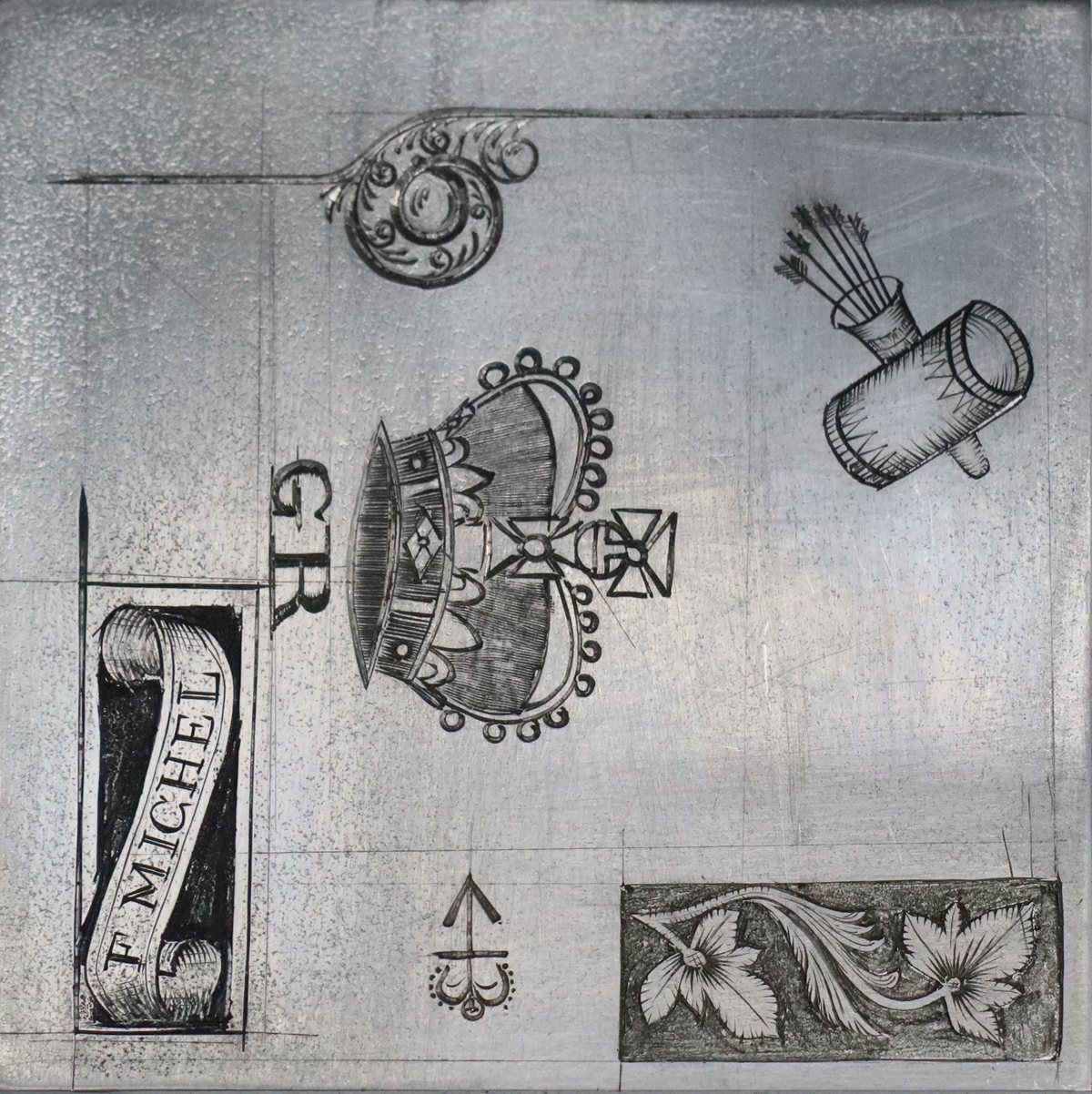

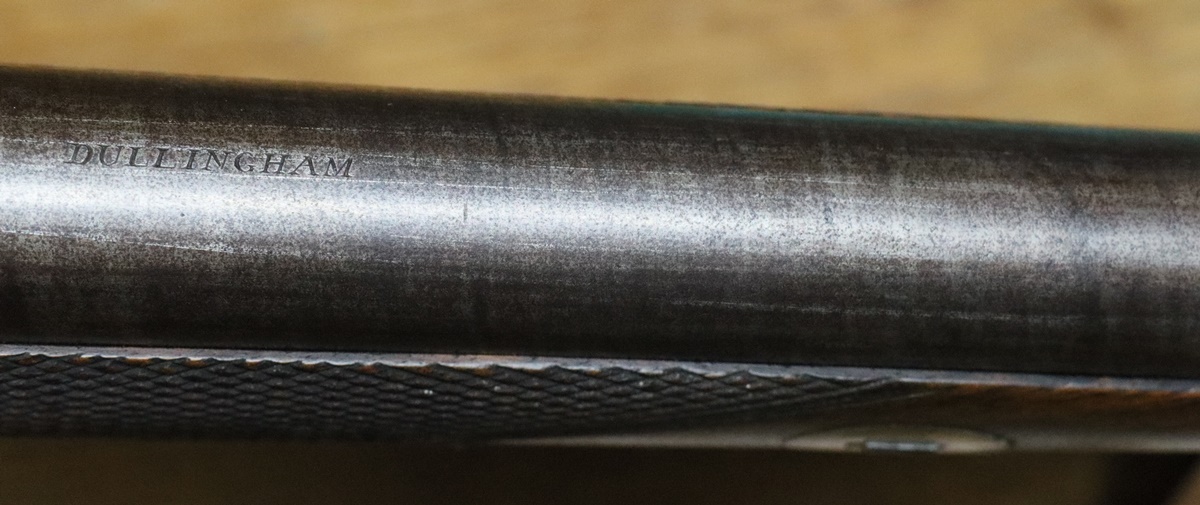

13th January. I am at last getting round to engraving Fred’s parts for a flintlock Cape gun (one rifle and one shot barrel). Its taking me a while to re-awaken my muscle memory and get myself into an engraving frame of mind, so lots of playing about with test plates. Fred is keen for me to engrave a bit deeper than I usually do, as my light engraving gets lost in the colour case hardening that he has done on his guns, which is pretty dramatic. I have been using my GRS air graver to try and dig a bit deeper, but its not quite as precise as push engraving, although I’m getting better with it. So these are a combination of push and air engraving. I did think of buying a Lindsey air graver – I’d looked at them a few years ago, and when I looked the other day the prices had doubled and I can’t justify that sort of expense ($3000 + Tax and carriage). On the standing breech I’ve been doing the traditional thing and using a cut out background with the pattern raised – its more work because its fiddly cutting out the background – I have been using the air graver like a little pneumatic drill with a fine rounded point to stipple the cut out background, which seems to work quite well and should stand out however it is case hardened. I have one more bit to sort out – the bit of rib between the barrels, so I tried a couple of ideas on a test plate – I’ll talk to Fred about what he wants. Then I have to engrave the locks – the tail ( stand of arms) is OK, but its always tricky to put names on the centre of the plate as the pan gets in the way and you can only effectively cut verticals from the bottom up, and for small lettering its very difficult to get clean starts to strokes, so doing it in a single cut makes it difficult. The name will probably end up about 2.5 mm (0.1 inch) lettering, and the location, which is 10 letters long will probably be around 1.5 mm or so – also the location (Shrewsbury) has a number of tightly curved letters – 2xS, R and B that are a struggle when the lettering gets small. Why can’t gunmakers have names and live in places that are made up of letters that are all straight lines, possibly with the odd O or C ?

When I need a break from engraving – about 2 hours in every 3 – I’ve been playing with a number of Raspberry Pi computers as its time I re-learnt how to write code and run systems – its a struggle at times! I was slightly heartened that when I got stuck on getting one computer to connect to the internet – my son Giles, who now is a professional programmer in Vancouver, gave up after half and hour. I later partly got there!

If you are interested in green energy I found an app for my phone that lets me see at any moment where the country’s electricity is coming from. For most of the last month or so we have been importing around 25% from half a dozen other countries, wind has varied from 2% to 70% (I think on a very windy late night) but is has mostly been around 35 to 45% – the app is ENERGY WATCH GB. It is a strange and unfortunate fact that UK electricity prices are pegged to the price of gas when over half our electricity comes from renewables (a bit over 40% at the moment) and nuclear (16% at the moment). Electricity is significantly cheaper in Europe! Anyway the wholesale price of gas has halved in the last month or so…….. A lot of energy companies are raking it in!

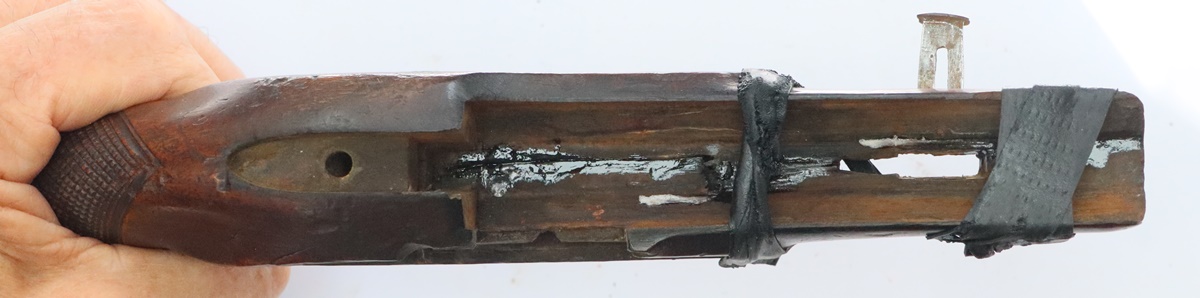

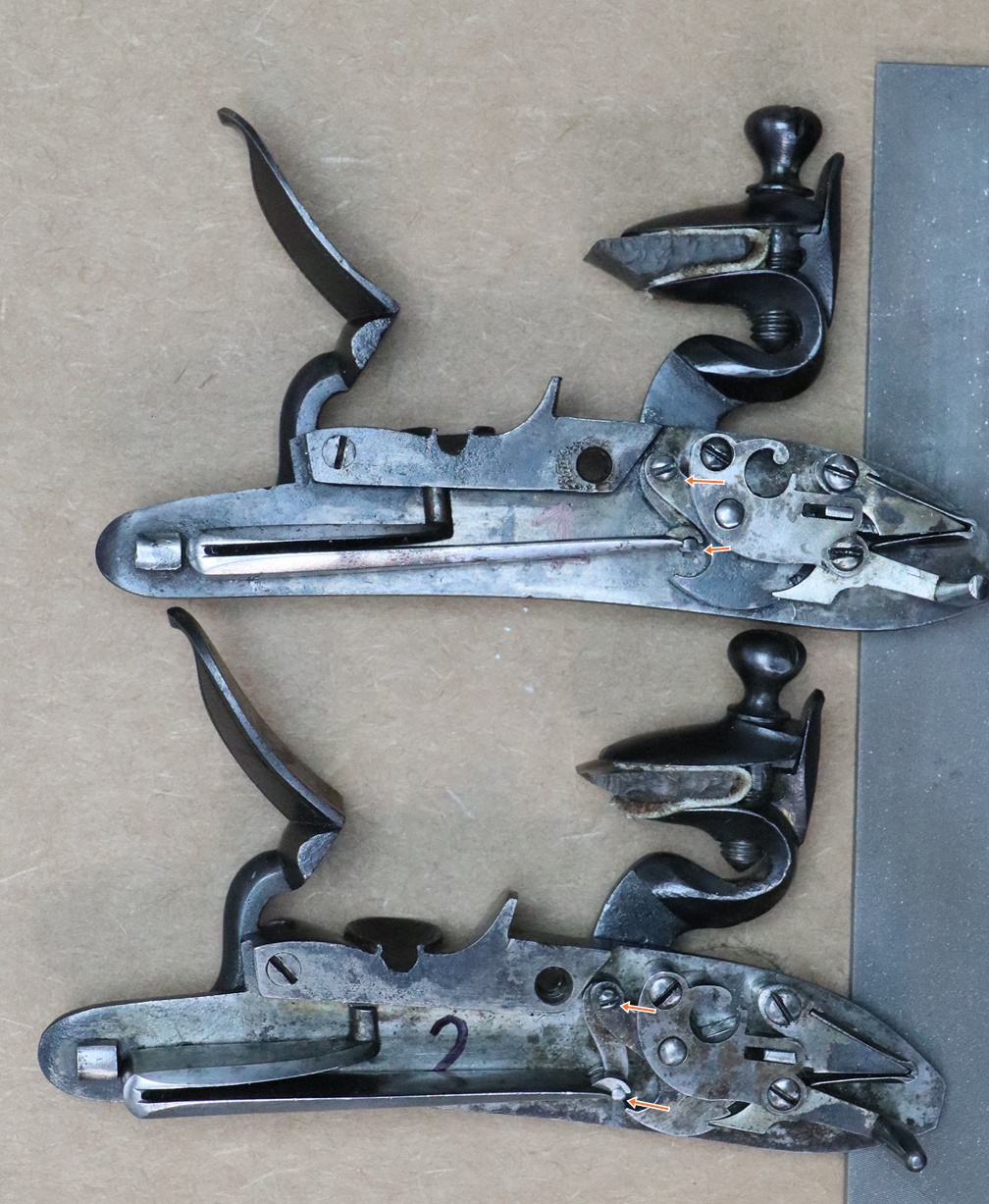

Notice that the tail of the tang is curved to the left – must have come from a cross stock for a left handed, right eyed shooter.

Notice that the tail of the tang is curved to the left – must have come from a cross stock for a left handed, right eyed shooter.

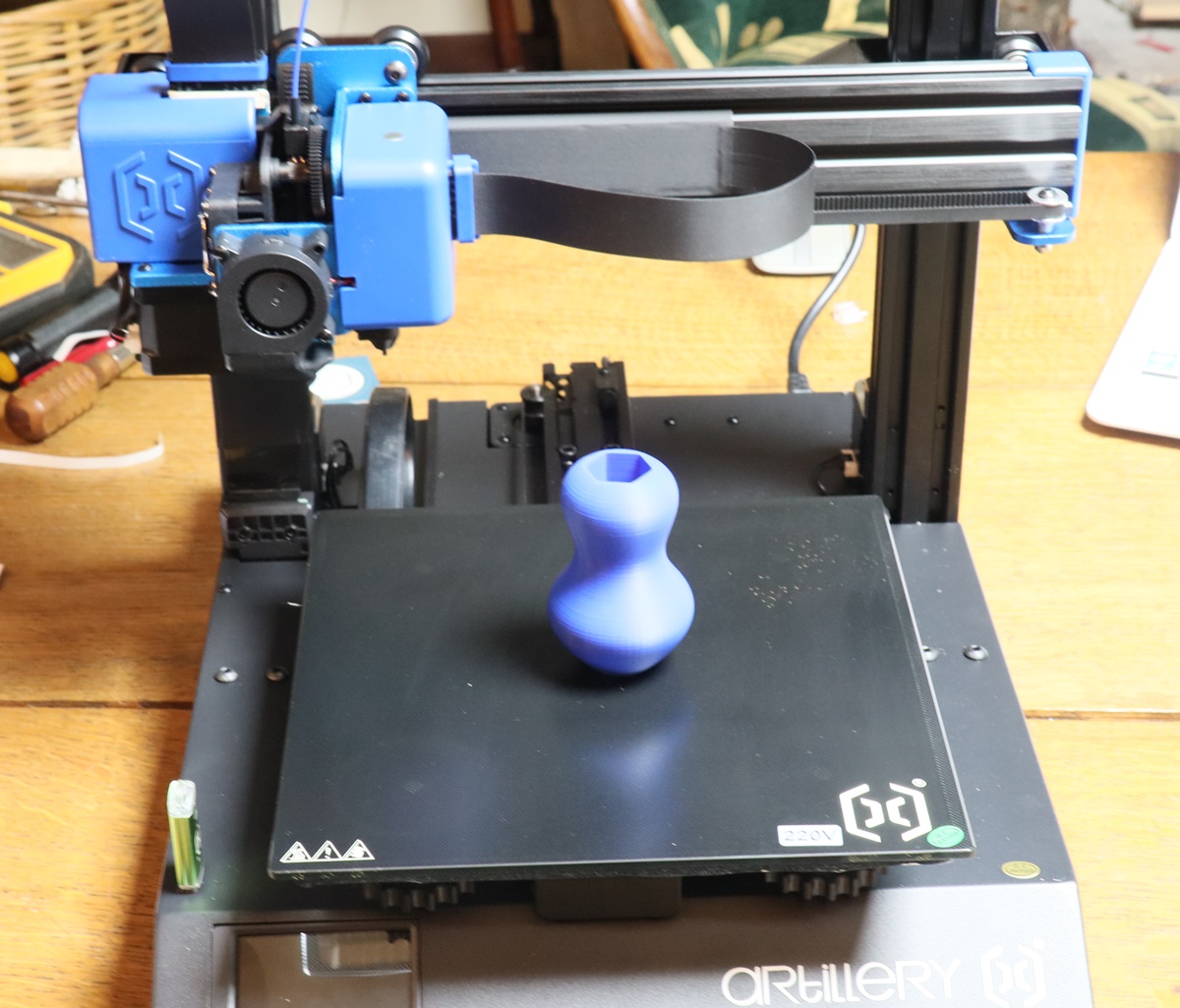

Crown is for a military pistol – boxes are possibles for rib.

28th December. Well, my good intentions to restart my blog at the beginning of November didn’t get far! Still busy with the secondary double glazing, which I just got done in time before the temperatures went below 0C . It has made a huge difference to the kitchen and living room, considering that our external walls are flint and chalk rubble about 12 – 15 inches thick. Anyway I’m now doing a gun encraving job on a set of furniture and locks for a Cape rifle that Fred has built – he has been waiting months for me to get in the frame of mind to do it – I’m now tackling it having done a few days practive on test plates. One problem is that test plates are nice, uniform, soft steel that cuts consistently and easily, whereas the bits for the gun are re-used bits form other old guns and are much less kind to the engraver! I’ve done the trigger guard border and a drum and quiver of arrows on the bow, and it was sort of OK metal but with nasty pockets of ‘rot’ that leave a bit of a hole if you hit one, and patches of harder metal – I am now doing the trigger plate, it has some original engraving – if you can call it that! Its hard metal and was from a very cheap gun so there is no finesse in the original engraving. I can’t do much more than dig our the rust and try to plough a few replacement strokes on what is already there – it will look better, but remember the saying “you can’t make a silk purse out of a sow’s ear”. I haven’t tried to cut the locks or cocks or the breeching, so that another treat to come! Quite a lot of my time before Christmas was taken up with sorting out the 3D printing of the Christmas decorations the school children had designed – that meant I had to go over all 30 designs to make sure they were printable, and then print them all, plus another 30 or so to sell at the school fair! All done in time, I’m pleased to say!

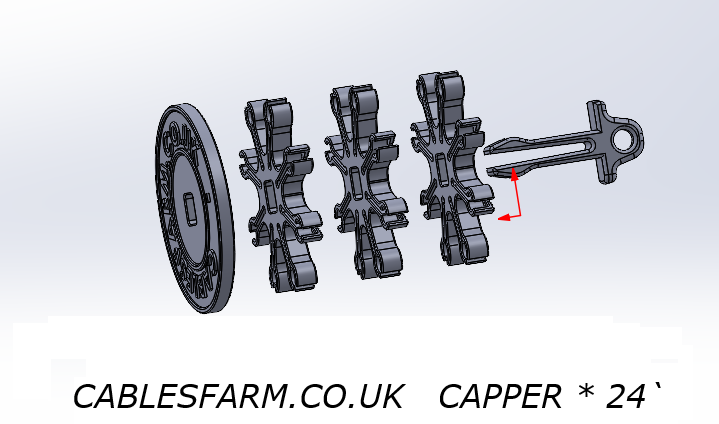

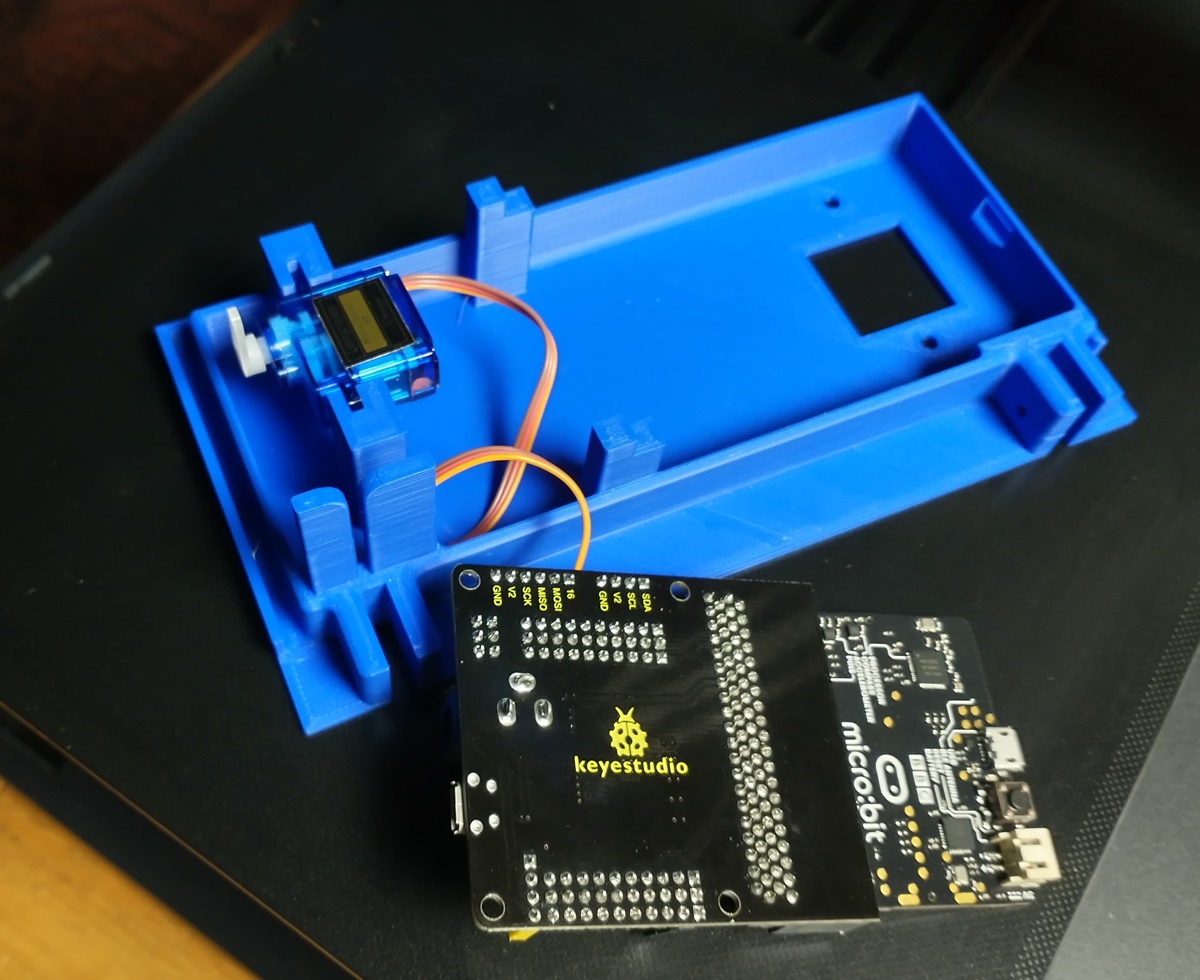

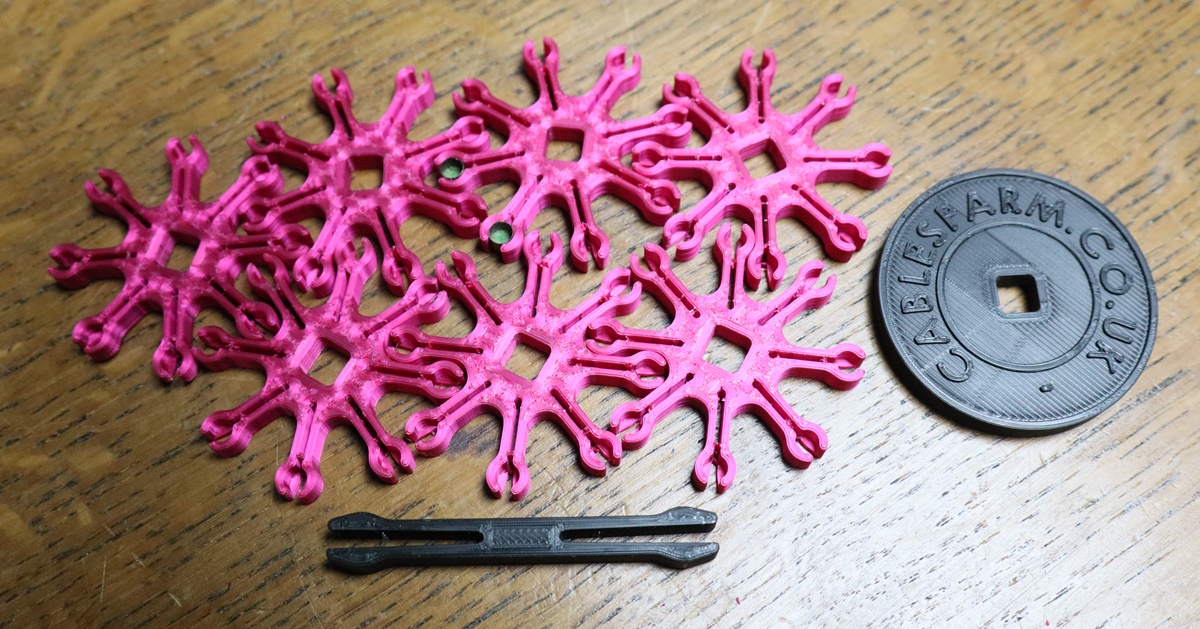

1st November – Very heavy hail and rain storm today – out of the window I saw a great torrent of water streaming off the roof and over the gutters which were full of hail – fortunately it only lasted a few minutes. I got another secondary glazing window in at the weekend with Tom’s help installing it – 4 down, 2 to go. My STEM club has started again at school on Monday nights – there were 5 children, all keen on crafts and making things, and very keen to get involved with 3D printing. Dave, who helps run it, and I are very keen that whatever we do has a tangible outcome, so we introduced the children the the 3D design software Tinkercad and more or less left them to it, with a bit of occasional help. By the end of the hour they had produced plausible name plates, and most of them carried on with the software when they got home. I find it the difference between learning and teaching quite intersting – I saw the teacher’s lesson plan for teaching them to use the 3D software in 6 lessons, whereas our ‘plan’ is to show them how to start and then let them get on with it – children very soon work things out and just get on with it if they are motivated – I wish I could pick up things as quickly as they do. I guess the problem for teachers is the ‘if they are motivated’ bit – they have to cram it into the brains of those that aren’t as well as those that are… Glad I don’t have to! The ‘tangible outcome’ of course means I have to print a whole lot of bits on the 3D printer…. Dave’s daughter and her partner have just bought a 1904 house and as an ‘expert’ on old houses I went over and had a look to give my view on the work they were planning – I can’t supress the scientist in me, so I think I’ve set them off looking in detail at insulation values and trying to optimise the way to spend limited renovation resources in a sustainable way against a potentially large and permenant rise in the cost of energy – its an issue that concerns me here too! My simple answer is insulate better than you think you need, and put in as many solar panels as possible, and maybe a battery of 40 kW.hrs – then at least you can take electricity from the grid when its cheap. There is a tarriff from one supplier (Octopus) that lets consumers buy their electicity depending more or less on the spot rate on the wholesale market in 1/2 hr chunks – in 2021 that varied from 2p to 100p per unit, i.e from 1/20th to 3 times the current price, so with a decent battery system (cost ~ £6000 ?) you can survive throught the periods when its expensive and charge when its cheap. There is even some suggestion that the spot rate will go negative. Given that the battery system will probably last up to 10 years, that could be a win – you would need to use around 2400 kWhrs. a year at half price to break even. Needs looking into and the sums done properly – but I think thats the way things will go for many users – if you don’t have batteries the use of things like car charging will be linked to spot prices – actually it already is for some systems .

28th October – The warm weather continues here – up to 21C today – wish I hadn’t lighted the AGA but if I let it out it will suddenly get cold! I went to take back the gun with the repaired nipple and have a look at the gun with the cleaning jag stuck down the barrel. I could screw the rod onto the jag. but the thread wasn’t secure enough to turn or pull the jag out, so I secured the (double) barrel on its own in a cleaning jig and fixed that in a vice with the blocked barrel upward, and poked a small pinch of Swiss No 1 powder into the ‘touch hole’ – it was a tubelock so I’m not sure that’s the right name for the hole that the tube fires through. Applying a lighter to a small heap of powder on top of the hole produced a small puff and drove the jag to within 6 inches of the muzzle – now, what you mustn’t do is try to put a charge in when the obstruction is part way down the barrel – that’s when burst barrels happen, so it was a case of either getting the jag out from there or pushing it back to the breech and using a bigger charge. Fortunately there was just enough thread on the now looser jag to pull it out, so job done. I did wonder if firing a tube on its own would have shifted the jag, but the gun was already stripped down so it was easier to do it the way I did. The jag was made of white plastic and the thread had partly been stripped – it went in the bin. I don’t use plastic jags in muzzle loaders – they are OK for breech loaders as they can’t get stuck – stick to brass ones!

26th October – I’m getting back into the late night habit – curtailing my after dinner siesta! I got the Locktite 270 and put the sleeve in the Manton – I’ll deliver it tomorrow and have a look at the friend’s double that has the broken jag down one barrel. Like many people I’ve been conscious of the increase in the cost of all fuels, but particularly electricity, so I decided to do a thorough check of our energy consumption – the weather is still unseasonably warm – I think it reached 20C today – so we haven’t got any heating on. I did a check on all our electicity uses by turning off all circuits and devices etc until the smart meter said zero watts. I have a monior system -Efergy- that records peak and off peak current but I’d turned off the necessary computer for the experiment so I relied on the smart meter. switching things back on one by one gave me a pretty good idea of where the power was going, and I was able to account for all the consumption except for 30 watts – after a bit of head scratching I found that I’d left the loft light on since I’d finished the bedroom 6 months ago! That may not seem like a lot of power, but at today’s price it is around £40. The biggest surprise was our 20 year old fridge freezer – I bought a cheap plugin monitor from ebay that records the consumption of any device on a 13 Amp plug which showed that it was consuming around 2 kWhrs per day or £260 per year, Our kitchen lights, all LEDs, would cost the best part of £300 p.a. if left on all year. Looking at advice and figures for electricity consumption on the web I’m shocked that when they list appliances in order of power use they get it all wrong – putting high powered devices like cookers and washing machines at the top, whereas in reality its the things that are on for a long time and often that eat up the power. We are trying to be green, and looking at how we heat our house, but comparative figures for the cost of heating by different methods make depressing reading – we currently use oil in the AGA – that is currently costing about 12 p per kW of energy, and a coal burning stove that is currently costing around 5 or 6p a kW hour as we bought extra fuel before the price went up. We looked at an air sourced heat pump run on eletricity, but to be efficient it needs to run at a low water temperature so, as we can’t fit underfloor pipes means very big, ugly radiators. Even assuming an efficiency of around 250% it will still cost more than the oil and much more than the coal = and the capital cost will be around £25000 plus = so it just doesn’t add up. Thats the real dilemma in home heating = the only thing things that make sense are fitting solar panels – with the increase in price of electricity, with more to come in the spring the payback time for solar panels is now probably less than 10 years, and it will probably now pay to fit a big Tessla battery to juggle power and of course adding insulation if you can do that reasonably. Its really unfortunate that electricity is so much more expensive than any other source of domestic heating, especially now that over 40% of our electricity comes from wind and solar, neither of which is that much more expensive now than it was a year ago.

While I can see that we might be carbon neutral up to 100% of our current electricity load by 2035 if we can find some good storeage methods, I can’t see how we can replace more than a fraction of our massive overall energy use with green alternatives on that timescale, let alone find substitutes for all the petrocarbon feedstock! Having said that, we really have no alternative but to try…………..

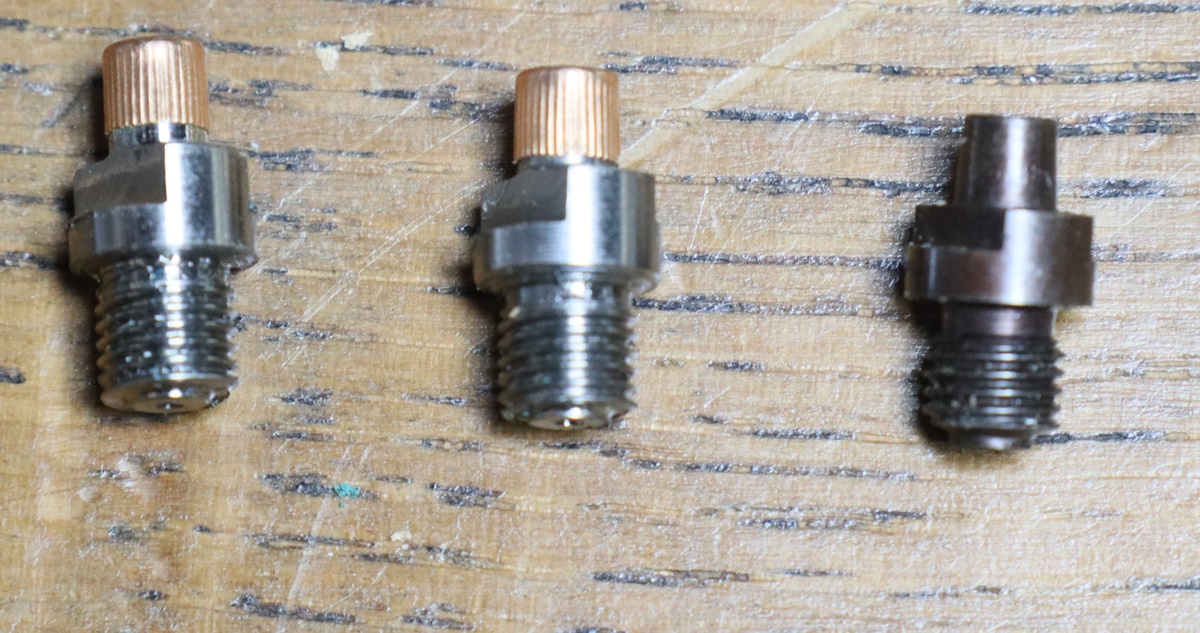

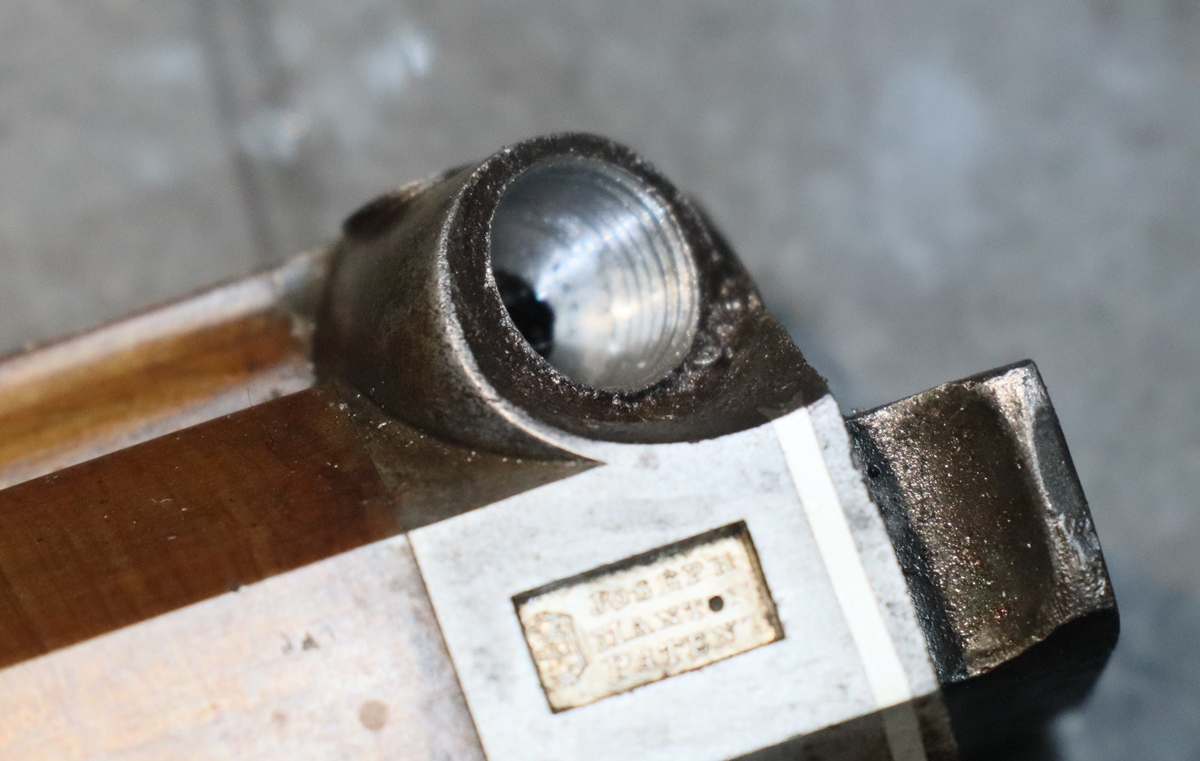

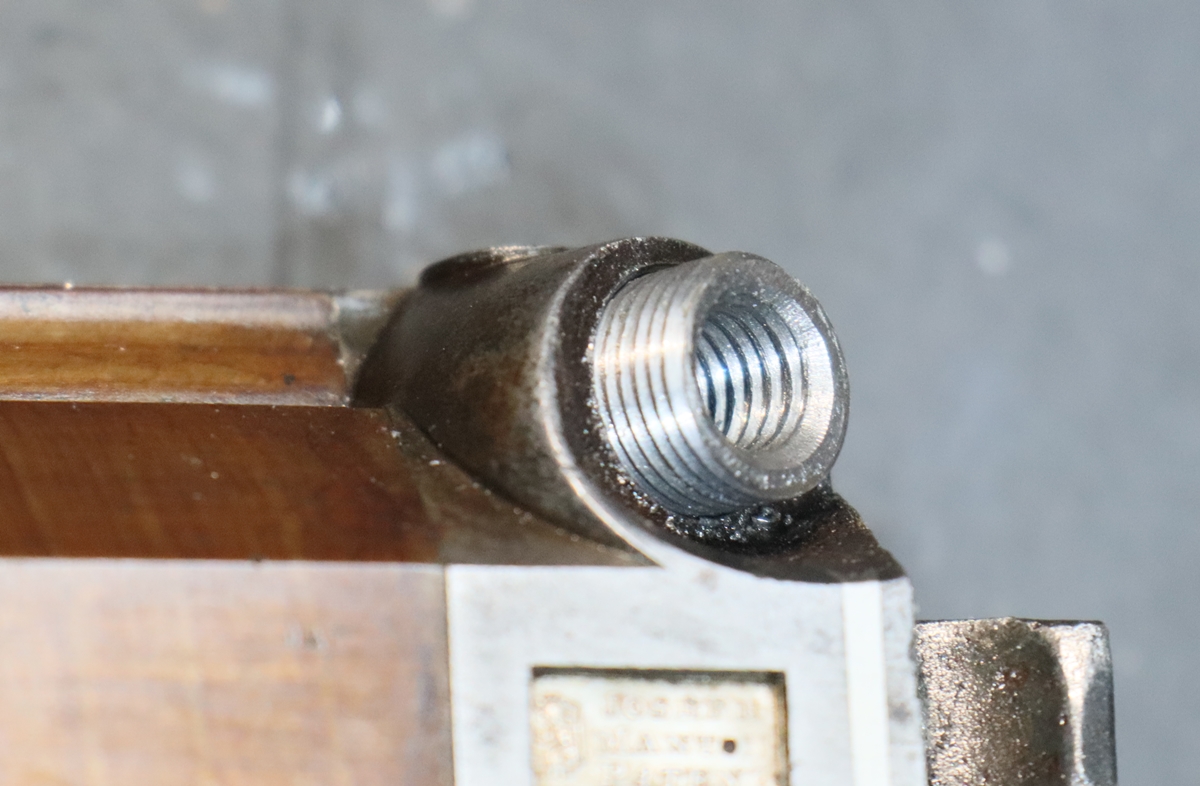

24th October Busy making the frame for the next secondary double glazing – I bought the oak in the form of 50mm x 200 mm kiln dried lengths and am machining that down on my old radial arm saw and planer surfacer. Mostly its going well. except that one length of wood I wanted to use for the 850 long uprights had a mighty shake up the middle that I didn’t discover till I got it down to size, so a bit of remaking was called for. I can’t imagine how anyone could do any woodwork without the means to convert timber – although I did buy this timber specially, mostly I can make things from reused timber or some old oak gateposts I bought many years ago. We’ve been trying to clear out some of the junk that has accumulated over Covid and which is effectively clogging up a whole large room – I managed to sell a couple of old computers on ebay today – thats a start! My Haematologist offered me an Evusheld antibody injection against Covid – apparently its available if you pay but not from NHS or the medical Insurers – on balance, given my impaired immune system and the fact that I am going back into school to run our STEM club and help in class this half term, I bit the bullet and opted for it – tomorrow. I’m also having a meeting tomorrow to sort out with Dave what we are going to do with the children in STEM club – be great to get that going again. Talking of school remined me that last week I had fixed with other people to take the boat round to Ipswich on Thursday, and on Wednesday we got an urgent email from the school saying that the ‘expected some time‘ OFSTED inspection of the school was taking place on Thursday and we had to attend – I couldn’t as too many people were depending on me so I really couldn’t change my plans – we haven’t yet heard the result of the inspection, but people thought it had gone well. Here are some (rather poor) photos of the insert I have made for the Manton – still waiting for the Locktite. Drilled and tapped 3/8 x 32 M. -The thread is much better than it looks here!

Drilled and tapped 3/8 x 32 M. -The thread is much better than it looks here!

part way in…. I don’t want it to get stuck before it has the Locktite – 1/4 BSF x26 nipple thread

part way in…. I don’t want it to get stuck before it has the Locktite – 1/4 BSF x26 nipple thread

22nd October – I’m back after a bit of a long break, for which I apologise! I seem to have been quite busy, although I’m not sure what was occupying me most of the time although I’ve done a fair bit of work on the boat that we are going to base in Scotland from next spring. We sailed it from North Fambridge to Ipswich to get some work done at Fox’s Marina on Thursday – actually sailed is the wrong word as we don’t have any means of putting up the mainsail at the moment as there is a problem with the inmast furling gear, so we motored all the way – when we got to the River Orwell the engine started to play up, but we managed to limp up to the Marina – so the engine is another problem to sort out. I have started to make and install the frames for the secondary double glazing for the leaded windows in the old bit of the house – the result is fantastic. as I mentioned in this blog before, I discovered a firm that made a revolutionary form of double glazing using two panes of glass separated by a near perfect vacuum in a very thin layer that provides better insulation values than triple glazing, which conventionally fills the much larger space between the panes with gas, usually argon, that still conducts quite a lot of heat. The vacuum windows need some means of stopping the glass bending inwards under the external pressure, and has tiny dots on a 1 inch grid that keep the panes of glass apart. |The panes have to be specially made to size and finish up at about 8mm thick so are easy to incorporate in more or less normal frames. I’ve made oak frames to go behind the leaded windows, with a fixed panel either side and a sliding panel in the centre over the opening casement. I’ve done two in the kitchen and one in the living room so far and it has definately raised the temperature in both rooms. The thing that strikes one most when you put them in is the reduction in outside sounds and the slight change in acoustics near the windows – the vacuum is an almost perfect sound barrier – check out the glass, its called Fineo – as you might expect its expensive, but as a fraction of the overall real cost of the job its not too bad – costing my time etc I guess it accounts for 30% of the cost.

I have recently had a few days with a gun for the first time since the last shooting season. I took the Nock and a Beretta o/u to shoot some clays and surprised myself (and others) by managing to hit lots – must have been due to the long absence from shooting, because next time I couldn’t replicate that level of success. I have had one game shoot, last week, at Partridge and Pheasant on a glorious warm and sunny day in Suffolk. It looks like it may be my only game shoot of the season as with Bird Flu now virulent in the area and several shoots packing up during Covid there are not many opportunities for Black Powder shoots, and anyway the costs have escalated – last year’s £33 per pheasant has turned into £50 now.

I havent had any gun jobs over the summer – except for an big engraving job that I’ve yet to psyc myself up to tackle, but recently I was brought a nice single barreled percussion sporting gun by Joseph Manton that had blown out its nipple – luckily without any injury .. The gun was brought to me to ‘sort out’, of course minus the wayward nipple. The nipple hole looked much larger than a normal nipple hole and the thread finer than usual and quite messed up. Looking down the nipple hole with the microscope you could see that someone had screwed in a nipple with a different thread pitch than the one tapped into the hole – screwing a piece of sharpened wood into the nipple hole didn’t yield a clear pitch for the thread, but a piece of modelling clay pressed in showed that the pitch of the thread had been cut at 32 t.p.i but a nipple of some other thread had been inserted. Measuring the thread diameter showed that the nearest thread size was 5/16″ x 32 t.pi. which happens fortunately to be a standard M.E. (Model Engineers) thread. Quick shop at my favourite tool store Tracy Tools got me a 5/16 x 32 plug tap (£3) and die (another £3) by return post. I managed to get a decent thread in the bottom of the nipple hole, and if I had been sure the gun was never going to be shot again I’d have left it like that and made a new 5/16 x 32 nipple, but I can’t bring myself to do things like that! I quite liked the look of the 32 t.p.i thread so decided there was just enough metal in the breech to drill the nipple hole out to take a 3/8 x 32 thread ( another order to Tracy Tools for 3/8 x 32 taps and dies – total £12). I set the barrel up in the vice of my milling machine (with suitable packing) and with the 5/16 tap in the nipple hole aligned it with the axis of the milling machine and took the plunge and drilled out the hole. I kept the barrel set up and put the taper tap in the chuck and started the thread with mole grips of the tap body, then second tap. after that I took the barrel out and used the plug tap to get as far as I could, then ground the end of the plug down to cut as near to the base of the nipple hole as possible. result a very nice thread. Then turned up a sleeve with a 3/8 x 32 thread on the outside and a 1/4 BSF x26 hole in the centre, coned the end a bit to fit the bottom of the nipple hole and parted it off – result one nice sleeve – now waiting for some Locktite 270 to stick it in place – that is a very strong adhesive and will stand up to 180 degrees C so I think it will stop the sleveve being unscrewed when the nipple is taken out. I’ll post some photos when I have time to take some – I’ll have to change my habits now I’ve started to post here again – I always used to post late at night and go to bed very late – a habit I’ve got out of over the summer, snoozing on the sofa and going to bed around 11 and waking ridiculously early.

I have another job pending – someone has lost a plastic jag with wadding at the bottom of barrel and can’t shift it – its a tubelock so its not as if you could take the nipple out and pour in a bit of fine powder and blow it out – might be able to get enough through the flash hole to blow it out, or I’ll have to invent a way of drilling it out – I don’t like having to remove breech plugs in a double as there is always the chance of breaking the solder joint between the barrels. I have come across the problem of the cleaning rod and its load getting very tight in the bore – there is a technique for avoiding disaster- first always wind any cloth or paper or tow etc on by turning the rod clockwise as seen from the handle – then when its in the barrel turning the rod clockwise both tightens the cloth etc around the jag and screws the rod up. Now NEVER pull the rod hard without turning it clockwise at the same time – clockwise turns will tend to wind the cloth tighter on the jag and make it an easier fit in the barrel. It’s much easier that way! Similarly if you have to use a screw to remove athe jag’s load that you’ve left behind in the barrel, keep turning it clocckwise as you withdraw the rod.

Re 20th August – It turned out that the chap who serviced the engine this year had used the wrong replacement impeller when he serviced the cooling water pump so it wasn’t circulating the cooling water properly. It wasn’t obvious that the impeeler was too small as the position of the watr pump stops you looking straight into it, but I spotted that the O ring supplied with the impeller wasn’t the same size as the mark on the cover plate of the pump and that it had been pinched in one place. A proper Sole replacement is now in place and the ‘wrong’ spares disposed of. Years of using O rings for very deep water (4000 meters and more) has taught me that you have to inspect O rings very carefully and I’m always suspicious if things are not perfect!

20 th August – Still enjoying the good weather here – a couple of days with a bit of much needed rain, but not enough to do much good. I had a day down at the boat on Wednesday – I hadn’t realised that it was the first time it had been used since launch. Anyway we set off under engine and within 5 minutes it overheated and had to be shut down, leaving us drifting amomg the moorings – the skipper called up the marina launch and we were duly towed back to our mooring for a bit of a post mortem. I hadn’t been involved with the engine side of things, but the seawater side of the cooling had been modified and serviced, but I think the problem lies in the closed circuit coolant system – I suspect that 2 years of lying idle might have siezed the coolant pump – the system had been filled properly and checked, so it wasn’t lack of coolant. A trip next week is scheduled to sort it out.

15th August Been busy keeping cool! I’ve worked up to 100 lengths of the pool = I think Ill stick at that for the rest of theyear!. There was an article in the Sunday Times saying that the recommended daily intake of protein is half what it should be – recommending 100 gm per day – I checked out the calculations I did when I was trying to put on weight – mucsle specifically, after Covid in early 2020 and I came up with 85 gm to maintain weight, and more to build muscle. That’s quite a lotto put away – meat is around 1/3 protein or less, and to get that much protein from vegetarian or vegan diet without supplements is very hard work. I’ve found that its very easy to loose muscle – a couple of months back I noticed my calve muscles were quite reduced, and I was struggling to lift things that hadn’t been a problem a year ago, like my outboard motor (20Kg) – anyway I made an effort to eat more protein, including a cooked breakfast, and it seems to be working – the swimming probably helps, and I do a short burst of weights most days. I was quite conscious that my sense of balance wasn’t really up to clambering around on the moving deck of a of a sailing boat at sea, so I’m practising that too! Problems you never really think about until they hit you as age creeps (or rushes) up. I’ve been busy making bits for the boat on the 3D printer – I’m addressing the issue that there is nowhere in the cockpit to put down a cup while sailing – an important facility that most boat designers ignore! The boat is due to be launched today and put on her mooring – I’m scheduled to be sailing next week, but there are going to be a lot of family on board, including baby and dog, so I might just leave them to enjoy it without my getting in the way! I’ve sent the Lowe pistol back – the client was happy for me to leave it as it was, and not attempt to get the set trigger firing to work – I’m convinced that if it ever worked, which I assume it must have done when made, it was, as they say, by the grace of God the design being, in my view, fundamentally flawed.

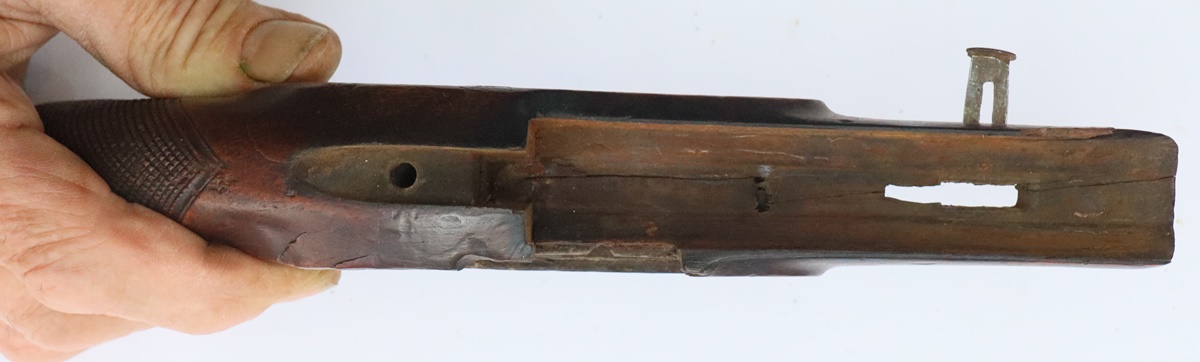

Before cleaning

The crack running from the barrel bolt now looks much less obvious

The crack running from the barrel bolt now looks much less obvious

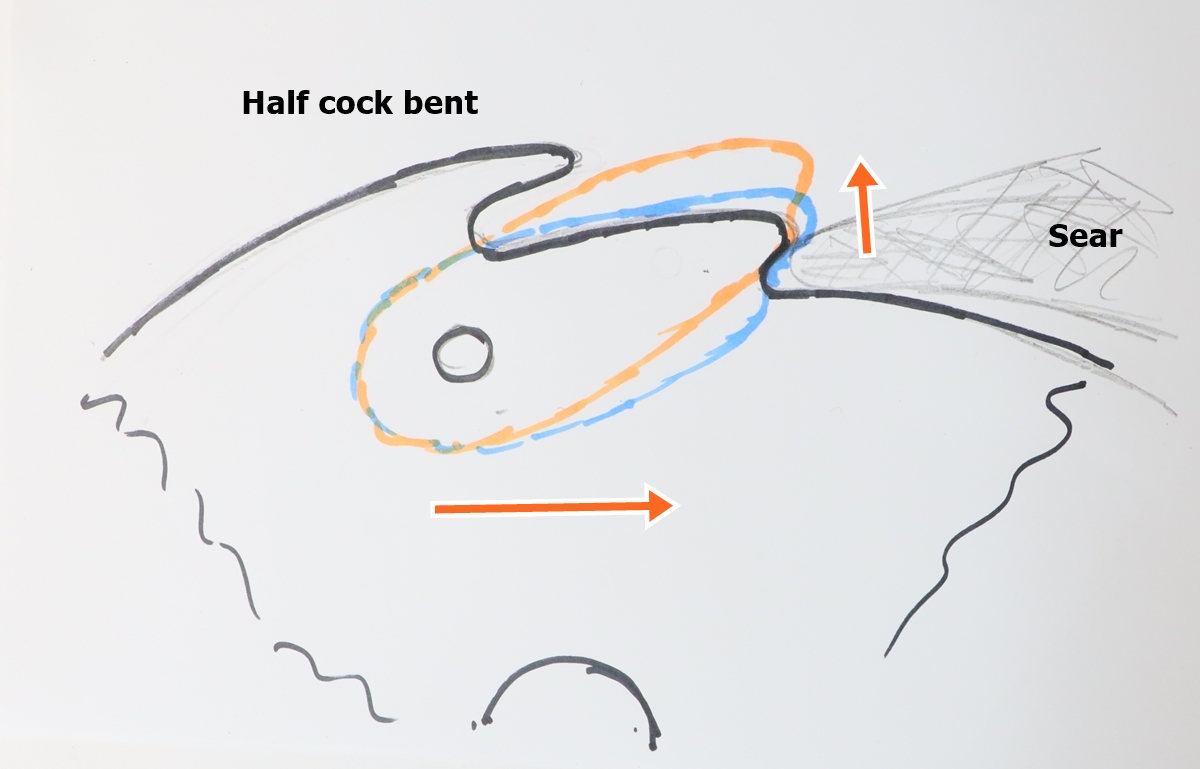

9th August (2). I had an order for a couple of gravers and sharpening jigs, so got that out of the way before I got down to sorting the Lowe Pistol that I’d left in mid air, so to speak. I had decided the barrel needed to come out as I suspected that there was a fair amount of rust underneath, and particularly at the junction of the wood and barrel, which is where its mostly a problem. I had a bit of a scrape around on the upper surfaces and found that they had a very thin black coating on top of a suggestion of rust. Getting the barrel out of an old pistol can be a tricky job – in this case the barrel bolts seemed set in their slots, and the visible rust along the edge of the wood raised the possibility that some of the wood might come away – there was already a split at the muzzle end suggesting that someone had tried to get the barrel out, and there was a lot of damage around the bolts where people had tried to prise the bolts out. My technique for removing the barrel is firstly remove the lock as the rear side nail is probably notched into the barrel hook. Then lay the pistol with the bolt heads down on a pad of bubble wrap or something else with a lot of give, and using a screwdriver that sits on the thin end of the bolt, tap very gently, checking that you are not lifting the wood around the bolt head end. Once the bolt has moved a few mm you might be able to pull it from the head end but DON’T lever against the wood of the pistol without putting something under the lever to spread the load and only lever gently. On this pistol the barrel bolts were very firmly in place and I had to make a 25mm long strip of metal to go into the bolt slot and drive the bolts out, which I managed without any damage. Getting the barrel out proved a little tricky too, although by this time it should be free and just lift out, this one didn’t want to come out, and I was worried it would break off some wood so I ran a razor blade between the wood and the barrel. I put a dowel in the barrel end and tapped it gently and eventually the barrel came free. It was, as I suspeted, quite rusty and certainly justified taking it out. I thought about trying to get the rust off, and leaving the barrel finish, but decided that it really needed to go in the electrolytic derusting bath for an hour or two. After washing and rubbing it down with tissue I put it to the fine steel wire brush on the ‘grinder’ and got a very good clean finish with a suitable dark finish that will do for the final surface, Before refitting the barrel I cleaned up the barrel bolts as best I could without removing them form the stock, and put some leather grease in the slots to ease the next removal. I also glued up a previos split at the muzzle. Looks good now! Then back to the lock – which I admit I’d been putting off ! With the lock back in ( you need to ‘cock’ the set trigger to put the lock in by pushing the trigger forward till it clicks ) I tried to fire the pistol with the set trigger, but it was not reliable so I stuck to manual trigger pulls to fire it, which worked just fine. I debated whether to take it all to bits and do some more micro filing on the detent, but decided that the whole system was so impossibly fiddly that I might easily end up with a pistol that wouldn’t fire at all. It made me think about why the system is so fiddly and difficult to set up, and I think I eventually understood what was wrong with this method of detenting a lock. In a normal detent the detent itself is not involved in the instantaneous release of the tumbler when the sear is raised out of the full cock bent – the detent is free to move a little and the additional work involved in raising the sear up the detent to clear the half cock comes entirely from the mainspring, not the trigger plate / set trigger. With the Lowe detent the sear has to lift the detent as well as climing out of the full cock bent, and as far as I can see also has to provide some impetus to climb to the height of the half cock notch, given the angle to the pivot of the detent – this additional force to lift the sear and detent must come in part at least from the trigger plate, or the set trigger if this is set. Since the set trigger works by inertia and has no other force driving it, it is perhaps not surprising that it is marginal. To me this explains quite clearly why this was not a common form of detent – as well as being very fiddly to make and set up, and prone to wear, its just fundamentally unsound in principle. Perhaps this drawing will help explain how it is supposed to work;-

sear in pencil – detent in blue is ready to fire, orange is in position to guide sear over half cock notch. Sear needs to do work to raise detent and climb over it.

I have to admit that the proper shape for the end of the detent is conjecture on my part, but somehow the sear needs to get on top of the detent without pushing it down?

9th August. I could have sworn I posted a new post yesterday, complete with a couple of photos, but I must have forgotten to click on ‘publish’ I suppose. I’ve been down in Cornwall, part sorting the cottage, and part holiday. We towed our 16 ft dayboat (Cornish Coble) down and parked it at Mylor Yacht Harbour and had several sails around the Falmouth Estuary in lovely weather, and chopped down the encroaching vegetation round the garden – the rate things grow, particularly sycamore trees, in Cornwall is something else! By the time I’d finished cutting back enough to be able to see out of the garden I’d generated more than we could fit onto the available space, so I had to go and buy a shredder to compact it – I got a £66 one at B & Q which is the same as the one we have at home – its fantastic and shreds branches up to about 45mm which is about 2 or three years growth, so ideal. Cornwall continues to get better as a holiday destination – its now much easier to get good food from farm shops, and there are three or four good bakers producing artisan sourdough bread that is really worth eating – which makes a lunchtime diet of sandwiches quite bearable.

At anchor opposite Falmouth for lunch

We even had a swim at Lamorna Cove!

22nd July I was having another fiddle with the Lowe pistol this evening, trying to reshape the little detent that I hardened yesterday as it was getting worn by the sear and I wasn’t sure it would keep its shape. I did a trial fit again but this time it was exactly like the original problem – no full cock. I think I spotted where I need to take off a bit of metal ( with a diamond file as its now hard) and was removing the pivot pin with a pair of fine long nosed pliers when the pin pinged off across the workshop, never to be seen again. It was about 1.5 mm diamete and 4mm long and slightly tapered – very fortunately I have a set of hard steel clockmakers blanks for shafts including one a fraction too big for this job, so a few minutes holding the rod in a drill against my diamond hone put a slight taper on the rod and reduced it to the required diameter. I had to use a diamond file to nick the rod deeply and then break it, and held the little bit in a micro chuck of a dremel while I honed down the ends to fit. – all in all it only took me about 35 minutes to recover from the loss. I need to try he revised shape – assemble the lock AGAIN etc etc. I’m not sure I’ll be able to give much time to it in the next week or so as I have some family business to attend to that will keep me occupied – plus I need to go down to the boat a few times to assist getting it ready to launch……… Just put it all together for the umpteenth time, and it worked, even to the extent that the set trigger fired it and it sparked up nicely in spite of using one of my home-made flints. I only tried a couple of times, but I’m optimistic that it will go on working (I hope!). I certainly wouldn’t want to try it too often, because even with my hardened detent there is still some wear and in my view the whole design is pretty marginal – I think I probably need to do a bit more to the pistol before I return it – I think the barrel really needs to be taken out as there is likely to be some rust underneath and I think it will require care to remove the barrel bolts as they are likely to be rusted into the wood. I removed some more hard black rust from the lock with the back edge of the modelling knife and 0000 steel wool and the signature now shows up well. I would put up a photo of the new detent, but actually it doesn’t look that different from the original and I don’t have a good enough macro lens on my camera to show it well.

20th July The owner of the Lowe pistol suggested that this particular design of detent might have been rare because it was so fiddly to make – I’d go along with that, and add that it would have been susceptible to wear that, like this example, would render the pistol useless for anything other than scaring adverseries! By comparison, the ‘normal’ detent on the side of the tumbler is much easier to make and much less critical and less susceptible to wear. I didn’t get a chance to do any more to it – I hope I can get it to work, but I’m not sure yet! I did a bit more on the boat, fitted the second jib sheet car, fiddled around with a new lock on the hatch board and fitted a bit of trim in the saloon. I also took down my little wooden dinghy that has stood in the shed unused for 20 odd years. I built it about 40 years ago as a challenge after aquiring a few sheets of 1/8th ply from a bankrupcy sale (“take as much as you can before the bailiffs come in this afternoon, and drop me a few quid in cash” – even included a nice BMW coupe that I couldn’t afford to insure so didn’t take – to my everlasting regret!). My challenge was to make an 8 ft dingy light enough to carry on ones back with the building taking less than 24 hours work. I stiched together a model from card and a needle and thread and then scaled it up to stitch and glue full size. I got it made and one coat of 2 part polyurethane in the 24 hours, I’m sorry to say that the secod coat over-ran! It is a fine boat – the seat ( ‘twart’ – obviously the wrong word as that implies across) runs fore and aft so you can always slide to balance the boat. The aim is to launch Sepiola in the next couple of weeks onto her mooring. Going from here to the boat I use Google maps. It offers you a choice of 3 ways that are almost the same time, but the one I use most often varies in detail from journey to journey and I often take a wrong turn, whereupon google routes me through many tiny roads because it won’t tell me I need to turn round ! Strange thing is that I always get a different route when I ask for the return journey – a slightly flakey routing algorith that I’ve noticed usually starts off on major roads and descends into back roads as you near the destination, When returning it takes you straight to a main road and then descends to smaller roads. Annoying!

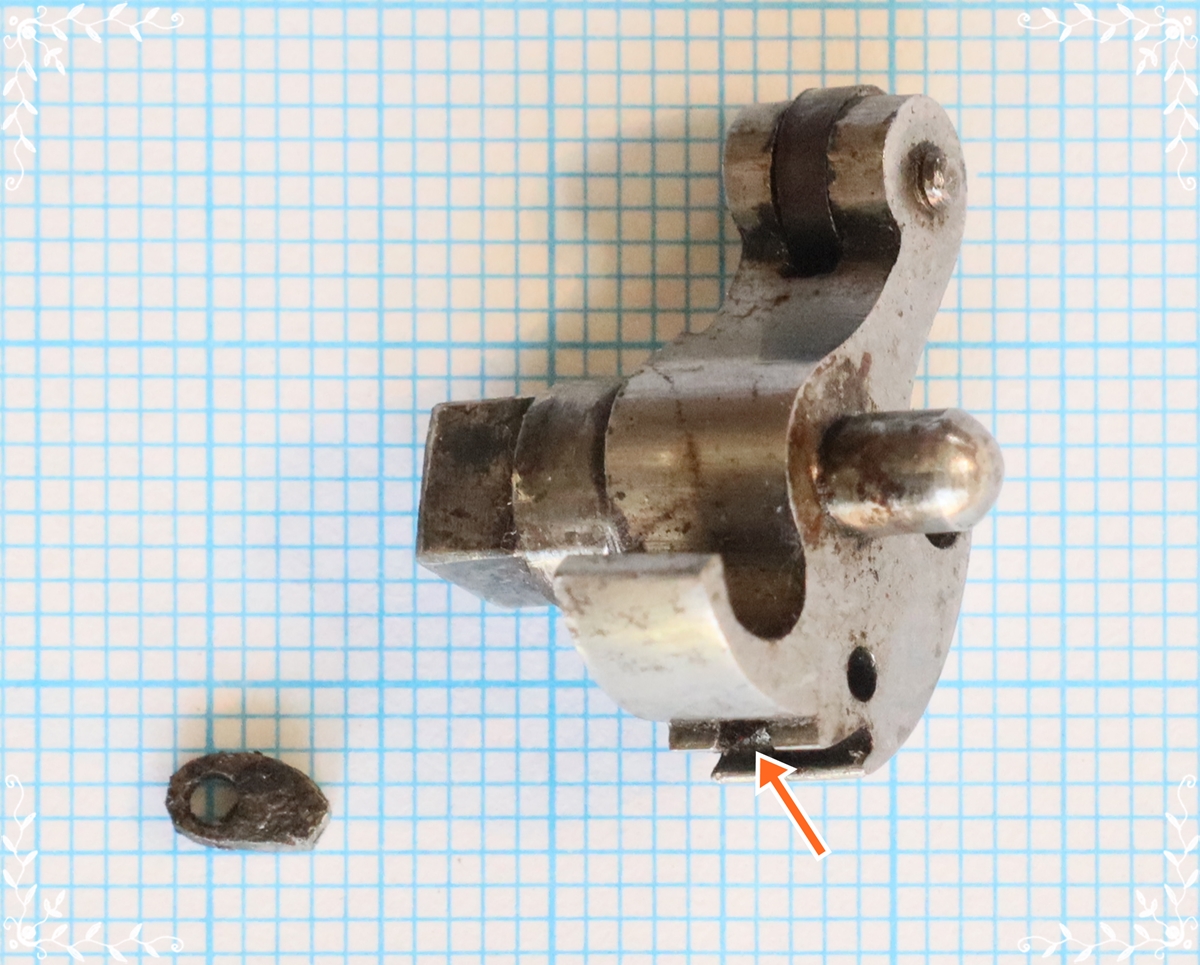

19th July One would almost say it was a hot day, I had to retreat to my workshop that stayed at about 25.5C so I was able to work on the Lowe pistol. Our house its pretty cool as its old and solidly built and has most of the accomodation in the North part, but if the heat lasted for many more days the advantages would be lost. Playing around with the detent, I concluded that the reason it didn’t work was that a vital bulge had been worn off so the sear could slip out of full cock without activating the detent to block the half cock notch. The only way I could see to try to make the lock work was to make a new detent, which is what I was doing today. I started with a bit of 2 mm spring steel and annealed it – that way I can harden it when I’ve finished if it works. Making an accurately shaped bit just about 4 mm x 2.6 mm is OK as long as its still attached to a bit of metal you can hold, but once you get to the stage of fitting and trying it you have to separate it, and then the fun starts – for one thing I am terrified that I’ll drop it, and I’d never find it on the old brick floor, then to file it you have to hold it so you need a small high precision vice. To get the shape right I threaded the old one and my version on the same axle and checked under a X15 microscope, then took a few strokes with a very fine file while holding the part in the vice, then checking again. When it came to getting the bit that engages the sear, I filed it under the microscope with my finest file. I’m still working on it – of course to check if it works you need to put the whole lock together, mainspring and all, and also put it back in the pistol as you need the trigger blade. I must have done that at least half a dozen times so far, and taken the detent in and out about 20 times. I think I could strip a flintlock with my eyes shut now! I’m not there yet – I have now got it so that it will hold both half and full cock, and fire from full cock with a firm pull as the sear has to climb up a bit of the detent – it won’t yet fire by the set trigger – at least that is an improvement! It’s by far the fiddlyist job I’ve ever had to do, and of course I don’t really know the correct shape for the active face of the detent – I just hope I don’t take too much off and have to remake it! I did manage to get a swim in – 50 lengths, the pool is getting a bit green in this heat despite the chlorine – probably needs an algicide. I finished the sear spring yesterday – I carelessly forgot it was a left handed lock and bent the spring the wrong way, so I had to straighten it out and rebend it – I didn’t close the joint fully up as I didn’t want to overbend the metal twice – its a bit wavy too but it works just fine. Off to do a few jobs on the boat tomorrow…..

1 mm graph paper – critical surface marked by arrow.

17th July – Quite a warm day, at least up to about 3 p.m. – every nice day I’ve planned to have a swim at about 4 p.m. and every day it’s clouded over about then. I did get up to 60 lengths yesterday so not doing badly. Still messing about getting the boat ship shape, and doing odd jobs outside while its so nice. Today threatened to be too hot so I moved to the indoor workshop for a bit of work on the Lowe & Son pistol. Actually all my workshops are pretty cool in summer – probably the evaporation of all the damp! Anyway I thought I’d try Bev’s suggestion and turn the little detent up the other way, so I knocked its pin out to release it. Tip;- if you have to knockout a pin rest the object on a bit of lead sheet folded 2 or 3 thicknesses and hammered flat – that way the object is ‘dead’ and won’t bounce around and the pin can sink into the lead and doesn’t get lost – it even works for driving the barrel pins out resting the wood on a lead block – it avoids accidentally driving out a chip of wood. I found a pin punch that was the same size, more or less, as the pin so I could easily put the detent back in and inspect its action. So, sad to say, that doesn’t seem to be the answer – put in the other way up the detent wont go down far enough to let the sear into the half cock bent, although from the point of view of the full cock bent, things seemed a little better – so original orientation half cock works but full cock wont hold, reversed I havent tried assembled, but it looks as if the opposite happens – full cock works but it won’t engage half cock……There are some signs of wear from the sear on the detent, which might suggest that it did work once, although the ‘nose’ of the half cock bent does appear to have been impacted by the sear and burred over. That is a bit of a mystery too, as would probably have stopped the gun being fired – why do that enough times to burr over the top of the bent? So I’m no further forward on that puzzle – I am still trying to believe that the gun has worked with the parts that are there now, but my faith is wavering! I decided more evidence was needed – I need to make a new sear spring so the I can see the gun in action properly, so I got a bit of 5 mm spring steel and milled it down for the blade – its now ready for final fitting – I need a UNC 3 die to cut a new screw to hold the spring – I managed to get the old rivet out of the lockplate, and the original thread in the lockplate was intact, and a slightly loose fit to UNC 3, so I’ll have to expand the die as far as possible.

Tumbler and detent on 1 mm squared paper – arrow points to slot in tumbler for the detent.

This is how it was – you can just see the detent in the main bent – see arrow, the perspective is a bit unhelpful!

Here the detent is reversed and is visible blocking the half cock bent it won’t go down any more.

Reversed – this is a s far down as it will go, so stopping hte half cock bent.

Part made sear spring.

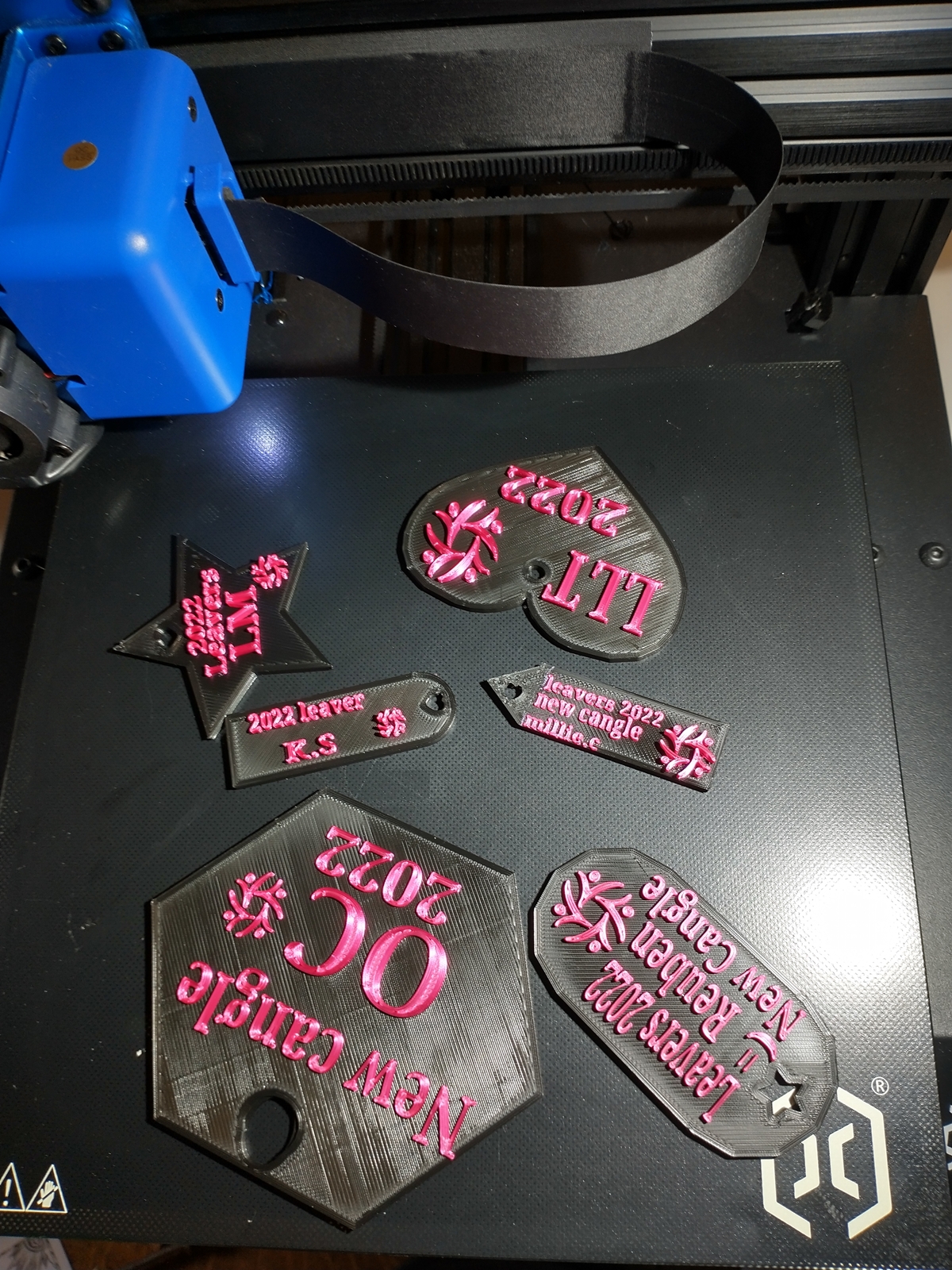

13th July Decided to strip the carburetor of the 4 hp outboard for our dinght as it will only run with the choke out, suggesting that the fuel isn’t getting to the engine. I seem to remember checking the fuel pump some time ago and it was OK, the fuel filter is OK too. The dependence on the choke suggests that one of the jets is partly bunged up or some other part of the carb after the float chamber. Anyway I had a look on YouTube for an idea of what to expect during the job and took it all apart – a bit of muck in the float chamber but not much evidence of bunged up jets. I remembered that I’d ‘inherited’ a small ultrasonic cleaner when Giles emigrated so put all the parts in that and got quite a bit of muck in the bottom of the cleaner that must have come from somewhere. Now waiting for the new gasket etc set. I had a problem with it overheating when I last used it, and stripped and replaced the water pump, which was completely solid with salt, and took the head off to clean out all the water passages. It still got too hot even with the thermostat fully open, so I removed it altogether and it was better. Now I’m trying to get it all right! Saturday is the Helice Shoot at Rugby – I’ll be there! Just got another two of the kids’ keyrings to print for tomorrow morning, unlike most of the 3D printing which will run unatttended to the end, these require the filament to be changed to give a colour change just for the text, so it has to happen at exactly the right point.

New sheave and axle assembly

12th July Busy printing 29 keytabs for a class at a Haverhill school where a friend teaches – the kids designed them, so one or two needed a bit of remedial work. I’ve been gently working on the dinghy to get it in shape for taking to Cornwall later in the summer. Bev left a comment about the detent on the Lowe and Son pistol suggesting that it has been removed and mistakenly replaced the wrong way round as had happened to one of his locks. Makes sense as no amount of wear would explain why the sear hits the detent when its trying to engage the full cock bent to cock the pistol. I’ll try reversing it when I get a moment. Its not the sort of job an amateur would undertake, so I guess it might be done by someone who had never seen this type of detent – but why would they leave it in place the wrong way round? And why for Bev’s lock too? Mystery….. We’ll see if it works when reversed…. watch this space. I’ve been gently cleaning off a few bits of rust on the pistol – my preferred tool is the back edge of a modelling knife blade, very slightly polished to make sure it isn’t scratching the metal – it scrapes off the rust without damaging the patina underneath, then a very light rub over with the 0000 steel wool and oil stop more rust and leave a good surface. I guess it really needs the barrel taking out as there is bound to be rust underneath at the edge of the wood. Its a fine pistol and I’m trying to avoid doing too much to it as its originality is important. If its something like the Rigby wreck I did recently, anything is an improvement, but the better the gun, the less is justified in my book. Oh and I finished turning a new sheave and bearing for one of the ‘cars’ on the track that adjusts the angle of the jib sheets on the boat — not the dinghy ( sorry about the jargon!). (makes me realise that I jump around from one hobby/pastime/job to another at a dizzy pace – perhaps that why I’m not really an expert in any of them!)

Keyrings designed by the 10/11 year olds using CAD software – pretty good effort.

10th July Received a nice pistol to work on – Hermes left it on the doorstep of next door, who were away – they are terrible (Hermes, not the neighbours)! Anyway now have it and its quite unusual – A silver mounted pistol, not hefty enough for a duelling pistol, but I suppose what you would call a ‘horse pistol’ to be carried in a holster in front of the saddle – a pair that is. Anyway its unusual because its a mirror image of a normal pistol, with the lock on the left side – its a complete mirror image, the barrel bolts even go in from the right side – they usually go in from the left side like all pins etc. Made by Lowe and Son of London with hallmarks on the silver for 1787 and the maker’s mark for Moses Bent, a fine silversmith. It is in good condition, there was some superficial rust on the lock etc that was hidden behind some sort of blacking, but the engraving, which has very fine lines, is still sharp, and its cleaning up OK. The faults are that the sear spring has broken, and somehow the lock fails to engage full cock. The inside of the lock is in very clean condition with only a trace of rust around a few bits of the edge. There is one very unusual feature of this lock – it has a set trigger, with adjustment behind the trigger, rather than in front as is usual, so it needs a detent to carry the sear past the half cock position – the seat only gets a tap from the trigger blade if the set trigger is used, so will fall into the half cock bent without the detent to guide the sear past the half cock notch. This pistol has a form of detent that I’ve never seen before – I havent seen it described either. The tumbler is quite wide and a tiny detent is pivoted within the tumbler. It looks as if its meant to lie flat when the sear is in the half cock bent, but then when the sear is in the full cock notch it catches the detent as it climbes out of the full cock bent and the detent deflects it over half cock bent. The trouble appears to be that the detent gets in the way of the full cock bent and the sear engages it, causing it to pivot up and carry the sear over the half cock bent rather than fitting properly into the full cock bent. I suspect that the detent is worn or damaged – I dont see that it could have had a spring within the tumbler. Anyway, I will sort out the sear spring first – some bodger has made a rivet and rivited it through the original screw hole – Anyway a nice pistol and a nice mysterious project for the blog…. In the meantime I’ve got my small outboard motor running and started to varnish the spars of the dinghy that we are taking on holiday to Cornwall later in the summer. I had fun with the 3D printer – I bought some new filament called PLA + and found that if I followed the specified setup for PLA+ the print of my mug holder took 28 hours instead of 16 for normal PLA! I tried both settings, but the slow one is definately best, so I’m now watching while my printer chunters through that job…. Oh and the awimming pool has come into its own – I manage 40 lengths – about 350 meters today, I’m trying to increase by 10 lengths a day up to 100 lengths…. And here are some photos of the Lowe & Son pistol – they worked in London and had premises in Westminster from 1796, not sure where they were before this. Blackmore’s book lists them as in business from 1792, but they were clearly working earlier that that on the basis of this pistol.

Notice rivetted head of Sear spring fixing

Notice rivetted head of Sear spring fixing

Tumbler with the mystery detent – I’m not sure in detail how it should work – as it is it won’t let the sear engage full cock

Tumbler with the mystery detent – I’m not sure in detail how it should work – as it is it won’t let the sear engage full cock

6th July Guns are a bit neglected at the moment, although I am going to the Helice shoot on 16th at Rugby Clay ground – its a great sport and the Anglia Muzzle Loaders make it an annual event (Covid excepted). Its really tricky shooting – I’m not particularly good at it but enjoy it – son Tom only shoots about once a year but is pretty quick – last year he just missed out on the shootoff. I’ll need to get the dust off my faithful Nock. I’ve been down to the boat several times – I spent Monday lying on my back with my head in a cupboard fitting new hoses to the loo – not my favourite job, then on Tuesday I was helping Tom plumb in a new sink – lying on my back with my head in a cupboard……. getting a bit boring. Being in the boat mood, I will have to recover our dinghy from the farmer’s field and check it out – maybe use it once more and then sell it – I’ll have to fix the outboard first. Bit of 3D printing – clips and bits for the boat – I’m also making mug holders to fix somewhere on deck – in Scotland in particular, hot tea and hot soup are essentials for the helmsman, so they need somewhere to put a mug down that won’t slide off when the boat heels – I think if I 3D print one with walls with air spaces it will help to keep drinks hot – little creature comforts are important !

3rd July – months tick by – perhaps we’ll have a bit of proper summer, its been a bit miserable for using the perfectly functioning but cold swimming pool. We’ve given up shooting over the peas, the pigeons have migrated to the wheat and our farmer doesn’t have any so that game is over – I’m still sitting on 200 No 6 catrtridges. I’ve been busy on bits for the boat that friends kindly let me work on – I had to remake one of the blocks (pulleys) that fit on the deck to take the sheets (ropes) from the jib (foresail). It was a bit of a puzzle as to how to take it apart, although a post on a website helped, so I made a short video of how to do it. I’ll put it as a post on this website so a google search will find it – its also on You Tube @ https://youtu.be/rTFfx7-J-7w. A regular client is sending me another flintlock pistol to work on the lock – it looks a little unusual from the photo, and has a couple of faults – the sear spring is broken, and then fired from full cock it gets caught in half cock. I quite like fiddling with lock mechanisms, so that should be a bit of fun and will provide some proper gun stuff for this blog – at the moment I’m not working on my own guns, and not shooting the muzzle loaders, so not much to report.

27th June – I can tell you confidently that the wood pigeon has become almost extinct overnight in our part of the world, and not because of our success in culling them! On the previous occasions when I’ve been out I get through 40 or 50 cartridges in 3 or 4 hours and see hundreds of birds over the pea fields, even if not very many of them come our way. Tonight I managed 4 shots in two hours, and that only by taking anything vaguely possible – The two of us managed one pigeon each! Not sure why – I think maybe the pea leaves near the ground, which is what the pigeons are after, are getting a bit dry and yellow, also it was overcast and the wind was quite variable – we didn’t even see many in the distance. Maybe we left too early, but one feels a bit of a fool standing idly in a field all evening. We’ve been trying to work out what the pea crop will be used for – the peas are clearly not for the table although about ‘eating’ size now, – the farmer says they wont be harvested for another month by which time the foliage will all have died back and the pods dried out, maybe a fodder crop.

26th June – Sorry about the void in blogging – last week was hectic – Dave and I did a class on Earthquakes at school that required a lot of preparation, and we also did STEM club. On Wednesday I had another Covid jab and went down to see a friend’s boat (Moody 37) that we may be able to sail in Scotland next year – by happy chance it is similar to the type I was looking to buy a month or so back, so I am glad I didn’t! I will help with working on the boat a bit to get it ready to sail up there, and probably help sail it there. By the time evening came I was reacting to the jab with flu like symptoms that laid me out for a day. As part of our STEM club I’d 3D printed a set of parts for the children to make SAFE boxes, but stupidly left the safes in the back of my car in full sun on Tuesday, forgetting that the PLA platic I used is not very heat resistant – anyway nett result was 2 sets were warped out of all possible recovery, so had to remake them – 10 hours printing each plus a few hours assembly – all done now but I feel stupid! I haven’t done any more gun stuff as its really too nice to be indoors – the swimming pool turned out not to be leaking noticeably if I shut off the pump, so we are now swimming – its quite chilly in there still, but pleasant. I went pigeon shooting again on Monday using my multichoke Berretta 687 and got on with it Ok – I think at the end of 4 hours I was getting my eye well in when the pigeons tailed off! I’m going again tomorrow so we’ll see how my eye is! This gun has a hard butt plate, and I only had a thin shirt on, and used around 40 29 gm 1450 fps Superfast Pigeon cartridges so I’m thinking that I might slip a sponge butt cap on ! I could get away with a little longer stock as the comb is a tiny bit high and it would slightly depress the barrel end – we’ll see – I also have to remember to take my specs with a bit of sellotape over the top of the left lense to stop it mastering – if I’m not careful I end up rifleing if my eyes get confused and that is not good – I need to keep both eyes working, just enough haze in the left to let the right eye dominate – its amazing how the brain and eyes work it out.

17th June My optimism concerning the swimming pool and leaks was not justified! It is leaking at a rate of around 500 litres/day. I spent a couple of hours today injecting red dye near any possible leaks to see if it would be drawn in to the leak – the loss amounts to around 1 litre a minute, which should give a just about discernable flow rate close to the leak. So far no success. I decleared an end to the browning of the harding pistol, and put it together – it is now officially finished, at least until such time as I feel energetic enough to remake the frizzen spring with a roller. I spent a happy few hours yesterday late afternoon standing in a pea field shooting pigeons on a flight path with my o/u 12 bore and an odd assortment of cartidges – some heavy loads for high game, so I never knew what recoil I’d get – I am lucky in that I’m not particularly conscious of recoil, and can happily shoot full loads with only a light top. I was shooting with Pete, who has now had around 170 pigeons off that field – there are hundreds of them feasting on the peas – unfortunately some of the ones we shot fell amongst the peas, and its not really possible to get them without doing more damage to the crop than the pigeons do, so they are left for the foxes, red kits and buzzards. Here are a few pics of the Harding;

Complete with working home knapped flint!

Complete with working home knapped flint!

14th June – We are having a few hot days, so will be trying the swimming pool – miraculously it doesn’t appear to be leaking, or only very slightly – not bad for a 14 year old plastic bag! I’ve been in and out of school this week as the year 6 are having their leavers trips etc – a group of 8 are doing a MasterChef week cooking a starter, a main meal, a dessert and then some canopes and I’ve been the main judge – quite a responsibility. but the children have done pretty well – Their main courses were all well cooked and appetising – I helped one pair with their main – they had a sirloin steak and wanted it medium rare so I had to tell them to half the cooking time given in the recipe – I dread to think what would happen to a fairly thin (1/2 in) steak if you cooked it 4 minutes each side – not so nice! Anyway I offered to make some prizes on the 3D printer – which I am doing at the moment. Starting in black and changing to flourescent raspberry for the lettering is quite pretty, so thats what I’ll do.

12th June – the pump on the swimming pool filter was seized when I came to test it, so a couple of hours spent stripping it and freeing the rotor – not sure what was stopping it rotating, probably rust between rotor and stator – anyway now seems Ok. ( Thinks – thanks to WD40!) – I guess being in the garden all year round for 14 years is bound to take its toll – I’m amazed that any of it works – last year I had to patch a rubber hose joint – using self amalgamating tape and hose clips as the rubber had more or less perished and I couldnt find a replacement. I wonder if in future I might be able to print a flexible pipe on the 3D printer? I decided to use the frizzen spring without a roller, as I want to put the job to bed for the time being. Bit of a problem tempering the frizzen spring as I’d just let the AGA out as it was pretty hot in the kitchen and its summer! I just about managed a dark straw temper… I knapped a small piece of flint that fitted the cock and put the pistol together – minus the barrel that was in the cellar being browned. To my great surprise the flint produced a healthy shower of sparks – twice…. so my wobbly flints do work, at least twice! I do need to replace the copper washer behind the cock as it shows – I’ll have to turn off a thin steel washer on the lathe and file a square hole in it.

11 June – Started to fill the giant plastic bag that is our summer swimming pool. Tom (son) came over to help struggle with the bag, which is a massive and heavy object about 30 ft long – I’m dealing with 3 Toms at the moment – all about the same age, and am reminded that in his year at school about 1 in 8 boys was called Tom! A bit more work on the frizzen spring for the Harding. I’ve got the fixing done and made a new screw (No4 UNF) to hold it in place and filed up the peg to go through the lockplate.. I now have a dilemma – I was planning to make a simple spring that just bears on the heel of the frizzen without a roller, which is the easy way, but when I went through my collection of small pistols I found they all have rollers on the frizzen spring. That means that a) the end of the frizzen spring with the roller must be in exactly the right place, and b) that I have to do a bit of blob welding technology to thicken the spring enough to get the roller pivot through it, which will be tricky with my crude welder and welding. If that doesn’t work I’ll have to start over with a new blank and leave the end thicker…. bother! Annoying because if I’d thought of it in the beginning I could have left a thick bit to finish off.

I always leave a ‘handle’ on any small part I’m making until the last minute as it makes holding much easier.

I always leave a ‘handle’ on any small part I’m making until the last minute as it makes holding much easier.

10th June – Summer rushes by! Wasted a morning trying to get my 3D printer to pause in mid print so I could change the colour of the filament, only to discover that there is a bug in the software and it doesn’t do what its supposed to. Oh well, think of something else! I filed the square in the cock for the Harding pistol – the cock is quite slim and the square on the tumbler is longer than the thickness of the cock, so I have fitted a washer behind the cock to take up the extra space. the only thin metal I had was copper sheet, so I used that. The safety catch is one of those that works on the ace of the lock and slides into a notch on the back of the cock, so that has been cut. All works fine now – I am now in the middle of filing up the blank for the frizzen spring – I found a bit of 4.5mm thick spring steel, that’s thick enough to make the boss on the spring, so I milled down the rest of the thickness to around 2mm and am filing it into shape – looking OK. I’ve done quite a lot of work on the wood of the pistol – there were a few pits and a couple of visible cracks so I have put a coat of shellac over the whole pistol, and then put a build-up of layers of shellac over dips and the crack and sanded them off each time – it takes a while for the shellac to harden so its not a fast process, but it is giving a good result and the defects are slowly disappearing. The barrel is starting to brown. I’ve just finished getting a decent brown on the barrels of the Nock pair and just need to put a final finish on the wood and they will be ready to return to their owner.

The horrible cracks at the back top of the lock have now been replaced by an inserted repair – quite pretty now, just got to brown the barrel….

The horrible cracks at the back top of the lock have now been replaced by an inserted repair – quite pretty now, just got to brown the barrel….

7th June Made the harding top jaw and top jaw screw today – about 3 to 4 hours work, but looking OK. I might have to thin down the top jaw as the cock I have looks very light, and my top jaw may look a bit top heavy. I was messing about for an hour or two trying my hand at flint knapping having watched a couple of videos. I sort of got the hang of it and at one point I did maage to knock off a series of flakes that almost looked like proto gun flints! I took the flakes that looked most likely and trimmed them into rectangles, and got a whole pile of ‘almost’ gun flints. I guess if I was marooned in a flint rich part of the country with a flintlock and a supply of powder and shot I would be able to make flints that would last a shot or two.

6th June Cracking on with the Harding overcoat pistol – I got the last wood repair finished off – not too bad! I’ve started to refinish the stock – a coat of red oil followed by a coat of sanding sealer or two, then polish with 0000 steel wool and more red oil. Along the way a few strokes with a walnut coloured wood touch up pen to blend things in a bit – hides a multitude of sins! I hsve managed to get it a fairly light colour, as I didn’t want another dark old pistol! Did a bit of filing on the replacement cock – it was a Blackley casting that had had the tip of the spur re-welded, difficult to reshape as its mostly a concave surface, but I think it will do – I need to make a top jaw and top jaw screw, and fit the square, then make the frizzen spring……… meanwhile the front hedge cries out to be cut!

5th June Splendid party making Elderflower wine (indoors as it was a bit damp – fortunately not the heavy rain that had been forecast earlier) It was so nice to meet up with old friends we hadn’t seen for over 2 years – one begins to feel like a member of the human race again. I’ve done a bit of work on the overcoat pistol – I’m sorting out the woodwork – very carefully sanding it off without rounding off the corners or changing the shape – quite a challenge – the repair I made first is bugging me a bit, so I may just cut it off and do it again – not sure at the moment. There were a series ofgaps and cracks around the top backof the lock that were not going to be easy to hide – in places the wood was below the proper level. In circumastances like that its always best to take out a big chunk of the bad area, and replace it with a single piece and reshape that. I have a fine Japanese saw with a kerf of about 0.3mm that I can cut into the stock with and leaves a very clean edge, so two cuts and chisel out the bad stuff – its always best to make the cut out bit in the form of a wedge so you can push the new bit in tight – now I’ve mislaid the proper wood glue, and I am a bit put off instant glue just at the moment! Having cleaned off the surface of the rest of the pistol with 400 grit I was left with a number of black stains, mostly along the edge of the steel furniture, particularly the trigger finial. As its basically an iron stain you can mostly get rid of it with a solution of Oxalic acid in water – a few grains and a thimble full of water will do. There are a couple of small stains left, but most have gone. The chequering was a bit dirty so I scrubbed it with a toothbrush and Nitromors paint stripper which did a reasonable job, but some bits werefilled up and I had to go over the chequering with one of my home-made chequering points – now looking OK – its in pretty good condition. So just the block to glue in now, then apply a finish, (but what?) and re-brown the barrel and fit a new cock and frizzen spring…. It’s getting near the time of year when our big plastic bag has to be errected and filled with 30 tonnes of water to become a swimming pool, so thas a job for next week…………………….

It will need major surgery to remove the damaged area!

It will need major surgery to remove the damaged area!

4th June – A session of lawn mowing called! We are into peak grass – not enough to support a sheep, but the idea is nice – I did once borrow a goat – that was when I discovered that goats don’t eat grass, they eat anything that grows above the grass – including garden flowers, hedges and anyhing else in between. It took a year for the garden to recover from a day’s goat! I decided to ‘strike off’ or file down the barrel of the overcoat pistol, which I more or less have don

3rd June Anotther gorgeous day – We are going to an outdoor party on Sunday and its forecast to rain heavily, the only day in the next two weeks that won’t be fine! Such is life. Well, I did put the Rigby to bed with a nice foresight. As I was packing it I realised that the trigge guard tang wasn’t fitting very well, so that had to be sorted, but its all paid for and ready to post on Monday. In the background for the last however many days Ive been browning the pair of Nock barrels – still not got where I want to be, but coming along. I started on the little overcoat pistol – there isn’t any major woodwork damage, but I’ve never seen a stock with as many small cracks and splits – most won’t move but are very slightly open, some can be closed up – anyway Ive been going round with superglue trying to stabilise it, then there are a couple of places that will need a small new piece of wood let in. I steamed it to get some of the dings out, which has raised the grain – its a sort of dirty brown colour – I’ll have to see if I can clean it up a bit. Also the chequering is filled up with something quite hard in a couple of patches, so I’ll have to work on that. The lock is not too bad but needs a new cock – I have one that will fit, more or less – and a new frizzen spring, which will be a fancy bit of construction – either filed from solid or a bit of weld-blob technology, we shall see. I think the barrel might look good if it was struck up fairly thoroughly – I don’t usually like to do it, but I’ll see when I’ve done the stock what the overall aim needs to be. I’ll start the post on LOcks and Detents while I have the photos to hand.

1st June – Missed a day and didn’t put up the photos I was going to as my access to the website went funny and I couldn’t edit or save any changes and so couldn’t do anything. I came back to it this evening and it wouldn’t even let me look at the website! I tried another website and that got the same impenetrable message. I remembered I’d installed a new VPN and ‘threat protection’ a few days ago, so I deleted them all and I think its now back to normal – I hope! I finished the Rigby today, or at least I thought I had until sitting on the sofa playing with it I realised I hadn’t put a foresight on it. I spent a good few hours fixing the half cock bent- I’ll put a separate post on Locks and Detents and describe it in detail, but in summary I stuck a couple of tiny blobs of weld on the broken ‘top’ to the half cock notch – a really tricky job as I didn’t want to weld up the whole half cock notch and start again, then filed it to shape – it has to be just the right shape as I’ll outline in the post for the detent to work. The detent consists of a small ‘flag’, the ‘fly’ that pivots through about 10 degrees in a recess on the tumbler and stops the sear from falling into the half cock notch when the gun is fired, but allows it to enter when you want half cock – on a ‘normal’ gun or pistol you pull the trigger hard enough to keep the sear out of the way when you fire the gun, but that doesn’t happpen with guns or pistols set up for very light trigger pressure, or those fitted with a ‘hair trigger’ so you need the ‘fly’ to guide it safely past the half cock bent. Getting the tumbler, sear and fly to work together is about the trickiest job in setting up a lock if you have remade any of the parts. Anyway that is done and works well, I’m really pleased to say! I made a new barrel bolt escutcheon out of copper sheet and silver plated it (quite thinly using my little brush plating kit, and also fitted a finishing escutcheon or ramrod pipe, also out of copper, silver plated – its a very small object and I couldn’t think of another simple way of doing it. The barrel bolt was another job – in the past I have had a job cutting a neat slot in the middle for the pin that stops it being lost – I cracked it this time by marking a line of holes by sliding my centre punch along a straight edge as I tapped the marks – they came out perfectly in a straight line, and my Dremel with a cut-off disk joined them, then a small flat needle fire finished the job. For the ‘knob’ on the end I used ‘blob technology’ with the welder again and filed it up, then heated it to red heat and sprinkeld on Blackleys case hardening powder and quenched it, then wire brushed it and popped it on the AGA for 10 minutes at about 280 C (I didn’t bother to check the tempreature, but its usually about 280 at that place on the second plate.)

I wAs thinking about why I do some of these jobs – some are obvious – nice things in reasonable nick with a single fault that needs fixing where you can charge a reasonable rate for the job and it is still viable. Others, like this Rigby I do because I don’t like to see a salvagable pistol get discarded – I can’t make a silk purse out of a sow’s ear (although I’m working on it!) but I can make something that is worth hanging on to and will give pleasure to someone. Even if, as in this case, I take shortcuts and don’t do as thorough job as I could, I end up taking many more hours than I can reasonably expect a client to pay for so I revert to thinking about it as a hobby that earns enough to pay for the tools and materials. If I were to do a thorough job on the Rigby from start to finish it would probably run to well over £1500, which is well above what the pistol could ever be worth, and its still only a poor conversion of a nice pistol.

30th May 2022 I’ve had to restart my diary here as I couldn’t get the old one to work – I couldn’t put any more on the blog as it wouldnt let me publish it so I’m guessing that its full. Now I just have to find out how I make it appear first on the ‘front page’. Well sort of – bit of a mystery so for the time being this will just sit in front of the other one and I’ll hope I can at least save and publish on this post – who knows!

Probably divine intervention becasuse I missed a few days of the diary! Actually I had a bit of a problem with the infection I got – my GP surgery didn’t listen when I explained which antibiotics worked, and so gave me the ‘wrong’ one, by the time I’d collected the prescription and saw it was wrong, then managed to see a GP in person and get the right meds, the infection had got out of control and I ended up in A&E with intravenous antibiotics for a couple of days – no lasting harm done, I hope, but not best pleased with the Surgery for not listening to what I said. So back in full swing, and I hope no more sofa days or half days. Trying to finish off the Rigby – its more or less done, now put together and looking pretty good compared to what I started with – shame about all the old irreversible repairs or it would be reall good. I’d welded up the mouth of the cock fairly generously so it took a while to file it to shape and mill the cavity. The first replacement nipple I put in was too short for the hammer, but I found an old one that was about right, and it will now ‘cap off’ in a satisfactory way. I’ve put the re-etched barrel back – there is currently no barrel bolt so I made a quick and dirty ramrod out of dowel to hold the barrel in place – works fine. So there are a few more jobs I could do if the client wishes – there is no ramrod pipe, barrel bolt, one barrel bolt escutcheon and the half cock bent needs welding and filing as its broken out and won’t catch. All in all its an improvement of several orders of magnitude

26th Sorry about the missed post yesterday – I have a nasty infection and a mostly sofa bound. I did manage a bit of gun work in the mornings. The Rigby is coming on. I more or less finished the woodwork, and etched the barrel in ferric chloride which seems to be what the damascus knife makers use, then gave it a soak in hot logwood to blacken it. Now bad! I welded up the mouth of the cock – just have to file it into shape. There are still some issues with it -; no barrel bolt, no foresight ,no ramrod pipe, no ramrod , and the half cock bent is damaged so it won’t hold half cock. I’ve already spent a lot of time on it so I’ll have to see what the client wants.

24th May Mix of heavy rain and weak sunshine. I’m spending more time on the Rigby than its really worth, but its a challenge and I think it will look good when its done. I had done the basic wood repairs, just needing finishing, but I didn’t like the look of the top of the projecting saw handle bit – it had a large hole, off centre and filled with plastic wood (remember the stuff?) and just detracted from the look of the pistol as it was the first and most obvious bit you see – I toyed with the idea of renmoving the plastic wood and putting in a wooden plug , but there was also a smaller hole with a plug, so I decided to bite the bullet and cut a slice off the top of the projecting bit and glue on a piece of walnut with a more or less matching and interesting grain. I’ve oscillated on this job between using instant glue and proper wood glue. Instant glue is obviously fairly fast, so if you keep a can of activator handy you don’t need elaborate clamps to hold things, but on the other hand if you need to position and clamp the repair, wood glue gives you time to get things right. Mostly my instant glue gives me a few seconds to position the pieces, but one bit I stuck on today set instantly before I had even a couple of seconds to move it – luckily it was just OK. I had a look at refreshing the engraving on the Rigby barrel – its one of their pistols that have the name in Olde English Lettering – I had never done any and I couldn’t quite make out from the worn letters how some were made up – anyway the web came to my rescue and google images produced a pepperpot revolver with the right engraving. I think if I put the barrel in for etching I had better protect the engraving somehow mmmmm- I’ll think about it….

Good self-amalgamating tape as a tension binder.

23rd/24th May Busy with gun jobs – stripped the Rigby and glued a couple of blocks of walnut into neatly reshaped cavities – one more piece to add when I’ve shaped those two. Someone had been messing about with the pistol fairly recently – there were cracks glued up with a very hard glue – unfortunately they didn’t close up the gaps before the glue set, so I’ve had to try to remove the glue. I’m hoping that it will all go together – I can’t reverse some of the repairs so it wont be perfect. The barrel needs re-etching – Rigby pistol barrels were almost always of etched fine damascus, this one could do with a little refreshing of the etching if I can find out what to use ?Copper Sulphate? Nitric Acid? I’ll have to do some research…………………. I’ve started to brown the two Nock barrels – lets hope it goes better than the last pair of pistols I browned, which took 14 rustings and were a bit stripy for my liking.