to buy anything, although I have a few things to check out for friends and a couple of guns to take back for people who will be at the sale, plus a couple of guns that are going into the next auction. I must try and find a day to go on another car hunt – I’ve promised to find a small car for a friend, so I’m looking at the baby version of the car I got for Penny – a Mazda – not as common as one might expect, but right at the top of the Warrenty Direct reliability index, and they should know as they insure cars against mechanical breakdown – also cool looking, although I’m not sure my friend will be as keen on a red one as Penny was ( I’d already bought it when she saw it so in truth she didn’t have much choice) ! And I started to strike up the barrels of the ‘Mortimer’ to see how much work they needed – quite a lot of file marks to get rid of, it turns out! I’m hoping I can train my little CNC machine to cut the lock pockets and possibly profile the stocks – hope dies eternal in the human breast….. Goodnight.

14th March – I just noticed – something strange has happened to this website. A few days ago the number of daily visitors dropped from about 350 to about 170 – almost halved. My first thought was that all my regulars had given up as I’d vanished, but I didn’t think I had that many daily visitors! A careful check in my protection software showed me that almost all the attacks on the site that try to find a way to log in ( but don’t get anywhere near finding out how) had stopped overnight – so half the traffic to the site was spurious, and presumably since it all stopped pretty suddenly it must all have come ultimately from a single coordinating centre. I wonder if its gone for good?

14 March – Sorry, long time without blogging! I decided that all my old shot flasks leak and because of the way they are sewn it tears the leather beyond repair, so I thought I’d make another one, using a modelling clay block to mould some soft suede round and then clamping round the edge it with a couple of bits of ply with the right shaped cutout . Cutting out the profile for the clamping plates seemed like a nice easy job for my CNC miller but its got me totally confused – the actual milling seems OK BUT the mill shoots all over the work area before starting and usually crashes into one edge stop or another. I have tried editing the G code file but I can’t work out where or why its flying about in the pre-amble – maybe it will all come clear tomorrow! I went hunting for a replacement Land Cruiser today – its fascinating what you learn from people in the used car trade if you chat to them. I found that the reason there were virtually no 2009 or 2010 Land Cruisers on the market is that they all get shipped to Kenya, which won’t allow import of pre-2009 vehicles. The older ones go to Tanzania. Apparently a team comes over to the UK a couple of times a year from each country and just buys them all up to ship back – presumably new ones carry a huge tax and the bane of old Land Cruisers in the UK – underbody corrosion – doesn’t happen in hot climates so they last indefinitely. I might have found a good one but I have to wait for the boss to come into the showroom to see if he will accept my offer! Then I’ll have to get rid of my old one, rust and all, although I did get a fairly decent offer in part exchange – because he knew he could certainly sell it on to the Tanzanians. Unfortunately the P/E offer related to a Land Cruiser that I didn’t want to buy at a different used car lot. I often get queries about gun related matters via this blog – at the moment I’m trying to help unravel a J Probin flintlock that is missing the locks and has a gold banner with ‘WESTLEY RICHARDS’ on the barrel which seems a bit out of place…. any ideas?

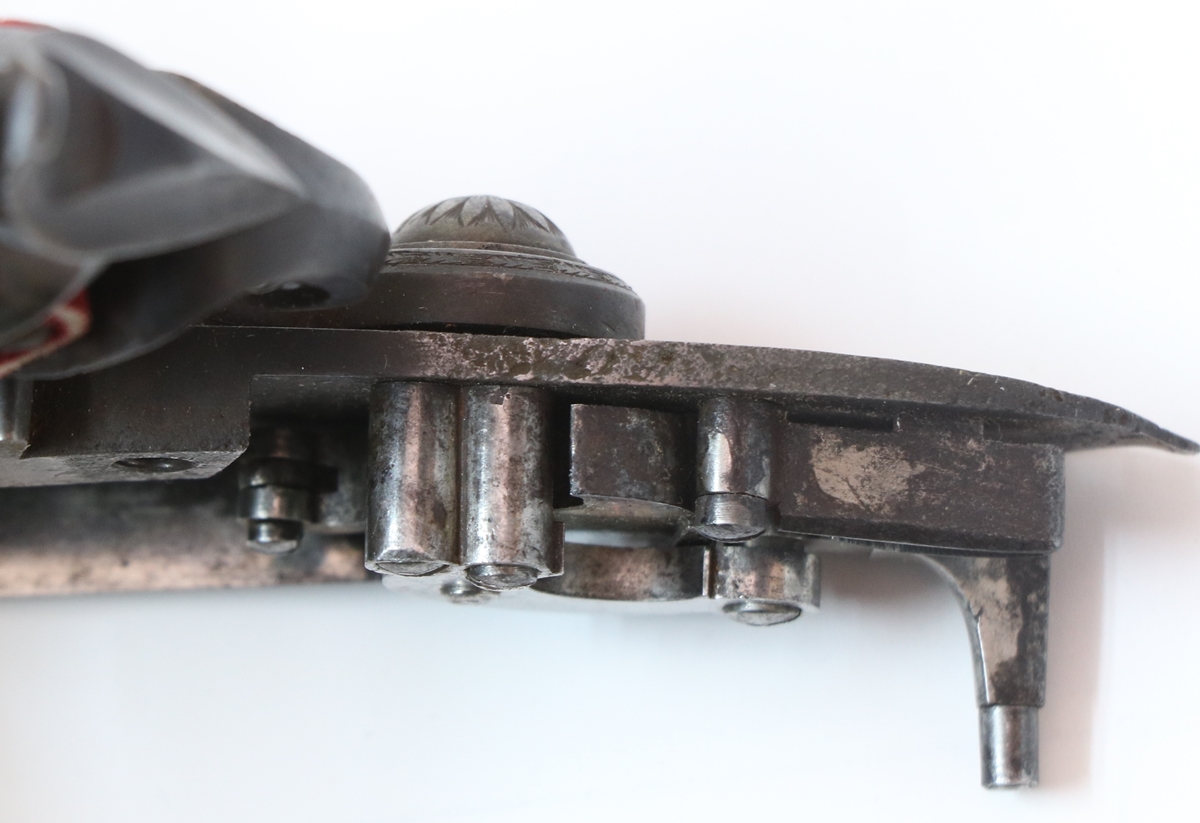

9th March – I am still working on the cnc miller, but making progress. I have found a workaround for most problems, and I created a model of a curved shape as a trial – although it was only a small shape 30 mm x 100 mm it had radiused top edges and they take a lot of passes to shape – the estimated time to complete was over 2 hours, but on the first run the cutter came loose in the collet and I had to abort the run – I couldn’t work out how to resume it, so I started again from the beginning with a new piece of wood . On the second try I accidentally closed the program on my laptop half way through, and that killed the job! But each time I get more things sorted out. The job I’d most like to be able to do is to cut accurate lock pockets, so I have started to look at ways to copy parts from photos as locks are not good for drawing using the normal tools in CAD packages! Anyway here are the photos of the parts for the pair of Manton Duelling pistols I bought off Dick – the locks were beautifully made by an ex-Purdy man – the cocks are wrong so we’ll get some older style ones. One false breech is wrong, but it is possible to make one from stock steel with an angle grinder and a bit of welding and a lot of drilling and filing! I’m not sure about the Blackley castings of the trigger guards – they may be a bit late – the originals would probably have had a simple acorn finial in front of the guard and a wider guard. I’m not sure about the set triggers either – a bit of research is needed! Going through some dating clues I would put the model for these parts at the late 1970s – it has the old pan shape, which changed around the early 1780s, but a fully octagonal barrel that came in during the 1770s. It could have been half stocked, but I think probably without a rib, but with loops for the ramrod fixed directly to the barrel. More research needed!

and they need mainsprings and frizzen springs………………………

6th March – I’ve been rather busy trying to get my little CNC 3040 milling machine working. Up to a point I have succeeded – well I’ve learnt a lot along the way. I haven’t done anything useful yet as I’m still struggling to get the host software (bCNC) working properly – after each job the P.C. looses its connection to the cnc controller box and has to be reset, which is a pain – I’m not sure if it will run a proper job without stopping but I’m getting near to trying. I’ll have to get a CAD program up and running to generate something to make – probably Fusion 360 as its free! I got a set of parts for a pair of fine duelling pistols from Dick – tehy were made by someone who was a Purdy gunsmith some time ago – the locks are fine – machined from solid, not castings but he didn’t have the proper cocks. They need a few more bits sorted but will make a fine pair of pistols. The barrels are nice but I suspect they are not twist so won’t pass as the real thing. I’ll make them up as a pair of inert pistols as I don’t want to bother with putting them on a certificate – at the moment the barrels are unfinished. I have some nice walnut for stocks, so it should make a good project – Dick says thay are copies of a Mortimer pair – I must look out some photos so that I can get teh engraving right. I’ll post some photos of the bits soon, when I stop playing with the CNC.

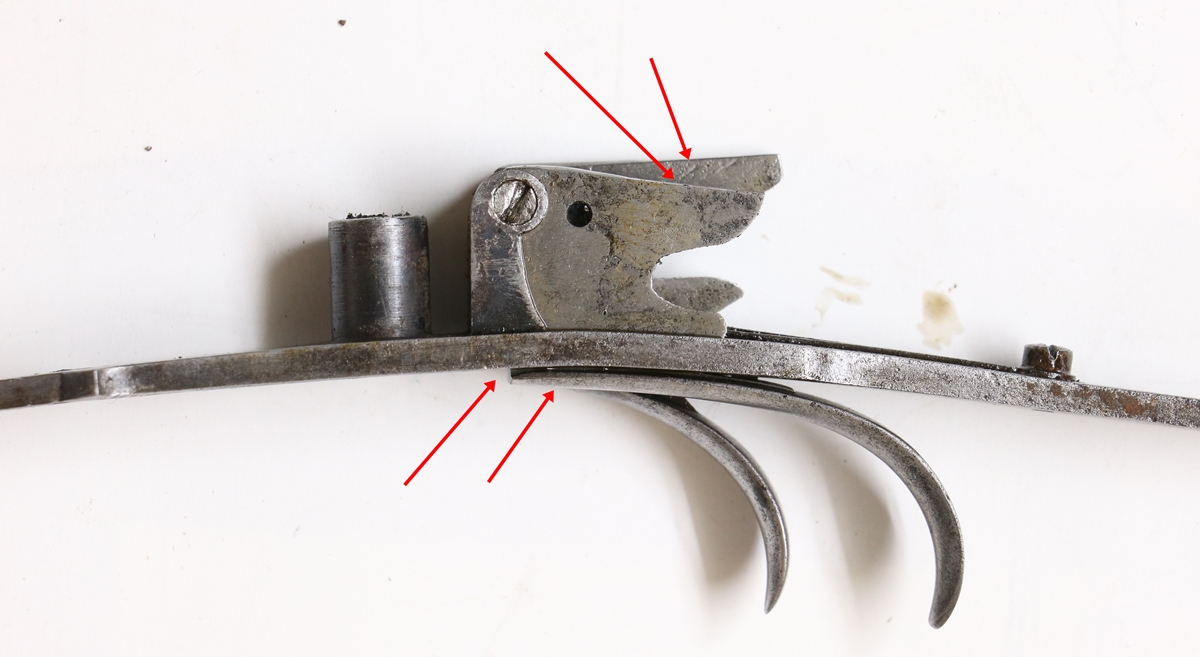

March 1st – Quite Arctic round here and a bit of snow, coming home last night my 4×4 was skating all over the road if it got half a chance. I spent the morning taping up draughts in the workshop as I couldn’t get the temperature up above about 16 C even with the woodburner and a 3KW fire going. Its now well above 20 C so OK. I bought a book from Amazon, well more of a leaflet, called ‘Firearms Lock Design’ by Steve Culver. Its actually restricted to the design of the sear and tumbler (or cock) and the proper geometry to ensure a safe trigger pull, but you can’t get everything in 26 pages. Its a commendable effort, obviously home produced although printed by Amazon – but with very clear diagrams. I am not sure I have come across many original guns that have the nose of the sear 0.9 mm across as he suggests, but the principles he lays down are sound and should help anyone who tackles the ticklish job of refurbishing a worn sear-tumbler engagement. I had hoped for some suggestions and advice on the cock-frizzen geometry in flint guns, but that isn’t as clear cut as the geometry of the sear-tumbler and anyway was more of a matter of opinion and development. Steve’s basic geometry requires the tumbler pivot centre and the sear pivot centre to make a right angle at the point of contact of the sear and tumbler – that way when the sear moves its end moves along a radius from the tumbler pivot. If that isn’t clear, best get the book from Amazon! I managed to get most of my ‘bandolier’ shot flask done and added the strap and buckle and temporarily put in the Irish dispenser so I could try it out – it seems to work fine, the leather is much softer than a traditional one, so its more comfortable to wear, and it holds a good load of shot – I haven’t checked how much. I’ve just got to add stitching to the straps. I have a number of old flasks that have started leaking and would be very difficult to repair neatly (rather than Bev’s technique that involves rolls of duct tape) so I might use their dispensers to make a few more flasks – I rather fancy a suede flask. My next project is getting my Chinese toy cnc machine ( a 3040) working with a new controller board – at the moment I’m trying to sort out the wiring of the new ‘Smoothieboard’. I can’t work out if it is capable of driving the stepping motors of the 3040 or if it is meant to rely on external drivers – the documentation is a little haphazard……. Also on the agenda are a couple of ebony ramrods – I ripped up a couple of square blanks from my nice stock piece, so now have to round them, but its much too cold to venture into the unheated outside workshop to do them…………………

Feb 25th Celebratory meal and a bottle of champagne at the flat to celebrate (almost) completion. It really is a super flat, the basic design is good and Giles’s interior design is brilliant, and my 4 month’s work is well justified! Result. Since it was the first nice weekend I’ve had free I ventured out into the garden _ I can see I’ll have to get tough with the rats that eat the chicken’s food – I did stand around with a .22 air rifle but it has telescopic sights so is almost impossible to use without baiting them – I need a No. 3 garden gun! Anyway poison will suffice after I’ve been to Horse Requisites tomorrow. I continue to get a good number of visitors to this site, about 350 a day -although about half(?) are bots trying to bust the site. I do get about 30 visitors from Google and other search engines including Baido, the Chinese search engine. I must justify all this support by putting some more gun stuff up!

Feb 23rd. Busy organising and then running a class on computer programming at ‘my’ primary school with my friend Dave. We have both done a lot of programming professionally and have a fairly dim view of the way its taught so we had a chance to try our way. I wrote my first program in 1966 on punched cards to run an an IBM mainframe, and we used old punched cards of that era to write down commands of our ‘people computer’ programs in class. For some reason the cards were never numbered, and a fairly simple program generated quite a stack of cards – so if you dropped the stack………..

I’m experimenting with leather to make an Irish pattern bandolier flask – making progress. I am revisiting Cruddington’s book on modern shotguns, Vol 3 to refresh my mind about single trigger mechanisms. The problem is that between 1889 and 1910 there were 91 patents from UK gunmakers for single trigger mechanisms as they scrabbled to find another innovation to keep the market bubbling after the hammerless ejector and self opener were established. The problem was (and is) that best guns last too long to sustain a trade without continuous new and wonderful inventions! There are basically two ways of making a single trigger fire two barrels without double discharging on the involuntary second pull that almost always follows when a gun is fired – the first invented and original English mechanism used a fairly involved linkage between trigger and sears to ‘loose’ the involutary pull – like for example the Boss rotating turret that moved with each pull and only allowed the gun to fire on the first and third pull. The other class of mechanism involves inertial weights that are driven by the gun’s recoil and change the linkage between trigger and sear – most modern production shotguns (Beretta , Browning and clones) use the inertia system. You can tell which your gun has by firing off snap caps – if mechanical changeover you will probably need to make a dummy pull between firing pulls as you won’t make the involuntary pull on a ‘dead’ gun. If you have an inertial changeover you won’t fire the second barrel without bumping the butt on the ground to mimic recoil between the pulls. I find it very difficult to work out exactly how the various patents work from the drawings in Cruddington, so I usually doze of while trying!

Feb 21st Still suffering from the effects of solder fumes – I thought I’d do a web search for solder with less bad flux, i.e. colophony free, but then I found I was already using that, so maybe I’ll go back to the normal, bad, colophony flux. I was trying to buy some faux ivory from the US as it claims to be used by various museums, and I thought I’d make a few brushes and a couple of pots for caps, but the minimum order is $50 and the carriage would be $60, so a bit pricey for something to play with! Maybe I’ll stick with the Axminster stuff. Or I could use ebony or horn or box.

I dug out a nice single percussion barrel that I bought with a junk stock and took out the breech block – the bore is quite good – I am sure it would hone to a perfect bore and still be a safe wall thickness. It has a percussion breech, although it might have originally been a flintlock. I was thinking that I might see if I could get/make a new breechblock so that I could make it up as a flintlock. The barrel has Birmingham proofmarks but the pitch of the thread is exactly 1.5mm – not an whole imperial size. The O.D. is 20.5 mm. I do have a not very nice stock that I have fitted the barrel to – the easy thing would be to make a percussion gun, but I don’t need another one! It might be a good barrel to try lapping………..

Feb 20th – I had to do some electronic assembly of printed circuit boards for a client today. I have a real problem with the fumes from modern solder flux which give me every kind of respiratory irritation and really crock me up, so I bought a new extractor/filter fan and replaced the activated charcoal filter in my old one, but somehow the fumes managed to escape the suction and got me – I’ll have to think of a better way – perhaps put the whole outfit in a large box with elasticated arm holes as for shot blasting or solvent cleaning. ……… I went to see Dick today and took the Walklate bits I had engraved, which he was well pleased with. Earlier he had mislaid the locks of the Blair and Sutherlands that I had left with him to get Jason to weld and Dick to reshape the frizzens and he was in quite a state – I was a little concerned as the gun is worthless without them, but I was sure he would find them, which he eventually did, in a pretty box exactly where he had put them for safekeeping! When I loose things I’m reluctant to move anything in the search, because I always assume it will turn out to be within plain sight. I think as you get older your sight might be OK but some of the higher processing gets a bit worse so you miss spotting things you once would have picked up on. ‘The flintlock lads’ are going to CGC on Thursday and I might join them, but I might have to do some preparation for my Mindstorms school stuff as I will have to be ready on Friday to keep 25 children occupied/entertained/learning – the really nice thing about not being a teacher is NO PAPERWORK.

Feb 18th – I’ve finally taken most of my tools back from Gile’s flat and given him back my visitor’s parking badge so I can no longer run away to Cambridge and buy the only decent bread in the county from Maison Clement on Hill’s Road! But I plan to get Giles to go in early and buy some of the ‘mother’ that they use to make the sourdough bread so I can make my own sourdough! Now I have to concentrate on helping with computing lessons in school using the Lego Mindstorms. The computing syllabus in primary schools is quite comprehensive and involves teaching the kids what ‘algorithms’ are – I know one when I see one, but defining what one is is another thing altogether! Anyway Wikipedia says that ‘defining ‘algorithm’ is quite challenging’, so I feel vindicated. I was trying to think of an example and came up with a handy one – find the difference between two given numbers, If I give you two numbers you can give me the answer easily, that is solving a specific problem, but if I ask you to write down the full sequence of basic operations by which you could find the answer for any two numbers, say a and b, then that is an algorithm, or generalised method ( clue -you don’t know which is bigger). Another little little chore awaiting me is to buy a replacement Land Cruiser as mine is getting a bit long in the tooth. I’ll have to get one about 10 years old and it won’t be much different from my present one (17 years old) , just, I hope, not so rusty. I’ve been watching the ads on the web for a few weeks and those on offer seem to be having price reductions so I haven’t been in too much of a hurry and haven’t really had time to drive round the country looking at them. Now I’ll have to concentrate…………………….

Feb 16th Another day of playing – where will it end? I cleared out my indoor workshop in the morning, and then my piece of faux ivory arrived so I thought I ought to use it. First I went through all the books I could find to look for photos of gun cases with brushes. There are a number in Keith Neil’s book on cases, although most don’t have a visible brush. He lists them as being accessories in cases but doesn’t illustrate them with his other accessories. I guess that they are the first accessory to get lost, and anyway will certainly wear out before any of the rest of the outfit so one shouldn’t be surprised that they are a rarity. Although they are usually thought of as a flintlock accessory they were, it would appear, included with some percussion pistols and ? guns as well as percussion revolvers. I found one design that seemed to appear in John Manton cased pistols and guns, including a pair of cased percussion pistols from the Paul Murray collection in the November 2017 sale and a very similar brush in a cased flintlock fowler in the same catalogue. As they were both from the Paul Murray collection one can’t be certain that they were originally with those guns – it would appear that a lot of ‘restoration’ went on, although having said that, there is a similar brush in a cased pair of John Manton pistols in Keith Neil’s ‘The Mantons’. I’ll start a separate post for these photos etc. Anyway I decided t make a rough copy of the John Manton pattern brush so I did a bit of scaling from the photos and concluded that the brushes were pretty small – the body barely 2 inches long. I tried turning the faux ivory, which is just a polyester rod on my wood turning lathe but I don’t have a short toolrest and can’t get the long one near the work if I’m using a live centre, as I was. The result is that it was impossible to turn the rod freehand as the tool just chiped the faux ivory (polyester rod) and eventually shattered the end off. It did cut in my metalwork lathe but of course I can’t do very nice curves using the handwheels. Still I got a fair approximation to what I wanted. I’ll have to find a way of sticking the bristles in without the glue running so far up the hairs – maybe epoxy instead of cryoacrelate.. I tried my new flask, and found that it doesn’t shut off very securely, so out came the spring for a bit of adjustment – anneal, bend, harden and temper – it now seems to be much more secure.

Feb 15th. Valentines’s Day went without my noticing it – shame on me! My first day of playing for the week. Every time I’ve used my flintlock I have felt the need for one of those little brushes that you occasionally see in cased flintlocks, I know you can buy them from Kranks etc, but that goes against the grain somewhat! I remembered that when I did lime plastering I use Chinese pig hair as a reinforcement for the first plaster coat on the lathes and it comes in neat rounds all standing on end, and I still have a couple of unopened bundles which look like a giant brush 3 inches in diameter and 1 1/2 inch bristles. I needed to use my wood turning lathe to make a former for the end of my flask, so while I was at it I turned up a little brush handle from a scrap as a proof of concept (more later on that) – a bit tricky to get a suitable bundle of bristles and then feed them into the hole in the handle but with the aid of masking tape it was done and a few drops of very low viscosity isocyanate put round the edge sealed it all in and stiffened the brush just enough – perfect. Looking at the photos in Keith Niels book on cases I see that most of the brushes seem to be handled with ivory – elephants not being available on ebay I settled for faux ivory and have ordered a piece of 1 inch rod to try out. Using the former I turned, I completed the end of my leather covered plastic bottle flask by clamping and gluing the leather and adding an eyelet – now completed, I checked and it throws 1.1 oz of shot ( or about 30 grams) which is fine. The full flask is a bit heavy but for clays I need that much shot and I can usually put it down on a table. I visited Dick to take the frizzen and screws I’d engraved and pickup another little job – a lock by Walklate needing a border and a couple of sunbursts and a border round the cock and frizzen – lock now done…. On the subject of ‘proof of concept’ I learnt during 40 years building specialist equipment for geophysical research and as a small company that if possible you should always try out a minimal solution before embarking on anything fancy – that way you either discover that the fancy wasn’t necessary, or that the whole thing doesn’t work anyway, or if you end up making the fancy version you save so much time and trouble because you know what you are doing/want that it saves time overall. A number of the jobs that clients bought to me were an unnecessarily fancy solution to a problem that hadn’t been thought through properly and I almost never managed to put them off, with the result that by the time I had done the design and was ready to make the kit they had backed out – I charged them 90% and delivered nothing – which was frustrating but profitable! I get the feeling that the government ought to try the proof of concept approach with all its horrendous IT projects that flounder.

‘proof of concept’ brush – should be ivory or possibly ebony or box

Border recut and sunburst on tail and in front of cock.

Feb 13th. A bit low on gun related activities – Mondays is my day for the work on the Bullard Archive of Geophysical Instrumentation when I’m not doing other things, and today I was fixing up Giles’s wardrobe at the flat. I must admit that I am reluctant to go into my workshop at the moment because its freezing and my little woodburning stove takes at least a couple of hours to heat it up because there is so much metal in there – for that reason its not really viable to do much work in the evenings. I did manage over the weekend to sew a leather cover for the plastic bottle that is the body of my shot flask – the bottle is a nice 250 ml bottle from a hand soap pump. I wondered how much shot you could get in 250 ml so a quick calculation… Lead has a density of about 11. So if full of lead the flash would hold 11 x 250 gms = 2.75 Kg, but of course its full of lead spheres so you need to take into account the packing coefficient which will be about 0.6 (perfect packing would be a bit more, perhaps 0.64 or so), so that reduces the weight in the flask to 1.65 Kg. A typical charge is 1 oz, which is 28 grams, so my flask will hold almost 60 shots. The dispenser, however, is supposed to throw 1 1/4 or 1 1/2 oz so unless I modify it by sticking a bit of packing in the tube, I’ll get about 47 shots of 1 1/4 oz , which is fine for a 40 bird competition and a few spares….. I need to work out how to finish the end of the flask, I’ll probably use an eyelet somewhere so I can hang it, but I’m waiting for some leather glue before I tackle that job.

The leather was sewn on a sewing machine and put on soaking wet. The external seams stop it rolling, which is handy.

Feb 10th. I have a project to make another shot flask as a couple of mine have splits in them. I did get a leather bandolier from Pete and made an Irish shot dispenser that fitted, but the bandolier ( which is a Kranks pattern) is a bit too stiff to be comfortable, and in sorting out stuff I had picked up as part of a job lot at auction I came across a steel Hawksley English pattern dispenser, and found a plastic bottle of suitable size that the dispenser screwed into. The Steel dispenser more or less worked, but didn’t close the first shutter ( nearest the bag) fully so No 7 1/2 or smaller shot could still escape. I figured this was because the spring fouled on the shutter, but when I looked at one of my working flasks I realised that the spring was in the wrong way up, and that it was the wrong size to fit properly – so I set about making a new spring from a piece of old spring of the appropriate thickness – making springs is one of my favourite jobs! The angle grinder and 1 mm cutting disk let me rough shape the spring in a couple of minutes, then I annealed it and filed it to the right blank shape and heated it to red heat and bent it where I reckoned it should be bent and hammered the bend flat. It was a simple job to fit the spring and get the right degree of opening, and I then heated it up to bright red to quench it in water – unfortunately my gas/oxy torch was a bit hot and I melted a bit of the edge – first time I knew that the little torch ( I bought it for lead welding) could get hot enough to melt steel! Still, it was usable so after quenching I polished it and annnealed it to blue on the hotplate of the AGA. The rest of the dispenser looked a bit patchy so I popped that on the AGA too, and it came out a uniform purple colour – I wasn’t trying to make it look authentic so the result is good – now I’ve got no excuse for not finishing the flask

The dispenser as found but after a dip in the derusting tank – the rust seen is loose and will brush off. Notice the spring orientation.

This is the old spring shown in the correct orientation – it is too long to fit properly, which is presumably why it was put in upside down.

This is a working flask – the spring is the other way up.

New spring made, hardened and annealed to blue.

Quick flash on top of the AGA to give it a uniform colour. The right hand shutter should be the other way round to clear the slot fully but I can’t get the screw out! It does work, just occasionally it isn’t as smooth as it might be. I know its not an authentic colour, but neither is fixing it to a plastic bottle – albeit leather covered!

Feb 9th. Finished off the bit of engraving for Dick’s funny pistol, which is coming along nicely. By coincidence the hammer (frizzen) needed a wiggle engraving similar to that on the trigger guard on the Alex Henry. The pistol is a bit of a joke and so Dick hadn’t spent too long on the parts and the hammer is a pretty raw casting from Kevin Blackley that Dick had in store from ages ago – I cleaned out the lines and did the border – it looks the part. The screws match those already fitted. Nothing very demanding there! I have now sold the Perrins youth’s fowler and am advertising my mint Mortimer reproduction single barreled 12 bore – it has hardly been fired and worked well for me, but I have an old single that I slightly prefer, plus my pride and joy Manton double meets most of my flintlock needs!

Here is the fantasy pistol restoration of a wreck found buried in a garden at an early stage – now nearly finished..

(This photo dates from before I got rid of the warm white tubes in the workshop!)

Feb 8th. Thinking idly about double charging a gun and flame travelling from the first charge to the second, I wondered about what was originally used as packing between the powder and the shot. My ‘unthought’ was that tow was originally used as wadding – tow is unspun broken fibres of flax, jute or hemp originally. From the late 18th century when best guns were often cased ( cost was probably around 2 to 5% of the gun price) a wad punch of the correct size was included – presumably that would be used for overshot cards too. There is an advertisment reprinted in The Manton Supplement’ for John Manton that is for ‘wadding’ and says that if you send the number of your (Manton) gun they will send you the wadding of the correct size – which clearly refers to precut wads similar to what we might use now. I seem to remember that accidents during loading were attributed to fibres of tow remaining in the barrel and still glowing. Presumably if loose tow was used it emerged from the barrel as a flaming mess – I have occasionally used a paper tissue as a wad, and can verify that it burns and smokes on the ground afterwards. Any information would be welcome. One reason why we are always careful to see where the wads land when shooting over dry grass in summer. I picked up a couple of pieces of engraving from Dick for a ‘funny’ gun he is restoring. It was dug up in a garden so there was only a bit of the stock remaining, so he has made a fine saw handled pistol and is restoring the remnants of very fine chequering – I don’t know how he does it, it requires much more patience than I can muster. I am to try to engrave a border on the hammer/frizzen. I’m always unsure which word to use for it, the traditional usage is that in flintlocks the cock is the cock and the frizzen is called the hammer, but in percussion guns the cock is often called the hammer – I’m not sure if it was ever still called the cock? I had to go to Giles’s flat to ‘snag’ a problem – in order to insulate the 25 mm gap between the plasterboard and the underlying brickwork in one (cold) wall I drilled a series of holes & injected aerosol expanding foam only to have it coming out round one of a row of power sockets. When it had ‘set’ I unscrewed the fronts of the three sockets but they were stuck fast. I didn’t think it was a good idea to have power sockets set in possibly inflammable foam, so today I prepared for a major job, probably involving taking out the sockets, boxes and all. Unusually it turned out to be much easier than I had feared because for some reason the foam didn’t adhere to the plastic of the sockets at all, although it stuck firmly to everything else including the wires and the screws in the sockets. Anyway I was able to pries (prise?) the sockets out and clear out the foam around the wires and eleswhere and put it all back in pristine condition in about 3 hours – that job done……. My next project, before I start on any more of my pile of guns to restore, is to get my little Chinese CNC milling machine ( 3040) working – Giles and I ran into a brick wall with it last time we tried as its control board runs from the parallel port of a P.C. and modern ones don’t have parallel printer ports and it you use an add-on port it doesn’t work fast enough, so I’m going to have to get a different control board from the web. CNC milling requires a number of processes, all of which are dependent on pieces of software, and if you don’t want to pay out for them – they can cost a lot more than the machine – you have to scrabble around to find free programs. The process consists of software for designing the shape, then software for working out the toolpath necessary to cut it, then software to turn that into G code instructions for the X,Y and Z axes in terms of distance, and then software to turn the G code into pulses to drive the X,Y and Z motors – getting it all to work without a commercial package to sort it for you is somewhat tedious…..

Feb 8th. I had an enquiry about the T Perrins I have for sale, so I got it out – it was one of the first guns I restored, and when I look at it now I think I did a decent job of it. I was fairly sure that it wasn’t a shooter when I restored it, but looking at it now I think it would stand a proof charge pretty well. There are pits on the outside of the left barrel but the 6 inches or so of the breech area is good. A lot of my friends shoot worse! Provided that there is no air gap in the load most old guns will stand double shot load perfectly well – I heard an account of a terrible accident when a beginner double loaded one barrel and it split at the breech with dire consequences. This raised my curiosity because double loading with two normal loads would be unlikely to ignite the second lot of powder because the wad, shot and card would be in the way. If it were just the normal first charge that ignited then you just have the equivalent of maybe 2 1/2 times the normal shot load which doesn’t add up to even a moderate proof charge and is something that any gun in use should stand or it shouldn’t be in use. So what went wrong? If the second charge ignited when the load was some way down the barrel it would have burnt quite slowly, but if that happened some way down the barrel where the walls are quite thin it could have split there. A much more likely explanation is that the second wad and shot load was never pushed down into contact with the first load – its a known problem that if there is a gap very high pressures will be experienced, as when a barrel is plugged with mud or snow, or a bullet is incorrectly seated. The maximum pressure occurs at the blockage as the pressure wave from the explosion is reflected by the block and effectively doubles the local pressure for a short distance – hence the ring bulge that forms in rifle barrels if the bullet is not fully seated, or gets jogged along the barrel. I suppose it is also possible that the second powder charge has such low density and so much air within that it acts as a gap. I have inadvertently fired a double loaded gun without harmful effects – even the recoil was quite reasonable – I am much more careful now – I use a marked loading rod so I can see immediately how much is down each barrel.

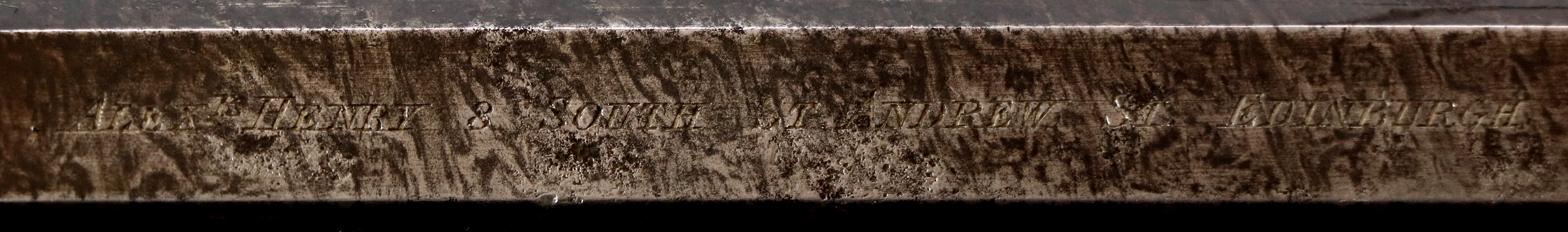

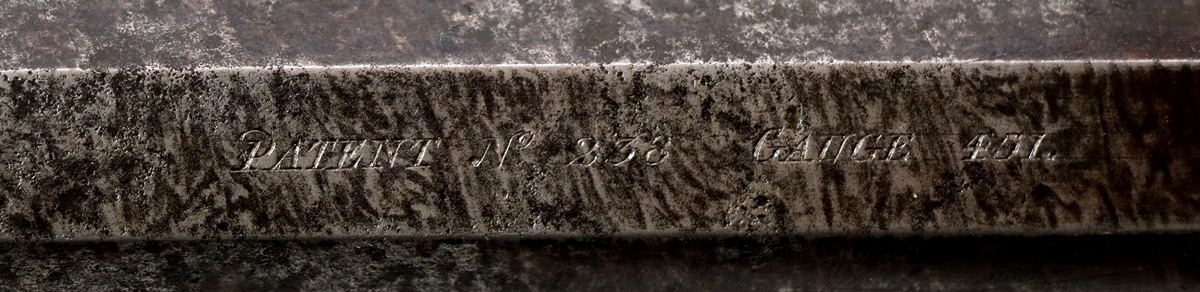

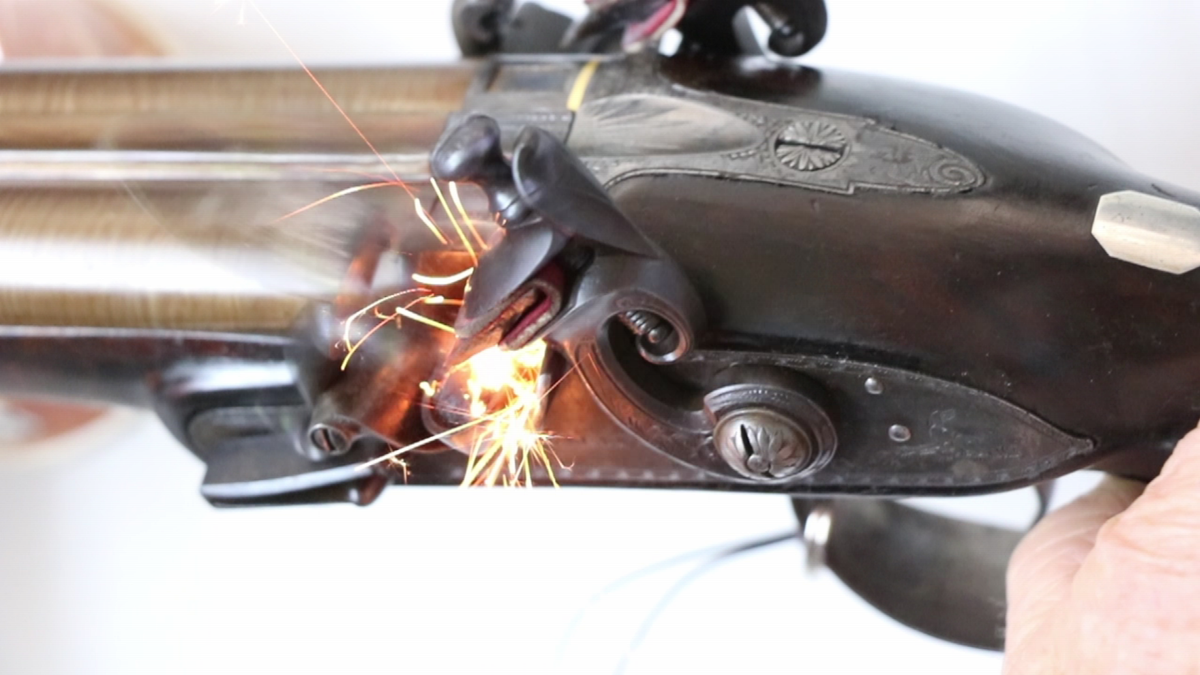

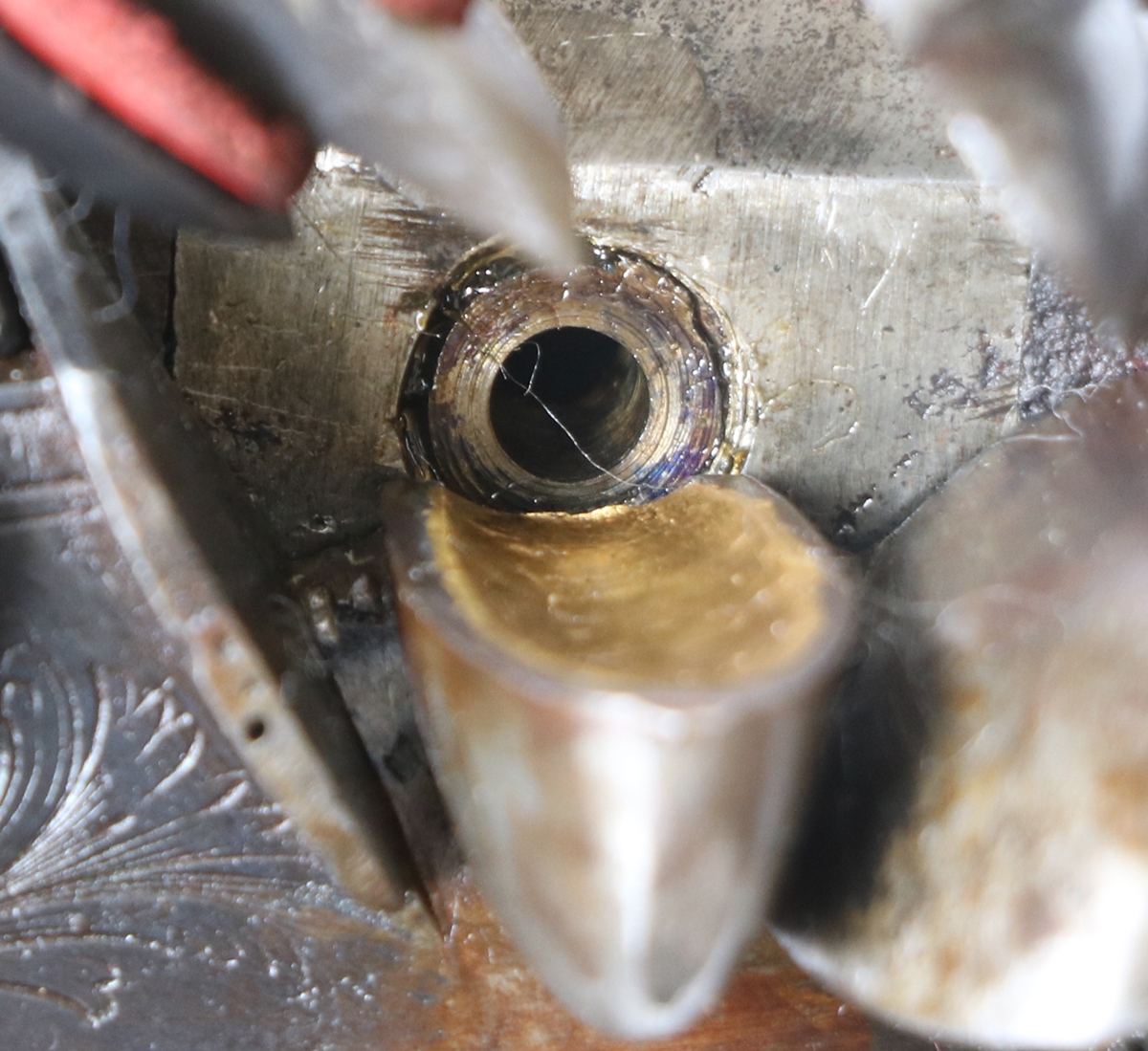

Feb 7th. Looking at the Alex. Henry again, I came to the conclusion that maybe the barrel engraving would benefit from a bit of TLC. My client had suggested it and I had thought it wasn’t necessary, but looking at the gun with all the rest of the engraving crisp, I could see that the barrel had the usual problem that the engraving had got filled up almost flush with the surface with a hard layer of rust and maybe oil so that it couldn’t easily be seen. So biting the bullet I carefully picked out the rust using a variety of engraving tools. The aim is to take out the rust, but inevitably you cut into the metal slightly, so you need to use the tools you would for engraving the letters. Basically in this case I used a flat that was the same width as the wide strokes, a slightly rounded onlette for the fine strokes and a ‘square’ ground to about 70 degrees for the angled bits of the serifs and the round letters. The engraving was interesting because the name and address engraved on the breech side of the rear sight is subtly different from the patent and gauge engraving on the muzzle side of the sight in script and also how it’s cut. Anyway I’m quite pleased with the improvement – worth 3 hours of very careful work! I also replaced the pin that holds the bolt into the stock – the bolt(s) that holds the barrel on should be captive, held in the gun by a small pin driven through the stock and running in the slot in the bolt. The pins are usually removed when necessary by sticking the edge of a blade into the pin near the top and pulling it out – for this reason it is better to make replacement pins out of fairly soft steel so the blade can get a grip – don’t be temped to break a bit off an ordinary domestic hard steel pin. Incidentally, I’m fairly convinced that the rifle was beautifully re-stocked some time ago and not used since. I cleaned out the nipple nipple and its hole – the nipple is an original and has a platinum plug with very small hole at the exit – probably around 0.7 mm – the thread is fine – safe to shoot. The nipple hole was pretty rusty so I can’t guarantee that the cross passage between the nipple and the chamber is clear – I ought to put a small brush down the barrel to clean out the powder chamber anyway. If I was about to shoot it I would probably clean the barrel with boiling water and pump it through a few times to get rid of any loose muck, but the bore looks good. The breech block has a platinum plug on the outside of the cross chamber to plug the hole where it was drilled – I would not want to remove it. Some double guns have a screw on inner face of the breech plug for access which can (sometimes) be undone to get access for clearing out.

I found it difficult to photograph the engraving because the rust pitting tends to catch the light – click on the photos for a better view.

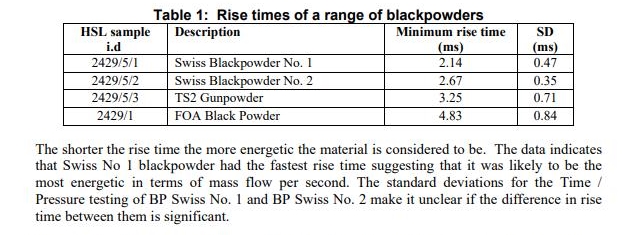

Feb 7th. – I realised that the ‘wear’ on the Alex Henry trigger guard tang was the result of filing out the worst of the rust. The notes on speed of ignition of gunpowder from the Health and Safety report on powder storage (see below) are interesting ;-

The argument about the SD (standard deviation – a measure of the variation seen in a number of experiments – applies equally to the difference between Swiss No 2 and TS2 – but its clear that in general the numbers support our experience of these powders – I wonder where Czech powder comes on the scale?