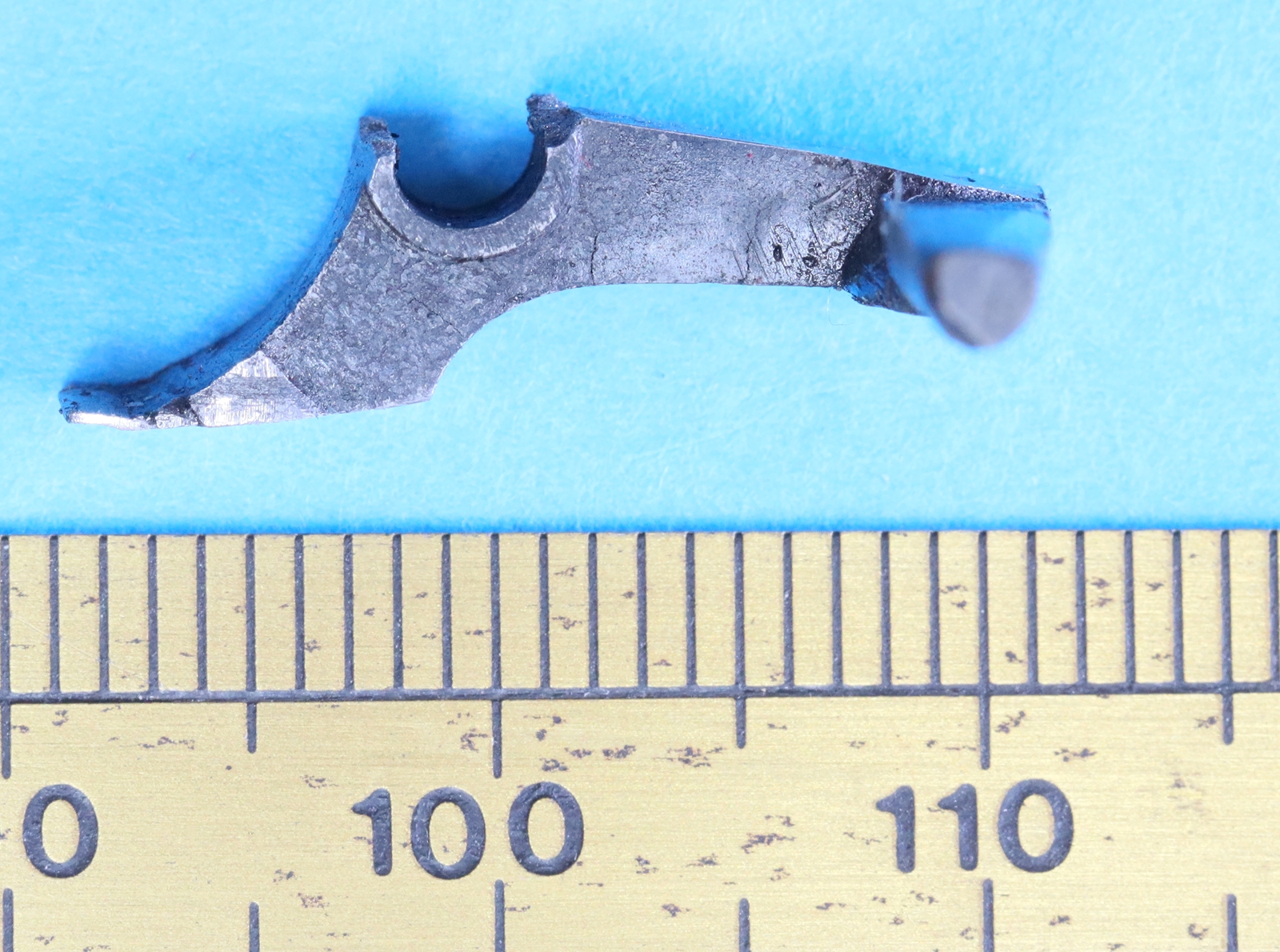

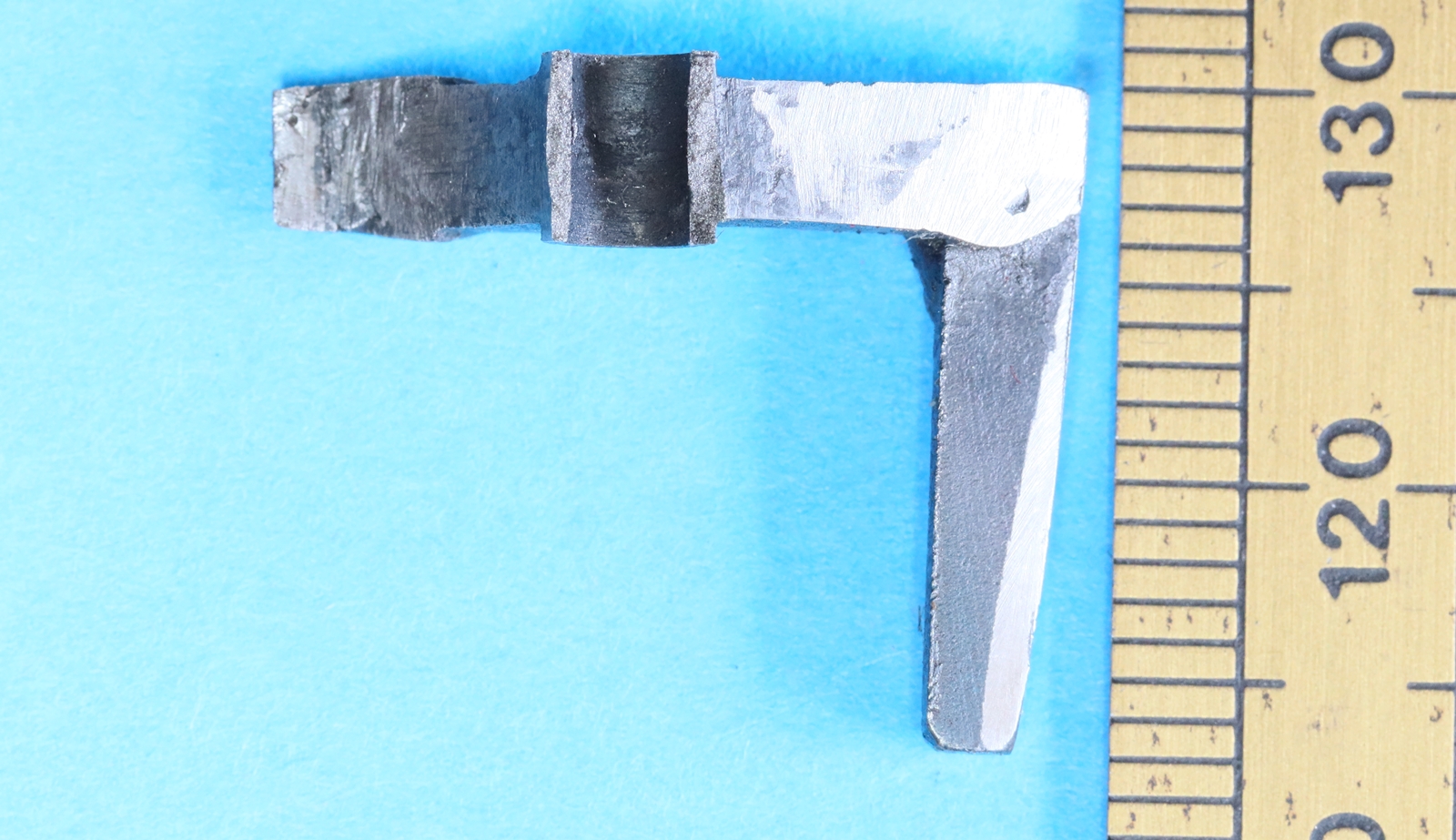

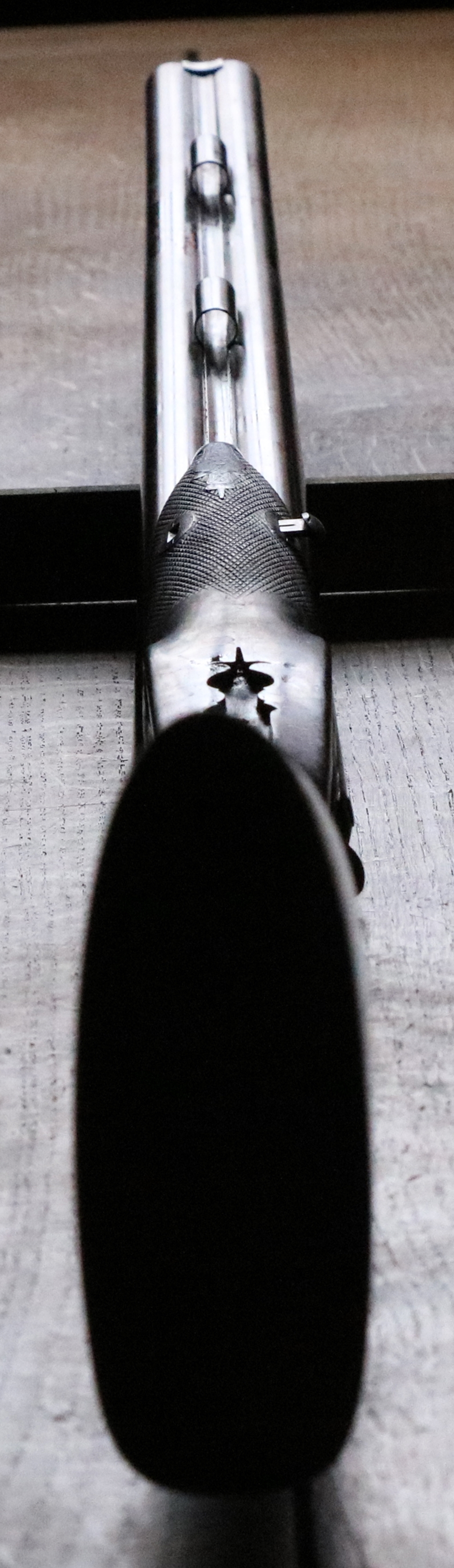

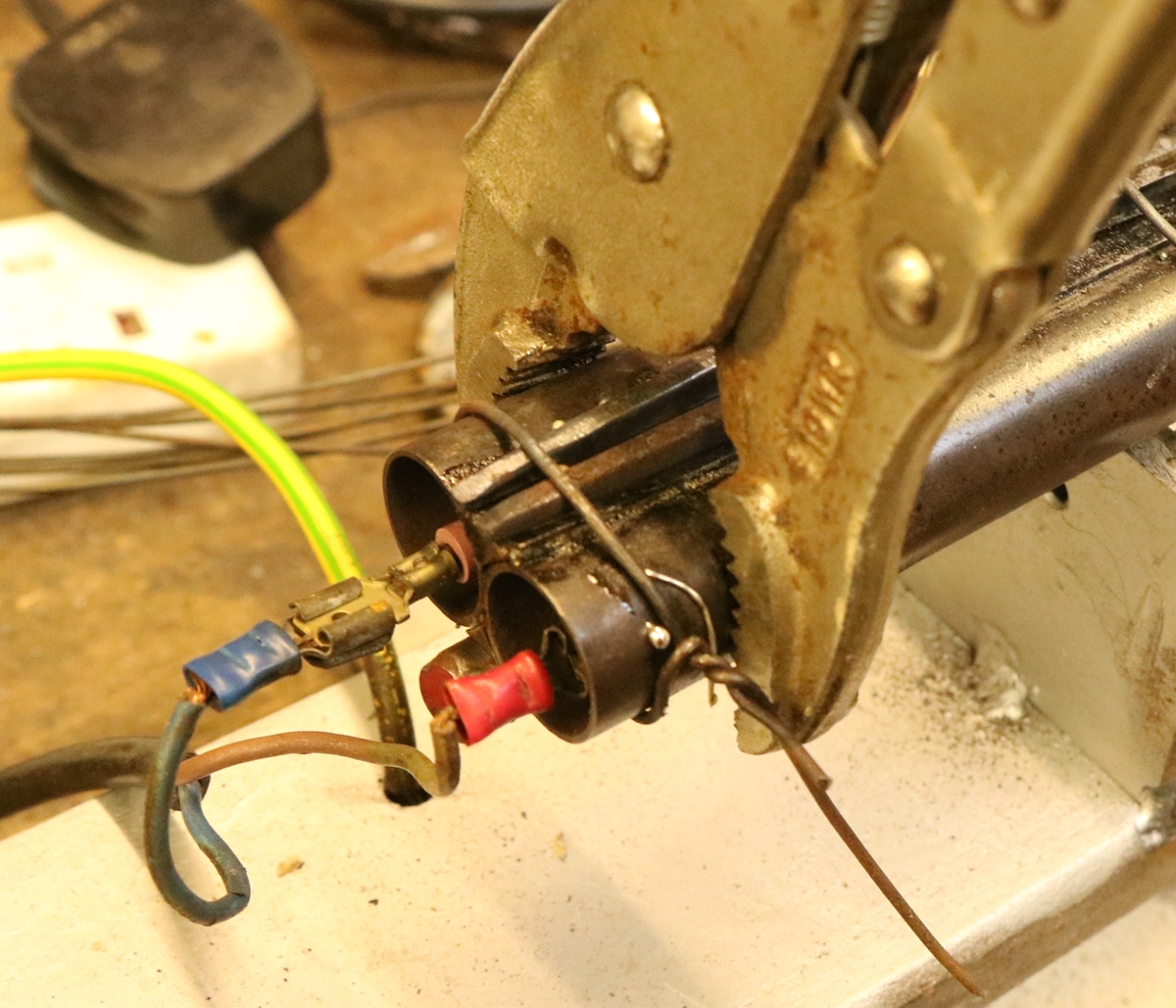

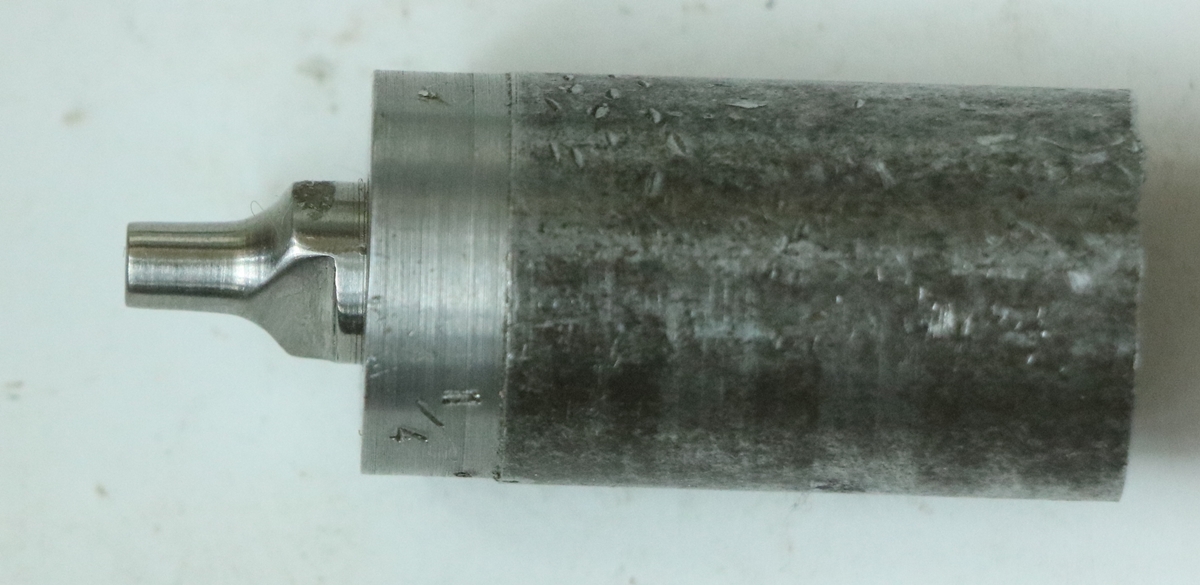

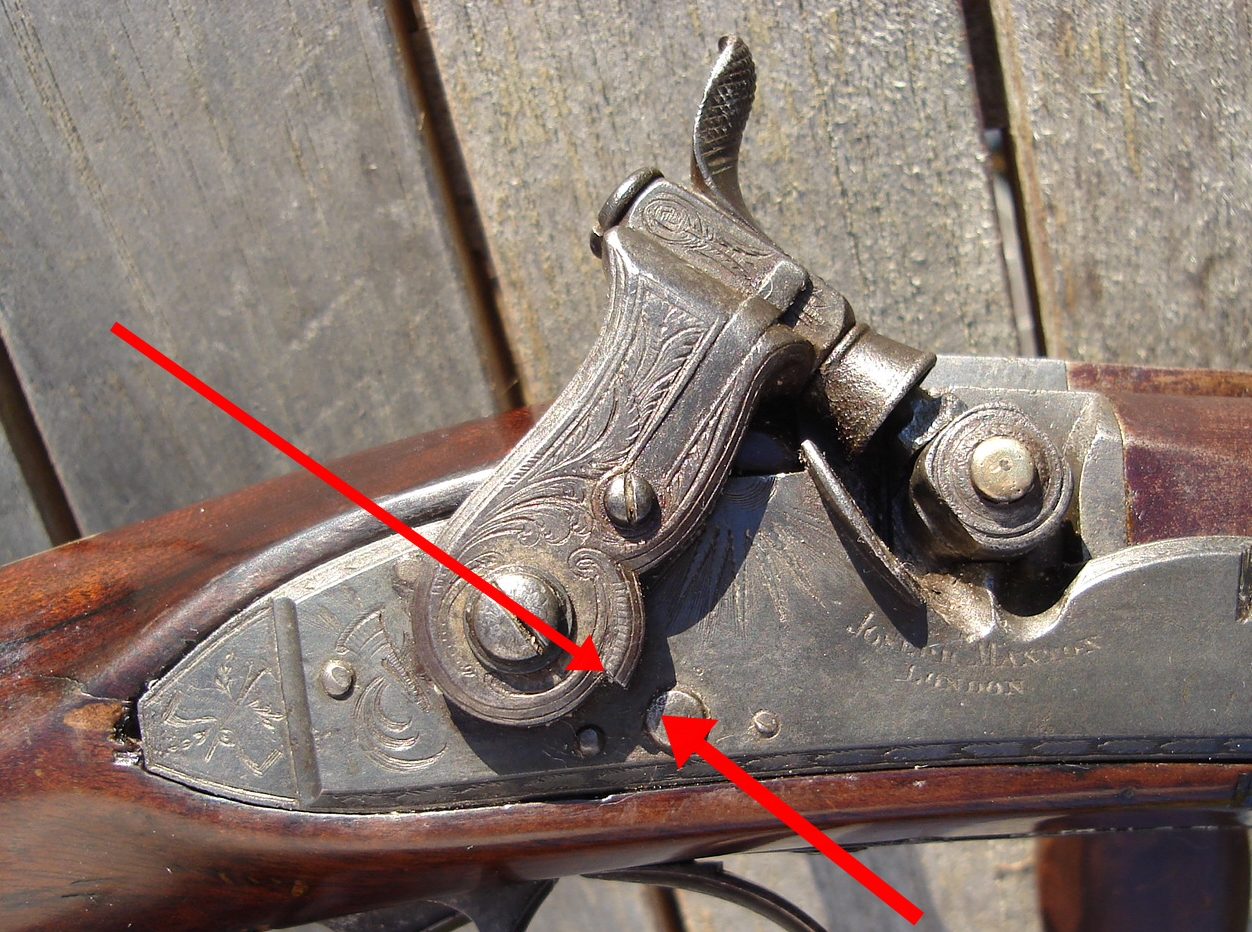

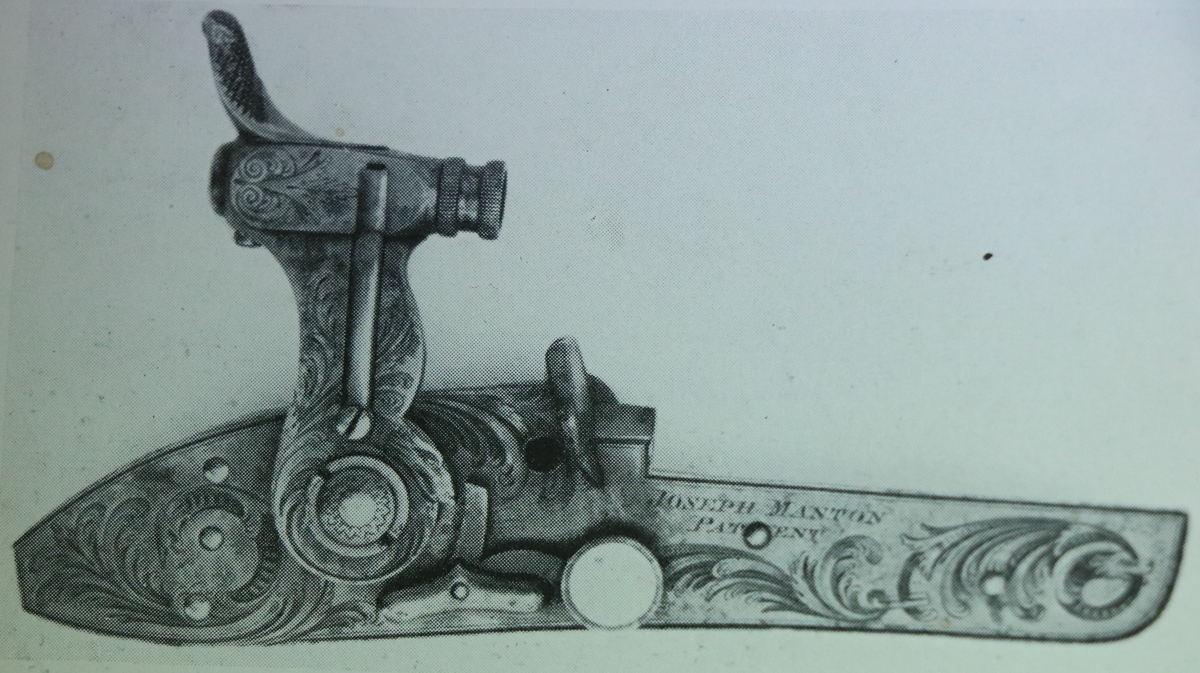

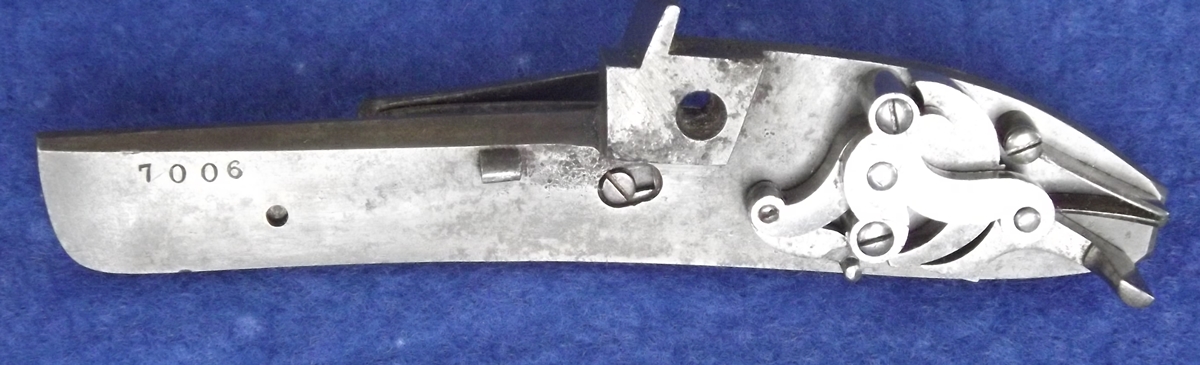

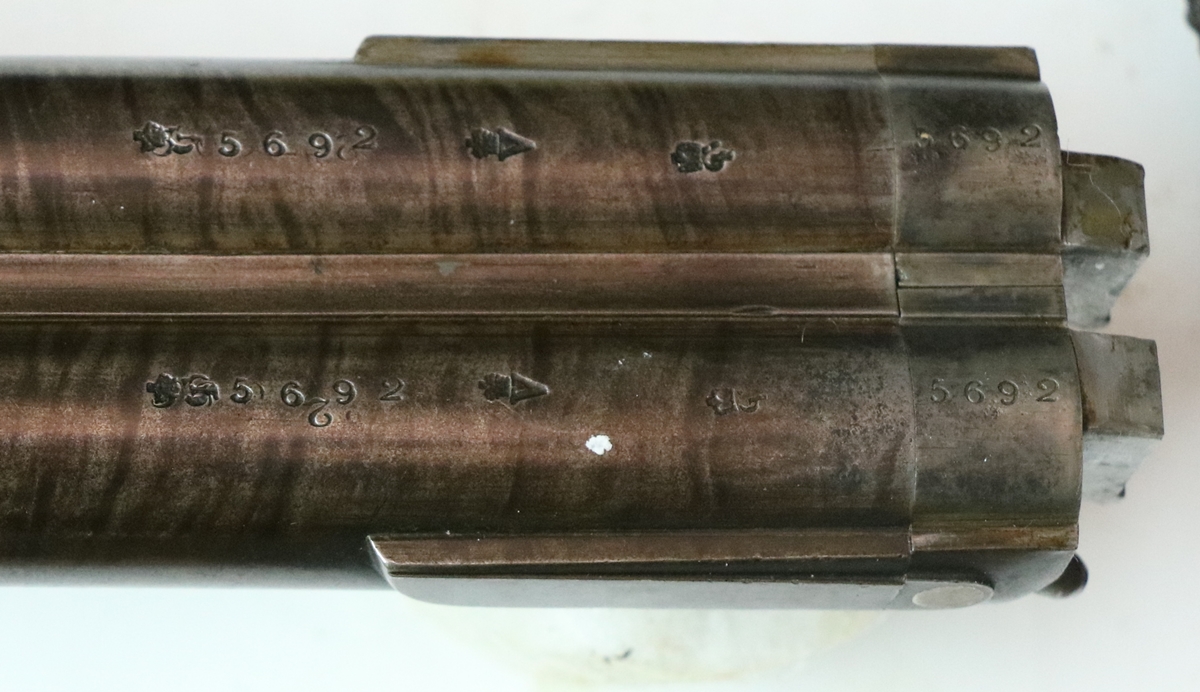

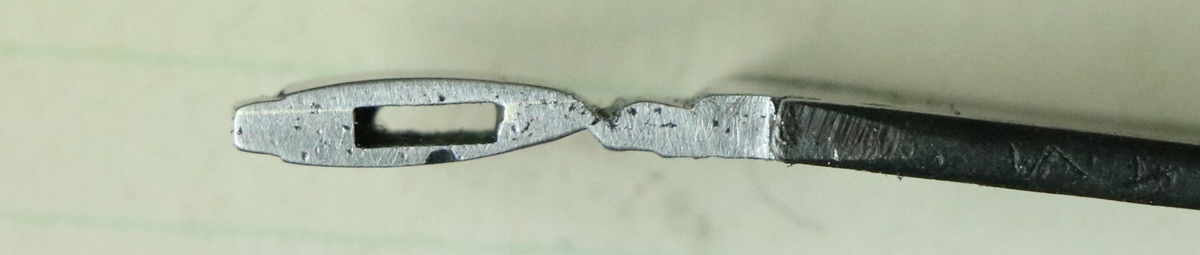

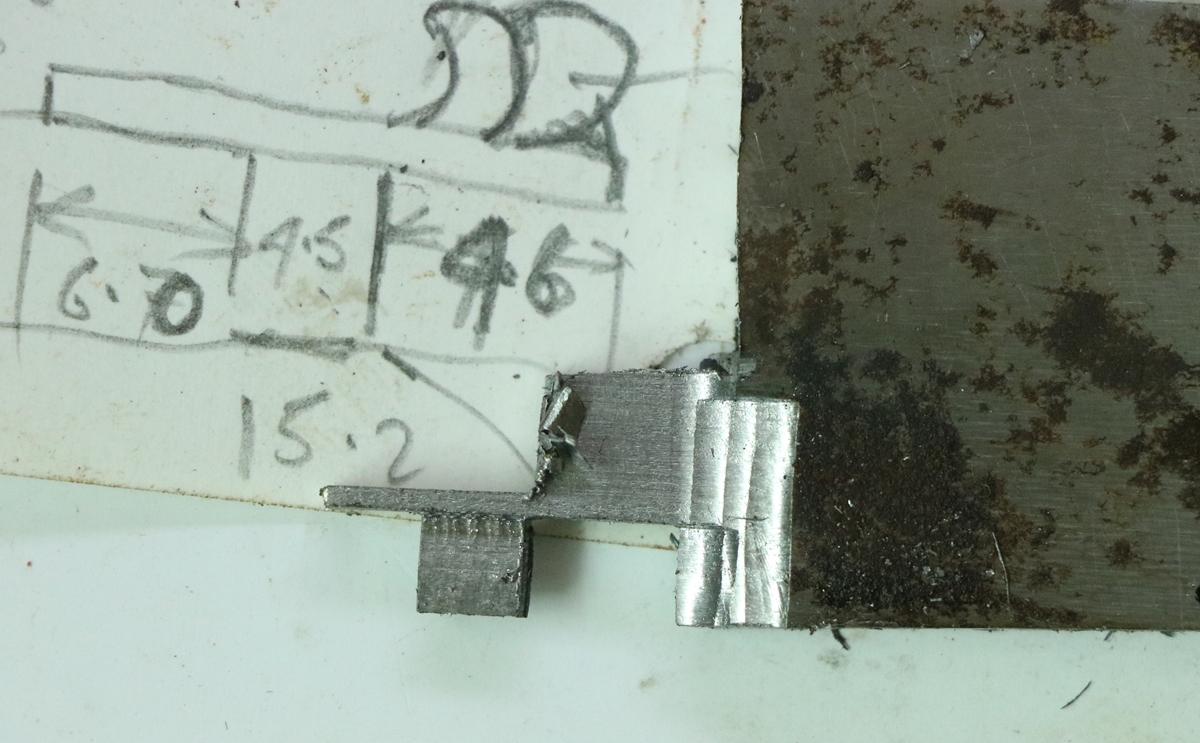

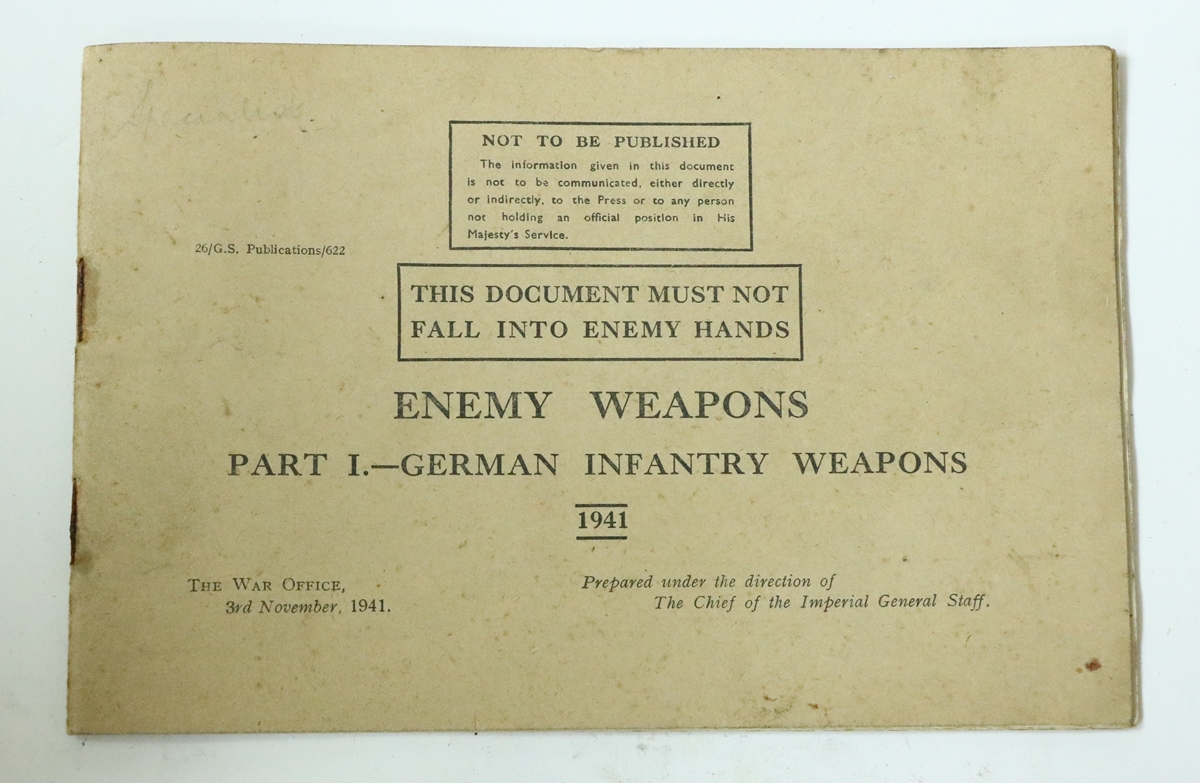

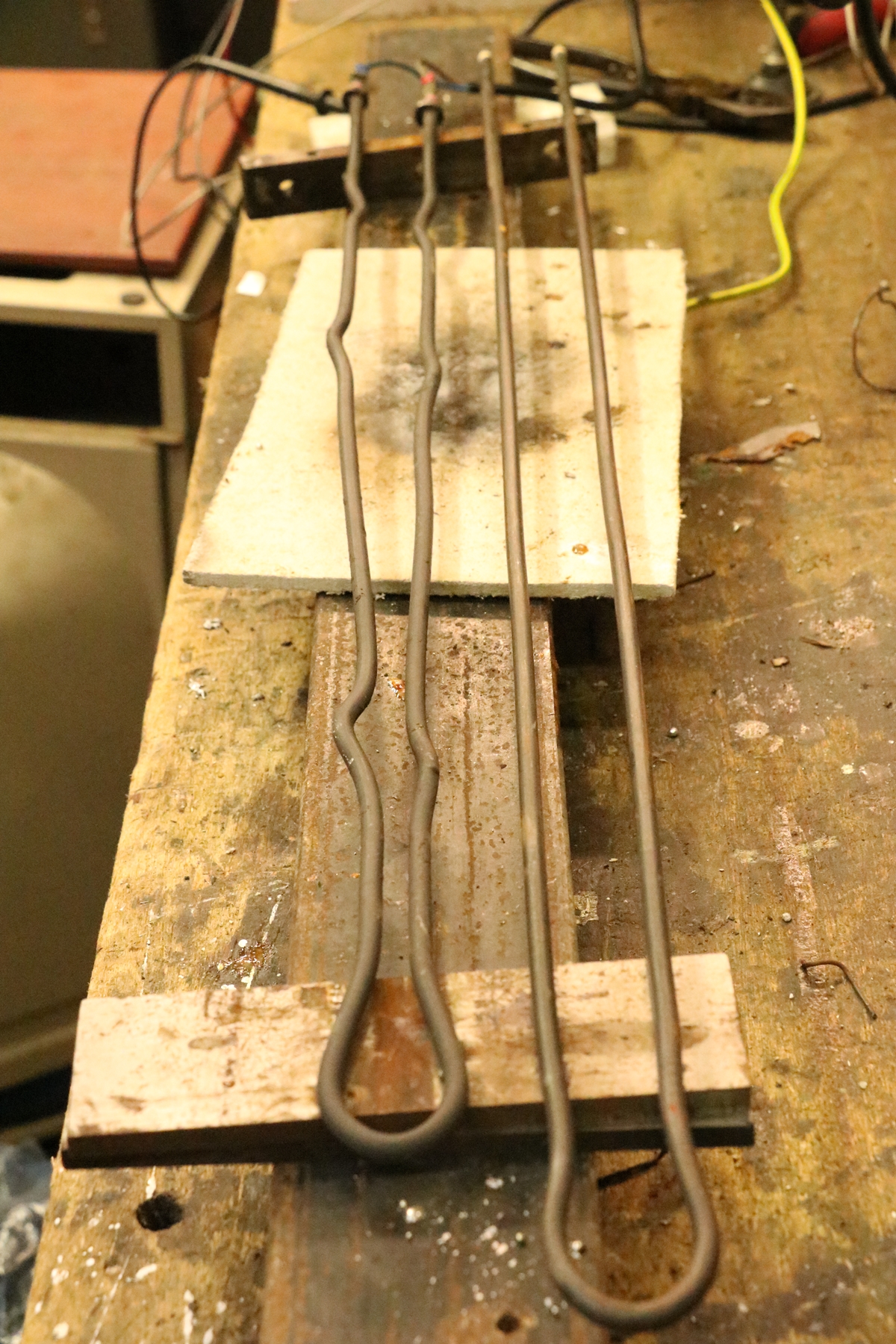

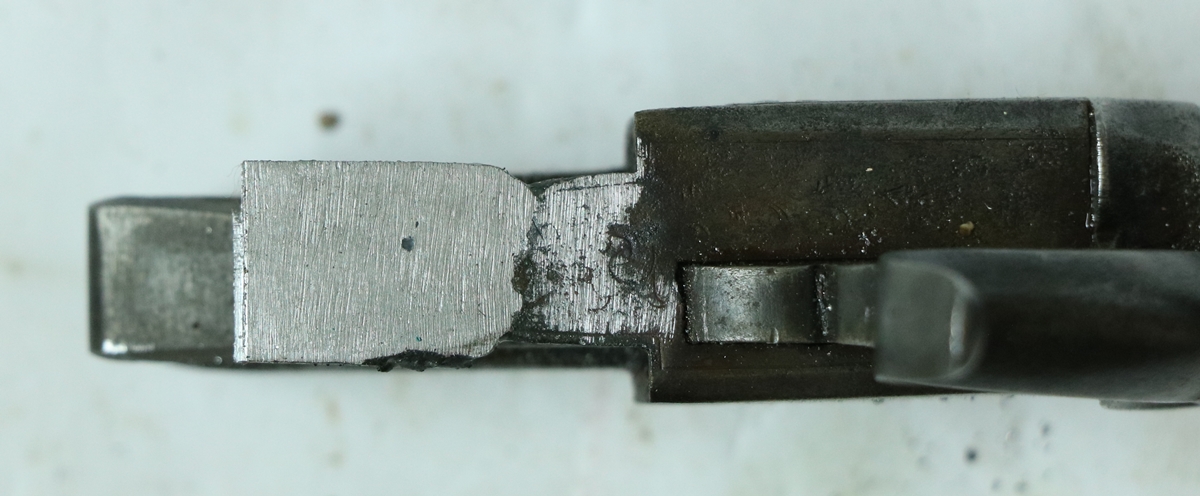

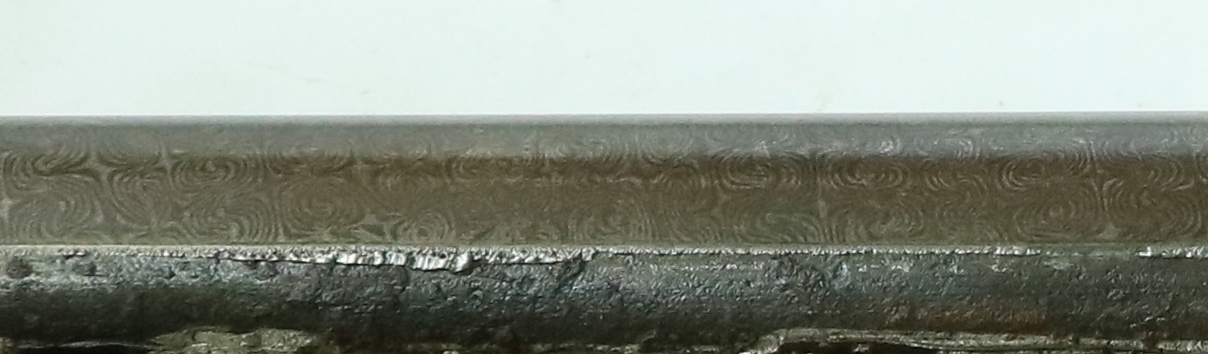

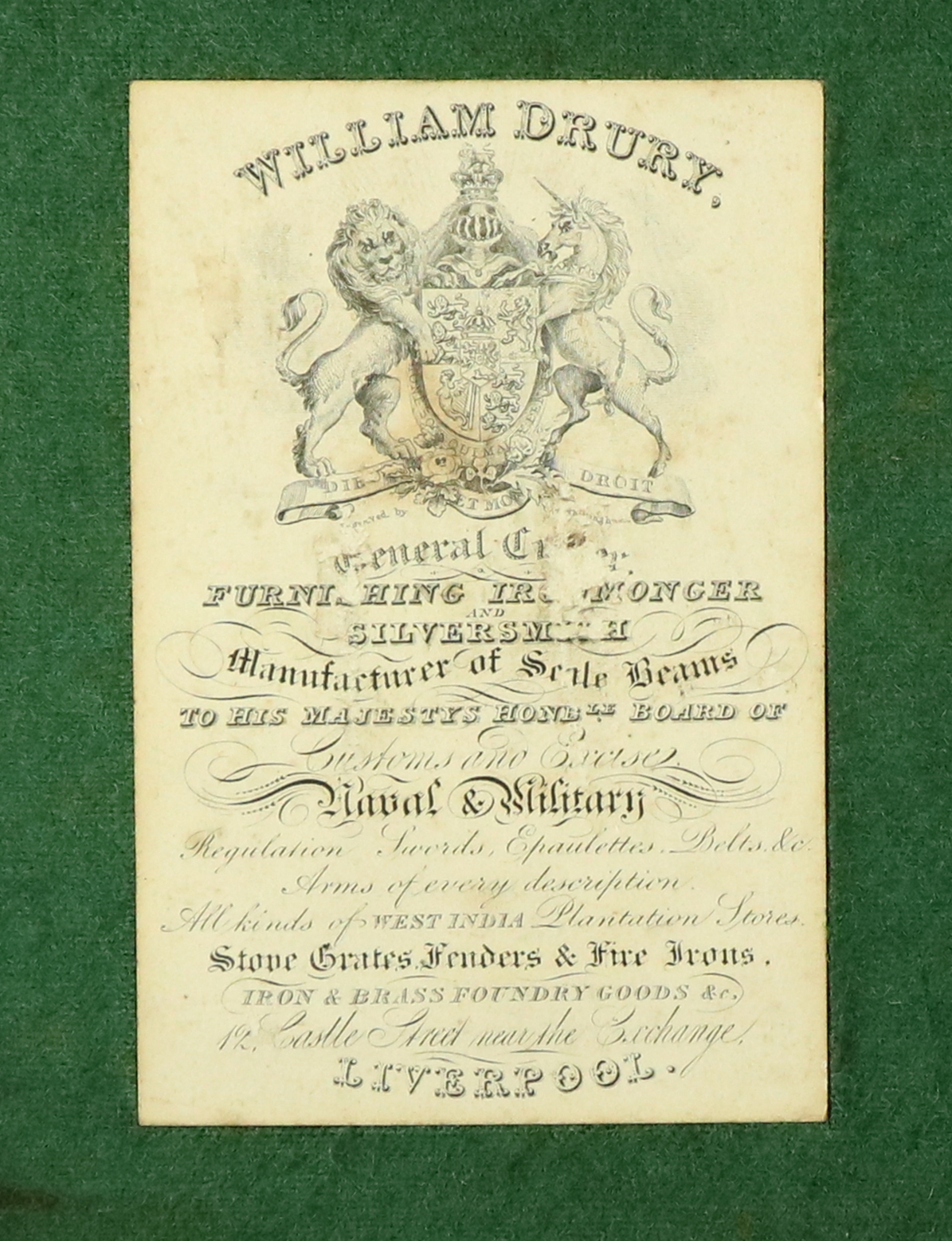

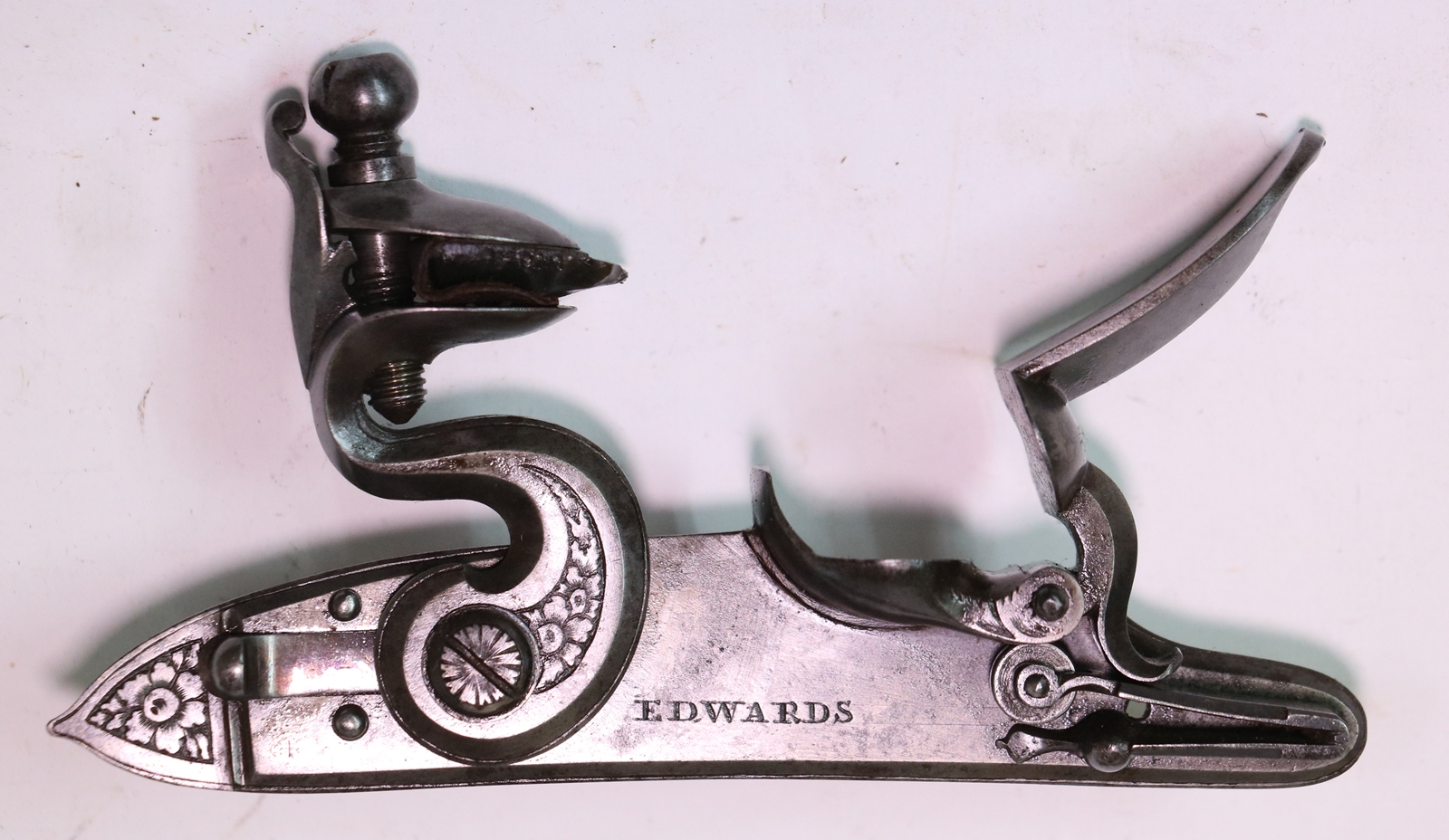

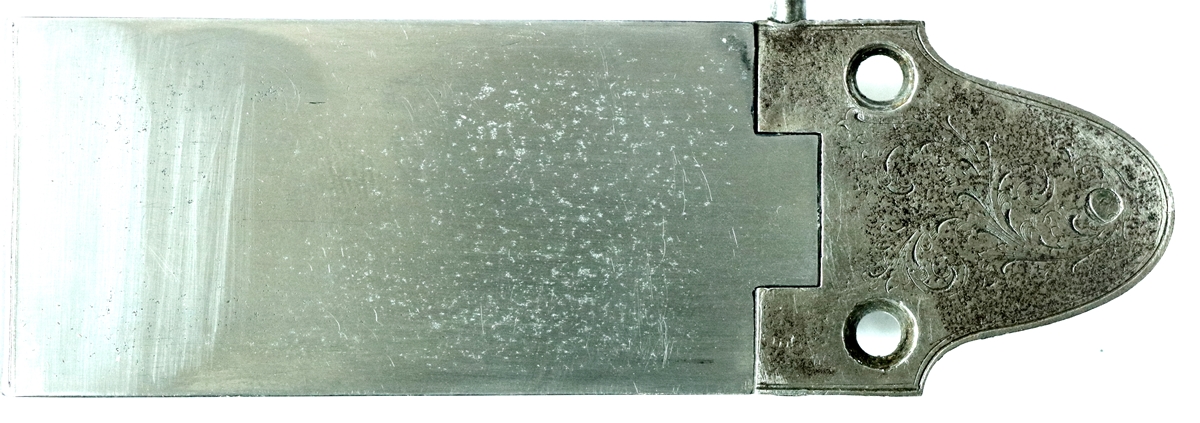

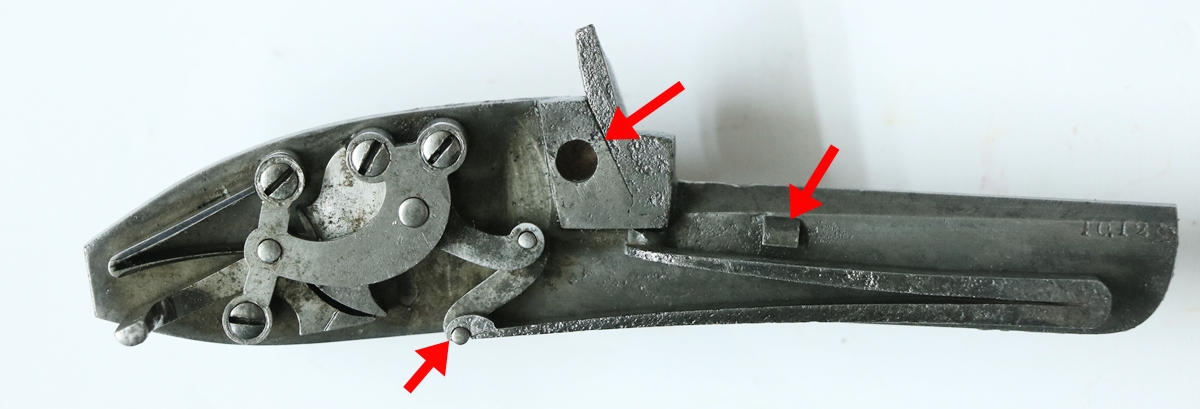

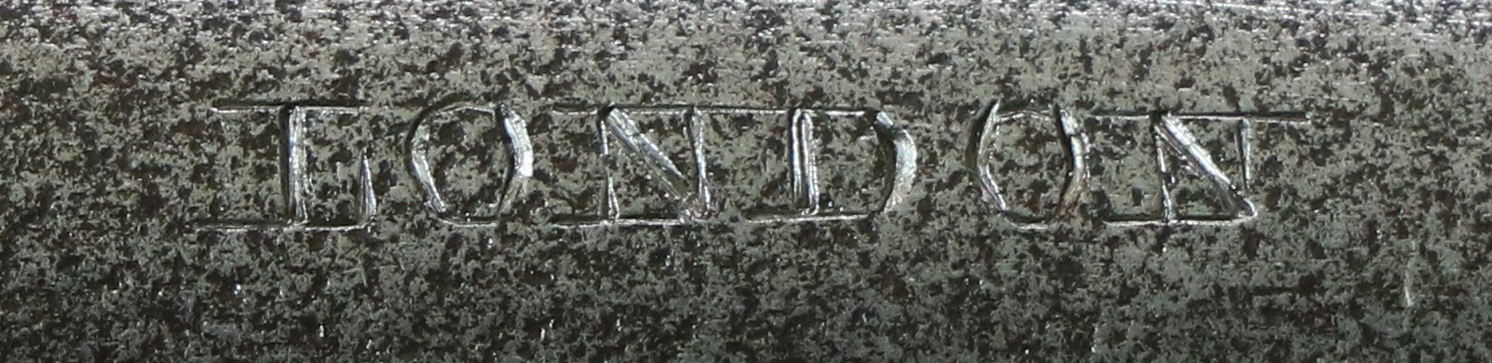

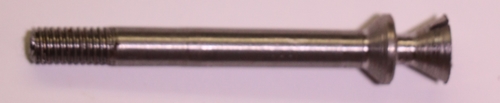

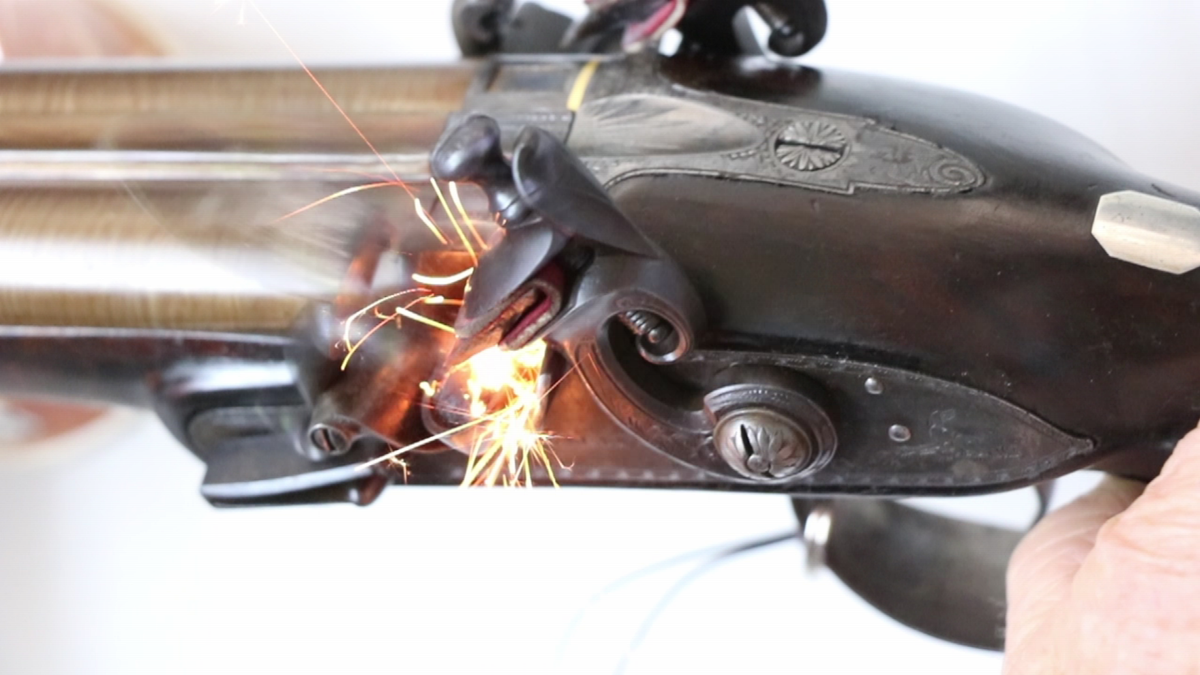

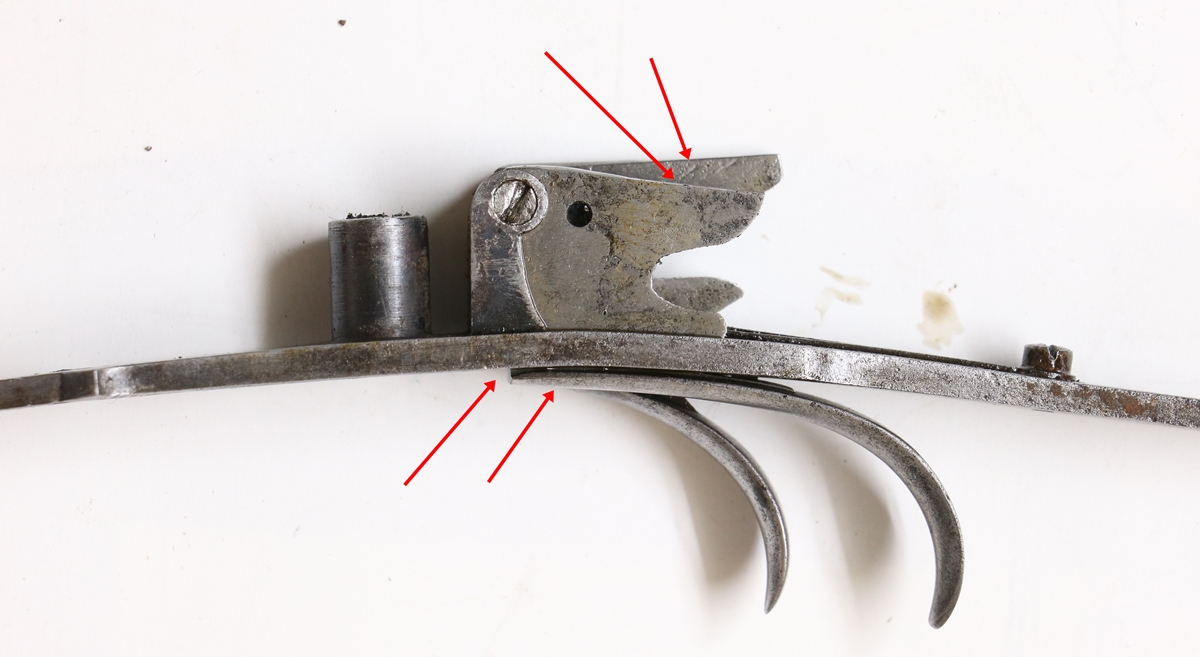

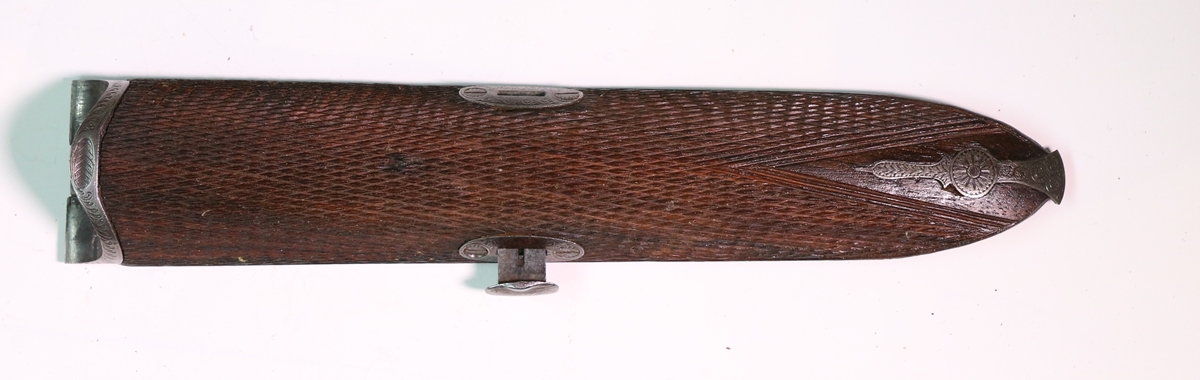

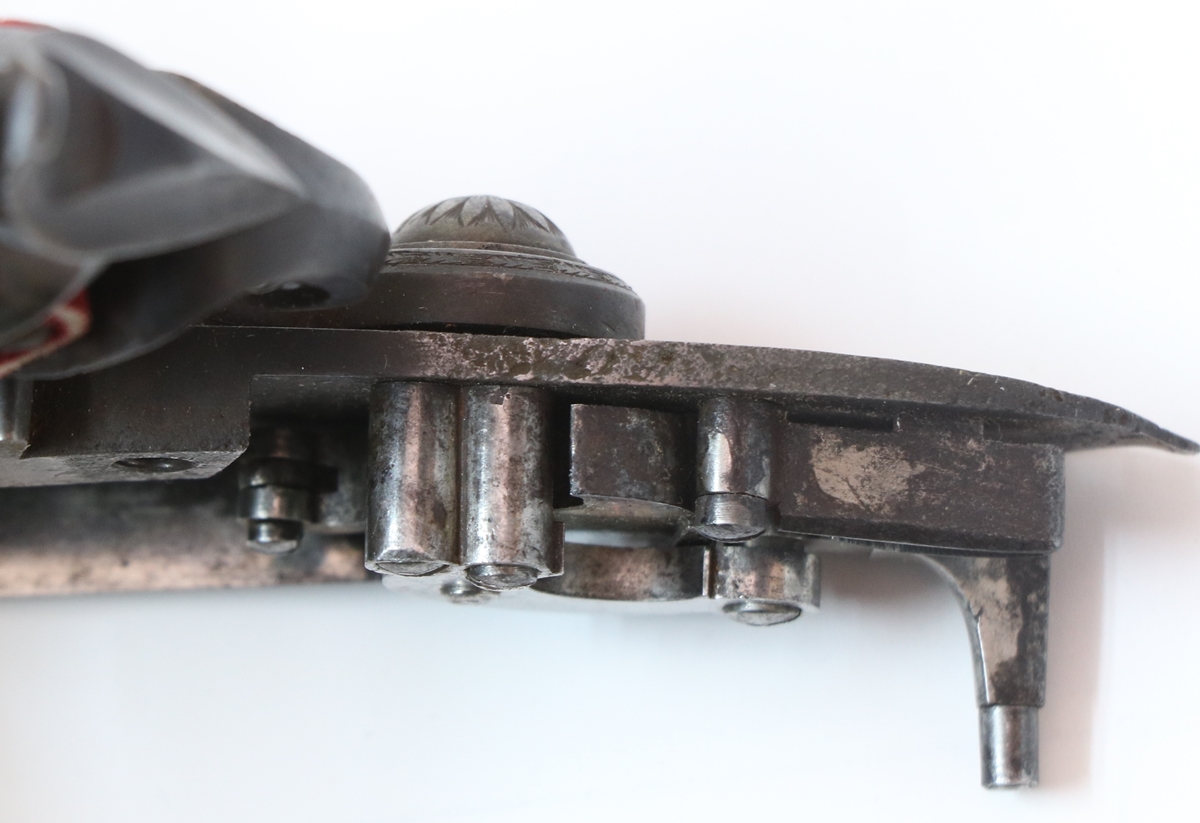

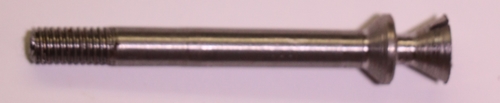

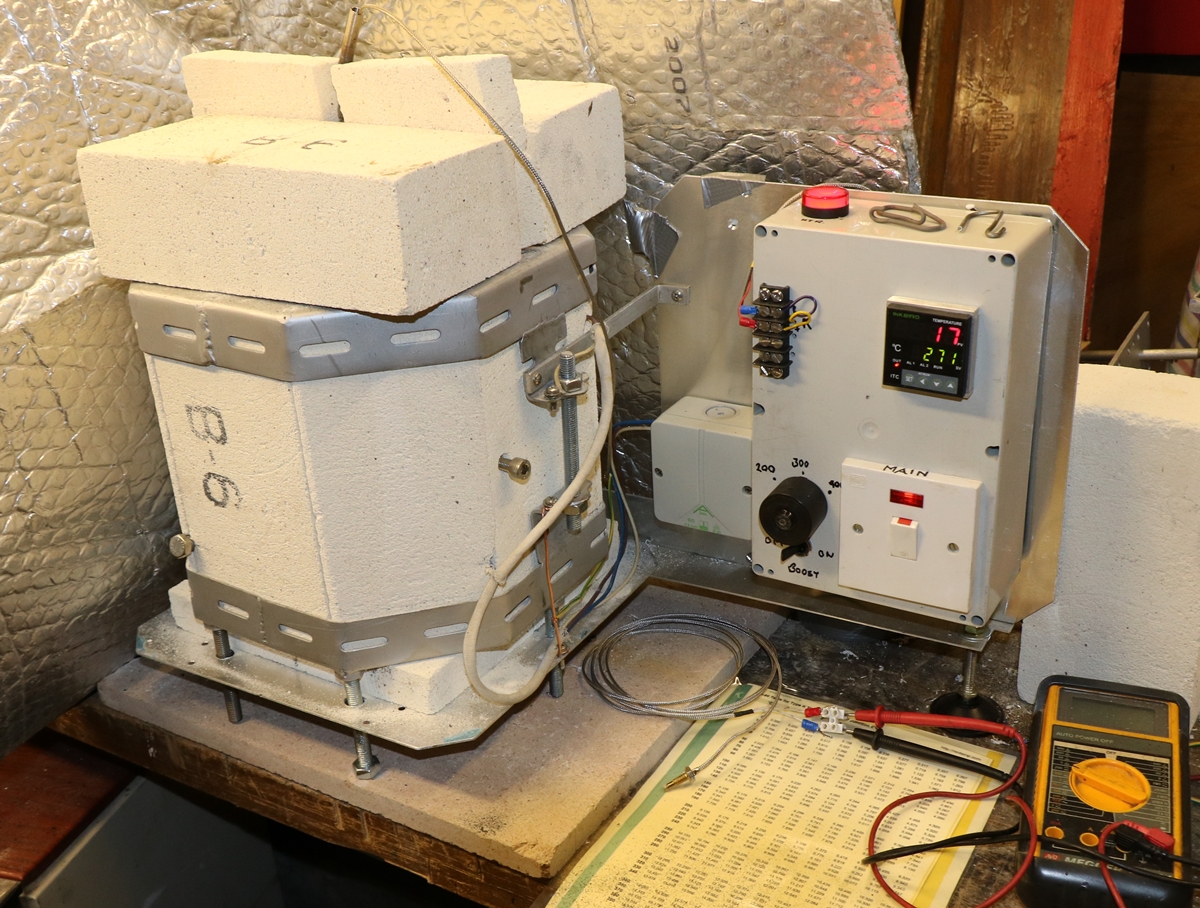

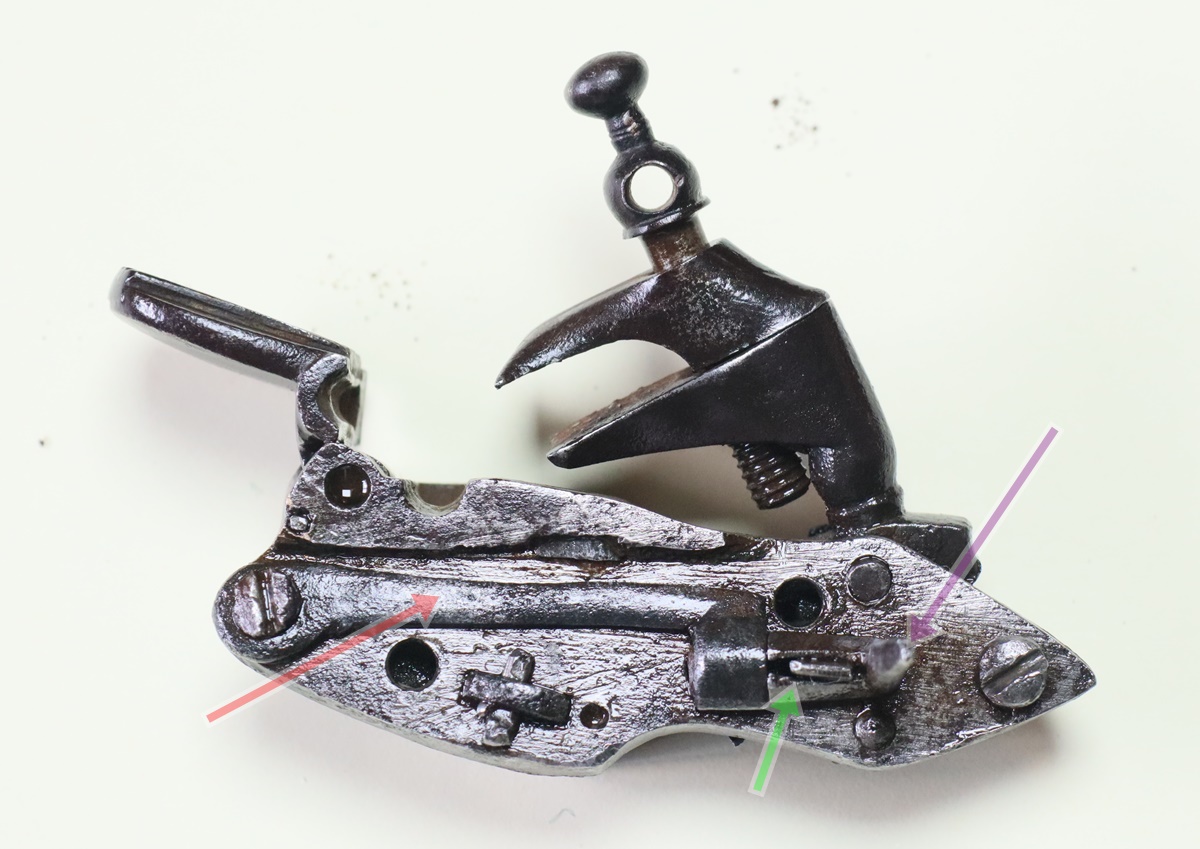

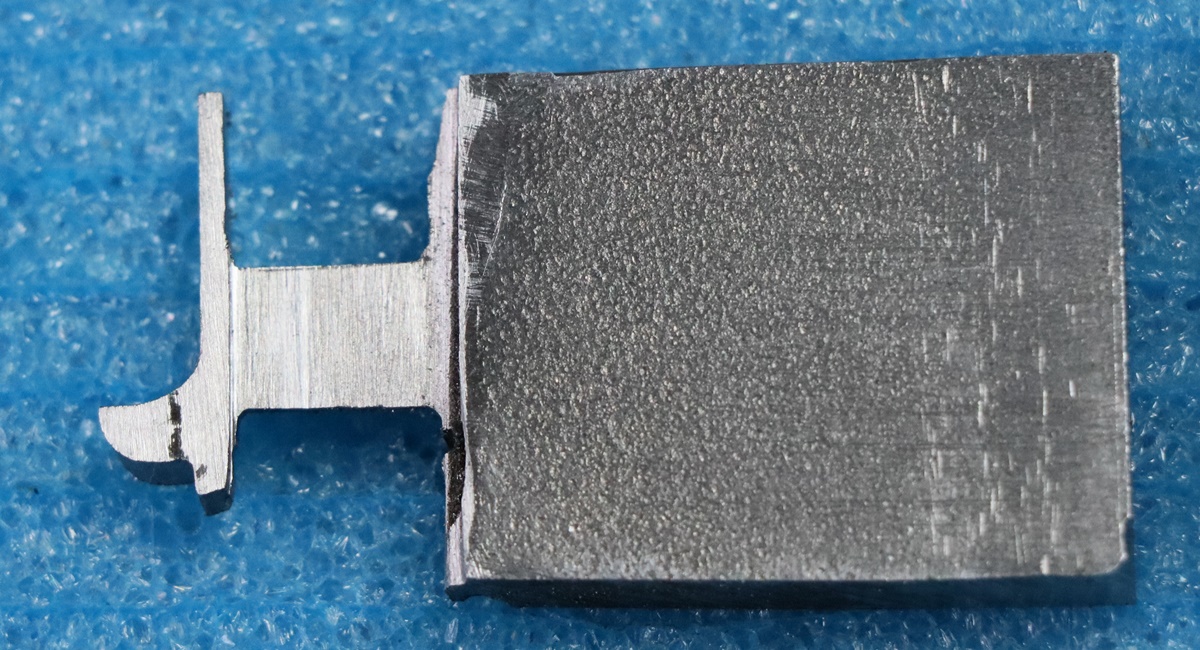

6th November. I was asked about safety catches on muzzle loaders by a correspondent, so I thought it was time that the website had something gun related! I’ll start a separate post ‘Muzzle Loading Safety Catches’ but in the meantime here are a couple of examples that come to hand. The ‘standard’ safety e.g. on pistols like the Andrews described on this site being back converted to flint – acts to lock the tumbler in the half cock position when the slider situated behind the cock is slid forward. The slider moves in a groove cut in the outside face of the lock plate with a tab passing through a slot cut through the lock plate within the groove – the groove and slot define the movement of the slider. A ‘ bolt’ is fitted on the tab of the slider on the inside of the lock and held by a pin. The bolt has a protruding square that engages with a slot in the tumbler when in the forward, lock, position. There is a small triangular spring which attaches under the head of the screw that secures the sear spring and covers the V of the sear spring. It has a small protrusion on the inside of the spring that engages with depressions in the bolt and acts as a detente to hold it in either the safe or fire positions. The spring has a small notch near the attachment hole that engages with a small notch in the sear spring and helps to hold it in the correct position. The safety spring is a very fiddly thing to make on account of the small protrusion and detailed shape.

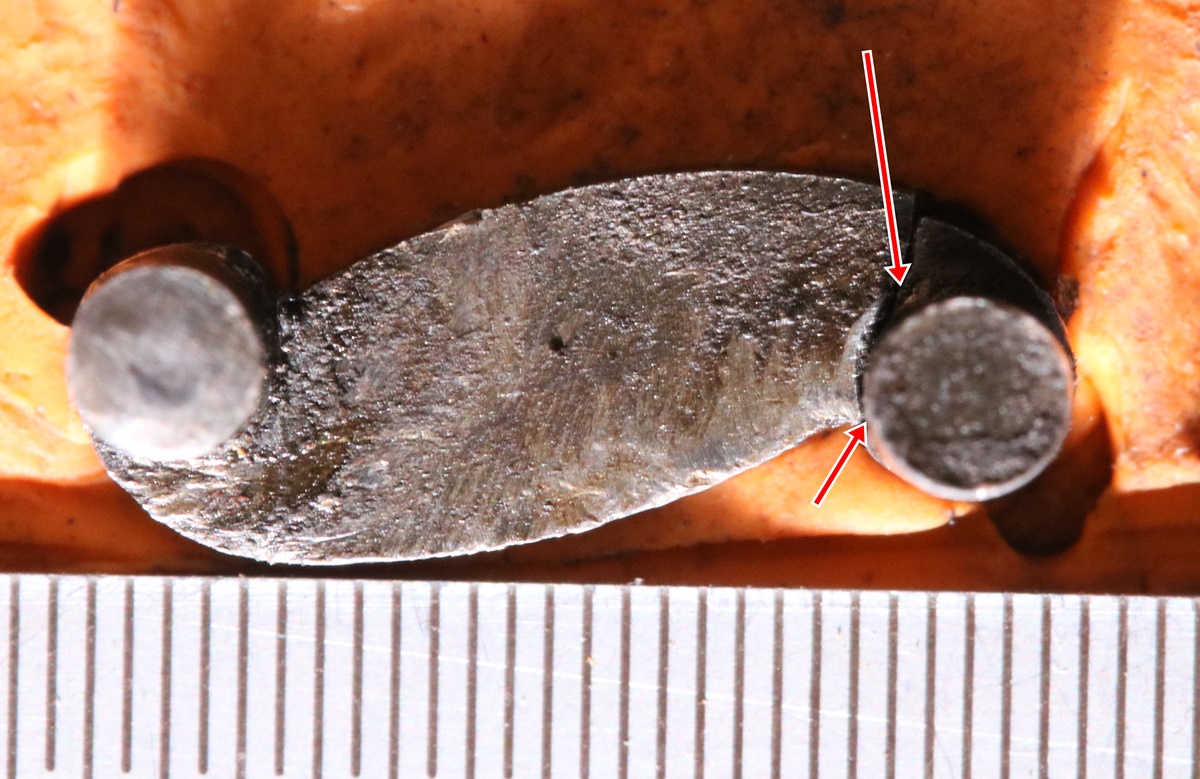

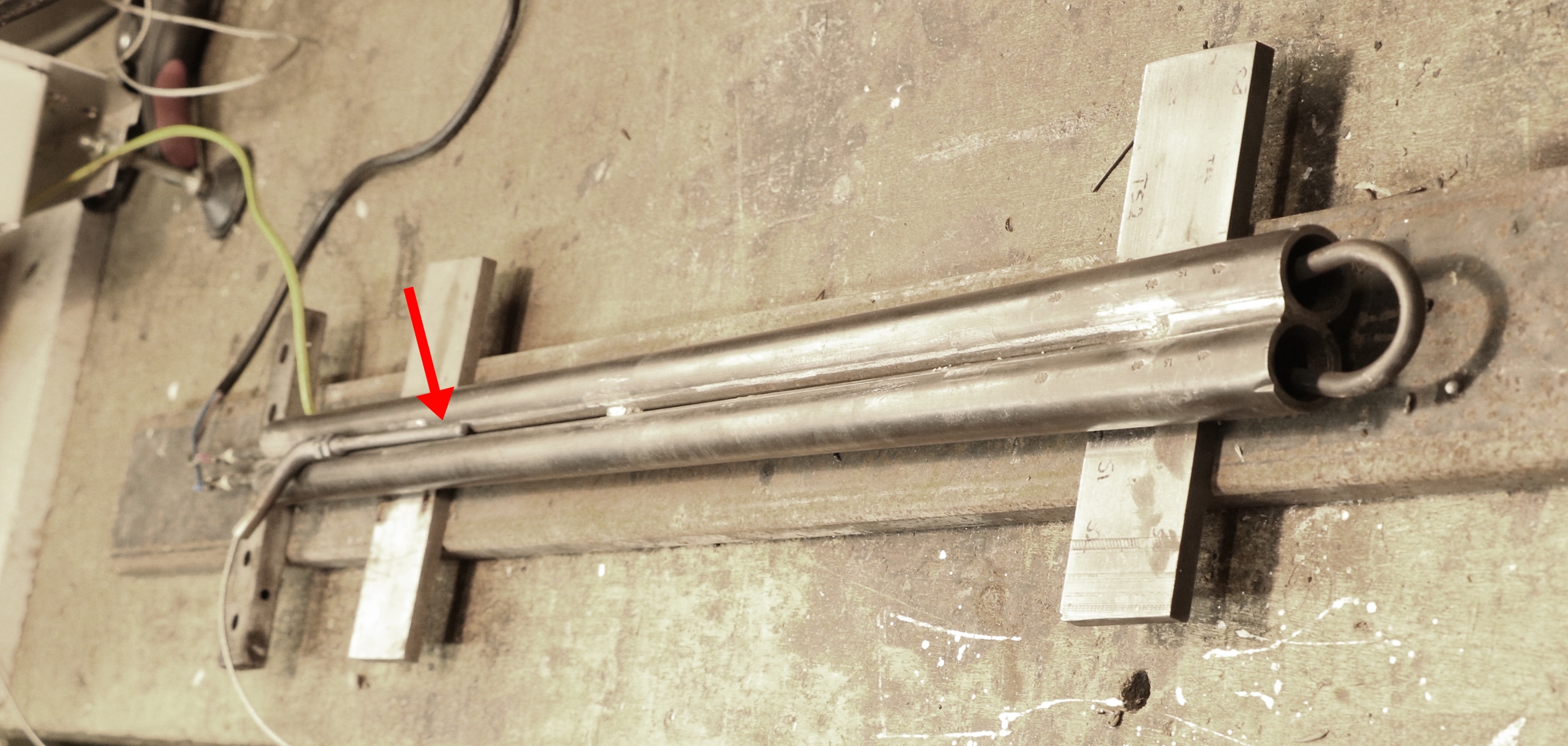

looks like a bit of rust on the safety!

The safety catch spring sits over the V of the sear spring.

The bolt on the back of the slider is held by the pin you can see. The tail of the bolt is shaped as a detente for the spring.

The next example will have to wait – I’m exhaused by all the building work!

5th November – Went with Giles to take the cast iron bath (in 2 parts) to the skip, so we struggled to get it out of the flat and down the stairs on the stair climbing sack barrow and just managed between us to lift it into the land cruiser. At the dump we got it out, and one of the dump men came and gave Giles a hand getting it up the steps to the skip – I think he then decided we were wimps because he then picked up the second half, put it on his shoulder and took it up to the skip and threw it in – we felt rather deflated at our pathetic attempts to lift it – office work doesn’t prepare you for heavy lifting. I was still a bit stiff from walking through thick gummy mud yesterday on the shoot with a Kg of mud on each boot – driving back I got bad cramp in my right leg – I had cruise control on but thought I might have difficulty braking in emergency – anyway a lay-by appeared before I panicked!

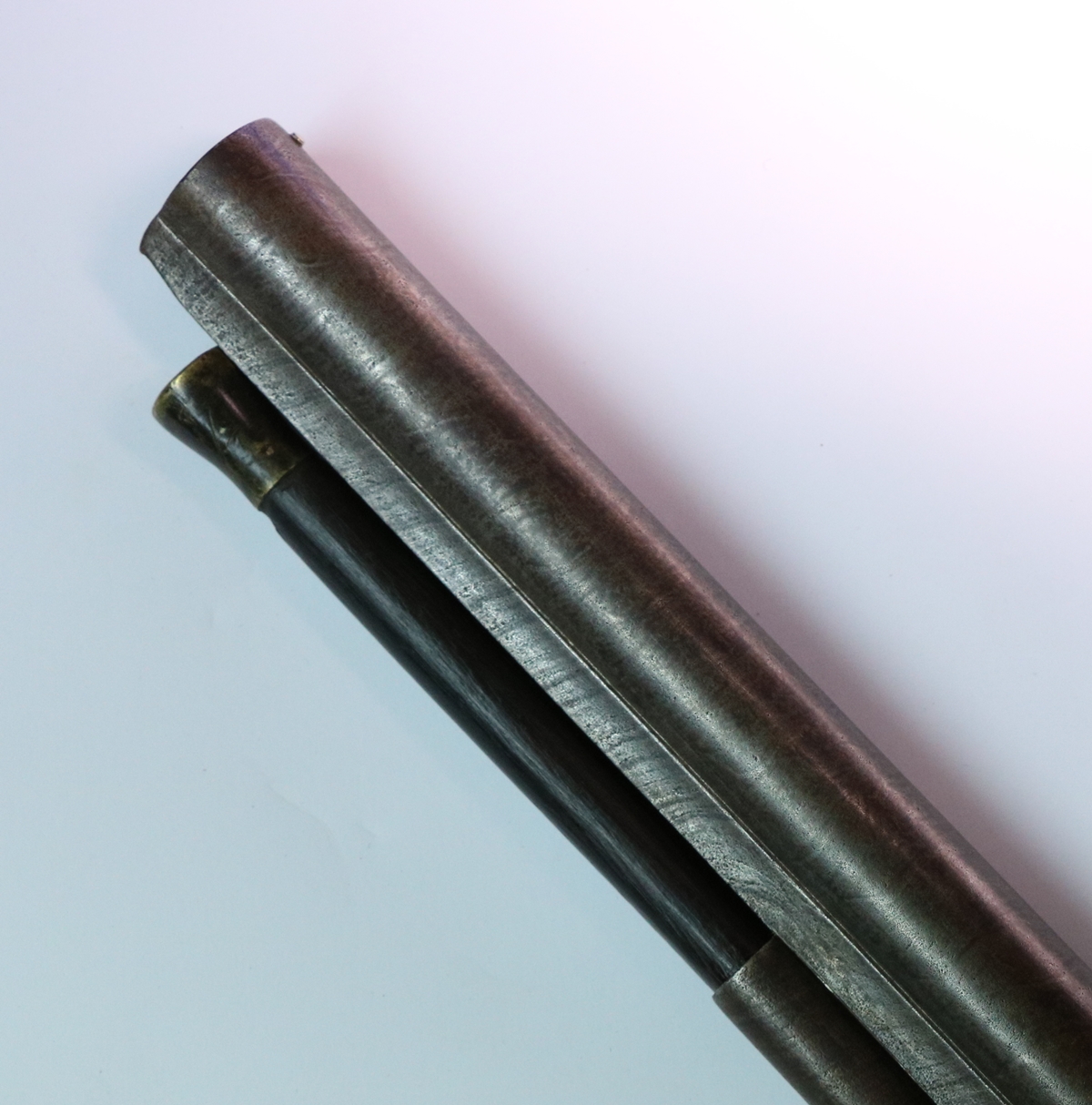

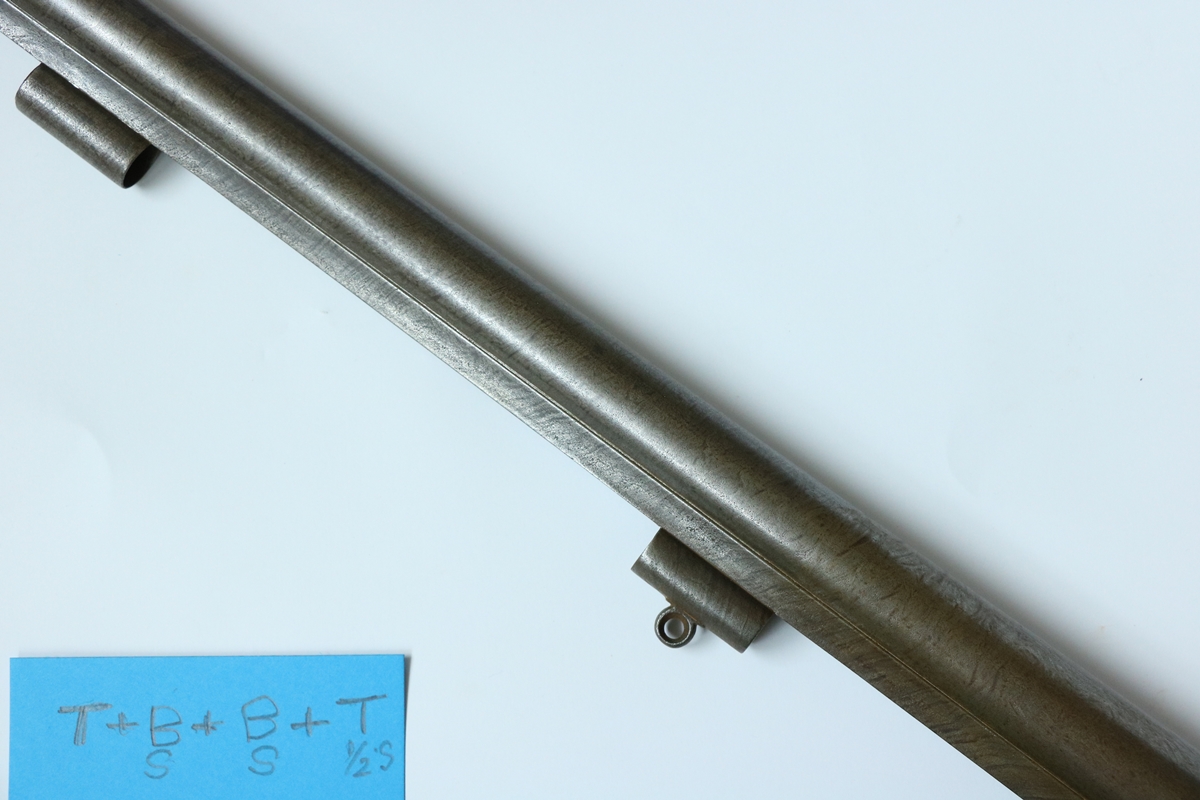

4th November – apologies for going AWOL….. busy & then some! Just come back from a splendid shoot near Beccles organised by one of our AML group. Quite damp, but not enough to spoil the day although by the end there were a couple of guns that had started to hangfire or misfire – the guns were quite wet, and mostly had to be carried from drive to drive inside a damp slip, so not ideal for their welfare. My Egg double 16 bore performed impeccably as usual (touch wood) – the only problem I had was when I forgot to put any shot in one barrel! about simultaneously Martin double shotted one barrel of his gun – probably just coincidence, but who knows? By the end of the shoot my Egg had developed a light pattern of rust spots on the barrels – it had been lightly oiled but obviously not well enough! When I came to clean it the spots merged into the browning after a bit of work with grade 0000 steel wool and oil, but I’ll be more careful to do something more protective next time there is rain about on a shoot! My shooting wasn’t too bad – I wasn’t on very plentiful pegs for several drives, although my peg partner (double pegging) managed two right & lets in good style – I had enough good shots to make the day both enjoyable and satisfying! I need a rest tomorrow, but its the only chance to get help taking the bath to the dump! I feel terrible about cutting the bath in half – I can hardly maneuver the lighter half, the whole thing must have weighted around 100 Kg. and apart from the enamel was in perfect condition – the casting was a very even 7 mm in thickness – a masterpiece of the casting art! Anyway we’ll try to get rid of it as its taking up space we need to work in. The windows are going to be fitted on Monday, so that is another bit of progress. I’m going to have to do my VAT tomorrow as I got a nasty letter from the vatman saying he was watching me! And so on…………

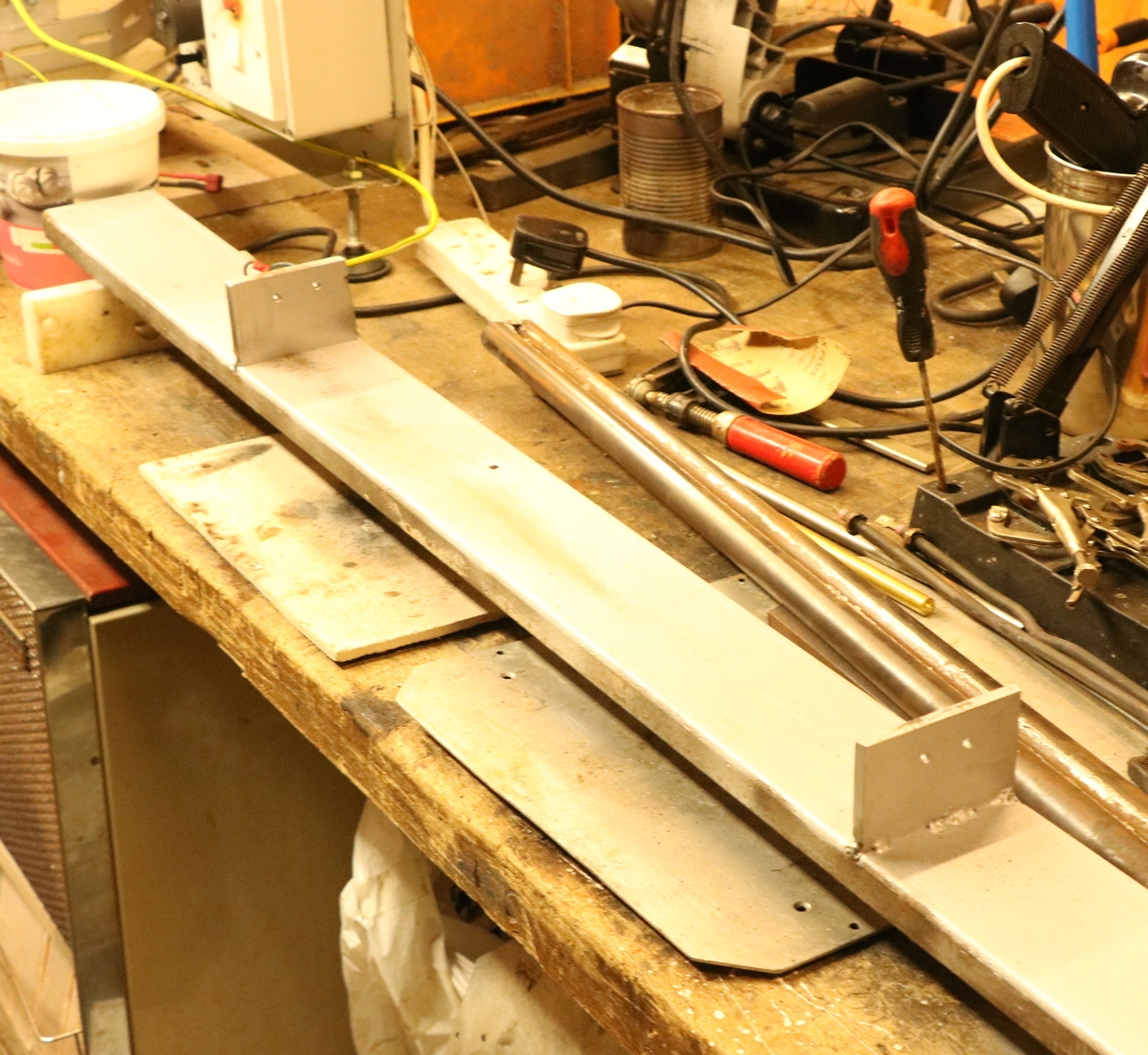

1st November – Another month gone! Still destroying Giles’s flat with abandon! The kitchen has paused and I am now reducing the bathroom to a shell. I spent most of today unplumbing the bath and washbasin, having taken most of the tiles off yesterday. In order to disconnect the bath and basin I had to remove most of the original plumbing, including some in the almost inaccessible service duct – very tedious! Having done that I tried to lift the full sized cast iron bath but it was jammed between the walls and very heavy – desperate situations call for desperate measures so out came the angle grinder and I cut the bath in half- I was amazed that it was so easy and only consumed a couple of disks, but it made a horrible dusty mess! I don’t know if I’ll be able to move it now – I went home immediately I’d done it and had a bath! My evening reading of one of the Badminton library books of the 1870s is quite interesting on the subject of gun cleaning, which seemed to consist of a lot of use of paraffin – two things seemed odd, one was the use of felt covered rods that fitted snugly in the barrels to keep them rust free (!), and the other was running mercury up and down the barrels to form an amalgam with the lead and thus remove it. Apart from some use of neatsfoot oil they didn’t seem to have any good oils, although it did mention the possible use of clock oil – presumably one of the only non-gummy oils available. Wikipedia explains that neatsfoot oil is extracted from the feet and lower leg bones of cattle and is used because it is liquid at room temperature, unlike the rest of the fat in the animal’s body – the lower legs and feet not being kept at full body temperature – so now you know – another pearl of wisdom courtesy of cablesfarm! I have another shoot this Saturday in Norfolk – I’m going to have to acquire some more No 6 shot after this one although I’m not sure where from as the carriage charge is so high!

Desperate measures! It was surprisingly quick and easy with 1 mm blades.

30th October – I’ve been oiling the worktops in Giles’s flat with linseed oil and driers (terbine) using paper kitchen roll and wearing latex gloves – the finish is coming on well, although I’m not sure it will be robust enough – any way the point of mentioning it is that I was aware that any rags soaked in oil could in theory ignite so I didn’t leave them in the flat but bought them home to light the woodburner – when I picked them up a couple of hours later they were very hot! I carefully put today’s on a piece of metal and bought them home again – this time they were cold but the paper was badly scorched and brittle! So be warned – the most dangerous combination is when fine steel wool, itself highly inflammable, has been used with linseed oil mix to rub down a stock. I burnt a hole half way through a 3/4 inch MDF benchtop with a spark from a grinder landing on a dry lump of 0000 steel wool the size of a bar of soap – I was lucky not to burn down the workshop as I didn’t see it ’til days later! – with oil it probably wouldn’t need the spark).

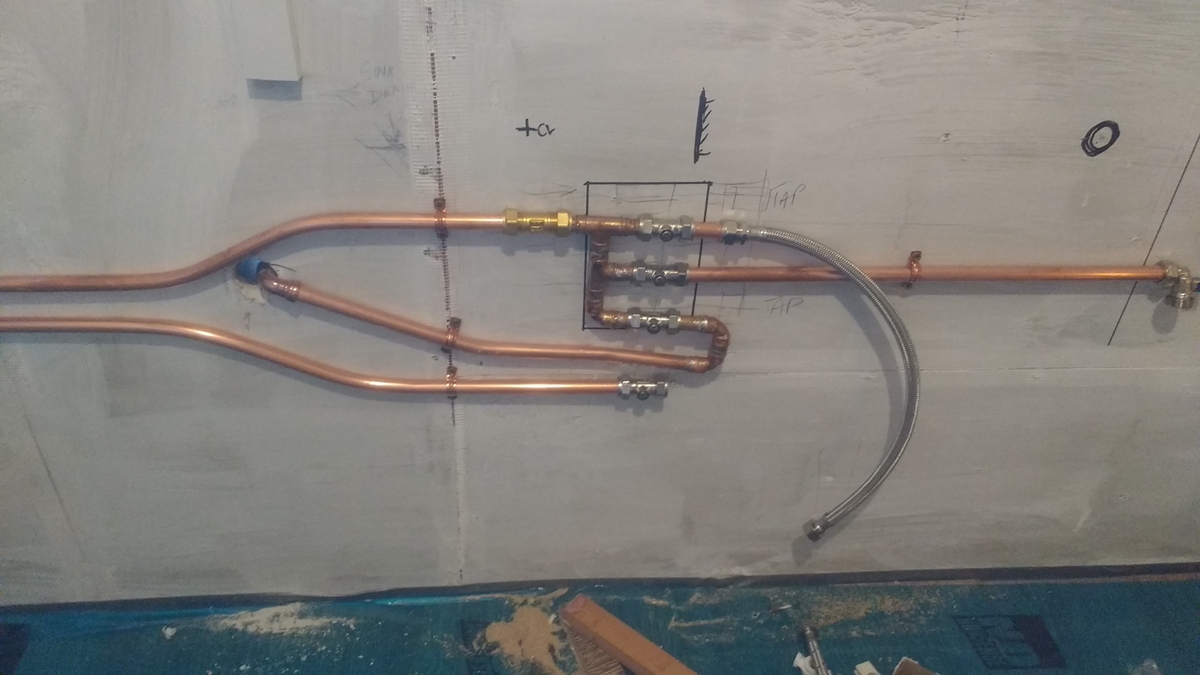

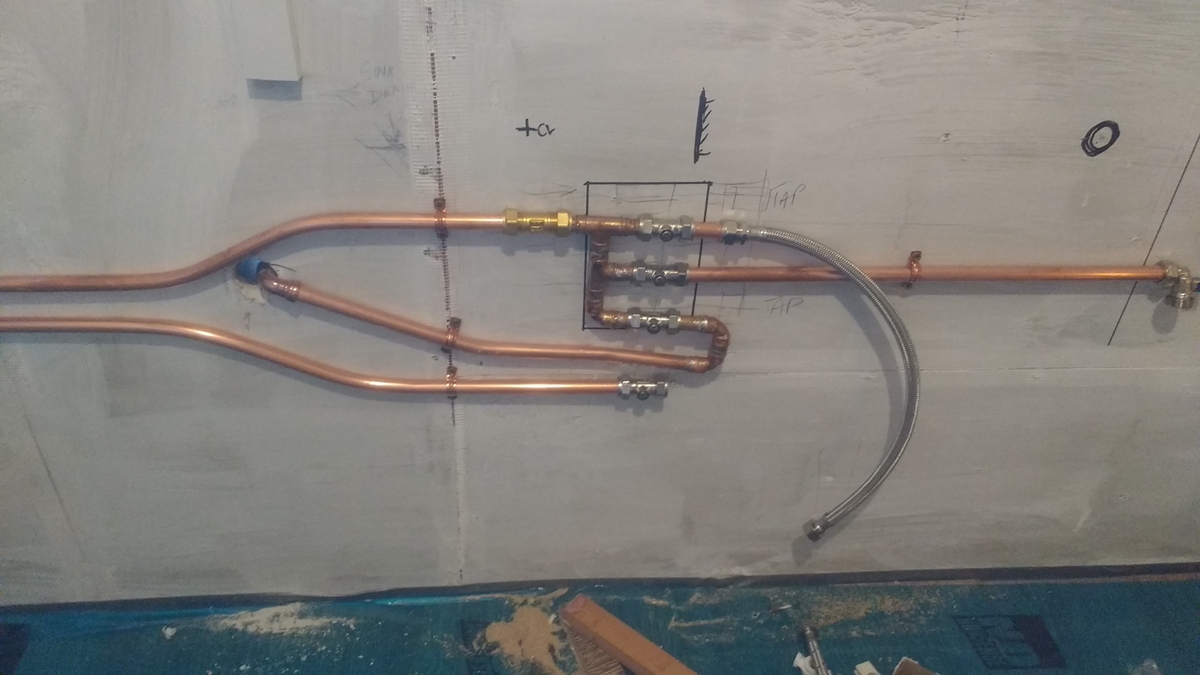

29th October – Handed back the Hawkes and Mosley pistol today and realised it was the dead spit of the Andrews pistol I reconverted – they were a pretty standard pattern of heavy personal protection pistols – presumably carried on horse or in a carriage, but not in the pocket! My shotgun and firearms and explosive certificates all need renewing together in January so I shall find out if my GP tries to charge me for a letter! I’ll use it as a good opportunity to sort out what could be returned to section 58 and what to include on the FAC from section 58. Shotguns are no problem but its a hastle to change the FAC so I might as well get it right. I gather that the Cambridge Gun Club is planning to open a pistol range in January, and there are several people wanting to shoot muzzle loading pistols, so I might see what I have that would be fun to shoot – the trouble is that I’d really like to try all my antiques, but that involves a lot of paperwork! Went to the flat with Giles and agreed on the bathroom layout and units in about half an hour – I guess choosing the wall & floor tiles will take a lot longer! I am planning to put down underfloor heating as its easy and out of the way – it is of course a very low wattage so not sure if it will provide adequate heat – I’ll probably put in an electric towel rail to supplement it, then if necessary we can install a bathroom fan heater (- we have one at home for really cold mornings). I got the instant water heater plumbed in yesterday – as usual there is one compression joint out of a dozen that leaked a bit, but I think that is now OK – I forgot to turn off the stopcock when I left, so I hope so!

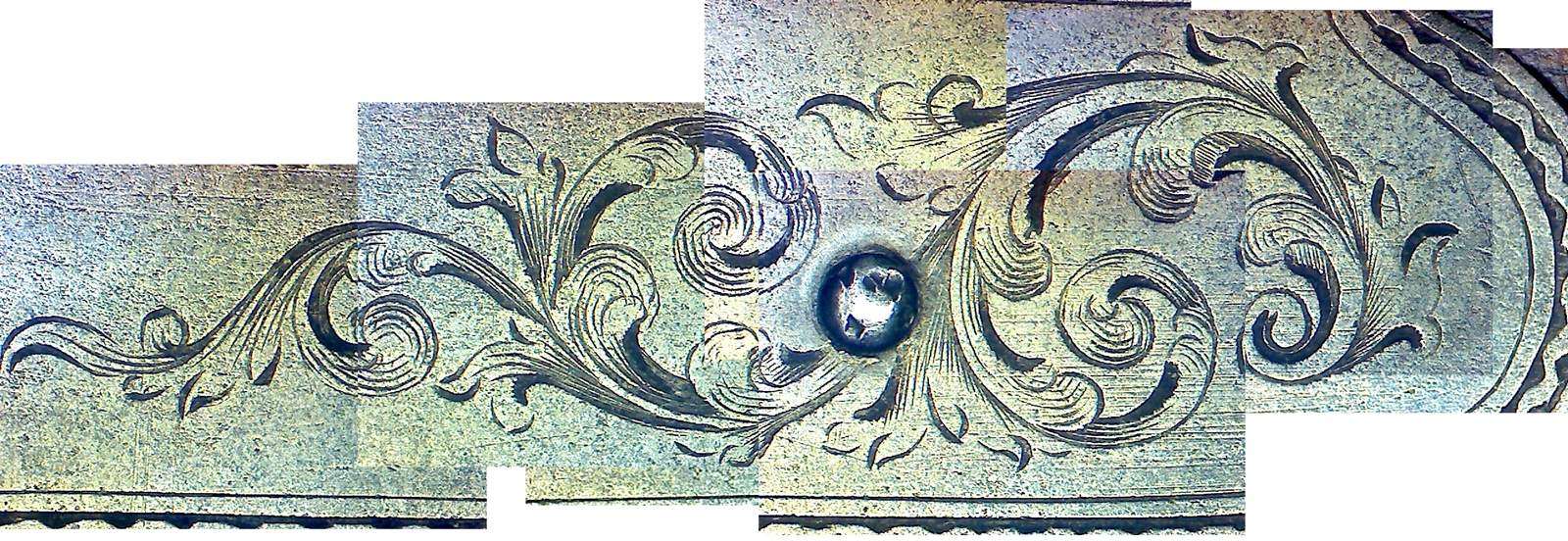

27th October – I collected the Hawkes and Mosley pistol from Dick and touched up the engraving on the cock – I hadn’t touched a graver for weeks but fortunately it wasn’t a complex job! Anyway the pistol looks great – when seen in the flesh it’s complete transformation without any fakery – the best sort! Photo below and a few more in the post on the pistol. I had a further email from my rifle club about the medical fee – the police are NOT asking for the fee, and in fact tell applicants not to pay it, and that it won’t change anything! Well done them. AML shoot tomorrow – its the Big Bore competition so I have got out my Gasquoine and Dyson 6 1/2 bore and made a batch of wads and cards and semi-wads out of cork table mats. I can’t remember if I can shoot with it or not – when I mount it my eye is above the sight line, so it will shoot high – I have put on a butt extension to correct it slightly, but the pigeon guns were designed to shoot high as the birds were always rising. I’ll probably load 3 drams and 1 1/4 oz of shot, maybe 3 1/2 drams – I’ll see. I really should stick with my usual gun as I do need the practice for game shoots – I am beginning to get a much better image of what the ‘bird’ should look like when I pull the trigger, so maybe the penny has dropped at last! Work on the flat continued – I was plumbing in an instant water heater but couldn’t find a fitting that mated with the inlet and outlet connectors except a flexible connector, which I used on the outlet side. The male 1/2 inch nipples on the unit look as if they should take a tap connector but the hole in the middle is too small for the nozzle of the tap connector – I’m sure there is a proper solution, but I just made a modification of the tap connector on a service valve and it fits fine for the inlet. There is the usual one leaky compression joint as usual – probably because the alignment isn’t perfect! One of the joys of working on the flat is that there is a fantastic boulangerie and patisserie – Maison Clement- just 70 steps from the door ( once you have gone down 4 flights of stairs) so my treat of the day is a trip out to buy the paper and have a cappuccino and pain au chocolat at 11. It also means I can pick up a decent loaf and don’t have to bake bread twice a week! Simple pleasures……

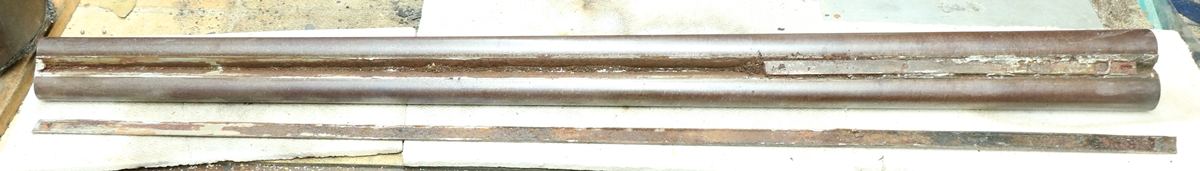

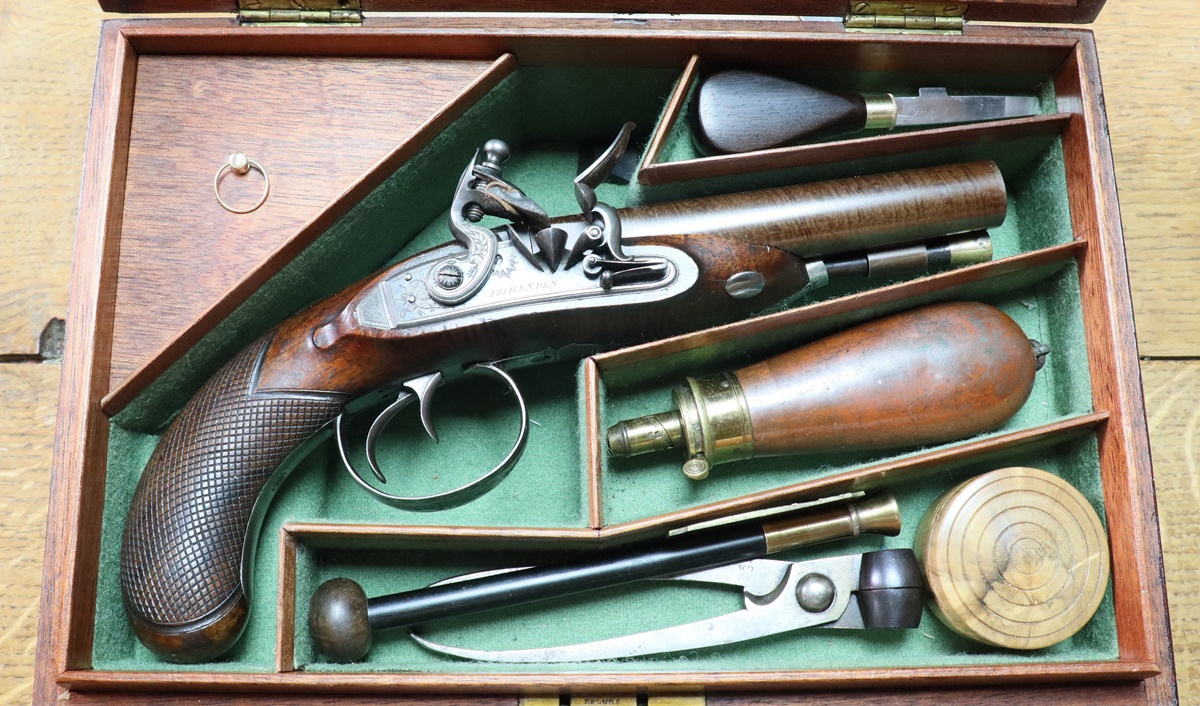

26th October – The Hawkes and Mosely pistol is now ready for return to its owner. The barrel has been lightly struck to restore sharp corners and it has come up with a beautiful twist. The damage to the wood came out with gentle steaming and its been lightly refinished to even it all out. The cock has been precision welded – it turned out that it was a break in an old weld repair, which is better than the more common brazed repair that needs extensive clearing out to get rid of the braze. Anyway it is a very neat weld by Jason and I doubt it will fail again. I am sure flintcocks fail because they are snapped off without a flint or with the frizzen open so that the cock comes up hard on its stop and inertia puts s strain on the back of the cock. If there is a proper strike of flint on frizzen the cock is substantially slowed at the crucial moment of impact. If the breaks were due to the impact of the flint on the frizzen then cracks would open on the other side of the cock, nearest to the frizzen – and that is very unusual. I have to pick the pistol up tomorrow and I’ll photograph it then. Work continues on the flat – we have now hit a snag with the location of the gas hob in relation to the units potentially not complying with new regulations, so probably have a bit of a rethink….. I removed the hot water tank today – to my surprise is seems to be made of fibreglass or similar and to be rectangular – its very shallow – less than 2 feet tall – and encased in a rectangular hardboard box with foam insulation with a plastic cold water tank above – obviously a ready to install unit with built in immersion heaters etc. Anyway its now gone and will be replaced by an instant water heater – it didn’t work a proper shower anyway so no loss.

25th – More flat work ( not what it means in the racing industry) – got thesink plumbing working – there is always one compression joint in a system that insists on weeping ever so slowly and resists efforts to tighten it – I had a bit of a battle with one joint this afternoon, lying on my back on the floor with a head torch watching for a tiny meniscus to grow – its a real contortion as I wear bifocals and so I can’t look up and focus on things close by! I think I fixed it but I’ll see in the morning – I wrapped the joint in tissue. The island worktop is now in place an the oiling process has started – its amazing how uneven the absorbance of the tops is – its what is incorrectly called butcher block – proper butcher block is of course end grain beech. The next problem is getting two waste pipes – from the dishwasher and washing machine – into the waste system with only a single inlet – I have now got hold of a non-return valve so I can plumb one directly into the waste pipe downstream of the U bend.

24th October – The Land Cruiser MOT gave me a bit of a scare as the mechanic said it needed the front wheel bearings replaced – as I had spent a small king’s ransom having the front wheel hubs completely rebuilt six months ago I was getting ready to do a bit of forensics and get legal – but it turned out that they just needed tightening – still shouldn’t have needed it but…………. anyway my number-plate lights obviously passed muster! One LED bulb is in a TicTac box and the other in a wee sample bottle – all held together with silicone sealant! Giles’s flat is now has a virtual kitchen – just needs the water, drain, gas and oven connected and the appliances fixed, plus the window and fix up some lighting. Then I have to remove the hot water cylinder and put in a 10.8 Kw instant water heater for shower and sink and build a couple of cupboards in the space it occupies…… and re-do the bathroom… and rewire the living room and skim coat it and put in a fancy fanned storeage heater…………….. and then re-decorate everything (except the kitchen, which has been done…….

Worktop in the foreground has to have its corners radiused and then it can be oiled to match the others.

23rd October – Just had an email from my rifle club saying that Cambs Firearms Licensing are ( at random) asking GPs for medical information when they receive a renewal or new application for a shotgun or firearms license and either they, or the GP are asking holders for a fee for supplying the information. This is contrary to Home Office Guidance and to the agreement made by Doctors representatives with the government during negotiations. The advice from BASC ( https://basc.org.uk/blog/press-releases/latest-news/basc-urges-members-not-to-pay-gp-fees/)and clubs is that you should not pay. If you don’t pay the firearms officer must, if a letter to the contrary is not received from the GP within 21 days, assume that there is no medical reason to withold a certificate…….. Giles’s flat kitchen has started to look a bit better now – the tiling is done, the worktops are in and the wiring is functioning – I was particularly pleased with the bank of switches and sockets in the tiles that have slate effect pop-on fronts and line up and fit perfectly – as Giles’s cousin says, it is a masculine looking kitchen, but that is appropriate! Inspecting the consumer unit I discovered that it only takes circuit breakers and switches etc that are of one particular make and design – I really hate proprietary bits and pieces – I found that the consumer units in our house were a proprietary design that became obsolete about ten years after fitting, so spares had to be located at great expense. The electrics in the flat were a bit hairy – there is a protective RCD on the power sockets, but the metal radiant heater on the wall of the bathroom has none! I am fairly gung-ho about some risks, but that is a step too far for me!……… I came home from the flat late and had to fix the number plate light on the Landcruiser as it has to have an MOT tomorrow – like many old LCs the bottom of the lift up back door is rusted, so I had to do a bit of improvising – I had some suitable 12 V LED bulbs that fitted, so was able to cobble something together – probably a better light than the original – lots of silicon sealant was used – enough said! Probably time for an upgrade, although the Land Cruisers have been on a downward trajectory since they started adding more and more fancy bits and pieces of electronics.

The American Walnut worktops are getting an oiling that would do justice to a Purdy – it may be some time before the sink and hob are fitted! The grain of the American is much more open that that of the European Walnut and the oil just gets sucked in in patches – I’m applying a little talc and a drop or two of driers with the oil to fill some of the grain – at the moment when you wipe off the excess it leaves a beautiful satin finish. Protecting it from dust is a bit of a problem! I probably should have centered the right hand sockets etc on the vertical tile joints at top and bottom – never mind, that would probably bring them too near the hob. The extractor duct is a little inelegant, but there is no where else to put it – the ceiling is cast concrete and its a party wall. I haven’t yet figured out how to get my phone to focus!

20th October – Still a lot to do to the kitchen – the nearer it gets to completion the more jobs emerge from the woodwork, so to speak. We have started fixing the units in place, and I’ve done about half of the second fix electrics and made reinforcing angles to stop the worktops bowing. Giles has painted the walls and ceiling. We need to sand and pre-oil the Walnut worktops before they go in, then we can fix the tiles after cutting them round the electrics, which will be quite a challenge. We ordered the kitchen window from ‘supply- only.co.uk’ and they told us a week ago that it had gone into production – when Giles rang today to ask for the delivery date they said that they had to order the sections in because we had ordered black, and there was something wrong with the specification – which they didn’t seem to be clear about. So that is still some time away, so much for 3 week delivery! I can see that Sunday working is called for this week! Even so it won’t be finished by Monday…….. Evening reading has now taken in hunting all the Indian animals that it was possible to hunt in 1890 – It was unsporting to shoot wild boar then because they were hunted on horseback with spears – pig sticking. An elephant charge was described as magnificent, although presumably less so if you are the focus of the charge. Apparently it is possible to shoot an Indian elephant head on, whereas an African elephant has a bony mass at the root of the tusks that stops the low velocity 8 bore ball (driven by 12 drams of powder, no less). By 1890 the writing gives some clues that big game hunting was recognised as not altogether good for the natural balance of things, and there was a concentration on collecting specimen heads and skins of the largest specimens – which mostly took out the older males, which is more or less what culling does now.

It doesn’t look much like progress – but it IS coming together, we keep telling ourselves! My plastering doesn’t look too bad with a little local rectification – its now gently rolling hills instead of a mountain range! Its mostly going to be covered up anyway.

18th October – Big push to get the kitchen sorted by the end of the week! It’s beginning to come together – I did rest of the plumbing and we got half of the worktop cut for the sink and the units perforated for the numerous wastepipes and plumbing that wends its way in and out of the cabinets. We have now offered everything up to check where it will fit, but so far haven’t permanently fixed anything. The oven arrived, weighing 55 Kg, but the Hotpoint delivery driver wouldn’t bring it up the necessary last flight of stairs from the lift on his own, and wouldn’t let us help him on health and safety grounds so we had to take delivery on the landing and bring it up ourselves, although he did, perversely, offer to help us ! – John Lewis hadn’t asked us if we had stairs, and had sent the delivery by a single driver. He had already aborted two John Lewis deliveries by the time he got to us and wasn’t in the best of tempers! Another annoyance trying to fit together the folding doors of the corner unit – it looks like a production fault in the fancy hinge parts resulted in a slot being too narrow to fit over a 2.5mm pin – since it will take weeks to get IKEA to sort it out, we’ll take a needle file and do it ourselves tomorrow. As you can see from the photo the new kitchen has a large double oven and a 5 burner gas hob – Giles takes cooking seriously! My evening reading – for as long as I can stay awake – was about tiger shooting in India in the 1890s – I hadn’t realised that India had both lions and tigers in those days. The lion was regarded as as a rather inferior animal and not so much sport to hunt as the tiger which as everyone knows from innumerable illustrations was most often hunted on elephants, with dozens of supporting elephants used to surround the tiger and get it out into a position where it would be exposed, when it often then selectively attacked the elephants carrying the hunters. Makes shooting pheasants seem like a walk in the park, which I suppose it mostly is.

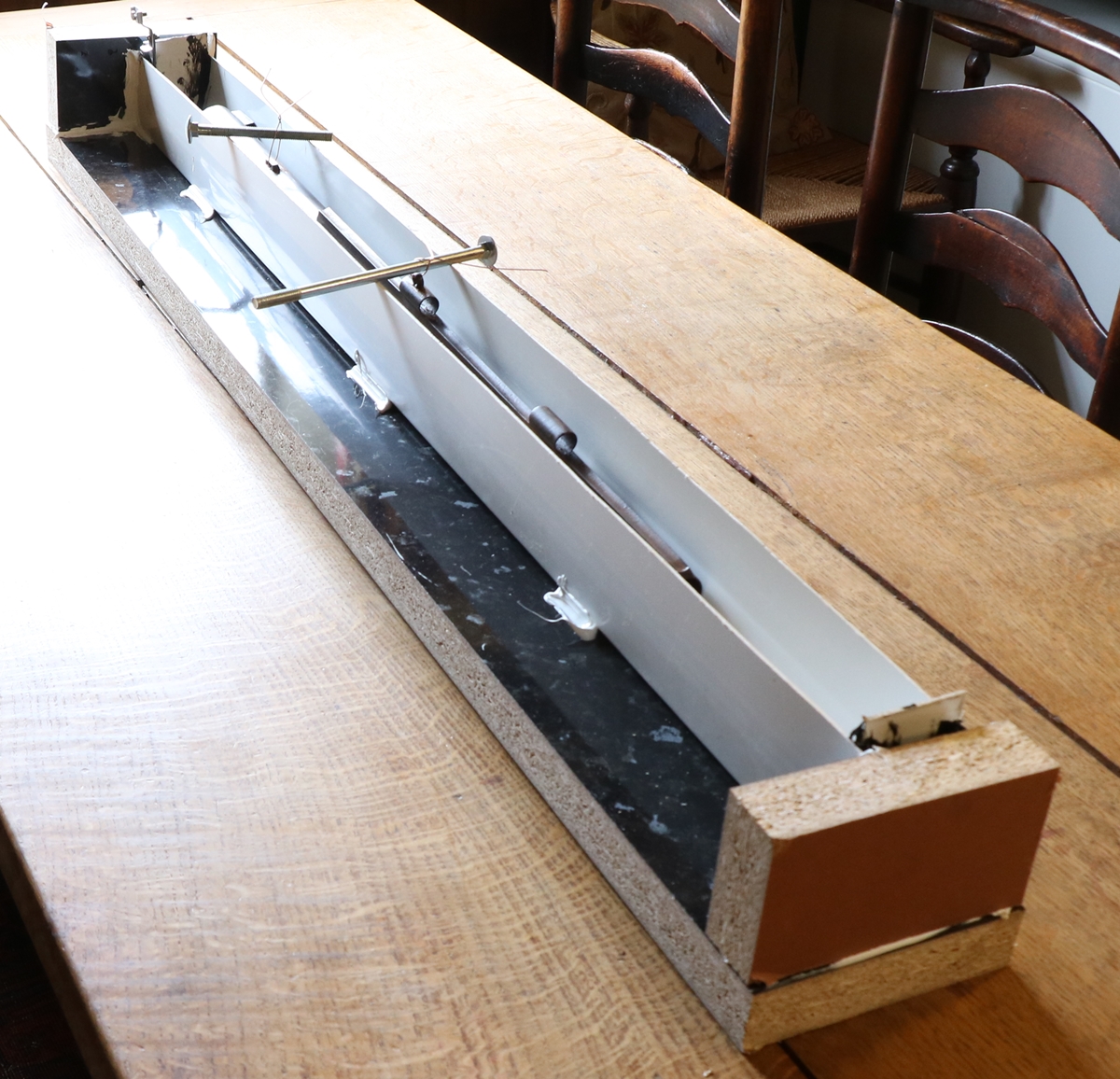

17th October – Had a fantastic day’s shooting at Glemham Hall in Suffolk with 7 other muzzle loading game shooters from Anglian Muzzle loaders on Monday. It started as a driven stand, that was followed by a walk up through sugar beet with half a dozen pointers working the beet field ahead of the guns which flushed a few pheasants, we then crossed a ditch into a beet field that converged on a bit of rough and more pheasants and a couple of partridges – I hadn’t been on a walk-up shoot before and had only seen dogs used to find and retrieve, but these dogs were amazingly well trained to hunt to the whistle and voice, and to point, and were controlled as if on rails. I was amused to see that when retrieving a dead bird, the dogs would point the bird and wait for the command to retrieve before collecting it. Giles’s flat continues to make progress – while I was out shooting he did a round of the ‘white goods’ emporia and bought a hob, oven, dishwasher, washing machine and fridge, all in a remarkably rapid trip! I am concentrating on getting the plumbing sorted – I always seem to end up with dozens of service valves – which are now normal on every tap or appliance. We are putting in a charcoal filter in the kitchen tap supply as the Cambridge water makes horrible tea (regular readers will yawn at another reference to tea) so that is another service valve – total planned so far is 5 under the sink! I just hope my plumbing is neat enough to put a photo on the blog – I normally use ‘Coppefit’ push fittings but they take up too much room for complex pipework so I’ll have to used Yorkshire fittings and solder them for the maze under the sink.

15th October – I went to look at the Hawkes and Moseley pistol that Dick is restoring for me – you would not recognise it as the same pistol, it looks fantastic – the barrel has browned beautifully and Dick restored the flats a little so it looks like new. I was intending to photograph it but by the time we had had a cup of tea the light was too bad. (I realise that tea has figured rather often in the diary of late – I wasn’t aware that I had become obsessed, but then one never is aware of one’s own obsessions!)

14th October – Two weeks into the renovation of Giles’s flat and we are seeing some progress on the kitchen – walls plastered, first fix electrics, floor laid, part plumbing fixed, window opening sorted with vent aperture, and units pre-assembled – definitely time for a cuppa! The aim is to get the kitchen usable by the end of next week when Giles starts his new job and moves in – I’ll carry on with the rest on my own as long as it takes to get the rest of the house in order – the only big job to be undertaken is the bathroom, which needs completely stripping out and underfloor heating installed. Getting a new bath up to the 4th floor will be interesting! I have another shoot on Monday this time partly a walk-up shoot over dogs, which I’ve never done before. This year I seem to have more shoots arranged than ever before – all muzzle loading. I think I am going to try to do a few with a flintlock, but I probably need more practice at clays before I swap! I’m also going to have to get some appropriate clothing for the period. On the mechanics of running this blog site, I was getting about a thousand attempts to hack the site every day – I keep a careful eye on who gets blocked by my security software for trying to hack the site, and every so often I spot a persistent attacker and contact their Internet Service Provider and ask them to stop the abuse – last time it cut the attacks down to 300 per day. It will build up again but by careful checking I’ll probably manage to stop a fair bit of it!

I appear in these photos as they were taken by Giles – not my choice!

The problem of lack of space behind the IKEA units was solved by half burying the waste pipe in the wall – the units are now spaced 25 mm off the wall – allowing space for the water pipes, trunking and half the waste pipe. On the wall to the right they will run inside the cabinets.

My plastering is not so hot – on the first wall I made the mistake of working from left to right so I kept touching the wet plaster with the hawk in my left hand!

13th October – Decided to start skimming plaster on the kitchen walls at 4:30 so didn’t finish till late – now well past thinking….

12th October – beginning to see a bit of progress on the flat – the first fix of the electrics in the kitchen is done and the plasterboard is back – so now its time to skim the walls and lay the new floor, then finish the plumbing of the water – which is fixed to the walls behind the cabinet backs ( there is about 25mm of space max) after which the cabinets will be fixed and the waste plumbing installed completely inside the cabinets – I’m still puzzling over the design of the IKEA units – even with 650 wide worktops we can’t get space to fix the waste pipes behind the units. For my evening reading I’ve been browsing another 19th century Big Game shooting book – this time about shooting in the Arctic, the prey being Walrus and Polar Bears – the author claims that its more sport shooting Walrus than Polar Bears, although by his accounts I’m not sure either sounds very sporting. The problem with Walrus is that their ivory tusks are not big enough to make billiard balls from (!), and that if wounded, even severely, they dive deep and are lost. There is a sporting element, I suppose, in that occasionally one will attack the small boat used to hunt them and puncture it (the boats carried sheet lead to make temporary repairs). The preferred method of taking them was to harpoon them, but that depended on a professional harpooner so didn’t seem to involve much skill on the ‘hunters’ part. Part of the difficulty in shooting them is that the front of the head is a mass of bone and the tusks and is difficult to penetrate – the (small) brain is situated in what looks like the neck. The recommended hunting trip was to leave Tromso in May with a 40 ton walrus boat carrying a couple of the light 20 ft.hunting boats aboard, with a crew of 15, returning in September – the cost was then estimated at £450 but that didn’t include tea! £450 then converts to around $60,000 now, which sounds like a bargain for 15 men and a boat for almost 4 months. Tea seems to be a constant in all Big Game expeditions from the late 19th century – about the only sentiment in the whole ‘adventure’ that I can share!

Things are on the upward path!

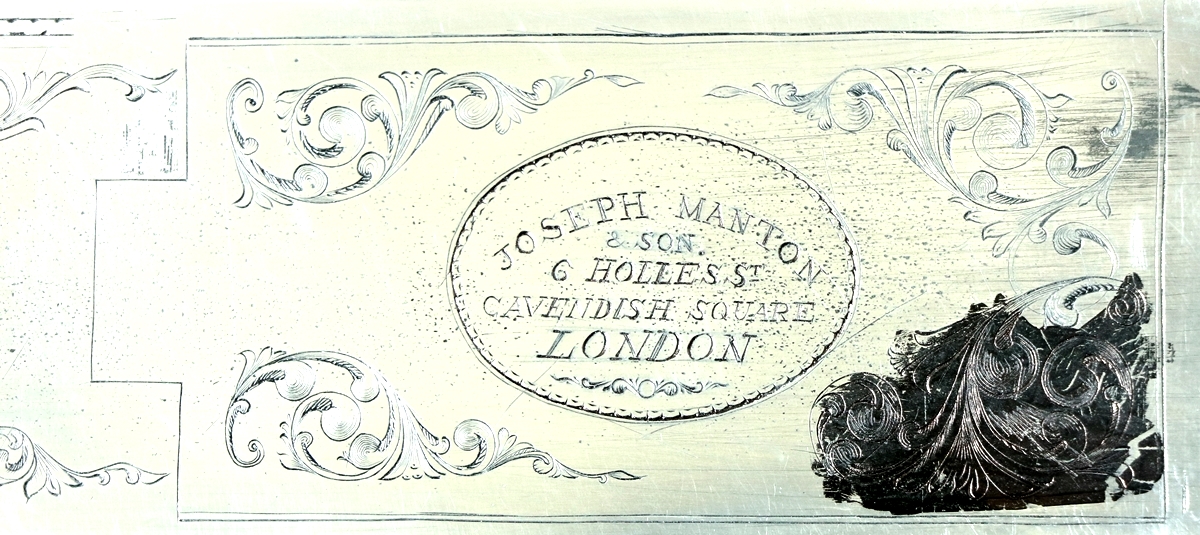

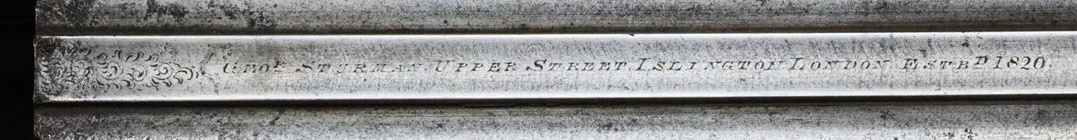

11th October – More renovation – started first fixing the kitchen electrics, it all seems very slow but we are counting on it speeding up when the floor and walls are done and we can move on to fitting the units etc., hopefully by the end of the week if we put in a few extra hours. I had a call from Dick, who has been working on the Hawkes and Mosley for me – he says that the quality is excellent, and the engraving very good – he has struck up the barrel and is pleased with the way the browning is going and the dents and marks have come out of the stock. Unusually the finial of this pistol is clearly poorer quality engraving than the rest of the pistol – this part is usually better engraved than the rest – I always think that it was given to a journeyman to demonstrate his skill, while the rest was banged out on an engraving production line! I will go and photograph it shortly, or bring it back if it is finished – I’ll have to touch up the engraving on the cock where the crack was welded. It promises to be a very fine London gentleman’s pistol – a cross between an overcoat and a horse pistol – I’m never quite sure what to call them – I don’t think they would have been carried about the person but kept in the home or possibly taken on a coach journey – a pretty deadly weapon at close range if you were a good shot – I did try a pair of quality percussion target pistols at man sized targets at about 11 paces ( a typical duelling distance) and while I could hit the area of vital organs (burst a balloon!) reliably after half a dozen shots, four or five experienced rifle shooters who were not used to pistols failed to hit the ‘man’ at all on their first shot – so my guess is that to be of use as anything other than a deterrent one needed to practice occasionally with the actual pistol you intended to use for defence. I feel its time for a bit of pistol shooting, but I have to keep my nose to the grindstone for a bit!

10th October – Doing my duty as a school governor this morning and Giles’s flat this afternoon – struggling to work out waste pipes and plumbing with the awkward IKEA base units – now I see there is the gas pipe in the way too! I had a correspondence with a new recruit to the blog about a ‘rash’ that he had on a barrel he had browned, which I suggested was probably caused by using copper sulphate to etch the barrel in an aluminium container ( the electrochemical voltage between iron & copper is 0.8 Volts, between aluminium and iron its 2 Volts – so plenty of potential for trouble (pun intended)). Copper sulphate is quite aggressive stuff – I tend not to use it as I have had copper plating out onto barrels before and its a pain to get off. I do sometimes use old printed circuit etching solution as a browning, and that is pretty loaded with iron and copper, being based on acidified ferric chloride. French barrels with fine damascus are sometimes deeply etched and left like that, but I suspect they acid etch them. I had a moment this evening to deal with the birds I bought back from the shoot yesterday – they didn’t have any way of selling them so we took as many as we wanted – I took 4 partridges and the cock pheasant I shot (the only one shot), and have crowned them and put them in the freezer – I’d have taken more but its full to brimming now!

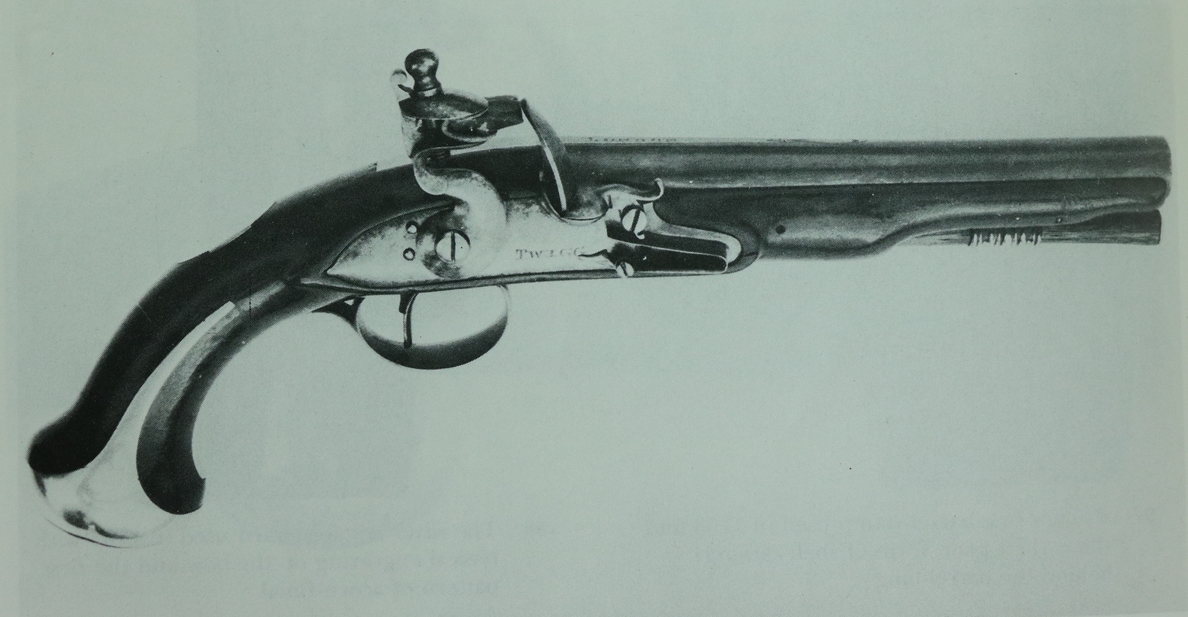

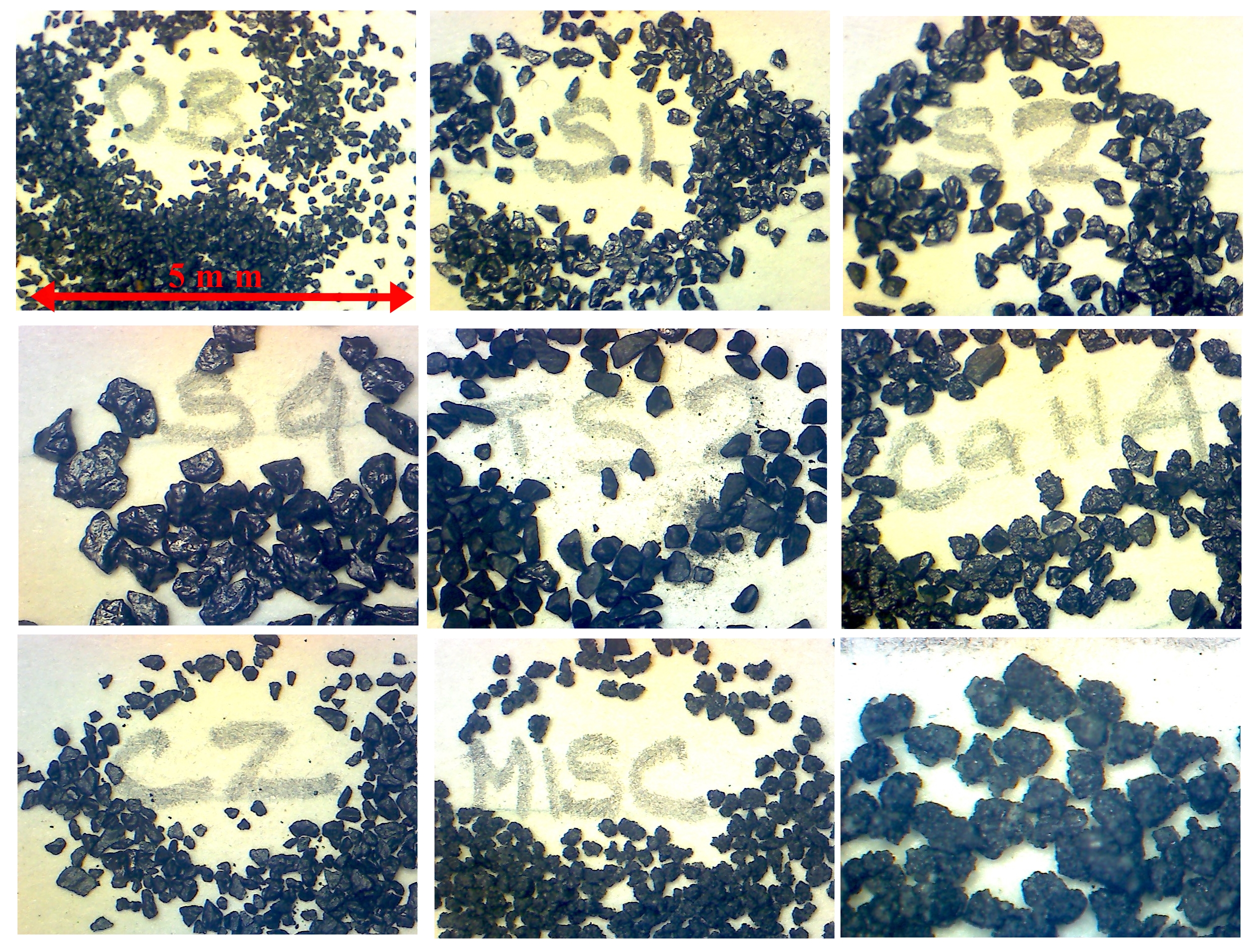

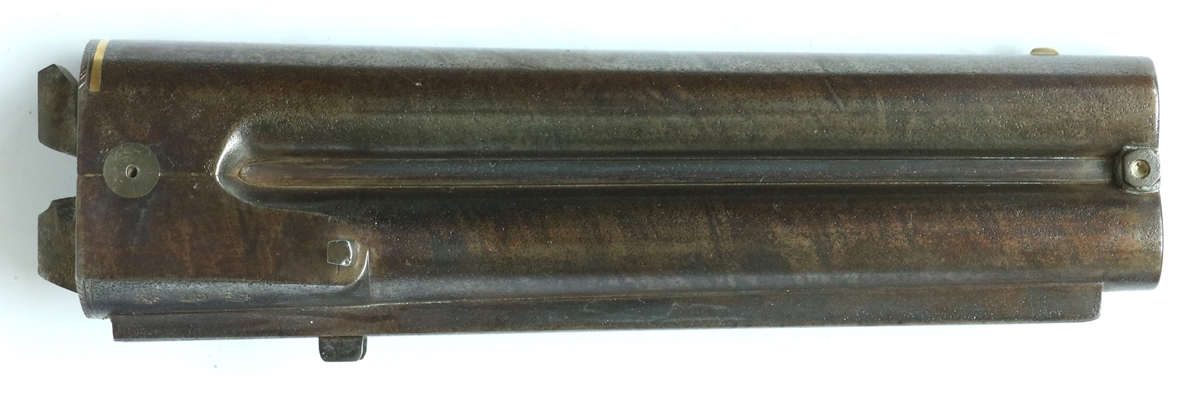

9th October – Fantastic day at Bareham Hall on a muzzle loading Partridge shoot – the bag was 190 for 400 shots and very few runners etc. The beaters were amazed at the performance, which they said was much better than the breech loader’s manage. Probably because we shoot all year round, and also you know how much bother it is to reload and you don’t want to be reloading when the best birds come over – so you let the dodgy shots go! Anyway there were some fantastic drives and I had plenty of good clean shots, and my average wasn’t that much different from the overall – so a good day out! I suspect we may have made some converts to the muzzle loading cause – trouble is it puts up the demand for shootable antiques! I managed to clean my percussion gun in about 30 minutes, and got to thinking about how people clean their flintlocks – I know someone who shoots high quality original flintlocks who takes the locks out each time and immerses them in boiling water, and I usually take out the lock of my ‘Twigg’ and give it a spray with cleaner and a wipe and then a light spray with lube – if it looks too dirty I pour boiling water over it and dry it on the AGA before oiling it. Manton cases for sporting guns were designed to hold the locks separate from the stocks – I guess that was because they were normally removed for cleaning. Nowadays I tend to use Napier cleaner quite liberally as it contains VP90 corrosion inhibitor that works as a vapor – I also put a sachet of VP90 in each of my gun cabinets – I noticed that Purdy used it in the (many) gun cabinets at Sandringham so I figured it must be effective as they were not obsessive about oiling the guns.

Giles spent part of today putting together an IKEA base unit for the kitchen – there is a BIG problem with these units – whereas all the previous units I’ve bought have a space behind the back panels deep enough to house a 1 1/2 inch drain pipe etc, the IKEA units only have about 1 cm behind the back panel so they will either have to be spaced off the wall or have the pipework run inside the cabinets – I can’t think why they would make them in such a stupid way, I’m pretty sure that other units have about 2 inches dead space for pipes – I bought one such from B&Q in April. We might be able to space them 1 inch off the walls, but it is going to be tight! We spent some time trying to find out how deep the space behind the cabinet was before we bought them but couldn’t find the answer. Anyway its yet another problem to overcome, or else we’ll have to take them all back for a refund, which will be a monumental pain – life is like that, no job is straightforward!

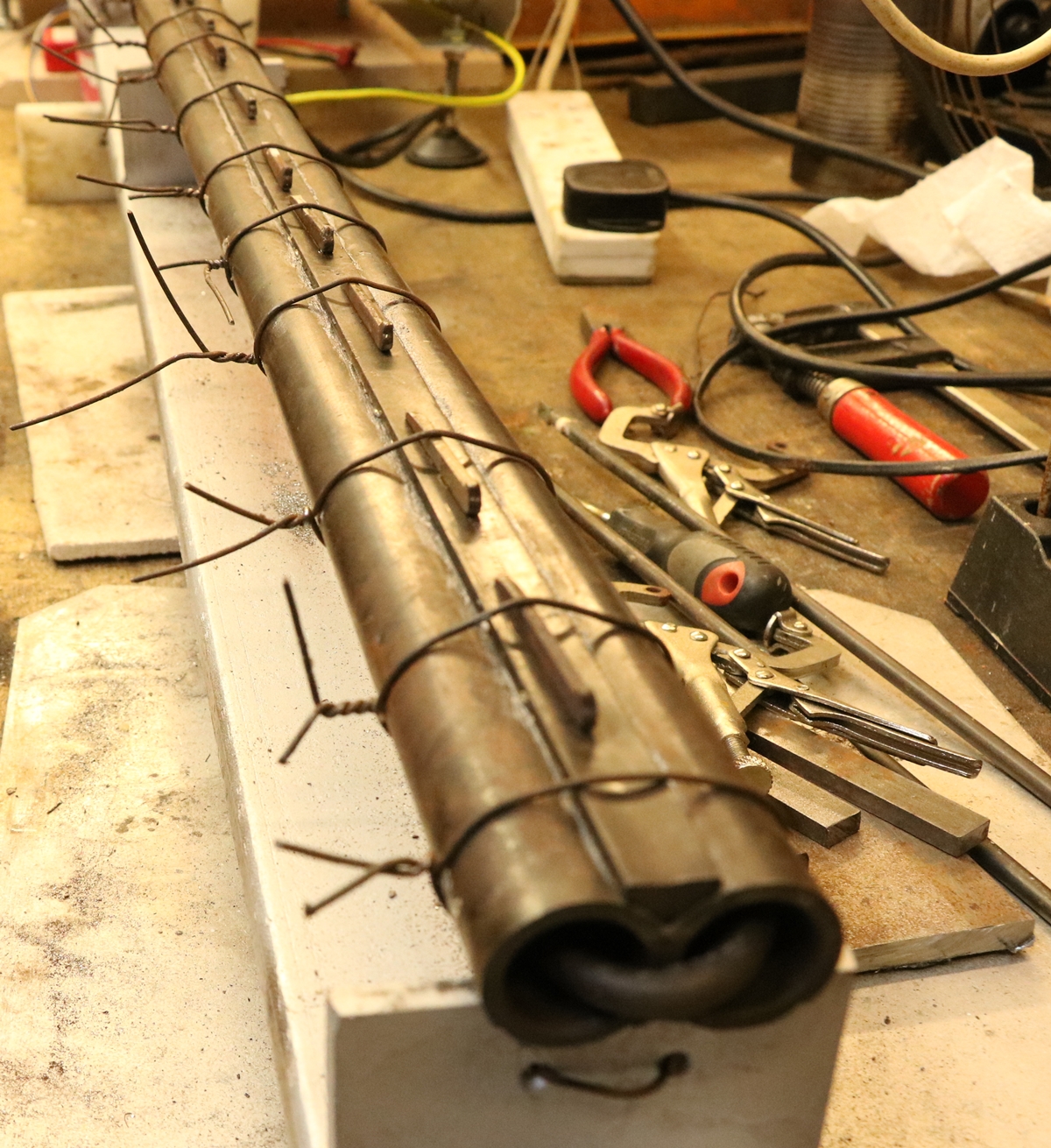

8th October – A day catching up with domestic duties like fixing the mower and mowing the lawns! I went over to Dick’s for the first time in a couple of weeks to collect the Stephen Grant that we had repaired the cock of some time ago as I need to return it tomorrow. I took the Hawkes and Mosley flintlock pistol to get his view, and he offered to restore it for my client – there is a small crack in the back limb of the French cock that will need a touch of weld from Jason, and the barrel needs browning and a few dings in the wood need raising and the spring on the safety is missing, but it will make a very nice pistol – its basically sound and genuine – nothing to hide or fudge here! Dick will make a very good job of it – I’ll get it back at some point to touch up the engraving on the breech block a bit. I’ll try and put up some progress photos but it may be a bit difficult. I’m off to a driven game shoot tomorrow so I got out my shoot gear – I am trying to minimise the stuff I take to the peg as it often involves a trudge across a muddy field and the less one carries the better. Like most (more) experienced muzzle loading driven game shooters I have a spiked tube that holds my loading rood that can be stuck into the ground so the loading rod can be to hand and keeps clean. I had a bin attached to the tube that held my shot and powder flasks, but they tended to fall out if I left them in while carrying the tube – I have now attached a piece of 1 1/2 inch plastic tube to hold my sectional unloading rod with worm, and changed the bin for a smaller, deeper one so the powder flask doesn’t fallout. It all looks a bit Heath Robinson, but it will do for a trial! I am expecting mostly partridges on this shoot, so I’m in two minds as to whether I should use No 6 or No 8 shot – I guess I’ll take a flask of both and take a straw poll amongst the more experienced shots! I got out my usual double, the back action Egg 16 bore, and as backup I’ll take my little 16 bore single Henry Nock percussion conversion. It’s very convenient that all the guns I use regularly are 16 bore as the wads and cards are common to them all. Converting the Nock back to flint has been on my agenda for a long time, and now that I think I can hit clays with a flinter, the conversion of the Nock seems an attractive prospect – my only reservation is that the barrel is short – around 26 inches – and I’m not sure that is long enough for the slower powder burn of flint ignition to take full effect – I’ll have to ask Bev as our flint guru! Giles was off buying stuff for the flat- he wants to get painting! The flat is just 5 minutes walk from the Cambridge Farrow and Ball paint shop – there can’t be many flats that close to an actual F & B outlet, so I guess the temptation is strong.

7th October – All the renovation has been leaving me with little energy or time for this blog, I’m very sorry to say! It is quite amazing how much of the time is spent shopping for bits, and then going back for more – I guess that is the trouble with being an amateur – you don’t have a big stock of materials and have to work things out as you go along… At a guess we are spending about 25% or more of the time getting stuff and shifting it from vehicle to flat. Yesterday morning was a trip to Ikea ( 4 1/2 hours) to buy all the base units and bits for the kitchen and today we bought a stair climbing sack barrow and shifted almost half a ton of the Ikea stuff (2 hours) to the flat- there is a lift but it only serves alternative floors and so we have one flight of stairs. Anyway its coming on, and I’ve got the positions of most of the kitchen wiring sorted – so the plasterboard will go on shortly. We spent some time trying to find suitable black electrical fittings – the ones we liked didn’t have a small 45 Amp cooker switch which we need, but in the end we found that we could stick the front plate from a 20 Amp one we liked onto a not so nice 45 Amp one – job done, or rather fudged…… I’m going to have to concentrate on getting myself into shooting mode tomorrow as I have the first shoot of the season on Monday – we are all using muzzle loaders and for this shoot will be doubling up on the pegs to give ourselves time to reload. One feature of double pegging is that you shoot one barrel and then hand over to your peg mate, so you have to reload with one barrel already loaded – to do this safely you need to take the cap off the loaded barrel (unless you get a left and right) – so I plan to make a few more de-cappers for sale. I’m also going to try out the idea of a plastic collar that fits round the cap and is held by the cock so that there is no possiblity of the cock hitting the cap and firing the gun – I’m not sure the idea will get universal approval, but I’ll test it out myself. I managed to sell the Passat on Ebay for a reasonable price, and it should go tomorrow. The flashy red Mazda that replaced it is much enjoyed, although apart from fetching it I haven’t had a chance to drive it! Tomorrow I’ll take the Hawkes and Mosely pistol (see below) to Dick for his opinion – he might like to do the work too.

4th October – Still working at destroying the kitchen! All the units have gone and the inside of the flimsy studwork outside wall has been stripped and the rather skimpy insulation removed. We removed the old window and have ordered a new UPVC one – the price for supply only was very reasonable, so we’ll fit it ourselves, which will enable us to move the opening slightly and lower the top of the window so we can get an outlet for the cooker fan above the window. The old floor tiles were stuck down with incredibly sticky glue – we tried wearing latex gloves but they got stuck to the tiles – we did eventually get the tiles off after getting through half a dozen pairs of gloves – the floor underneath is rather friable chipboard that has suffered from damp in places but I think it will serve as a base for the new laminate floor – we would have put down ceramic tiles but didn’t trust the sub-floor to be stable enough. We couldn’t face carrying all the bits of the old cabinets and plasterboard down 4 flights of stairs, so got a rope and lowered them from the external stair tower in about 10 loads. Giles stood at the bottom wearing a hard hat and high viz jacket, on the principle that probably someone would object if they thought a resident was doing it, but no-one ever questions a workman wearing a hard hat, as every criminal knows! We still have the old window to get down!

2nd October Busy today wreaking havoc in the kitchen of Giles’s flat! The units are on the way out, the tiles gone and the wiring has been carefully removed from the unsightly trunking running in sight, and will be put back in trunking behind the units where it can’t be seen – In my books that doesn’t count as rewiring, merely slightly re-arranging the existing wiring. I will get it checked when we have finished and I will consult the latest IEE regs as my understanding may be a bit out of date. All the wiring is in red and black T & E so is somewhat dated, but looks perfectly good. I tried to buy some special plaster for skimming all surfaces but found that no-one stocked it so I’ll have to use a P.V.A. layer to cut the absorption and use Multifinish. I think we are making progress on ordering things – we ordered two 3 meter x 650 mm worktops in 38 mm walnut but realised that getting them up 4 flights of stairs was going to be somewhat tricky as each weighed 75 Kg and they won’t fit in the lift – anyway we have got the supplier to cut each into the bits we want, so the largest is 50 Kg and will fit in the lift. It is a bit of a pain working on the forth floor and at the opposite end of the building to the lift! We also have reasonable quote for replacing the windows – I didn’t much like the quote for £3500 for four UPVC windows that you can buy for about £250 each including V.A.T. – I would fit them myself but we are pushed for time and can’t get at the outside so the windowns have to be installed from the inside – this way someone else carries them up 4 flights and takes the old ones away! We have 3 old storage heaters to dispose of – I’m tempted to throw the bricks out of the window, or more responsibly, lower them on a rope. Anyway as you might guess, no time for starting the pistol yet, although I might just nip into the workshop for half an hour tonight……….

Fuzzy photo of partially destroyed kitchen.

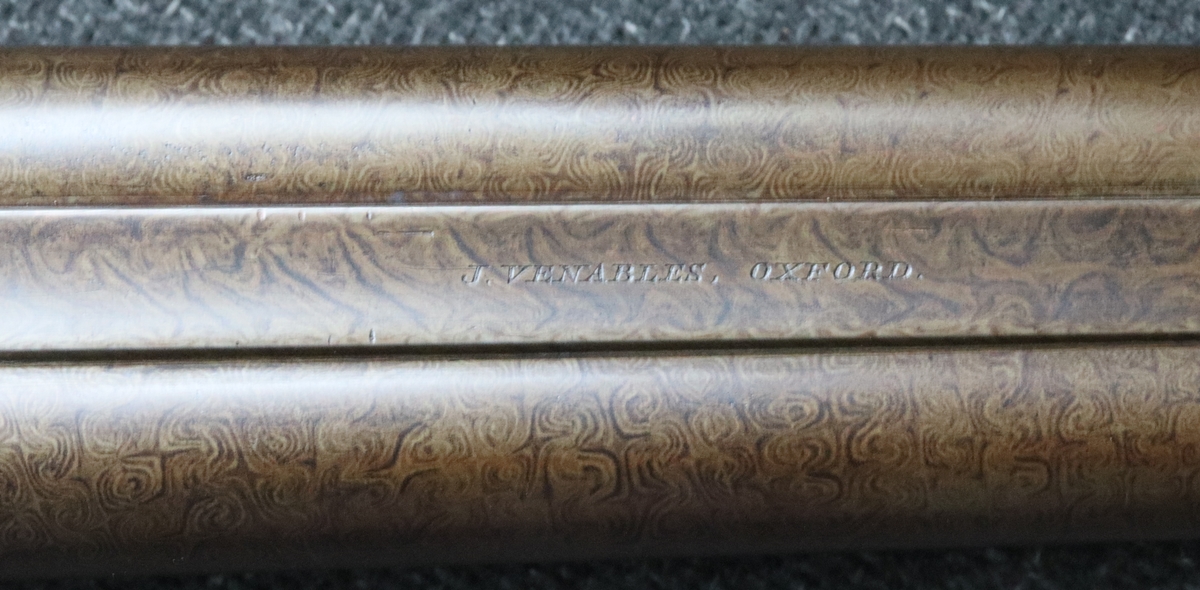

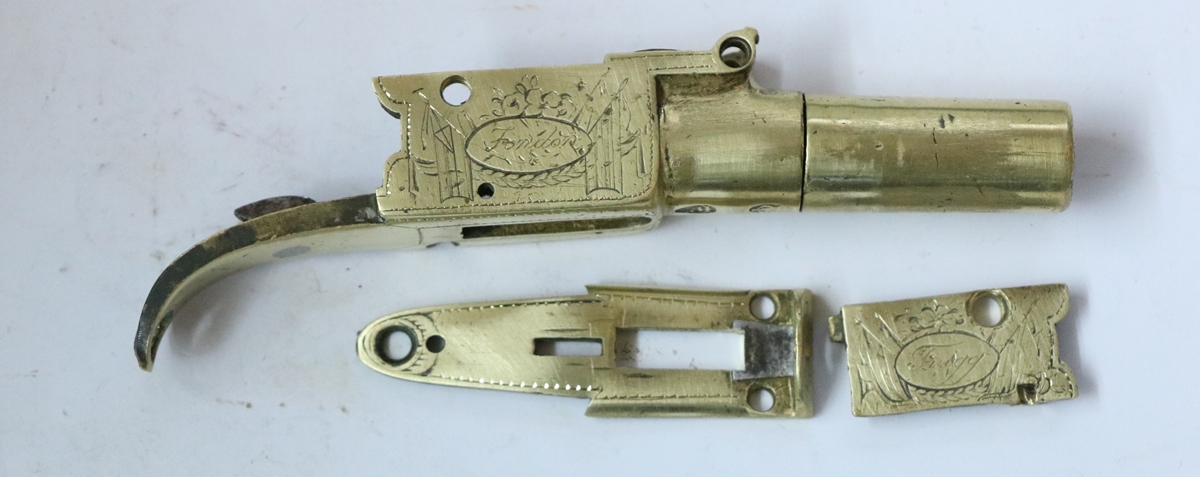

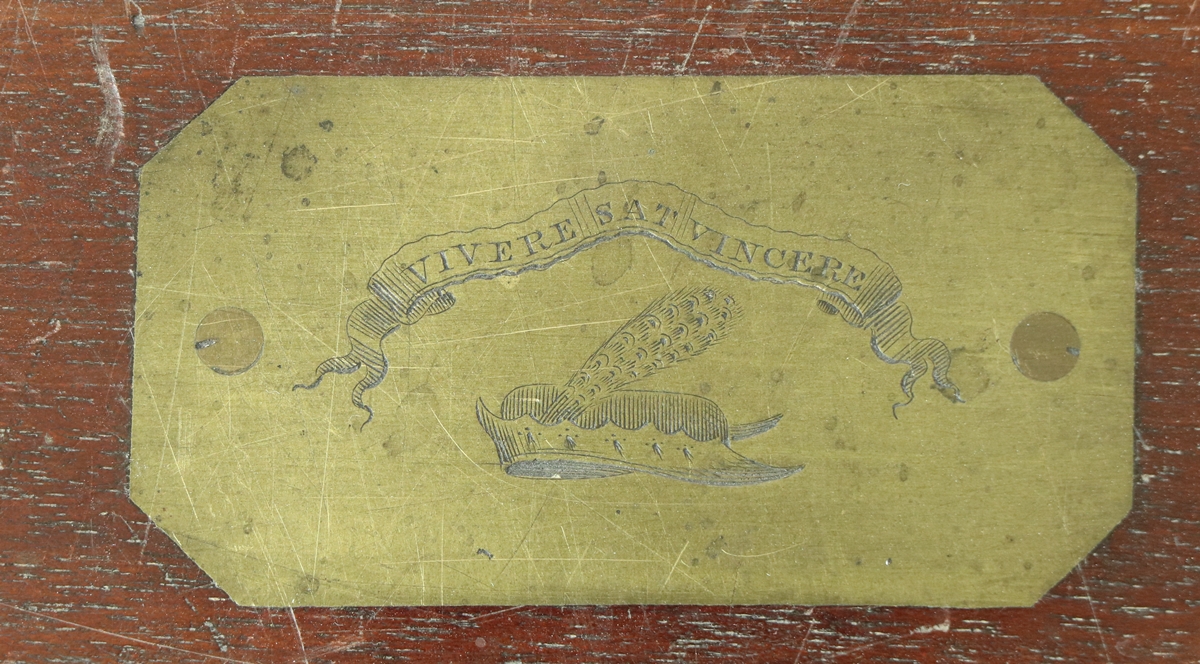

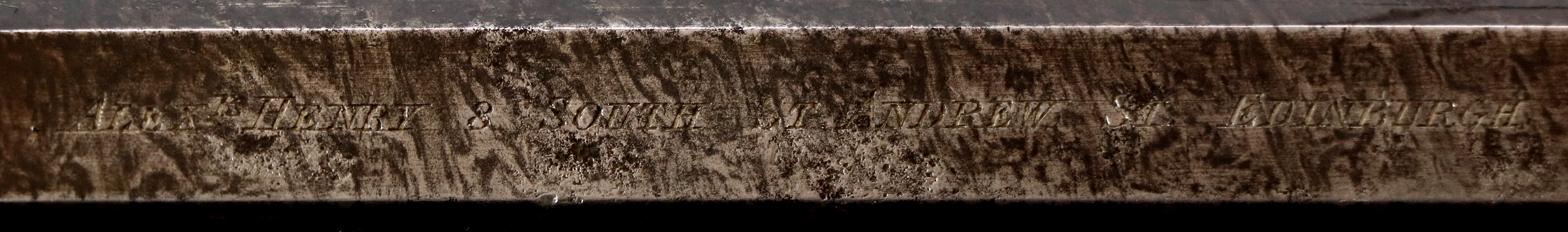

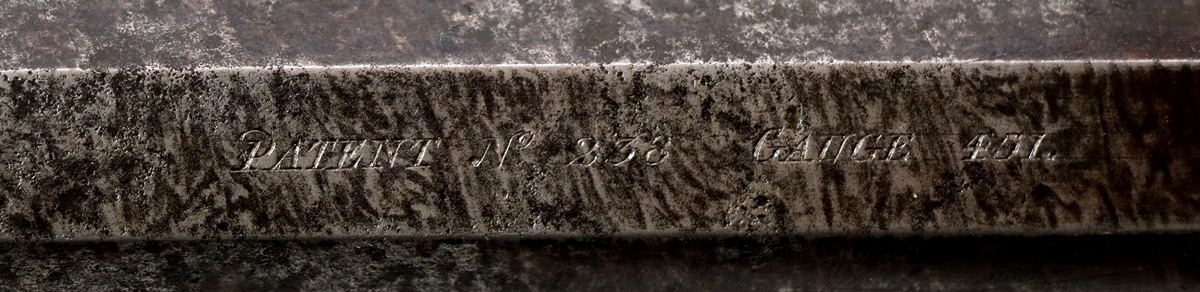

1st October – Here is the promised photo of the Hawkes and Mosley pistol I have to restore, the main obvious issues are the crack in the cock and the replacement cock screw. The lock appears to have been painted with silver paint, which is mostly removed but the residue may be hiding secrets! At the moment it looks original, although the spur on the cock looks a bit short? There are some nasty marks in the woodwork opposite the lock, and a few stains. The barrel is not too bad, but needs a little attention before re-browning. The action works well. I’ll show it to Dick and we can have a good look at it together. The lock needs paint stripper and then de-rusting and the cock welded and the cock screw replaced. Getting rid of the finish on the wood and steaming it will reveal how deep the marks are. I have started a new post for it, Hawkes & Mosley, with the original photos.

Three of us spent the day at Giles’s flat finishing the preliminary clean so we can see what we are dealing with – Some of the details need sorting, and I’m trying to understand the wiring. It looks as if a foam cornice was put round the ceiling edge then the flat was completely re-wired in surface mounted trunking including trunking skirting boards, and then a new floor was laid in the living room, butted up to the skirting, then a strip of coving glued on to cover the joint between floor and skirting. I now need to replace the trunking skirting as I want to skim the walls, and can’t get more sockets to fit that trunking. All a bit involved – the existing arrangement looks a bit of a mess, as does a lot of the plastic trunking! I don’t want to rewire the flat, but I think a bit of re-arrangement of the trunking is going to be essential to improve the look of the place. See post Hanover Court.

Giles removing the foam cornice.

Elegant wiring in surface trunking!

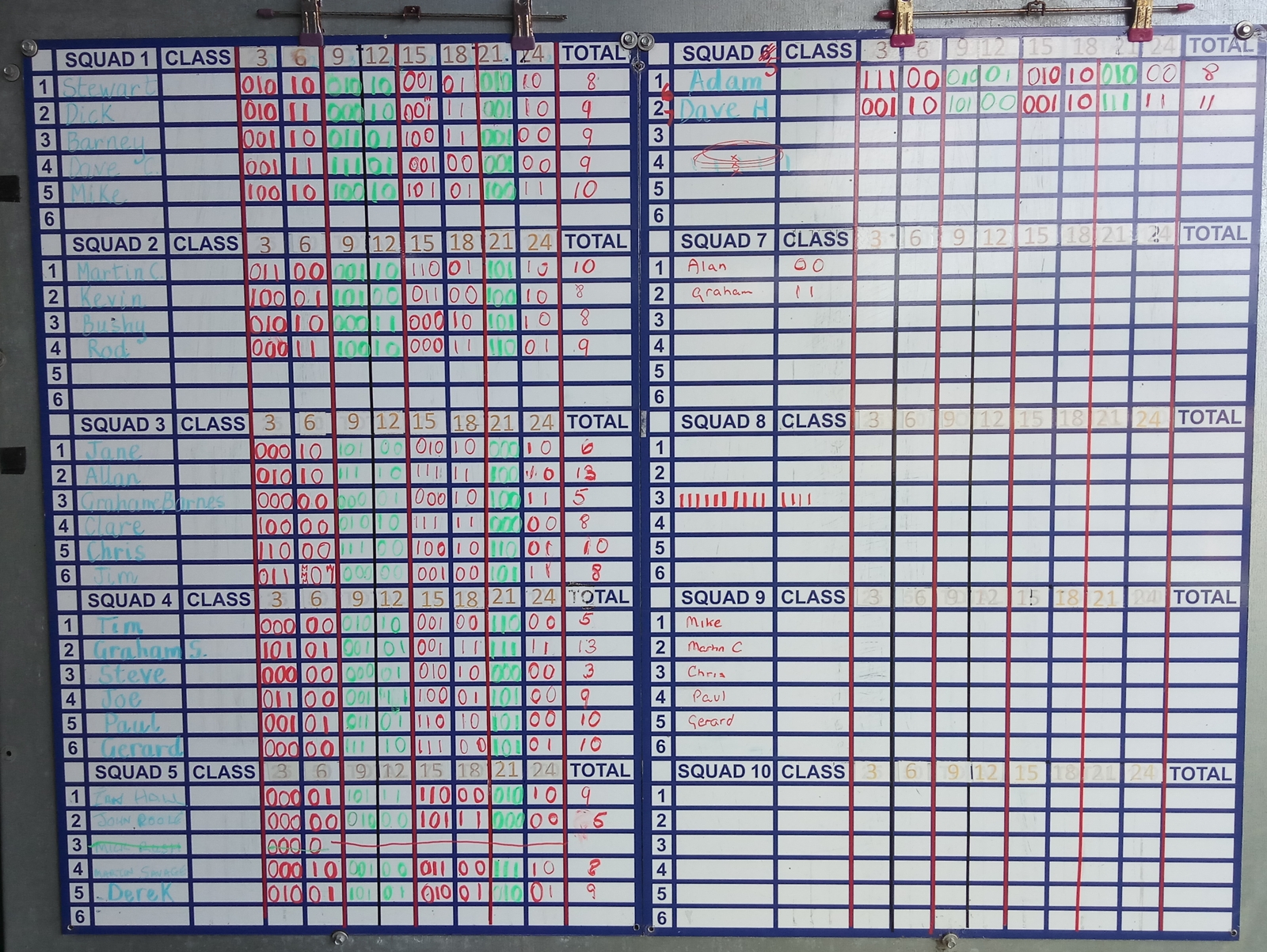

30th September – Back from the AML shoot where I exercised my ‘Twigg’ single 16 bore flintlock. Its the first time I’ve shot flintlock in a scored AML shoot, and I’ve only ever hit a couple of clays with one, so I wasn’t expecting much! I didn’t hit any for the first half dozen shots, and I made what for me is a capital mistake, which is to try too hard and shoot ‘gun up’ ( gun in the shoulder ready to pull the trigger as soon as its aiming properly) – the extra thinking time just spoils the flow for me, although about half of the group shoot this way, or at least nearly up. About half way through I had hit a couple of clays and began to think positively and reverted to ‘gun down’ where you don’t mount the gun until beginning your swing. At that point I got a bit more relaxed and hit a few more. The clays were not easy for flintlocks, which are more difficult to get kills with than percussion, which in turn are more difficult than breech loaders, but I did manage 10/30 and came joint second out of half a dozen flint shooters, so a very good result by my usual standard – I think I may stick with the flintlock for a while as its more fun. I managed most of the shoot on an old flint that looked so bad that I got teased about it – it carried on working for a good few shots before bits cracked off and I had to replace it. After lunch we had a breech loader shoot so I used my 1955 Beretta 20 bore hammer gun with reasonable results – both barrels are fully choked so it shoots a very tight pattern, and ‘kills’ well at longish ranges, but it calls for accurate shooting. At the shoot I got asked if I could renovate a flintlock 16 bore overcoat/horse pistol signed Hawkes and Mosley – who were apparently London outfitters, so presumably it was made elsewhere. At some point it has been silver painted, and that obscures some details. Photos will appear when I’m not being pressed to change ready to go out………..

29th September – At last, after six months and 2 days Giles’s flat purchase completed! So the ‘Great Renovation’ has begun with a clean – the flat has been unoccupied for 18 months and was looking very dirty and scruffy, but we’ve removed the worst of the grime from the living room and started to plan in detail. It looks as if the electrics will suffice with the addition of a few more sockets – its all in a plastic skirting board trunking with built in sockets, so its a matter of trying to find the same system now – under the current regulations its possible to extend existing ring mains without having it certified, so I’ll do that. The plumbing will mostly be redone as the kitchen and bathroom will be ripped out and re-fitted, but I can do that, and I’ll put in lots of service valves – there are none at the moment and there are several leaks so the water has to be turned on and off at the incoming main. We wanted American Walnut worktops and had to measure up and order them as there was a 17% off offer that expires on 30th Sept – so 6 meters x 650 mm of 38mm thick American walnut in what is incorrectly called ‘butcher block’ is on order. We spent some time yesterday looking at paint colours and collecting cards and samples, but ended up at the local Farrow and Ball outlet. One of life’s mysteries is why the F&B colours look so much more natural and agreeable than most other paint colours – I’m fairly sure its because almost all other paints are made from only 7 to 9 synthetic pigments mixed to (theoretically) give any shade under the sun, whereas the F&B colours use a much wider range of more basic natural pigments. Certainly if you get one of the F&B colour fakers to mix you a F&B colour from their 9 or so pigments it is just sufficiently ‘off’ and unnatural looking to make you want to spend at least twice as much money on the real thing. Fortunately Giles and I agree about colours so no discord, although its his place so I would defer to his judgement in the end! I also picked up Penny’s nice shiny red Mazda from Milton Keynes – I thought it was much more fun to drive than the rather boring Passat, and I’m rather jealous – plus its a much more sensuous shape! I can’t believe it is only £20 per year in Road Fund Licence – it is supposed to be capable of around 60 + mpg but I got the feeling from watching the figures on the dashboard that you need to take full advantage of the 6 speed gearbox and always be in the highest gear possible – the engine pulls well from about 1400 rpm so its not really necessary to go much above 2000 rpm unless being a ‘boy racer’ – as I normally drive an automatic I often forget to change gear, so don’t do very well on the mpg front in a manual car. Tomorrow is an Anglian Muzzle Loaders shoot at Cambridge Gun Club and, I believe, the flintlock competition so I’ll continue my new found enthusiasm for shooting clays with a flintlock – there are not many of us although more are joining all the time – those who shoot flintlocks tend to be the best percussion shots anyway ( except me). I’m resigned to my usual place among the back markers – but someone has to come last! Anyway the old ‘Twigg’ will be fired up, and I might treat it to a new flint as I had two ‘no spark’s last time………

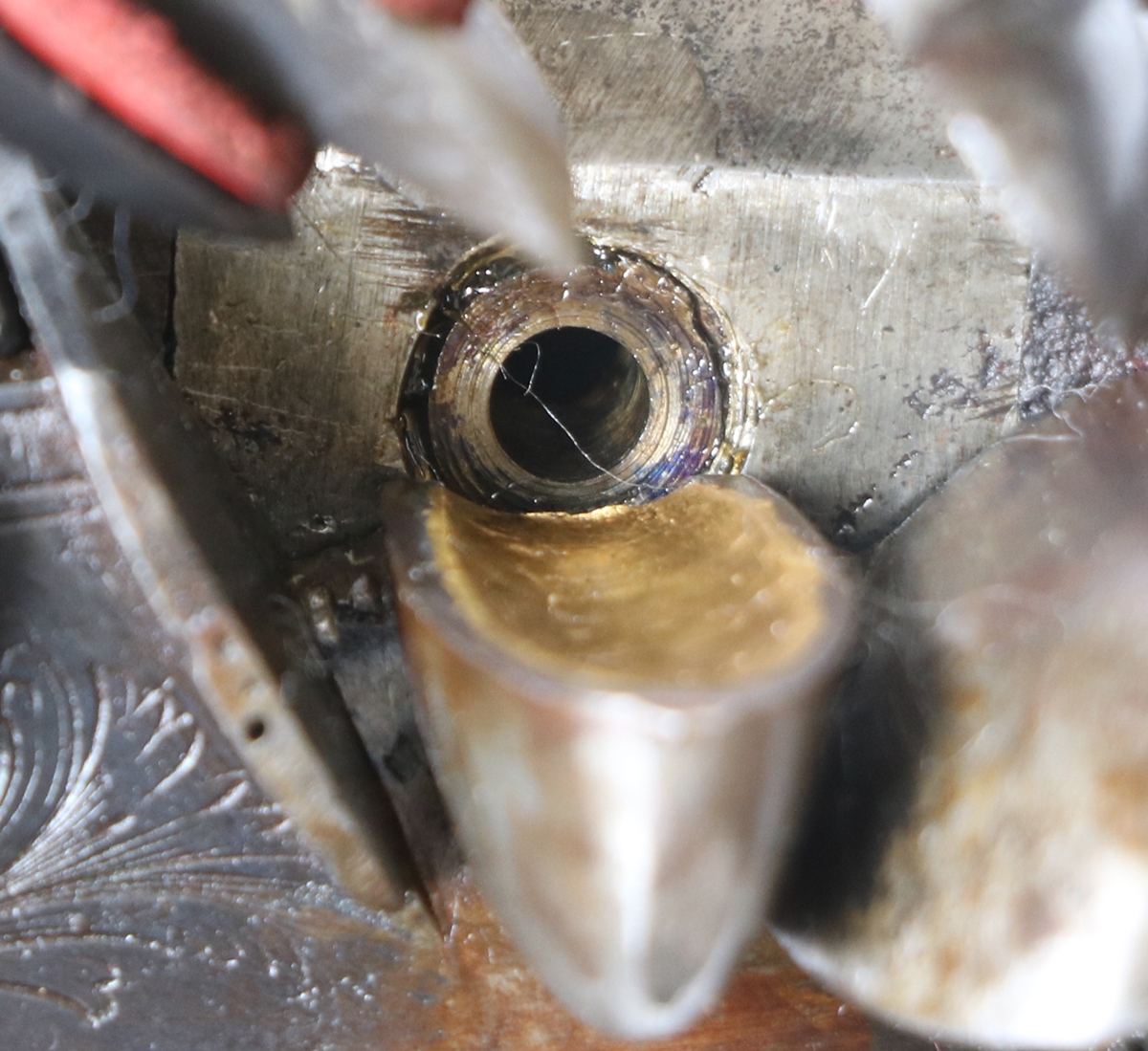

28th September – I put the Volkswagen on an Ebay auction this morning for repair or spares and within 30 minutes had 8 contacts offering to buy it – I didn’t take it off auction and its now bid over £1000 so I am glad I just let it run. Tomorrow is set to be an exciting day as I collect the Mazda in the morning and Giles expects to collect the keys of his new flat sometime during the day – then ‘The Great Renovation’ begins. I got my copy of Black Powder magazine today and was reading Fred Flintlock’s article on nipples. He is mostly dealing with revolver nipples so my experience of long guns is not the same, but he advocates nipples with the small hole at the bottom which is also the preferred long gun configuration. Interestingly ‘Stonehenge’ in his book (18 82) also favours them, rather than the opposite configuration as found on most old guns I have encountered. I have some guns with original nipples that have a larger opening at the bottom that almost never misfire, but if an original gun does misfire often it is almost always cured by making a nipple that is narrower at the bottom. I have found that original caps by Joyce and Eley seem to make a much louder bang than normal modern caps, so I assume they were stronger, which may explain why original nipples often misfire with modern caps. Fred discussed ‘blowback’ and the consequences of the hammer lifting, (which a video of a percussion gun going off will reveal as a common phenomenon) in terms of the Venturi effect, but that probably doesn’t apply in the case of nipples as its essentially a steady state effect and the impulse from a nipple exploding is a pressure pulse. The best way to illustrate the differences is to look at the bulge in a barrel that has ‘ringed’ as the result of a blockage – its purely a wave phenomenon caused by the reflection of the shock wave by the obstruction ( which doubles the pressure) and can’t be modelled by any quasi steady state physics, which would bulge much more of the barrel than a tiny ring. One difference between a revolver nipple and a long gun nipple is that while the former opens directly into the main charge, in a long gun there is a secondary volume next to the nipple. The Venturi effect is interesting, its actually one aspect of the Bernoulli principle – basically says that if a stream of fluid is accelerating the pressure is lower as the stream goes faster – so forcing a stream of gas into a reducing space causes the pressure to drop in the constriction. An interesting further effect is the cooling of a gas as it expands after being forced through a jet. Count Rumford exploited the effect in the design of chimneys at the end of the 18th century to stop firelaces smoking into the room, – his chimney design incorporated the throat leading into the chimney so that the smoke was accelerating through the constriction so the pressure dropped and the smoke was sucked up the chimney instead of escaping into the room. When I uncovered an inglenook fireplace in this room, it smoked so badly that it was unusable, so I applied the Rumford/Venturi principle to make sure that the smoke above the fire was always accelerating until it got past the narrow throat and by then it couldn’t get back. I built a streamlined shell of chicken wire plastered with lime mortar linking the top of the fireplace opening to the chimney with a movable flap to control the throat – the secret is to avoid any dead spaces where an eddy can form and spill out into the room – its now pretty smoke free unless you mismanage the fire. This blog continues to attract more and more viewers, but alas, I think many of them are not interested in the contents, just in hacking the site – luckily I have good software that defends it, touch wood!.

27th September – Wearing my school governor hat I had a governor meeting at school on ‘Safeguarding’ – I do have to bite my tongue at times – its quite sore at the moment. We seem to be rearing each generation less robust than the last and the layers of cotton wool we wrap them in get thicker and thicker until they can’t feel the world! The latest news filtering through to me is that students starting University in Cambridge are being brought by their parents ( as is usual), but the parents are staying around for a few days to ‘help the student settle in’ or some such nonsense- Ye gods, if my parents had come anywhere near Manchester when I went to university there I would have died of mortification – I only went there because it was about as far from them as I could find a suitable course! I trundled up the A6 etc from Colchester on my 50cc NSU Quickly – which was anything but with all my kit on the back and left home well and truly behind – I think I went back once after that. Our tame mechanic told me today that the Volkswagen clutch was nearly dead – its making a horrible racket. I’ll try to sell it ( openly) with a duff clutch as its quite an expensive job to repair as its a ‘dual mass’ clutch/flywheel assembly – the dual mass flywheel is a complex device that has become necessary with engines that are producing more power from fewer cylinders at lower revs to give the very high m.p.g. figures needed to cut emissions. The basic idea is that the flywheel is in two parts, one part attached to the crankshaft and one to the clutch assembly, the two parts being linked by springs so that the pulses in rotation caused by the cylinders firing compress the springs which then give back the energy before the next pulse – its a very complex spring system and is carefully tuned to smooth out resonances and reduce stress in the drive components. Anyway I don’t think I’ll be going anywhere in the VW from now onwards so I’m without a car until we pick up the Mazda and I can get my Land Cruiser back from Penny. I realised that there are two basic ways to buy a used car – you either go to a few garages and see what takes your fancy, or like me you spend hours researching different vehicles until you have a clear idea of what is ‘best’, then you go and test drive one and if it goes OK you then look carefully at all the adverts on the internet etc and try to buy the best of the bunch. There is a lot of information on the web – reviews, price guides, reliability figures from Warranty Direct etc, but I always get an up to date copy of Parker’s Guide to used car prices as it has all the models listed and you can work out depreciation rates etc and see how much ownership is going to cost you. I’m not sure which method is the best way to buy, the first method is certainly more relaxing and probably involves less travel. At the end of the day a car is just a box with a wheel at each corner! I did read more on East Africa, but this bit is not so interesting, being about the behaviour of the individual animals, which is just a repeat of comments made in the narrative part. He is very dismissive of the lion, and the Rhino, which he says is always half asleep and only wakes up in response to approaching hunters because the bird that habitually perches on it and cleans off parasites gives the alarm. The Rhino has a reputation for charging the hunter if wounded, but Jackson says that it isn’t a charge, its just running off and the hunter happens to get in the way very occasionally! Ah well, that’s OK then…..

26th September – My education into organising a big game expedition in British East Africa 1890’s style continues, although I feel I may just have left it too late – Jackson writes that between 1891 and 1893 the vast herds of buffalo were struck down with a form of anthrax, and the elephants also suffered from indiscriminate hunting, and all forms of game were getting more difficult to find – he cautions that hunters should only take the males of the species, but that there is still good hunting to be had with a little effort – he argues that its not the skilled hunter after trophy animals that is doing the damage, but seems to realise that the writing is on the wall for that form of sport. One aspect of his advice that I found interesting was his analysis of the relative dangers of the animals to humans – he rates elephants and buffalo as particularly likely to charge – but thinks that the buffalo is the more dangerous because it is not so easily spotted and so may take the hunter by surprise. The lion doesn’t seem to him to be so bad beacause it often slinks off if it can, and usually gives a low growl that gives its presence away. The very worst is a buffalo that is wounded, which will track down the hunter with great determination. Interestingly he thinks that his 4 bore rifle is not effective at 70 yards, and that he needs to be closer than 50 yds with dangerous game – some authorities would say that there is not much difference between a rifle and a smoothbore gun at that range…. I managed to buy a car for Penny today that met my targets exactly – a very nice shiny ex-lease 14 reg. red Mazda 6 with 83000 on the clock – should be good for another 100000 miles, by which time it will have suffered from our normal level of abuse and be on its way. I’ll pick it up in a few days when its had its first MOT test … job done, except for disposing of the tatty 09 reg VW Passat. I’m quite envious – my turn next! Now I need to sort out tools and stuff to take to the flat for the ‘Great Renovation’, which will probably begin on Sunday.

25th September – Rushing about a bit today. I’m trying to find a car for Penny – the VW Passat estate is on its last legs – it gets a hard life one way or another, and I’m a bit fed up with the constant drain on the battery that no-one has been able to sort out, so its time for a change! I’m a fan of Japanese cars, my Land Cruiser having done 10 years without problems (except those caused by garages!). We do at times carry a lot of junk about so a decent estate is called for and it will do around 15000 miles p.a. plus so has to be economical to run – Prime suspect at the moment is the Mazda 6 Tourer, which seems like a decent vehicle. I hate the thought of the £10K depreciation in the first couple of years, and I’m not afraid of cars that have done a high mileage, but as fuel economy has improved dramatically in recent years its better to get a newish car – my preference is therefore to let someone else take the edge off the price. Most of the cars in our sights are ex-lease cars with about 100K on the clock (the mileage at which the lease companies dispose of them) and around 4 years old, at about 1/3 of the new price – that takes in many of these cars on Autotrader so lots of choice. This time I’ll try not to ‘reshape’ bits of the bodywork on gateposts etc…………. I continue to prepare for an 1880s style expedition by reading the Badminton Library ‘Big Game Shooting’. Instructions for organising a ‘caravan’ for an expedition in the North East of Africa are interesting – The porters, of which there are many, were divided into teams of 10 and here carry the loads as wagons cannot not used as there are no suitable tracks or fodder for the oxen. Each porter has to carry his designated load of 65 lbs, plus his bedroll, his own staple food for 10 days (rice, beans – 10 to 15 lbs) and his water for the day ( 3 lbs?) and some had a Snider Carbine and 10 rounds in a belt (my grotty 1871 Enfield Snider conversion weighs 6 1/2 lb). The loads must have been difficult to manage – for instance, a crate of fowls. On the subject of arming the porters Jackson says that normally 25 armed porters (plus many unarmed ones) was enough for a trip as far north as Kimangelia, but a more extended trip to the Nijiri plains it would be better to take 50. He thinks the Masai warrior is a much over-rated individual but the porters fear them. For a trip to Suk country he would take 80 to 100 armed men. ” If the trip should be extended further North into the Somalia country, it would not be worth while running the risk of entering the country of such grasping, treacherous, religious fanatics as the southern Somalis are with fewer than 150 rifles“. So, a veritable army – some things never change………………. I begin to think that organising such an expedition may be beyond my means – maybe I’ll just stick to buying a car…..

24th September – More lawn mowing and hedge cutting! The Badminton Library ‘Big Game Shooting’ has now got on to F J Jackson’s 1880s recommendations for equipping an expedition ‘up country’ in Africa, which makes interesting reading. he doesn’t set much store by a .450 or .500 Express rifle for dangerous game, his preferred ‘battery is as follows;- A 4 bore single rifle sighted for 100 yds firing a spherical ball with 12 drams of powder and weighing 21 pounds, a double 8 bore rifle sighted for 100 yds weighing 15 lbs again firing a spherical ball with 12 drams of powder (I assume these are breech loaders, it isn’t specified), a double .577 Express rifle shooting magnum cartridges with 6 dram loads and 3 different bullet types, sighted 100 and 200 yds, a .500 Express, a 12 or 20 bore Holland Paradox and a .295 rook rifle – that ought to be enough? He recommends taking food from England and adds;- No expedition should be undertaken without a few pint bottles of really good champagne, to be used medicinally, as few things are more efficacious in pulling a man together in cases of extreme prostration after fever, or when thoroughly exhausted and knocked out of time from long and violent exertion…… of course they should not be taken until the sun is down ( which, this being the tropics happens swiftly and early) – one wonders about ‘pint bottles’ and ‘a few’. My mother used to recommend Lucozade for that, I prefer Jackson’s idea. He also includes brandy, wine and whiskey in his grocery list and suggests a teaspoon full of brandy stirred into a cup of champagne to revive a lost appetite. I was impressed by the following too;- (after recommending mosquito nets) .. Before having the mosquito curtains removed in the morning it is a good thing to take a cup of coffee or cocoa before getting out of bed ( at 4 or 5 a.m.), as I believe when so fortified a man is less liable to the influences of miasma, which, if floating about at all is worse just when getting up. (miasma or night air was thought to carry infectious diseases and germs in Victorian and earlier times) Although I don’t habitually sleep in mosquito curtains, or have a ‘tent boy’ to remove them, I do have a cup of tea before getting up, although sadly I have to get it myself – I’d never realised that my insistence upon this custom was to ward off the effects of miasma but henceforth I shall attend to the habit with renewed enthusiasm…….. but since its now evening and the sun is down and I’m exhausted, could you pass me a cup of really good champagne, with or without the teaspoon of brandy? Thanks………………………..

23rd September – Trying to get the lawn in some kind of order today – it has been ridiculously wet of late and this is about the only day it has been dry enough to cut. It was so lush that I had to go ever the lawns with the mower on its highest setting and with the grass-box fitted ( I normally self mulch) – the grass was just like an early spring flush, not a tired August/September parched lawn. I’ll have to go over it all again with a lower setting as soon as I get another dry day – I need to fix the mower sometime as the belt that drives the wheels has worn loose and there doesn’t appear to be any adjustment. I’ll have to do an internet search, there is bound to be a Youtube on it. I read more from my Badminton Library book on big game shooting over my coffee this evening -W Frank Oswell’s account of his African expedition. Some of the logic behind his slaughter of the game becomes clear as I read more, although to modern readers it sounds diabolical! In his journeys across Africa he does offer to feed whole communities in return for guides and helpers. In one place he offered to feed them but refused to give them ‘presents’ so got no help but at the next community the 600 inhabitants were starving to death so he offered to take them all (men women and children) on his expedition and feed them, which he did – on just one day shooting 6 elephants to dry into biltong for them to take back to their kraal. He claims that he sent back more than 60,000 lbs of biltong with them – they had to make several trips to carry it all. He of course was only interested in the Ivory which then fetched about 5/- per pound in Africa. A later writer (1880) in the same book wondered where all the game had gone, speculating that it might have gone elsewhere, or, just possibly, been shot to extinction! I wonder how much habitat loss there had been by 1890?

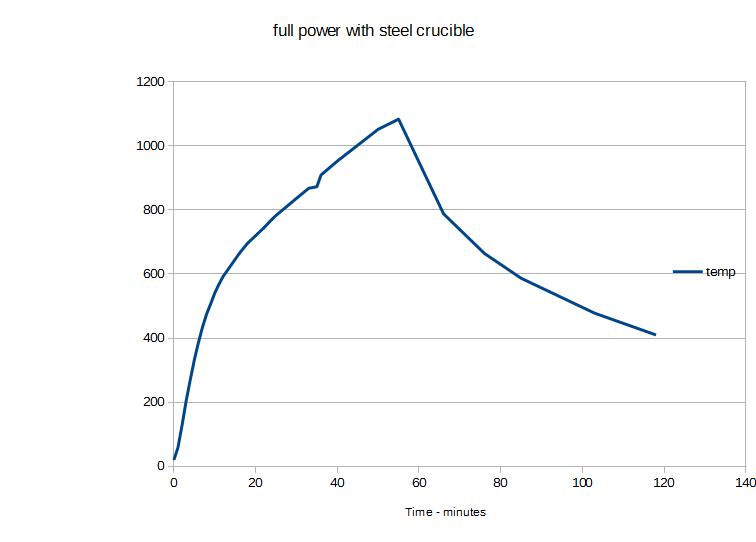

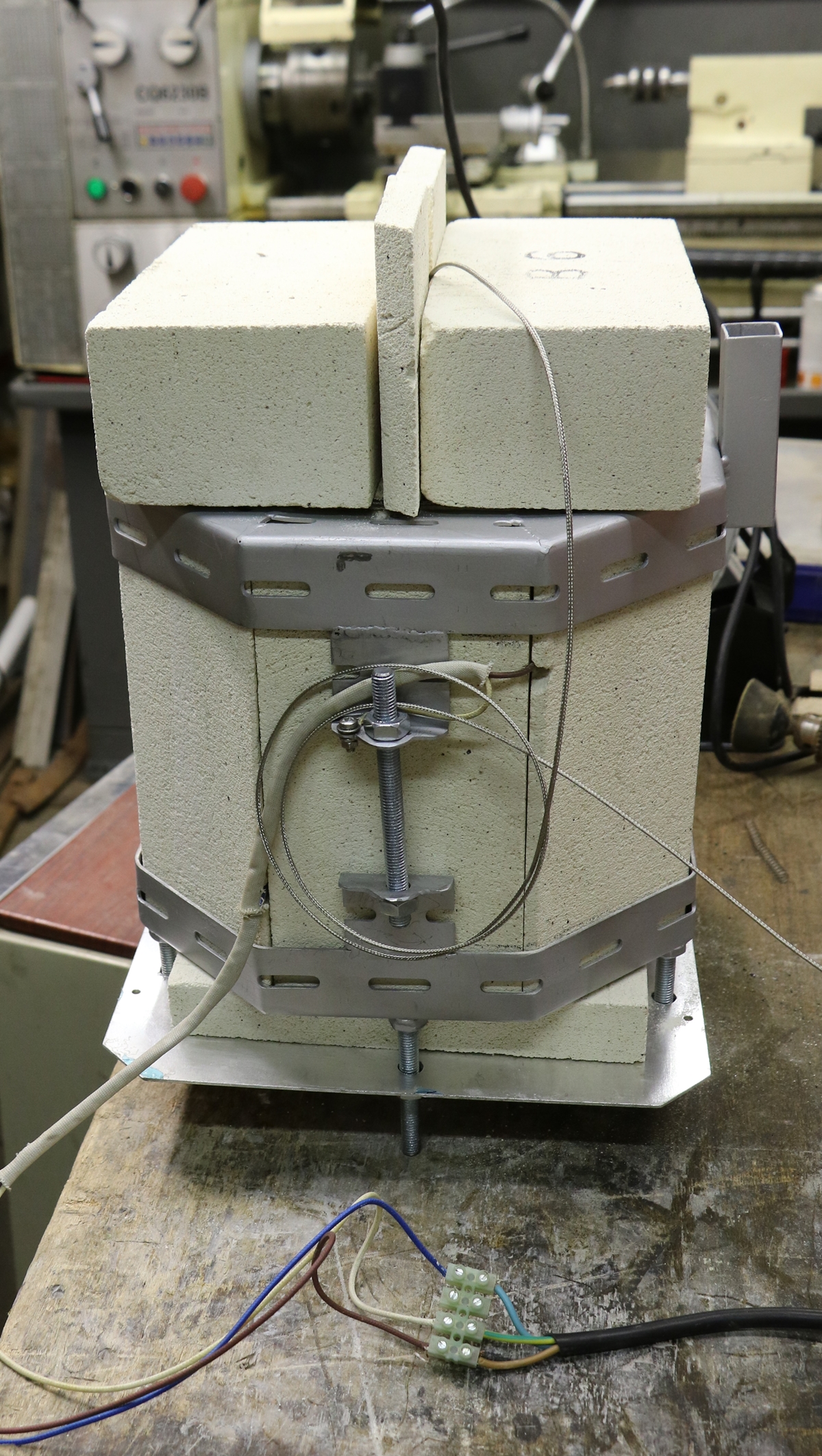

22nd September – Sorry for missing entries! I spent three days at the Cavendish lab at Cambridge University doing ‘Physics at Work’ presentations. I give 12 each day, of about 20 minutes each with a bit of time between each to allow the students to swap presentations. Its very intense as you have to get them interested and involved and participating – its not too difficult for those groups that are lively, but you still need to put a lot of energy into it to keep their enthusiasm up. The worst groups are those that appear dead from the neck up – you really have to work hard to get through to them! We get groups from far and wide, and all sorts of schools, state and independent and academies. Interestingly there isn’t any consistent pattern as to which schools will have the most buzz and be the most fun, although I always enjoy those from London and Birmingham that have very mixed classes. I think my deadest groups were from an independent girl’s school not a million miles from Cambridge. Anyway by the time I got home in the evenings I was well past blogging and just fell asleep on the sofa! Today a couple of loads of logs arrived and had to be stacked, so no playing, but I did manage to post a few parcels of camera bits I’d sold on Ebay. The good news for us was that at last, after yet another last minute hitch, Giles has exchanged contracts on the flat – completion is scheduled for next Friday so from then I’ll be up to my ears in plaster, wiring, plumbing and kitchen fitting for a few weeks ( or months!) – I’ll try and keep a blog going on the progress as I don’t expect there will be much time for playing with guns. I have been reading one of my old books in the ‘Badminton’ series on big game hunting – this one on hunting in Africa in about 1845 by the first hunters to venture into much of the country. Its interesting to see their attitude to killing the game – if they didn’t present a challenge then they were shot to feed the many people who were essential to support the camp as it moved by wagons and ox teams for months on end, or at least that was the pretext – referring to rhinoceros, the old hunter said the most he ever shot at one time was 6 as he needed that much meat for food! I would have thought one rhino would have kept a supermarket in meat for longer that it would keep fresh, although it is possible that the the bargain with the local people was that they would be provided with meat while the hunters were in their territory as a sort of ‘visitor tax’. The hunter used a double 10 bore smoothbore percussion gun weighting 10 lbs with a round ball closely patched by rolling it in the hands and cutting off folds, without any wad, with 5 or 6 drams of fine powder – as he often shot from horseback and reloaded there too, he found capping the gun the most difficult part – even on the ground I sometimes find it very tricky when standing in a windy field on a cold day in winter! He didn’t hunt in the way that a modern hunter would, using a rifle at ranges of 100 to 200 meters, but got within less than 50 meters, often much less, at times riding his game down for many miles until he could get alongside them – although many game animals are faster than a horse, the horse can outrun most animals over long distances. That reminds me of some recent research that showed that women can sustain their running performance significantly longer than men, and can compete equally in extreme endurance events! This blog is nothing if not a source of obscure ‘facts’…………….

18th September – I was at the Cavendish Labs today setting up my demonstration for the 13 & 14 year old school students who are coming over the next three days to find out what scientists & engineers do with their lives – well, leaving out the bits about shooting! I have a colleague from my school STEM club coming to help on Wednesday, so I won’t have to do all 36 talks on my own. I have finished the book on Wyatt Earp and his ‘Buntline Special’ Colt ’45 with a 12 inch barrel. The book ‘He carried a Six Shooter’ is supposed to be a factual account and uses a lot of historical sources to try to unravel the truth about his exploits. I found it interesting because, although he had a reputation as the fastest gun etc… he depended on careful observation and an understanding of the psychology of his adversaries to avoid too many shootouts – often disarming them or occasionally wounding them to control and sometimes to humiliate them. He and his brothers made many enemies among the bad men, brother Virgil was badly wounded and brother Morgan was assassinated, after which he was probably less generous towards the gang involved. The book, of course, has detailed account from witnesses of the famous shootout at OK Coral. The book was set in the 1870s to 1890s and covered the driving of the railways across the West to support the great cattle ranches and the associated massive cattle drives to the railheads, and then the rush to mine silver. The guns by then were all breechloaders, basically the Colt ’45, the 1873 Winchester carbine and sawn-off double barreled shotguns – presumably 12 bore, loaded with 9 buckshot per shell, with the wads split, which was claimed to spread the shot – the implication being that putting the slit vertically caused a horizontal spread, although that isn’t explicit in the book – Wells Fargo favoured these shotguns for the guards on stagecoaches – thus using them exactly as earlier coach drivers used blunderbusses . I have a Winchester 44-40 of later date but basically the same – my grandfather is reputed to have brought it back from the First World War but as he died and was buried in France I’m not sure about that. I do know that for a very short time the observers in the first, unarmed, planes were issued with Winchester Carbines to try to shoot down enemy planes, or rather the pilots and observers – possibly it was one of those. I guess in the very early days no-one had really addressed the need for armaments on planes as they were used exclusively for spotting and it was a little while before they worked out how to syncronise a machine gun to fire through the propeller without shooting off the blades. I seem to recall that the first guns just had steel deflector plates on the prop to deflect the bullet, but I may be making that up………………………….. Any way the Winchester is a fantastic example of perfect fitness for purpose – tough, simple and handy – its difficult to imagine a better suited gun for either of those situations. One day I must convert mine from a Trophy of War on my certificate to Sect 1. so I can shoot it.

17th September – to celebrate Penny’s birthday we visited Oxborough Hall – a fine National Trust property in Norfolk built in 1482 and subsequently altered and ‘improved’ by the family that has lived there for many generations and still does. I’m quite an old buildings nut, so I enjoy that sort of place although I am rather conscious of things that don’t seem right – a lot of the windows were added or altered in the late 19th century in brick that doesn’t match the old structure and most of the large windows have fairly recently had their leaded glass removed and plain, modern glass put as single panes into the frames. I always look to see what the National Trust does about the display of firearms, which of course would have been a major part of almost any grand house, from the personal sporting guns and pistols of the owner and family plus those of his guests to the matching sets of muskets that would have been provided for the militia – most wealthy families had guns from famous manufacturers and kept them for generations. At Oxborough Hall the ‘gun room’ near the entrance had but 4 guns on the wall very high up where you couldn’t see them, and looking neglected – a blunderbus, an Austrian military air gun, an English musket and a foreign musket. In the ‘King’s Room’ things are even sadder – there is a a pretty poor pair of nonedescript percussion pistols that look like something cheap from Liege but were supposed to be Venetian ( I wasn’t sure they weren’t repros! – I could have made more convincing pistols myself), and a more fancy but still fairly uninspired flintlock pistol from France or Italy, it was so unremarkable I can’t even remember what the steward said, but she was quite amused when I said they were pretty poor examples of anything! I should have taken a photo but I’m sure its forbidden. Its a real problem that bodies like the NT think anything to do with guns is politically incorrect or anti-social, whereas in reality it was a big part of life in times past and has a rightful place in any true representation of how things were. Part of my ‘trouble’ is that I say what I think about guns, although I have given up commenting on guns for sale as it was getting a bit embarrassing telling dodgy dealers what had been done to their guns! Which reminds me, I forgot it was the Birmingham Arms Fair today and I can’t make it to the viewing at Holts so I am safe from buying any more guns at the moment! I still have a few to shift, must put them on this site.

16th September – I was busy clearing up the house and sorting piles of old papers and came across an old loose page catalogue from my father’s things. There is no indication of the firm’s name but a page with a letter to customers is signed Kit Ravenshead, Framlingham 1969. It offers a wide range of parts for restoring flintlock and percussion guns, more or less a combination of Kranks and Dysons or Blackleys, including castings for all parts, barrels, reproduction flintlocks, and restocking of all pistols and guns. With it are two separate price lists, one dated 1968 and one dated 1969. As you would expect the prices are very different from present day prices, but interestingly the factor between now and then differs enormously for the different items and for labour. It is also interesting to note that some prices jumped by a lot between the two price lists. I’ll give some prices taken at random compared to Blackley’s website;-

Gunpowder was 11/- a pound in 1968, and 13/6d in 1969 – quite a steep rise, but its now around £20 a pound a rise of about 30 times.

A Repro Queen Anne pistol kit was £12 in 1968 and £15 in 1069 – Blackley’s price £339 but that includes springs and screws, about another x 30

A New Land Pattern lock set was 160/- in 1968 and 200/- in 1969 – Blackley’s is £125 including springs, a price increase of about x 15

A flint cock casting went from 32/6d in 1968 to 70/- in 1969 – Blackley’s price would be £20, a rise of x 12 ish from 1968 or x 6 from 1969!

Browning solution was 7/- but had to go by rail – Blackley’s now £15 an increase of x42

A repro Kentucky flintlock rifle was £55 – I guess depending on what it was like, between £600 & £1000 now – around x 15

The catalogue quotes guide prices for various jobs – £15 – £25 for restocking a shotgun, £2./10/- for a wooden ramrod with screw, 10/- to £2 for making up a spring to a pattern, £3 for relaying ribs and thimbles etc…..

1968 was during Harold Wilson’s premiership and after the pay freeze and the 4 day week – inflation for the year was 4.7% – The Beetles were in vogue! A pound then is worth about 12 pounds now according to the retail price index. I wonder where Kit Ravenshead went and where the castings came from – some of the stuff came from the US. I’m not sure when Ed Blackley started – (I must ask him, he’s a friend of Dicks and lives nearby) – he started not far from Framlingham I wonder if there was a connection? I’m sure someone will tell me…………

I’m still engrossed in the Wyatt Earp book – I used to enjoy Westerns and WWII stories when I was a teenager but my father thought they were just trash and discouraged me from reading them, so I stopped reading fiction of any shape or form, and still don’t. Not the effect he intended, but the law of unintended consequences plagues parental attempts at control – he was never smart enough to realise this.