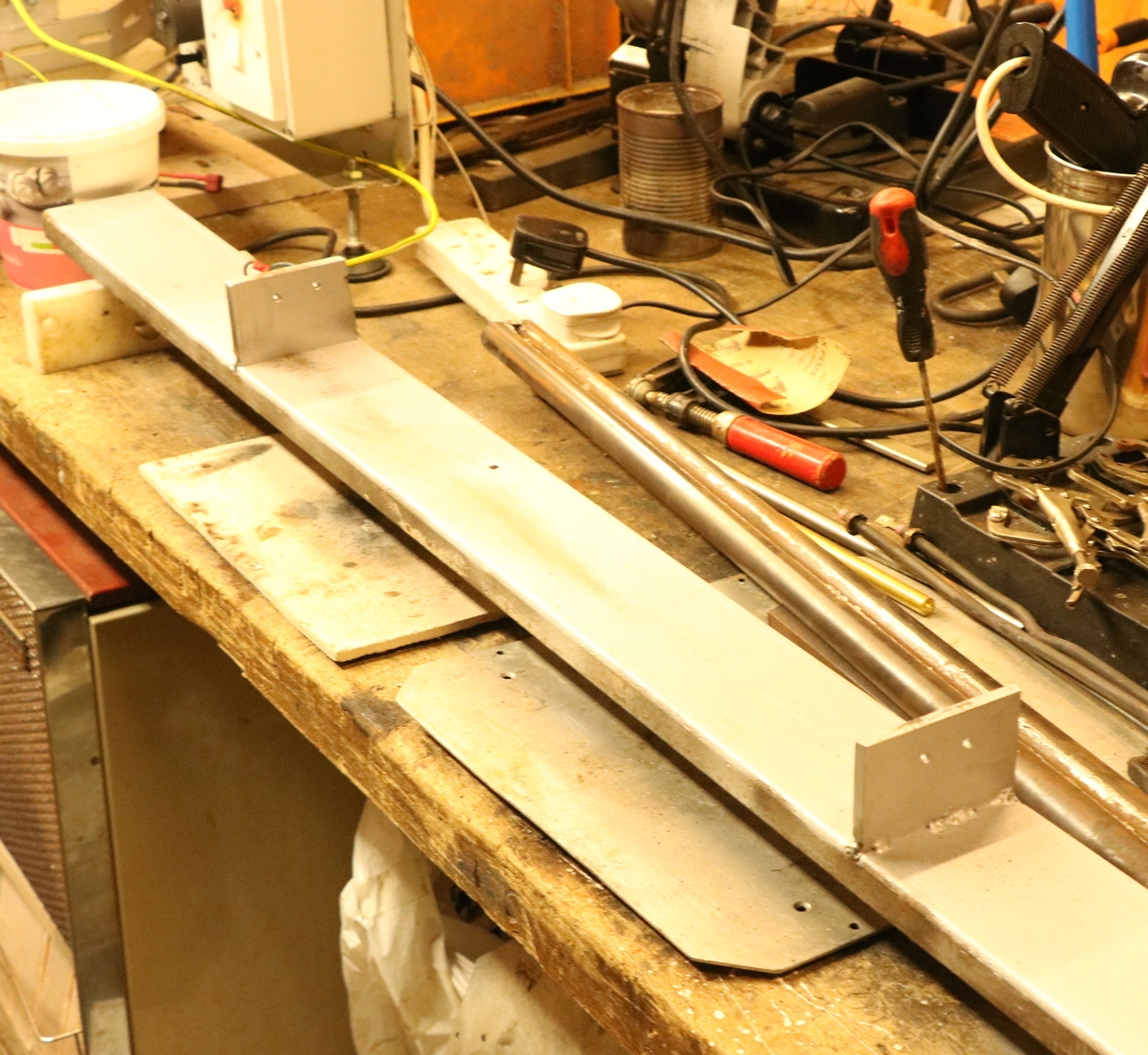

27th February – I made a few more nipples yesterday so I have a bit of a stock, although some are a bit on the slack side – It would probably be easier to get a decent fit if I put a bit more of a taper on the slide when I did the final cuts – I’ll try with 3 degrees instead of 2 next time. I had an ‘order’ for two to replace a couple in a gun I sold some time ago – the old one were ones I had made of steel, presumably to my normal ‘small hole at the bottom’ spec but had opened up to being more or less parallel all the way down – they had seen quite a lot of use, but I hope the titanium ones last indefinately. I also did a bit of touch-up engraving on a bashed about little brass pocket pistol – nothing special but the client wanted it refreshed where it had been filed off . Today I decided that I had to sort out how to make a decent job of resoldering the barrels of the Venables – I’ve made a number of half hearted attempts and I was reading an article in an old copy of Muzzle Blasts from about 1956 on resoldering barrels of a double rifle that gave me some ideas. Apart from actually getting all the bits to fit together it is vital that the barrels are parallel in the horizontal direction although in a vertical direction they are ‘regulated’ to converge so they both hit the same point at about 25 yards to allow for the tendency of the gun to move right when the right barrel fires and v.v. Obviously its more important with a double rifle and varies markedly with the load, but still necessary on a shotgun, The article mentioned having a steel plate to keep the barrels aligned, I had been using a 3 x 1 inch bar as a base but had just used packing pieces to support the barrel to clear the ramrod pipes etc which made life difficult as they kept coming out just when you needed them in place. So I welded two plates to the bar to form a level base for the muzzle and the breech a couple of inches above the bar so that I can get to the underside of the barrel if necessry. The plates have holes so I can wire the barrels down firmly to ensure alignment. I checked that the tops of the plates are exactly parallel. I have the electrical heater to fit inside the barrel, with a manual temperature control and Dick is coming over on Friday and I am absolutely determined that we are going to crack it this time – its quite stupid not to be able to do the job reliably – hence the new jig. Its not in my nature not to be able to do something, after all there are hundreds of thousands of guns out there with their barrels soldered together…. I will get there in the end. Tomorrow is the funeral of David Purr, a well loved village character who fabricated most of the steelwork needed in the village – his speciality was security gates and he made a couple of beacon baskets for the village – his legacy will live on for years – I shall miss Dave, he was a great help with lots of my over ambitious projects like my home made 4 wheel boat trailer.

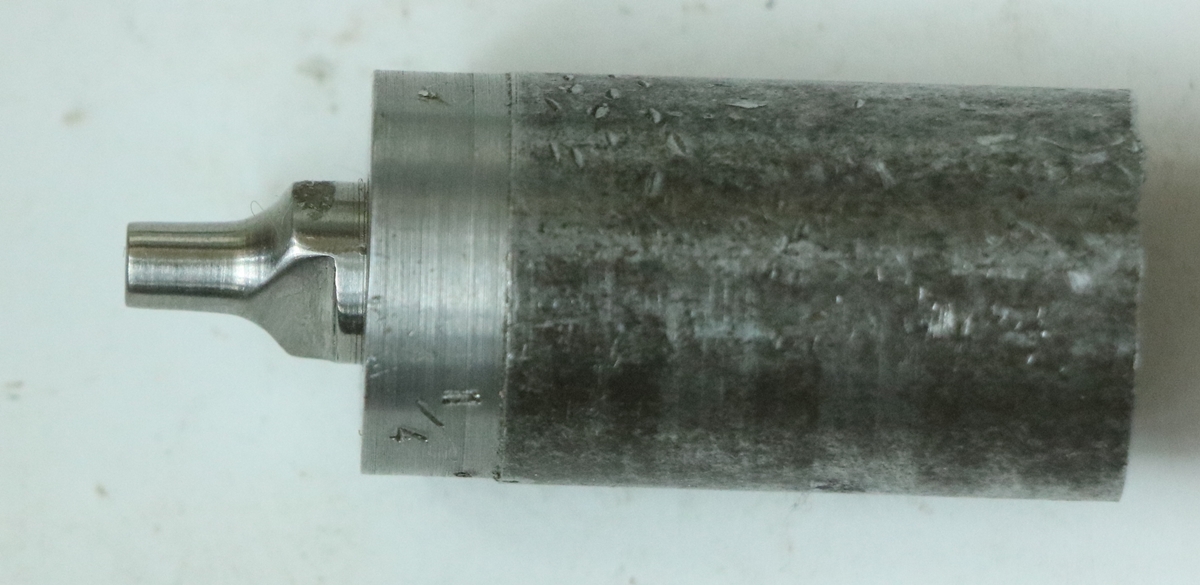

24th February The unseasonably good weather had me out battling with the garden this weekend – I eventually got fed up with piles of sticks and bits of apple trees lying about from when I had to cut back trees for the neighbour to get at his roof so I splashed out on a cheap Mac Allister shredder from Screwfix (about £80) which turns out to be fantastic – it just eats anything less than 40mm diameter – almost literally gulping it down – and fills bins with chips that can go in the waste bin that is collected fortnightly. I did manage to sneak an hour or two to make some titanium nipples – I do like working in titanium, but you do have to be careful to keep cutting or the surface hardens up and polishes so its difficult to get started again – I use sharp tool steel tools with some top rake. The technique is to chuck the 10mm bar (Titanium T6 from ebay) and turn down 25mm to 8.50 mm then turn down 5.5 mm to 6.40 diameter, slightly chamfer the end and cenre drill a pip and drill a 1.2mm hole about 4 mm deep, then cut a 1/4 BSF (26 t.p.i) thread with the die adjusted to cut to the finished size in one pass as trying to recut only swages it. I turn the die over – the other side is ground off so the thread runs to the surface – and cut up to the shoulder, then slightly undercut the shoulder with a parting tool before parting off an >11.5 mm length of the 8.5mm section with the 5.5mm long 1/4 BSF thread on it. I then chuck a piece of 25 mm bar with a 1/4 BSF tapped hole in the end and screw the proto nipple into the bar tightly – I use the tailstock chuck to grip it and tighten it. This is then faced off to exactly 11 mm from the face of the bar and drilled 2.2 mm to a depth of about 13.5 to 14 mm, followed by the 1.2 mm drill to make sure it goes right through, leaving around 2.5 to 3 mm of the 1.2 mm hole at the end of the 2.2 mm hole. I then use a radiussed tool to turn the nipple leaving about 4.5 mm of the 8.5mm diameter part intact. The cross slide is used with a 2 degree taper to get a good fit for the cap – its very easy to make it a loose fit, beware – you need some fresh caps by the lathe to check. One problem with Titanium is that it can be difficult to get very fine cuts as it burnishes, so try to get good control of the diameter as you converge on a good fit – its particularly difficult with the slide at an angle as the dials or DRO don’t give a lot of help. I generally put the flats on with a file, as its difficult to hold the nipple for them to be milled (most of my cutters are not really sharp enough for titanium!) I’ve been using titanium nipples on my Nock for some time and have probably put around 800 – 1000 shots through the gun without seeing any damage to the nipples. Cutting the thread is quite hard work and even backing the die off is almost as hard as cutting – I find it is almost impossible to make a second cut with the die as it is very stiff and removes no metal – it maybe that my dies are a bit blunt, but they work OK first time…… I always put the nipples in with a few turns of PTFE pipe tape as a gas seal but the titanium doesn’t seem to be affected anyway.

WARNING – Titanium swarf is highly inflamable and cannot easily be extinguished – you need either a special extinguisher or sand to smother it. It takes a spark or serious heat to set it alight but then it is pretty much unstoppable, so don’t let swarf build up on the lathe – STOP the lathe before attempting to remove it – it can be sharp. Use a water based coolant if you need to cool the work, but better still use very sharp tools and fine cuts and DON’T LET SWARF BUILD UP. ( I’ve seen the fire brigade called to a lathe fire with titanium – it was some years ago and WE had to tell them not to use water)

Nipple is screwed into bar to turn shape and file flats.

22nd February – getting ready to take my Flintlock John Manton and my Percussion S. Nock to the Have a Go shoot I realised that I had overdone the re-work of the bent on the left barrel and it was going to be uncomfortably hard to pull off, so not good for beginners. I manged to strip and re-work tumbler and sear and get it all back together in about 15 minutes and it now works fine. As I know its OK, I should take it all to pieces and harden the tumbler – I think it’s too soft. A couple of AML members ended up having a discussion about cleaning guns (makes a change from BXXXXt – as an aside, if you don’t think the EU is capable of making our laws, do you think that either hopeless mob in Westminster are really going to do any better? ) which is always guaranteed to bring out different techniques. A number of my friends favour using a steam cleaner for the barrels, so I made up a probe from a bit of 7mm steel tube and attached it to my wallpater steamer. I cleaned my gun ‘normally’, which some peple would call a bit ‘casual’, and then applied the steam cleaner, expecting a stream of dirty gunge to emerge as promised by the steam fanatics. Alas, I ended up with a couple of cupfuls of water so clean that I could have made tea with it (I didn’t) and nothing came out of the barrel when I wiped it out that wouldn’t have come out anyway. The essential part of barrel cleaning is allowing very hot water to flush out the muck – the stuff that will cause corrosion is basically all water soluble salts, and it is a basic truth of physical chemistry that things dissolve better in hot than cold water (except proteins) – once they are gone its mostly lead, which probably acts as a lubricant! I do have a few barrels that come out really clean as they have been honed, but most continue to wipe out a bit black, and I don’t worry too much about it.

21st – One of the pleasures of running this blog is the emails I get from the many regular viewers with questions about their guns or repairs they need doing, or their interests in guns – although some of them do stop me in my tracks! Some time ago I got an email with an attached photo of a pretty derelict flintlock pistol – the accompanying text asked me how he could convert the gun into an automatic pistol with a magazine that worked! A bit disturbing to my equilibrium…. I have also had several emails from enthusiasts keen to make themselves shootable pistols by the back door – I’m happy to reply with an email explaining what excellent accomodation Her Majesty is able to offer – an offer they are unlikely to be able to refuse if they follow their intentions. I can speak with good inside information as I was for several years an independent prison monitor at Highpoint prison and got to know it well – in fairness to the prison you get three meals a day (budget for all three is £2.06) and heating, I do think some Old People’s Homes might be worse – units 6 & 7 for ‘good boys’ were quite acceptable. It is possible to make yourself a pistol provided that it can pass certain conditions as specified in the Home Office Guidance on Firearms (see LINKS) and be classed as an INERT pistol – in essence this means that it is a reproduction of a pistol of not later than 1870 that cannot fire and cannot be made to fire with ‘normal’ DIY tools and skills as might be used for the construction and maintanence of the home That always seems odd to me – I don’t see where a cement mixer comes into making a gun work! I can offer only limited advice as to what that restiction might mean – for instance it is better to remove metal than to add it, so a 10mm slot milled from under the barrel from breech to near the end of the wood (leaving the barrel loops) and a chunk of bar glued in the barrel to restore balance is pretty difficult to put right, but ultimately it is down to how the courts interpret it and there is NO certainty. Better to start with all main metal parts from old guns so what you end up with is clearly a section 58 firearm restored – and keep well away from anything breech loading!

21st Re pistol below – another little detail that you can just see that confirms the butt as being wrong is that the trigger guard tang goes way too far down the butt to be right.

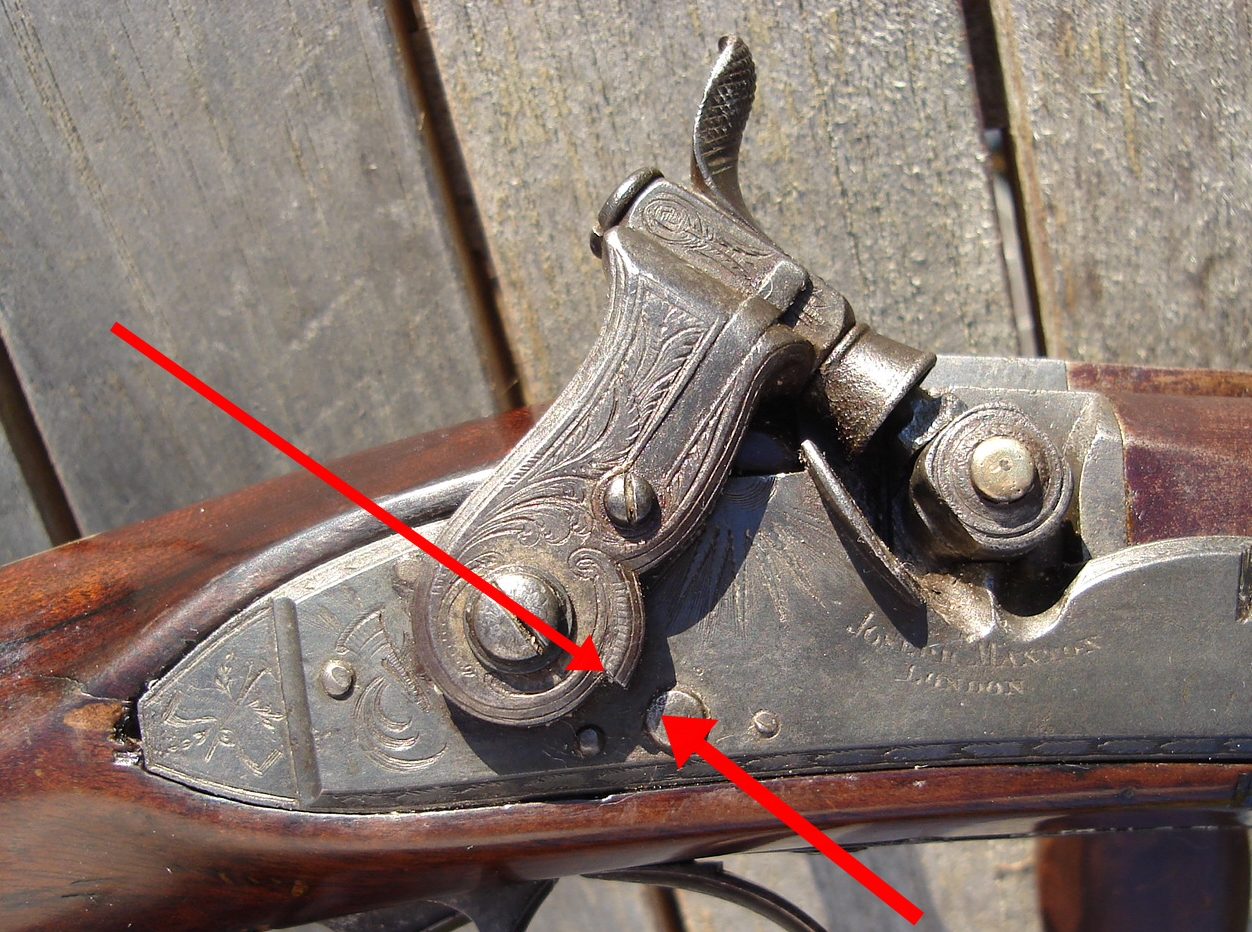

20th february – You are in luck – another set of gun photos for comment has arrived – a Twigg Pistol. Lets have a look at what we can surmise about this… (We will refer to ‘British Gunmakers 1740 to 1790 by Keith Neil and Backs. for inspiration – rich in Twiggs!). You may need to click on the images to get enough detail – back arrow to get back, logically enough!

Ok, what have we here? A ‘proper’ conversion from flint to percussion of a TWIGG flintlock pistol. The signature is his second one, dating the gun to 1770 to 1775 or thereabouts. The arrow points to a just visble set trigger adjuster – right for that time as is the safety (just?). The pointed tail of the lock is an earlyish feature too.

The engraving you can see is all from the date of conversion except the signature

Looking at the whole pistol, and bearing in mind the fairly certain date of 1770 to 1775 ish, the half stock is wrong – at that date it would have had a stock running to the muzzle and no under rib. Also the butt shape is probably wrong – it would have been curled right round to past the vertical, or with a cast cap – you can jsut makeout that the tang of teh trigger guard goes too far down teh butt. Barrel bolt in the wood – has moved on from pins, but not yet escutheons under the bolt. ends.

Barrel signature is again TWIGG mk II and contemporary with the 177X date, The rest from the date of conversion? But what has happened to the false breech tang? UGH.

Not sure who the barrel maker was, possibly Twigg

Notice the metal insert as a bearing for the breech tang .

nothing noteworth here except the single lock screw – a useful dating feature.

OK, what did you get from that? It all looks as if the lock, barrel, trigger and trigger guard started out as a TWIGG flintlock of reasonable quality, probably an officer’s pistol. The lock would have been plain and the breech would probably have had a plug with the tang on it rather than a breech and false breech with tang. The trigger and trigger guard look right and the set trigger is OK for the period, The engraving added on conversion is quite rudimentary as if the engraver was not used to working on steel – it just doesn’t ring true to me. The worst bit is the tang of the false breech, which looks as if it was executed by a child! The big question concerns the stock – it was definately not half stocked when TWIGG made it, so that was a feature of the conversion – but is it the original stock? The butt is the wrong shape for the flint date, and it looks a bit wrong for later pistols, but it looks ‘of a piece’ with the pistol in other respects. My guess is that it was restyled on conversion – obviously the chequering would then date from conversion or probably even later – it looks very sharp. Difficult to put a date on conversion but obviously it served at least 50 years as a flintlock – maybe an 1828 -1838 conversion date? What is particularly interesting about this pistol is that details were changing rapidly at about the original date of manufacture and by about 1780 things would look quite different – examples are that up to about 1775 locks were held on by two screws (this pistol has one) and by about 1775 Twigg had started to use the shell carving on better guns and pistols. In 1780 the barrel bolts started to have silver escutcheons and roller frizzons came in – so lots of changes and aids to dating or just more confusion? (Read the book mentioned above for more details or see the GUN DATES page on this blog!) I’m sure I’ll get some idea from observers of this blog, and I expect I’ve missed a few essential things – I haven’t spent much longer looking at it than it has taken me to completer the blog, and I obviously don’t have the pistol to hand, so please forgive any errors……

19th February – I had another look at the troublesome left lock on the Samuel Nock that keeps dropping to half cock when the right barrel is fired. I didn’t think there was much wrong with the bent in the tumbler and think that the problem is the old one of the sear arm touching the wood of the lock pocket – the sear arm does seem a bit close near the edge of the lock so I filed a little off the arm (it was a bit thick anyway) and carefully eased the lock pocket. I tried to check if that was effective, but with no-where handy to fire the gun it is difficult. To be on the safe side a slightly reshaped the bent so it has a little more engagement – I noticed that I’d just about got through the case hardening on the bent. I’ll check it out when I next go shooting, and if its OK I’ll re-harden it – I might have overdone the engagement. I am helping at an AML ‘have a go day’ at Cambridge Gun Club on Friday – probably a corporate ‘do’; but I’m not sure – I just turn up with a flintlock and a percussion and let the punters have a go – luckily under the auspices of the MLAGB so its insured. I managed to finish the sear spring of the little post office pistol – very fiddly as I’d run out of Oxygen for my very tiny torch and had to use a kitchen blowlamp for heating and bending! Still its done – its looks in the photo as if the spring sticks too far back, but it is the perspective and it does just fits the lock pocket – just as well as I have no intention of making another in a hurry! I have now got to adjust the mainspring and fit the safety catch. I ought to make the cover spring detent for the slider to finish the job off……….

The sear spring doesn’t really stick out like that – its perspective!

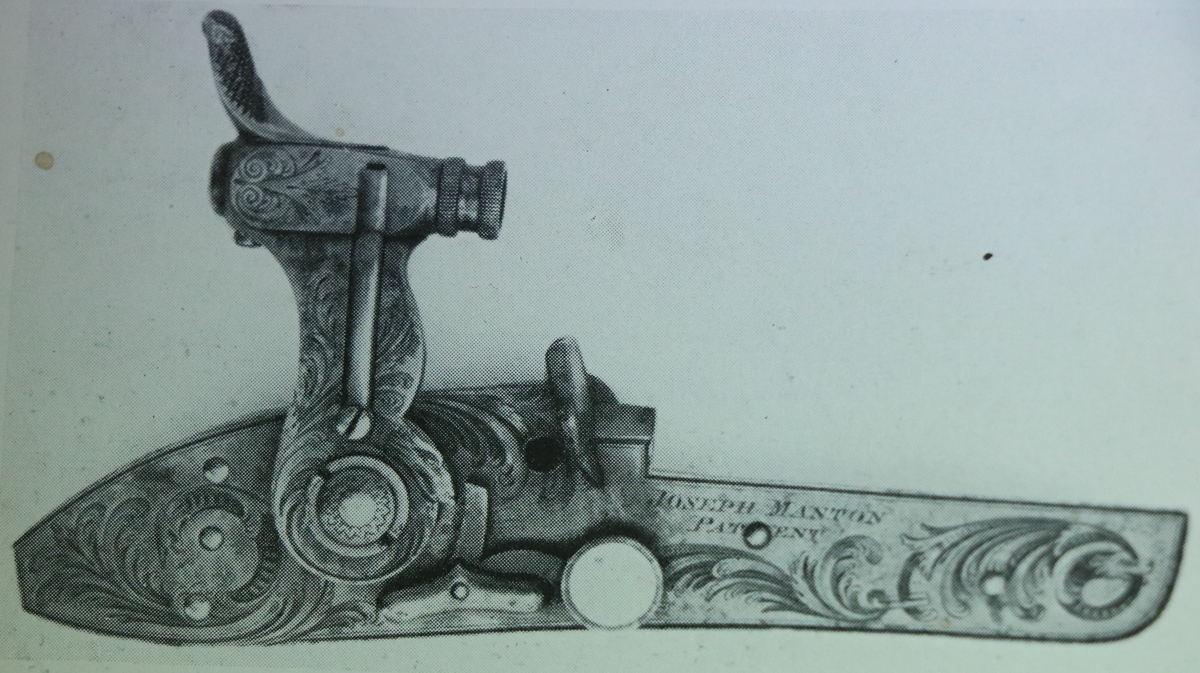

18th February – Today was the last day for exporters to ship goods to China to arrive before Bxxxxt, from today anyone shipping to the Far East for the next 40 days will have no idea of the rate of duty they will have to pay to land the goods! I had a further email related to the Joseph Manton guns I put on the blog recently, pointing out that the New Zealand gun 6031 had been made with gravitational stops (I missed them), which were on the same Joseph Manton Patent 3558 of 1812 as the water drains, also with an addition to the lock to sound a musical note when the trigger was pulled! (No know examples exist, not surprisingly!). Interestingly the replacement cocks used on conversion had notches for gravitaional stops, and so must be Joseph Manton cocks. I still think it unlikely that Joseph Manton did the conversion as it is too rudimentary for him , but whoever did it had access to Joseph Manton cocks – possibly off another conversion job? It raises the interesting question of whether these cocks were chosen to retain the gravitational stops ( which were not much liked by shooters as they were prone to stick and also prevented you from taking overhead shots) and the stops were removed at some later time, or it was just chance that the converter had a pair to hand that had the stop notch and just used them, while removing the stops at the same time. Or maybe I’m just wrong and it was a conversion by Jo Manton? The barrel incription ‘New Improvements by His Majesty’s PATENT’ should refer to the features of the 1812 patent so I had another look at 5692 – it has new later locks on conversion so is unlikely to carry signs of gravitational stops, but although it has been rebreeched I might expect to see a plugged slot in the trigger finial if it had the water drain, but the finial is intact, so I don’t think it originally had drains…….. Always more questions than answers in this game.

6031 showing stud filling gravity stop pivot, and notch in cock for stop.

An 1816 pellet lock converted to caplock – plate 108 in the Manton book – the light blob is the gravity stop counterweight.

I started to try to sort out who made what in the way of detonator/pellet/patch/tube/cap locks in the period from about 1809 through to about 1830 when caplocks were pretty established |(except for later tubelocks) but I don’t have any good source books – Winarts Early Percussion Firearms is mostly about American firearms and isn’t really clear about who was making what and when – I’ll need to keep at it a bit longer but if you know any good books let me know….

16th February – Shooting clays at Cambridge Gun Club today with the Anglian Muzzle Loaders. Bit of a revolutionary shoot – all simultaneous pairs. I got off to a bad start as my Sam Nock hadn’t been fully cured of its habit of dropping the Left cock when the right barrel fired – I did spend some time looking at it and reshaping the full cock bent as best I could without softening the tumbler but all I had suceeded in doing was to make the left cock slip into the half cock bent when the right barrel fired – at least that didn’t produce a nasty recoil and waste a load! Anyway I soon learned to shoot with the left barrel first, and only had a couple of shots where I forgot and pulled the wrong trigger. I like sim. pairs and given the gun problems that cost me a clay or two, I was not althogether unhappy to score 19/40. I’ll have to do the full cock bent properly, which really involves annealing the tumbler and reshaping it and re-hardening and tempering it. My inbox continues to get emails about Joseph Manton guns of the same era as Derek’s. I had a nice string of photos from New Zealand of a converted Joseph Manton double shotgun Serial No 6031 from 1813. This one has been converted by drum and nipple, keeping the original lockplate, which shows what the locks of 6592 and the gun that lock 7006 came from must have looked like with their earlier style of (simpler) engraving. As with the others, lots of ancillary details are right for the date, the barrel has the Joseph Manton New Improvements by His Majesty’s Patent wording, (1812-1816 ish) and it is interesting because it has the elevated rib on the barrels (more pronounced than in 5692) he patented. It doesn’t have gold or platina stamps on the barrel, but there isn’t room. It also has the rain water drains that collect any water from the barrels & frizzens and drain it down through the breech plug and out through the tigger finial – another patented feature – its nice to see those features, it was a ‘top of the range’ gun with all the latest bells and whistles ! The cock is interesting because I think it belongs to a pellet lock or patch lock – variations of percussion ignition that filled the gap between the Forsyth invention of 1807 and the general acceptance of the percussion cap in the mid 1820s. The spring on the outside of the cock was designed to enable the ‘plug’ of the cock to be removed and replaced with a new precharged plug without the need for any tools. Later similar cocks (eg that on 5692) were used for caplocks but generally lacked the spring as they were not intended to be changed often, just as a replaceable hammer. The conversion wouldn’t have been done by Manton as he always made new locks and re-breeched barrels, but probably by a provincial gunmaker. Maybe the cocks were a pair he had lying around, so he just replaced the plug with one designed for caps?

No 6031 – Cock fitted on conversion was originally pellet/patch cock?

Notice the very small front trigger – rather extreme for that date but probably a choice by the buyer – maybe a crude modification – difficult to judge from the photo? Compare with 5692 below.

You can see the Patent water drain above the drum & nipple, and you can just see it emerging from the trigger guard finial in the photo below.

.

No proof marks (not uncommon) but WF barrel maker’s mark, possibly William Fullerd.

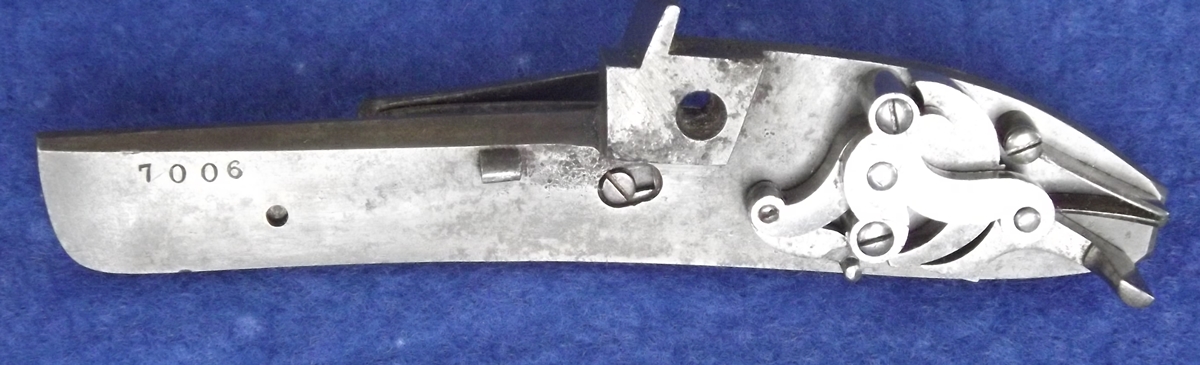

14th February – In London yesterday so didn’t do much useful stuff and this morning I had to finish off my patent review, but I did manage to weld up a new side screw for a pistol – the old one had lost part of its head, but outside the slot. anyway a new head was made and engraved and butt welded onto the old screw so that I could use the (odd) thread. I had an email about the Manton I had put up onSaturday. Turns out that he has a right hand Joeseph Manton lock – without a gun – that is very similar except that it has a different bridle and a very long sear nose. His has serial No 7006 and the Manton Supplement book lists a separate Left hand lock with the same serial number. The one I put in the blog has a date 1812 of original manufacture (as a flintlock), and this one the serial number belongs to 1816. Its not quite clear if it was a pellet lock originally (it is just about possible in terms of timing & Keith Neil lists the L.H. lock as possibly pellet lock), although I suspect that it is like mine, this lock was made as a conversion from flint. Anyway very interestingly it has an identical sliding safety in front of the cock which I think belongs closer to 1660 than to 1816. I might speculate that this lock was one of a pair with the one in the book that were made by Joe Manton to convert a flintlock Joe Manton No 7006 to caplock within about 6 – 10 years of its original manufacture and as sometimes happened the old lock and breech etc were retained and its been converted back and the caplock locks discarded. Any ideas welcome – join in the fun of speculating! The secret is not to believe too firmly in your guesses!

Here is the Joe Manton 5692 I showed on Sunday.

No 7006 – I think it was made as a caplock because it has ‘Patent’ on the lockplate which is taken as indicative , as does the one above.

Look at the extremely long nose on the tumbler- it looks from the geometry if the cock needs to come back a long way to engage the full cock bent?

I am a bit thrown by the safety slider, which I have only seen on rifles from around 1850 – 1860. It is, nevertheless, strange that two very similar locks should turn up with that safety

11th February – Went indoor climbing in Cambridge this afternoon, so am too tired to attend to the blog – sorry!

10 february – A nice gun for you today! Derek brought a gun that belongs to a friend of his for me to cast my eye over, so with his consent, I will put a few photos on the web and we can enjoy a little specualtion about the gun together!

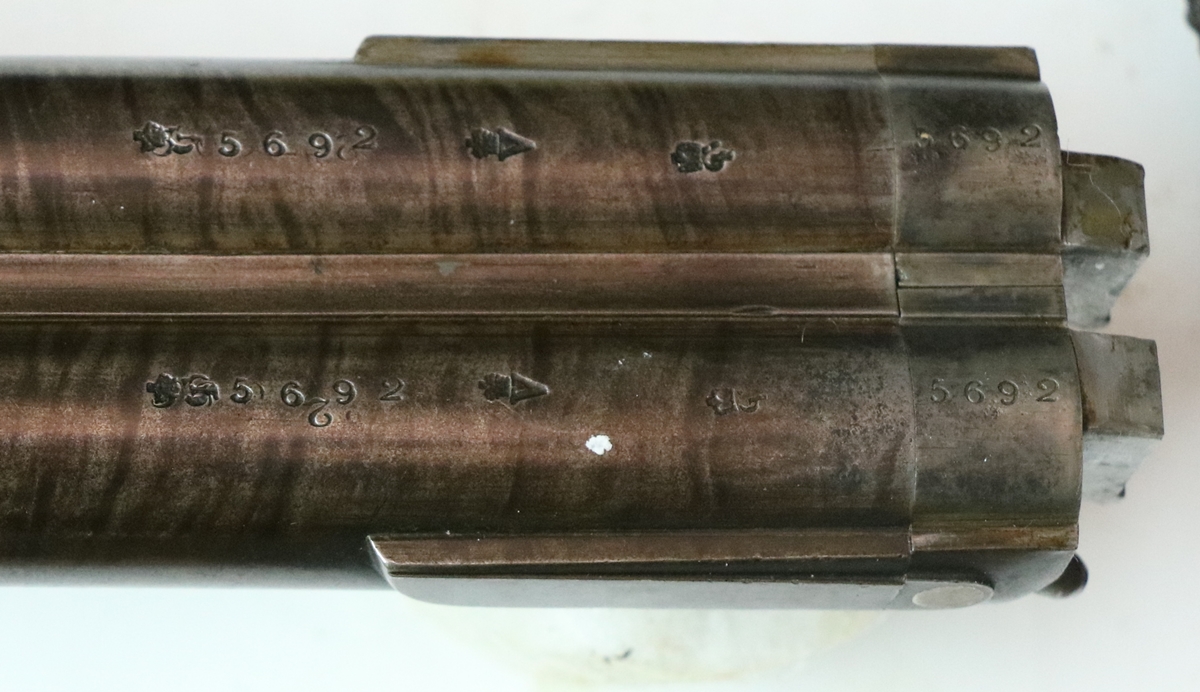

It’s a high quality percussion gun signed Joseph Manton on locks and barrel and with the serial number 5692 on the underside of the barrels, the breech block, the inside of both locks and the tang of the trigger guard. By the Manton book that serial number belongs to 1812 ( this gun is not in the book), still in the flintlock era although coming up to the tubelock and pellet lock transition period before the caplock, which this is by the usage in the Manton book. Its about 22 bore double with 30 inch barrels but without the elevator rib that Jo Manton patented before this date (? or a small one?). So it looks as if it is a conversion involving new locks and new breeching, or that it has been renumbered or is from a period later when his numbering MAY have gone haywire. There are a lot of interesting clues in the gun if you can bear to go through them;-

1) It has the cocks with removable hammers – a follow-on from pellet locks and used around 1828.

2) What are those sefety catches in front of the cocks doing on a shotgun? (they engage in a slot cut in the back of the cock when its at half cock – I think they are a later feature.)

3) If its a conversion the ‘bolsters’ on the barrels above the locks look odd??

4) In addition to the sliding safetys on the cocks there is a grip safety – but it is engraved John Blisset Patent even though Jo Manton claimed to have invented it. There is a burr at the backof the slot that suggests it may be a retrofit. I can’t see manton putting a grip safety with someone elses name on it!

5) The barrel wording is ‘Joseph Manton’s New Invention by His Majesty’s PATENT’ – a form of words that he appears to have used between 1812 and 1816 and not at any other time? It may have a slightly elevated rib – Manton’s most recent Patent – I don’t know what constitutes ‘elevated’.

6) The numbering on the barrel looks as if it may have been restamped after previous numbers were dressed out – possibly also the numbers on the breech plugs. One breech plug is a bit misaligned.

7) It has two sets of CP proof marks on the barrel – one set looking as if they have been dressed down.

8) Everthing looks OK from on top although the breech plug doesn’t align perfectly with the rib – but the engraving is continuous across the joint.

9) The locks have the number 5692 very clearly stamped on them. The trigger guard tang also has the number 5692 engraved on it and looks original.

10) The locks have the classic Joseph Manton ‘sea monster’ engraving by Gumbrell that was seen on his guns around 1820 – 1828? Oviously the front safety catches were not intended when the locks were made and engraved.

Now we can begin the speculation if you are still with me!

A good point to start is the locks –clearly made by Joseph Manton around 182X (on grounds of percussion caplock, engraving and style) or so and clearly numbered for 5692 and so intended for an 1812 gun of his. The locks have the sliding safety catches which can’t realistically be contemporary with their manufacture(?) but almost certainly a later modification but are unusual on shotguns, being much more usual on rifles, (and introduced at a later date then the 1820s? – maybe 1830 – 1850?). If he had wanted to put a safety catch on a gun in 1828 he would almost certainly have used one behind the cock intercepting the tumbler not the cock itself as on pistols of that era. Joe Manton didn’t make very many rifles. When you add in the grip safety, which looks like a retrofit on account of Manton claiming to have invented it and it having another gunmaker’s name on it (grip safetys were not in fashion for long as they are pretty unreliable) The grip and cock safety together might suggest that it was possibly converted from a rifle (unlikely) but more likely that it had a very cautious owner at some time – possibly at conversion but probably some time after – possibly in two phases, grip safety and then sliding safety. The condition of the blueing of the sliders suggests that the gun wasn’t used much if at all after they were fitted ? The gun has not had a lot of wear at any time – maybe some prior to conversion, but relatively little use as a percussion gun as there is almost no corrosion around the nipples or the breeches.

The stock and furniture seem OK for 1812, and the number 5692 on the trigger guard tang is almost certainly original so I’m inclined to put it all down as original – the engraving throughout is consistent in quality and design and could date from a few years earlier than the Sea Monster lock engraving.

The barrels are interesting – the signature etc is right for the serial number date of 1812 ( used up to 1816). There is no gold or platinum stamp on the breeches, but they are very small and maybe not wide enough to take his stamp. It looks as if they have been struck off and renumbered and rebrowned and reproofed but I believe that the gun has been untouched in the same family for many years and it is quite possible that the work was done when the gun was converted or when one or other of the safety devices were added – it is almost certainly not a recent rebrowning. While it is possible to speculate that the gun was at one time a rifle and has been rebarreled, one would have to allow that the present barrel was contemporary with the original 1812 date or else re-signed in perfect imitation of the earlier form.

My current guess is that the gun was built as a flintlock 22 bore shotgun in 1812 and carefully converted by Joseph Manton to caplock in about 1828 (say 1825 – 1830). At some point it was owned by a hyper cautious owner who had the safety grip added – maybe by John Blisset himself ( he became Blisset and Son in 1867). It is possible that being very cautious the owner had the barrels reproofed at that time or they may have been done at the time of conversion, although Manton did not always send guns to the proofhouse – he preferred his own hydraulic test. I incline to think that the sliding safety is somewhat later than the grip safety ( I’ve only seen it on guns of 1840 to 1860) and so may have been added later.

So its tentative history ( a guess!) ;

1812 made by Joseph Manton

1828 ish converted by Manton to caplock

1830 ish grip safety added – ?by John Blisset? (probably before 1840?)

(1840 -1850) ?? front safety catches added and reproofed(?)

I’m sure I’ll be proved wrong – I will take the gun to Geoff Walker at ‘The Flintlock Collection’ as he knows his Mantons much better than I do.

Things to check include any date for Blisset’s patent for the grip safety, and a more accurate date for the sliding safety in front of the cock – all these things had a relatively short period in fashion and can be useful for dating, although occasionally clients demanded out of fashion features.

8th February – I visited the London Proof House yesterday as a guest of the Gunmaker’s Company who still run it, having been established in 1637 for the purpose of regulating the gunmaking trades in the City of London and a 10 mile radius thereof. The present building was occupied in the mid 18th century and is virtually unchanged – it is on Commercial Road a stone’s throw from Aldgate East station and surrounded by high rise flats on 3 sides. The site is pretty small, the largest space being taken up with the dining room where the liverymen of the company have their magnificant lunches. The work areas, which are responsible for the proofing of the guns made in London or brought into the UK, plus many military weapons (although those are mostly proofed at the maker’s sites by personnel from the Proof House). What I found astonishing was that the total space taken up by the working part is less than my own workshops! And its all distributed in a warren of passages too.

It seems incredible that they do all the proofing so close to the City, with all the transport to the site, and all the costs associated with London premises. I can see that they would need to maintain a presence somewhere in London as they are a London Livery company but to me its incredible that they don’t move the gun proofing bit to an industrial site somewhere. Anyway it was an interesting visit and I enjoyed the lunch and the booze……

4th February – Having trouble with the dates again – last 2 entries were actually 3rd! Oh well, worse things happen at sea! I did my STEM club at school today but most of the children weren’t in a mood for concentrating – funny how some weeks they do and some they don’t. I have been keeping an eye on which posts on this website get the most traffic – there are lots of visits to ‘guns for sale’ which makes me think I ought to put a lot more stuff on there – maybe time for a sortout! I have been hoping that the Mortimer flint repro would sell as I want it off my certificate so I can put something else on. I’ll have a look next week when things cool down a bit. I’m at meetings all Wednesday and in London on Thursday and Friday including a visit to the London Proof House which promises to be very interesting. Before then I have to sort out the cock of the flintlock that Dick has re-squared- he ran out of gas so I am having to silver solder it for him.

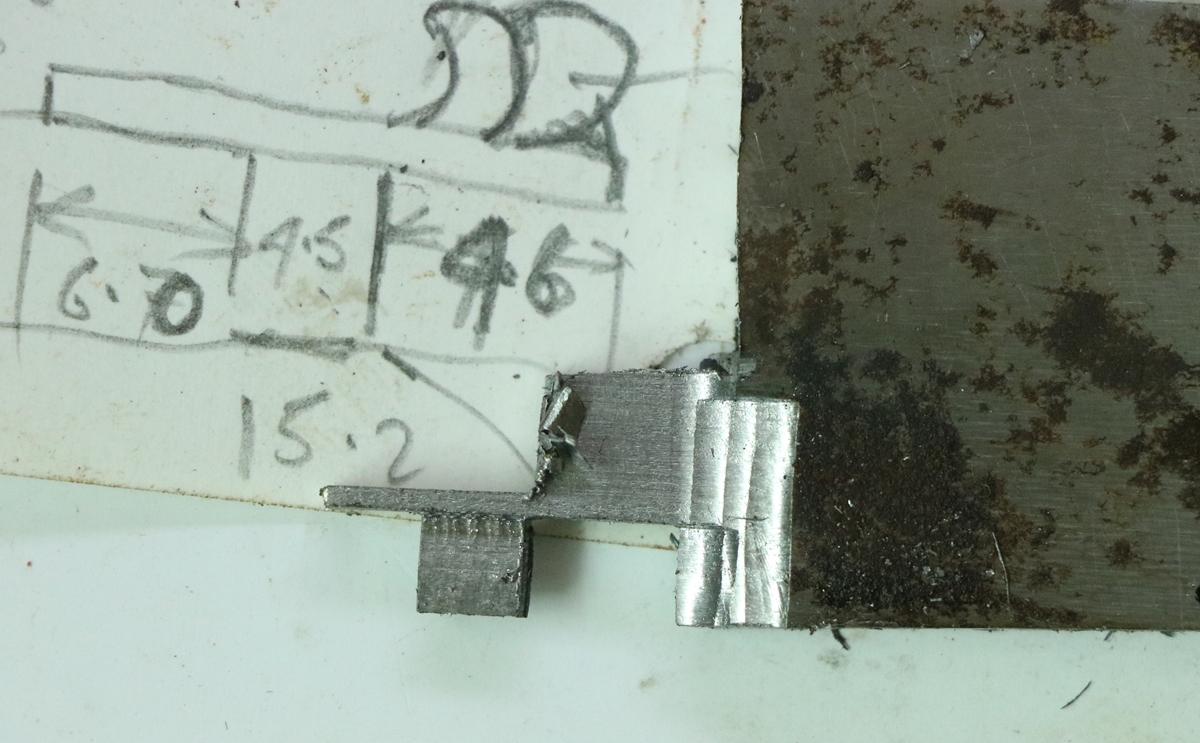

4th Feb Update – did a bit of work on the Harding Post Office pistol safety catch today (workshop was up around 25C!) – I couldn’t see a good way of making a 1.5mm wide slot through the inside bolt for the tongue of the external slider – my mill is nowhere near good enough to use such a small cutter, so I decided to mill a groove in a strip of metal and silver solder another piece over the top to complete the slot – worked a treat… And it all fitted together after a bit of filing – you can’t see the silver solder line. As before I left the part attached to the strip of metal until the last minute as its much easier to handle that way.

Strip with milled groove and piece silver soldered on top.

Shaped bolt still attached.

The bolt fits neatly over the tab on the slider – it will need pinning.

Safety slider is now engraved.

4th February – It continues cold, although I did get the indoor workshop up to 25 degrees C yesterday by burning wood at a rate of knots for 6 hours. I need to do a bit of TIG welding but by Argon has run out – annoying because it has leaked out of the cylinder – I’ve not used much in two years but its empty so I’ll have to change it. I couldn’t do that with the loan car as it wouldn’t fit in. but I’ll take it on Tuesday. I got some parts from Fred in the US to engrave for a gun he is making, so I’ll have to do a bit of design work. I have the Post Office pistol to finish making the safety catch parts for, and the Venables barrel to re-do, plus a bit of silver soldering for Dick on a flintcock to fix a disk for a remade square. I have converted Dick to using Bev’s method of re-doing the squares in cocks by milling out a hole and silver soldering in a disk. My method is to mill a stepped hole so there is some depth location when it comes to the soldering, but Dick has done a plain hole – We shall see if that works as well. The advantage of the stepped hole is that you can have a smaller ring of silver solder on the cock face so it doesn’t show round the cock screw but get an increased area for the solder as you can make the back mill of greater diameter. Anyway we shall see which is best…. I mentioned that my Nock had fired both barrels together on the shoot – I’ve had this happen before but there is usually a slight lag between the two shots as the second hammer doesn’t come down until the recoil unlatches the sear. This time I didn’t notice a lag, and all the other guns said there was only one report – they were expecting me to fire the other barrel at the bird. I was surprised to find that both barrels were fired when I looked at the locks – so I’m not sure what happened, although I’m pretty sure both barrels were loaded and capped to start with and both empty at the finish. Had it been a flint gun I might suspect a ‘flashover’ but not on a percussion gun….. mystery!

2nd Febuary – Got my Land Cruiser back from the body repair shop thank goodness ( I had a little disagreement with a driver who did an emergency stop in the outside lane of a dual carriageway for no reason) – driving round in a loan MiniCooper in the snow and ice isn’t my cup of tea! Had to take a couple of days out from gun playing, partly because the workshop is freezing and partly because I have to do a bit of sorting out for a US patent case that I’m a consultant for – which does mean I get paid! I had a look at the catalogue for the March Holts sale – it reinforced my feeling that reasonable percussion doubles that might make good shooters are about as rare as hen’s teeth – prices continue to rise and there is now not a lot of difference between a decent percussion and a usable flintlock! Both are pretty thin on the ground in that sale – lets hope Bonhams come up trumps.

30th January – Back from a ‘last of the season ‘ shoot courtesy of Bev – things get a bit scrappy at the end of the season, and shoots usually want to thin out the cock birds, so this was a ‘ see what comes up, but hope its mainly cocks’ sort of day! In fact cocks were pretty thin on the ground – more importantly also in the air – so it was mostly hens that were shot. It was one of those days when its so nice to be out in the country – cold day but warmed by the sun and little breeze – that the size of the bag is a secondary consideration for any sensible gun. We managed 30 for 8 guns, which is fine although one or two guns didn’t see much action. My Sam Nock double fired off the left barrel when I shot the right – a habit it had when I first got it and which I had eliminated by reshaping the bents – I had a careful look at them under the microscope and they look fine – I thought that perhaps the sear arm was a bit near the wood in the lock pocket so I have done a little reshaping of the sear arms but I can’t see anything else wrong. Our next clay shoot is simultaneous pairs, so I will need that aspect of the gun to be 100% by 16th Feb! I also tightened up the barrel bolt that wasn’t holding the barrel tight – I used the corner of a chisel to prise out the pin retaining the bolt, and bent the bolt slightly down in the centre so it pulls the barrel down onto the stock better. Yesterday I started on the safety catch slider for the Post Office pistol – I took a chunk of 8 mm EN8 and cut out a tab of about the right size on one end so I could work on it and have a decent bit to hold in a vice. I milled the rough blank – slightly oversize and still attached to the chunk – and filed it to fit, only separating it from at the last minute to shape the knob. It looks fine, or will do when I’ve engraved the slider – now to do the internals.

26th January – Just got back from the climbing wall with Giles and a couple of his friends – its difficult enough to keep up with 20 somethings without ending the 2 hour stint by all trying to climb as many of the fairly easy climbs in the room as possible in ten minutes! To say I’m k*******d is an understatement! And I had managed to make 24 jars of marmelade in the afternoon. I’ve been wondering about the cock we put on the little percussion saw handled pistol as I wasn’t sure if we had got the correct shape and neither was the owner, but I had a quick look through the last Bonham’s catalogue and low and behold there was a saw handled pistol, albeit a boxlock, with a very similar cock profile – I made a quick overlay to check it out. I’m still not quite sure we got the right cock but it matches others used!

Click on the photo for a better view, back arrow to restore.

24th January – I have ‘pruned this post to cover just 2019 – the contents from late 2018 are in the new post ‘ Blog September to December 2018‘ – it makes it easier to scroll if the post is kept a manageable size.

24th January – Switched back to my little Harding Post Office pistol. I needed to remake the square in the cock as the cock was from another pistol. As mentioned I decided to bore out the tumbler hole in the cock and silver solder in a disk and put the square hole in that. The cock was Araldited to a scrap of wood and centered under the mill/drill and a 6 mm end mill put through – the square on the tumbler is a 5 mm diagonal, approx 4 mm square. I then dropped an 8 mm end mill into the back of the cock 1.5 mm deep, and turned up a disk to fit the two milled holes with about 0.2 mm proud on the back surface and a 3.5 mm hole in the centre to start the square from. I had intended to put the square in the disk before fixing it in the cock, but there is no way to hold it so I silver soldered it in place with ‘easy’ silver solder paste that melts at 650C (dull red heat). I then filed up the square hole very carefully to fit and , I thought, in the right orientation – but it turned out to be about 10 degrees from where I wanted it, so I just heated the cock up to dull red and turned the insert with the end of a screwdriver to the correct angle. That all went well so I worked on the sear to get it all aligned as I hadn’t done the final shaping until the cock was on. I am not sure that all the parts I had were from the same pistol, and the shape of the full cock bent was a bit too ‘re-entrant’ for the motion of the sear and you couldn’t fire the lock – so the bent had to be opened out a bit. All done so I tweaked the mainspring and hardened it and tempered it to blue – and then broke it while clamping it to put it in place! It was my fault as I couldn’t find a small mainspring clamp and used a mole grip too near the ‘elbow’ and overstressed it – another job to do, although I might just try welding it.

The cock is actually stopped by the step hitting the edge of the lock as it should be, but the ‘chin’ of the jaw is a bit close – the cock needs slightly reshaping, although I’ll have to be careful not to loose the square insert if I heat it to red heat…..

23rd January – Amongst other things I had a go at sorting the percussion pistol with the extreme full cock position and overbent spring. I’m not sure what has been done to the lockwork but it is not right! I did manage to get the full cock a little better by honing the sear slightly (.25mm off) – I didn’t like to take too much off as it alters the geometry and, with the fly or detent, it might not work. I took off the bridle as the lock was very stiff, and found that the inside tumbler pivot had been peened over so that it was a tight fit in the bridle – I couldn’t see any reason for that so I filed it off and punched it out and adjusted the fit – – while it was in pieces I also ground down the pillar on the mainspring so that it isn’t overbent at the full cock position. Although it isn’t perfect, it now cocks and fires much more smoothly. I’ll add a photo when I can get access to the website editor on my main computer – \i’ve had a couple of times when it won’t let me get into the editor and I have to resort to the laptop, which hasn’t got my photo library on it’s hard Drive. I was going to put the little Nock pistol back together, but somewhere between my workshop and Dicks we have mislaid the sear. I Araldited the cock of the Post Office pistol to a piece of wood in preparation for milling a disk out of the back…….. If you think I have too many jobs on the go at once, you are right!

22nd January – Meetings in school took up 5 hours, but I did manage to make a graver sharpener for a customer. I did design a sharpener that would do both the main 45 degree face and then could be turned over to do the 15 degree heels, but it needed rather a lot of parts and was fiddly so I am making them as two separate tools. They are not really economic to make as I have to turn and drill and tap each part separately and there are a lot of parts. I could save a lot of time if I made batches but I usually have to get them out of the door in a hurry so make them individually. If I could sell in quantity I could easily get them made by the 50s at an economic price, but that number would last at least until I am pushing up daisies – even if I outlive my mother who died at 98 – a good age! Just in case you think I was shirking on the tax, any moments I could fit in went that way……….

21st January – My apologies for no gun stuff today! Mondays is Bullard Archive and STEM club. The STEM children are getting their act together a bit – last week was a bit of a rabble. We are building prototypes for a weather station for the school – the anemometer worked – now we have to fit a digital readout to it using a BBC Microbit computer. Plans are in hand.

I have to report that my tax is not getting done very fast…………

19th January – As expected, another day pushing pieces of paper around the desk and searching for lost bills and invoices – I’m relieved to see that there is now a £1000 tax free allowance for online sales, so the few little bits and pieces I sell from the shop on this website don’t get taxed and don’t have to be declared! I picked up a copy of George Orwell’s Animal Farm with a child friendly cover and started to read it, thinking it was a child friendly simplification but realised that actually the book is the full adult one and so unsubtle and simplistic that you wonder why it ever became famous – but I suppose times change and we just expect better now. I packed up after one page – doing my tax didn’t seem so tedious after that……………..

19th 18th January – I got a bit confused about the date – I have just started wearing a watch again and it’s got the wrong date – it’s a day fast. I gradually built up a pile of Casio F-91Ws – cheap plastic watches – with broken straps but still working, so I got round to ordering 5 new straps from Cousins at £1.25 each – I now have 3 wearable ones, and a couple of straps left over – Tom has one that needs a strap, and I’ll no doubt need another some day. As expected I spent most of the day trying to make sense of my accounts for the tax man – I had an accountant to chase/bully me into getting everything I need, but she retired this year so its down to me! I did get down to Dicks to take the inlaid little pistols so he can finish them off and we had the usual cup of tea and a chat about work in progress. I have the little flint post office pistol to make the safety for and fix the cock and get the spring to work, plus I think I need to have a go at sorting the laid back cock of the saw handled pistol as it offends me! The Post Office pistol needs its replacement cock fitted, which involves completely remaking the square hole for the tumbler shaft – there are 3 ways to do this – 1) weld up the hole and drill and file a new hole, 2) mount up the tumbler on the lathe and drill out the shaft (after annealing it) and silver solder in a new shaft and put a square on that, or 3) drop and end mill in the back of the cock and silver solder in a disk and put the square in that. 2 and 3 do allow some fiddling with the orientation of the cock before final soldering, which is useful. 1) is quicker. I have used 1) – most often, and 2) before, but drilling out the tumbler is a lot easier on a full sized gun – I’m not sure I fancy doing it on this little pistol. I haven’t tried 3), which is Bev’s favourite, so I might try that this time. 2) would be difficult with a anything with a fly or detent, as well as a small pistol.

17th January – Had a shoot on Tuesday which didn’t go according to plan as the birds didn’t play ball! As the season goes on they get more wily and the stupid ones get culled, so the keepering gets more difficult. The first drive, which should have been good, produced nothing – not even the usual early exit of blackbirds etc. The poor keeper was tearing his hair out by the end, although there were a couple of passable drives for some guns. A couple of guns didn’t have any luck at all and in the end the bag was half what it was supposed to be, which in any case was very modest. I guess I can’t complain too loudly as I got my fair share of what there was to get and enjoyed the day out in the country. Ah well, its all part of the game! I came back feeling half dead and for the first time in my life I just sprayed my gun liberally with WD 40 and left it for the morning, for which I feel ashamed!

13th January – We had the monthly Anglian Muzzle Loaders clay shoot at Cambridge Gun Club today. Bev insists that I post that I shot very well (for me, that is). I surprised everyone, myself included, by being ahead after the first 16 clays = two stands, but alas it didn’t last, and I didn’t manage to connect with many of the long range targets – by common consent they were out to 50 or 60 yards and being carried rapidly downwind, and by the time we got to the driven stand I’d lost concentration a bit, but still my best score in ages. It augers well for a game shoot on Tuesday, and I’ve just got invited on a ‘Cock Day’ for the last day on the season, which will round off the game year very nicely. Don’t expect much gun stuff over the next two weeks as I have got to struggle with my income tax return for Jan 31st!

11 January – Interesting little problem – Dick put a replacement cock on a percussion pistol in the correct orientation for sitting on the nipple when the tumbler is down and the spring is almost at the edge of the lock plate, and it all works but the cock is very far back in the full cock position – it all works but both the half cock and full cock positions seem a bit too far back. The tumbler and sear all seem to be undamaged and original and it has a ‘fly’ or detent on the tumbler that works OK . The only things I can see wrong are that the link on the mainspring has been brazed and the mainspring short arm has a very long ‘stalk’ that rests on the bolster, so that the mainspring is overfolded in the full cock position – it only just gets that far. I can’t see what is wrong – the square on the cock could be a little out but not enough to cause the problem, and the link might be wrong, although neither would affect the cock position. Given that it has a ‘fly’ it is not possible to move the bents in the tumbler although it might be possible to shave a bit off the front of the sear. I guess Dick and I will have another think together! I managed to find an hour to solder the top rib on the Venables and it’s on pretty well – there is one small gap on one side but that is where the rib was previously filed down too much and it doesn’t touch the barrel – to have put it in contact with the barrel would have involved bending one side of the rib down by almost 1 mm, so best not attempted – it will be fine as it is, I hope – the rest is very solid. I do rate resoldering barrels as my unfavourite – job I’ll do it for my guns but not for others!

Position with cock on the nipple – it looks very upright!

Half cock.

A very laid back full cock – the mainspring is struggling!

10th January – I was helping a friend with an early spring clean and we found a cartridge bag which turned out to contain 50 12 Bore Bismuth cartridges on a peg, then we found another 25 in a bedroom, and 25 more in a cupboard, making a total of 100. While I don’t shoot live quarry with a breechloader very often, I can use the No 5 bismuth shot in a muzzle loader and can then shoot wildfowl if the opportunity arises. I had a quick look at the price of Bismuth shot on the web and it looks as if buying cartridges and recovering the shot is somewhat cheaper than buying loose shot by enough to be worth while – plus its much easier to get hold of cartridges than shot. The only downside is that you have a whole lot of primed, damaged cases – or perhaps I can find a way of unloading them so that I can use the cases for black powder cartridges, which I do use for hammer gun club shoots. Bismuth is supposed to be as soft as lead and OK for Damascus barrels, muzzle loaders etc. It’s slightly less dense than lead, 10 instead of 11.7 gm/cc so you need to go up a shot size to give a comparable range and penetration to lead, and you therefore end up with a somewhat less dense shot pattern, so you need to shoot within sensible range limits to give clean sure kills.

9th January – sorry for the gap in posting but more urgent duties took precedence – I actually managed to spend yesterday morning soldering the barrels of the Venables and thought I had done a good job, but after it cooled down and I cleaned it up on the fine wire wheel I spotted about 4 inches near the breech where the top rib hadn’t been in contact with the barrels on either side. I’m not sure if the tinning was OK or if it hadn’t taken, I tried to heat up the rib to fix it but stupidly overlooked the fact that the rib would expand and bow up as it was fixed at the breech and further down the barrel. I will now have to do a proper job and unhitch the rib right down to the breech so I can relay it properly. Fortunately the breech remains silver soldered together so it shouldn’t all fall apart if I heat it up. Just have to make sure the under rib and the loop for the barrel bolt stay in position. Not sure when I’ll be able to do that job as I have a raft of stressful jobs eleswhere to attend to… I’ve been trying to get down to Dick’s all week to take a bit of welding for Jason and collect the last lot. Jason is our expert TIG welder – much much better than I am. He really enjoys the challenge of the very fine gun work and would like to give up doing ‘bog standard’ speciality welding and take up gun repair! Not sure the market is big enough unless he does modern stuff – we only have about 1/2 an hour a week of work for him. It’s definitely time I got a few jobs out of the door – I’m beginning to loose track…………………. Oh, and Fred ( see engraving Fred’s guns ) has got another one for me to do sometime – I will have to spend quite a while getting back into the swing of it as I haven’t done any significant amount of engraving for a year or so.

6th January I bought a copy of Ian Glendenning’s 1951 book ‘British Pistols and Guns 1640 to 1840’ not remembering that I had a copy already – its long book (in shape) and only fits in my bookcase on end so you don’t see the spine and I had overlooked it. It is, however, an exemplary book for beginners as it is a very succinct guide with a brief history and much more comprehensive descriptions of typical pistols and guns than is usually found in books. Its a shame that photographs were not easier and cheaper to reproduce in 1951 or it would be better illustrated but it does contain a lot of line drawings of decoration. It has a brief history of developments, a comprehensive glossary, decent descriptions of pistols and guns in the author’s collection and a list of known makers. It’s a very good second hand book to buy if you only have one book and want to put a gun or pistol of that period in context, and much cheaper than almost any other decent gun book. If you want my spare copy for £25 including UK post, please email me – first come first served. It’s probably slightly wrong in one or two aspects – I don’t agree with his analysis of the ignition from flash pan to chamber, for instance, but overall its pretty sound.

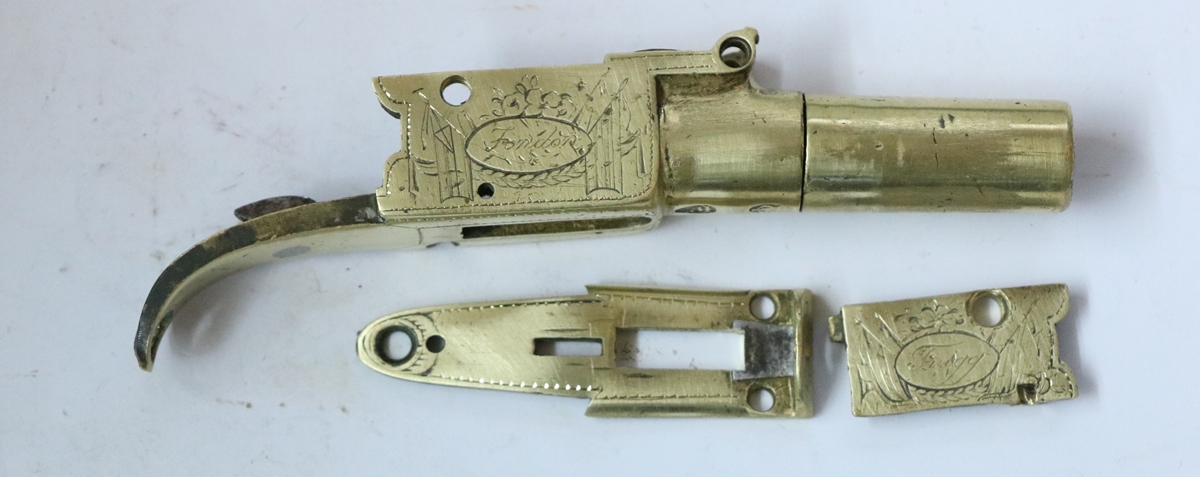

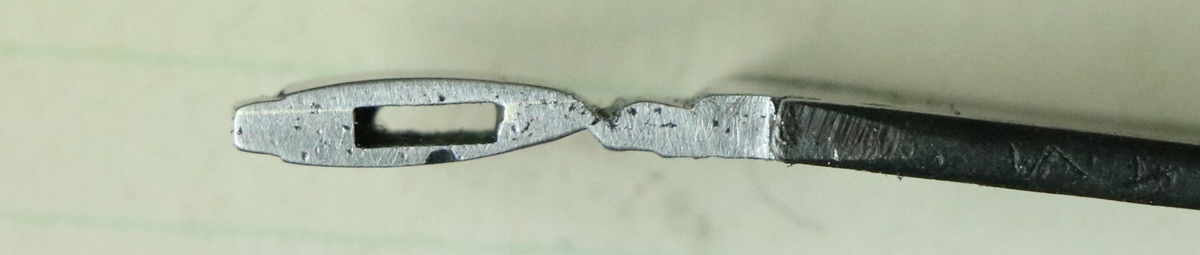

5th January – My calor cylinder in the shed ran out so that has put paid to finishing the Venables barrel until I can get heat back on. I got a flintlock pocket pistol by Nock today to sort out. It is in good condition overall but the ‘action is at fault’ as the auction houses put it in catalogues. The mainspring has some brazing on the hook end so has probably been repaired, and the sear isn’t holding. It was sent already stripped down – looking at the action was made easy because the side plate had been removed and you can see the engagement of the sear with the cock – the cock fulfils the role of tumbler as well as cock in that type of pocket pistol. The cock bents are in perfect condition, the problem lies with the sear, which is an extension upwards of the trigger – it isn’t hardened like the cock bents, and so the tip has got worn or broken away for about 1 1/2 mm. It rather looks as if someone used brute force to fire the pistol when the sear was very firmly in the half cock bent and sheared off a chunk of the sear – or possibly dropped the pistol on its cock when it was a half cock…… The sear is a bit wider than the cock, so its left a bit of the original sear sticking up either side of the worn gap that corresponds to the cock – the photos tell the story – the sear needs building up to the profile of the two bits that stick up either side – I checked by offsetting the cock and using one of the bits as the sear, and it functions properly. It can either be done by silver soldering in a piece of steel between the remnants of the sear, or welding more material on, which will inevitably destroy the original profile. I’ll think about that choice, both will work but the weld may be stronger?

As usual, click the photos for a better view, then the back arrow to return…

a chunk is missing out of the middle of the sear leaving a ‘horn’ either side

The sear, with worn down bit in the middle.

The cock bents are perfect.

2nd Jan 2019 I started to put the ribs on the Venables barrels – at least I got as far as tinning the ribs and lands on the barrels – I’ve probably been far too generous with the solder but I don’t want to have any more false dawns! I will probably go over it again and try to thin down the tinning to a more reasonable level or it will create loose blobs of solder within the voids under the top rib which will rattle around when the gun fires! I’m in school tomorrow as part of a pre term planning session to see what science is planned. On Thursday I am helping take all 100 odd children to the Pantomime in Cambridge (as one of 15 adults I’m relieved to say).

1 January 2019 Happy New Year to all our visitors, especially the faithful followers! I’ll be back soon – just got to do our New Year’s Party with breakfast for about 70 people and then I can think about doing things again!