Here is a post copied from the diary on reducing the 3/4 inch cast off on the 14 bore Venables of Oxford percussion sporting gun to something I could shoot with – around 3/16″ to 1/4″. It was a pretty straightforward operation, the effort goes into jigging it up properly before you begin so that you can control the bend to get the result you want, and so that you make sure the bending takes place at the wrist and not into the area round the lock pockets. The gun needs to be held reasonably rigidly so that clamping the stock doesn’t shift the whole gun. The secret (if there is one) is to heat gently and for a long time. I used an industrial heat gun and its easy to scorch the wood or damage the finish so I kept it on its low setting. The heat takes a long time to penetrate to the centre of the wrist, which is where you want to concentrate the bend. I wrapped kitchen foil round the lock area to protect it from heat, and wrapped a folded sheet of kitchen paper round the wrist and poured hot vegetable oil onto the paper, I played the hot air gun on the wrist from a few inches away and topped up the oil from time to time. Eventually you can feel that the butt is getting a bit ‘limp’ and you can begin very gently to wind in the clamp holding the butt to the reference board – be careful that you are not bending the reference board – mine was backed by a 1″ x 3″ steel bar so I could clamp it to that.

The wood will tend to spring back when the clamp is released, so it is probably safe to go 1/16th 1/8th inch beyond what you want to achieve and leave that in place while the whole lot cools down. This is when you really want to leave it for a considerable time to cool – two to three hours minimum or preferably overnight.

20th March – I bit the bullet and had a go at straightening the stock of the Venables which if you look back in the diary, you’ll see had a 3/4 inch cast off. First it is necessary to set up a jig to hold the gun (stripped of its trigger guard and trigger plate and locks) against a straight piece of wood that can act as the reference plane, packing the muzzle so that the centreline of the gun is parallel to the reference plane and clamping the muzzle to the plane and the bench so it can’t move or twist. The stock is clamped to the reference plane with suitable packing in the lock area. You can now measure the offset of the centre line of the gun from the reference plane and measure the amount of cast-off ( about 3/4 inch in this case). I wrapped the lock area in aluminium foil to protect it from heat as I wanted to restrict the bending to the wrist area, and wrapped the wrist in a sheet of kitchen roll folded in half. I poured a little very hot vegetable oil on the tissue and played a heat gun on medium heat on the wrist – it takes a long time for the heat to penetrate the wood, but eventually ( >3/4 hour) you should find that the butt will flex a bit, and its time to start gently tightening the clamp holding the butt to the reference plane and measuring the cast. There is no need to rush this stage and force the wood as it is likely to spring back if it isn’t allowed to relax into its new shape. The butt will spring back a bit when its no longer held by the clamp, so its best to tighten the clamp on the butt just a bit more than you want the evenatual cast off to be – I bent it to about 0 to 1/8 inch cast off and then went off and had lunch and did a few jobs so it had about 3 hours to cool – when I unclamped it, it has a cast of around 3/16th to 1/4 inch – just perfect for me. So I’ve now put it back together – the lockpockets were a bit of a tight fit as presumably the wood has changed shape slightly. The only bit of the job left is to find the nipples and the foresight bead….. I’m sure they wee somewhere! – there is always something else to do to finish the job.

This is how it started out – 3/4″ of cast off!

Caliper set to offset of centreline so still 1/2″ cast off

I kept the temperature to less than 100C – just takes time to work

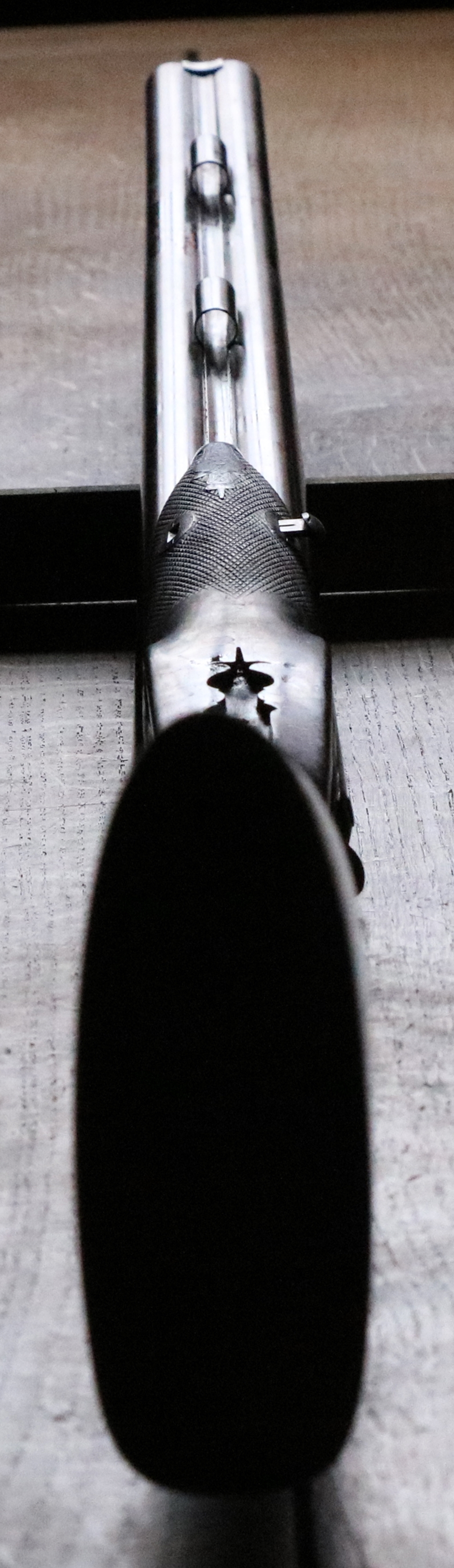

About 1/4 inch of cast off now – perfect for me.