12th June.. I have been a bit slack on the blog! I had a 3 1/2 hour very intense meeting on Monday that left me a bit disinclined to do much except swim up and down, after which I just slumped! Today I did a bit of sorting out of shot, wads and cards and powder for the trip to Scotland. As I’m taking 4 muzzle loading guns I though I ought to check which wads I needed for each, which led to sizing all the bores – of course no two guns are the same actual bore, whatever their nominal bore is, anyway I managed to cut it down to 2 sizes of wads, conveniently one size for Tom and one size for my guns. Tomorrow I must make sure the right guns are on my certificate! This blog is obviously being found by lots of people as I’m getting a steady stream of photos of guns and pistols to identify. I live in hope that I’ll discover a priceless antique gun for someone, but at the moment its rather at the opposite end of the spectrum. I did my STEM club with Dave today, but there was a football match on and we only got two kids, so they got on and built a robot while Dave and I programmed our line following robot to skirt round an obstruction – we got about half way there in 45 minutes!

10th June… I did say that the weather encouraged sitting in the sun rather than working away in the workshop! …..So we went to an Elderflower party today, a friend’s family has been holding one every year for the last 50 odd years to make elderflower wine, which they consume in some quantity. Around 30 people spend a few hours collecting flowers and getting the heads off in order to make 20 gallons of wine (it used to be much more) to last the year. After the work some of us played a game of croquet – it looks like a nice gently, very English, very genteel way to spend an afternoon. In fact it is about the most vicious game of skill and tactics imaginable – winning is more about scuppering the opposition than getting ahead – in fact getting an early lead isn’t necessarily a great help as I found out to my cost, since if you manage to hit an opponent’s ball you get an extra turn, thus if there are no opponents balls near you, you miss out! Anyway (son) Giles beat me ( that’s his inheritance down the drain!). The number of visitors and visits to the site continues to increase, which is nice – so far in the last 365 days there have been over 100,000 visitors and 670,000 items viewed – obviously a lot of those are regulars who get counted each time they visit – its a shame the software doesn’t analyse visits in more detail, but I think you have to pay if you want more detail, which of course anyone making money out of a site would do. I sometimes wonder whether there is any way I could ‘monetise’ the site, but actually I’m happy to do it for fun, and I do get some interesting work from time to time, and make new acquaintances and friends, so I’ll carry on for a bit longer!

9th June later… Shooting at Cambridge Gun Club today – our 1/2 oz of shot competition. No compromise on the difficulty or range of clays, and the hit rate was a little down on some normal shoots but still good – I did my usual mediocre shooting, but was reassured that several others got the same score! After lunch I switched to my little 20 bore Beretta hammer gun and did somewhat better – I am resolved to go and practice properly until I can shoot a bit better. I have in mind to try an interesting experiment, as I think that one often knows before one pulls the trigger that it is going to miss. My competition would work as follows – unlimited clays, but fixed number of shots allowed – score 0 for any clay you don’t shoot at, -1 for any you shoot at and miss, and 2 for each clay you break with the first barrel, or 1 if you break it with the second barrel. I reckon this would concentrate the mind! So a top score would be 40 and a lowest score would be -20, if you hit half the clays you score 20 and hitting 7 (1 in 3 shots) scores 1 . I now need to find someone to try it with. It could of course be a bit more expensive if you aim to shoot the ‘normal’ number of shots, but it might work with say 20 shots, using a very limited number of traps, say 5 hits at each of 4 traps…….. I took the Manton back to its owner who was well pleased – I forgot his slip, which I found on the peg when I got back – I’m very good at labelling slips and ramrods when I have guns to work on, as they are easy to mix up or mislay, I just forgot to look behind the door! Pete asked me to tap a hole in a cleaning rod to take the ‘normal’ brushes etc., but that seems to have opened a whole can of worms – The tap I have used is a 9/32 x 26 BSF but that actually cuts too tight – the web suggests 9/32 BSB ( brass thread ( similar to BSC cycle thread & always 26 t.p.i.) but I only have the BSF in 9/32 and that appears a bit smaller than the brush threads – what I thought was going to be a trivial job becomes a lot more involved – but then these challenges are what makes it interesting………………………

9th June – Back from 2 days in Norfolk at an outdoor activity centre with the year 5 & 6 children from the school I’m a governor at. Great fun and the kids had a good time and were very well behaved! The activity centre was based around an 1898 house designed by Edward Lutyens so I had great fun poking around and trying to work out how the house had been originally before it was altered in several waves – first in WWI as a convalescent home for soldiers, then back to being a private house, then the activity centre, which retained quite a lot of the old furniture etc in the ‘public’ rooms, including about 10 years of Hansard containg every word spoken in Parliament during that time – covered one wall! I could have spent the whole time reading MP’s speeches from 1975! Anyway back to real life – in particular our annual recession shoot, in which we shoot clays using 1/2 oz shot load – its not as bad as you might think…. anyway I’d better load up and head out…..

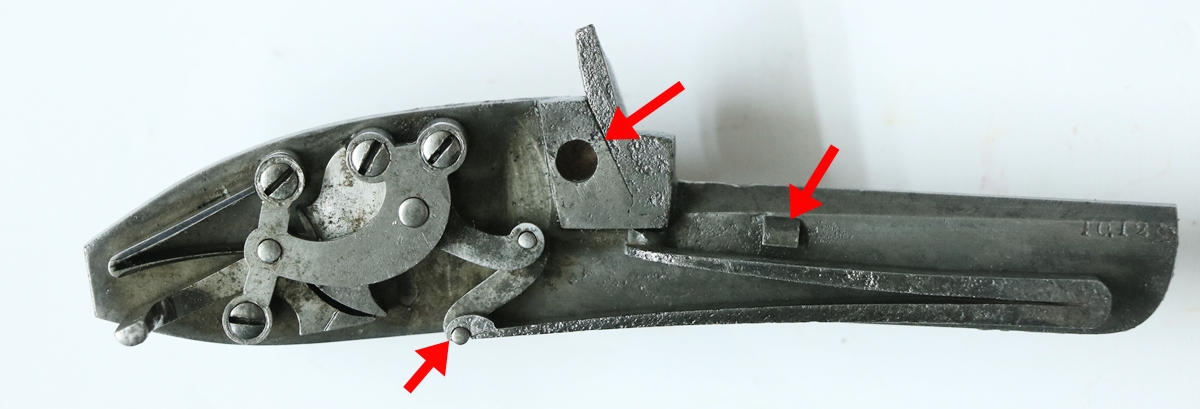

5th June Dick and I spent an hour together getting the locks of the Manton to fit – I had fitted new springs and Dick had re-fixed the ‘rims’ of the lock pockets that were a bit broken away. You may remember that we had found that the locks and barrel were original Manton, but had been grafted into a different and older stock at some point. We had two problems – 1, the springs were slightly bigger in places than the previous ones and so we had to adjust the german silver reinforcing sheet at the top of the mainspring slot, and second that the lock front extensions didn’t fit between the barrel bolsters and the edge of the lock pocket, and were opening an old crack in the woodwork – presumably the cause of the previous damage around the locks. Unfortunately the rim of the lock pocket under the mainspring was already very thin, so no room to cut more away – I realised that the reason the numbers on the inside of the lock above the mainspring had been half filed away was a relic of previous attempts to solve the problem. Anyway we filed the bolsters on the barrel down a bit – luckily the breech block was only slightly hard. Anyway judicious filing got it all together, and we filled the crack with a shim of walnut verneer and refinished it. – Job done and ready to go….. Now I’m off to Norfolk with the Yr 5 & 6 children to an activity centre… I’ll report back……..

4th June – Didn’t manage much today – just finished off the cartridge loading so I now have 100 Black Powder cartridges for Scotland. I promised to make another shot belt for a friend, and started on that – I think its going to be a bit smaller than mine, which is a bit heavy when full – for game shooting you don’t need a lot of shot and the less you have to carry across ploughed fields the better!

4th June – Excuse the absence yesterday, as I said, sitting in the garden took priority! Today a meeting all morning in school prevents the garden sitting, and anyway the weather isn’t so appealing! I have now managed to make 75 cartridges towards my 100 total so nearly there. The rifle is now getting the oil finish on its stock augmented as it was a bit worn, and I took a photo of the patchbox in situ – I think it looks the part, but these things are always subjective!

It’s in the process of having its oil finish restored – it has the smeared on flood coat waiting to gel and be rubbed off, so looks a bit of a mess!

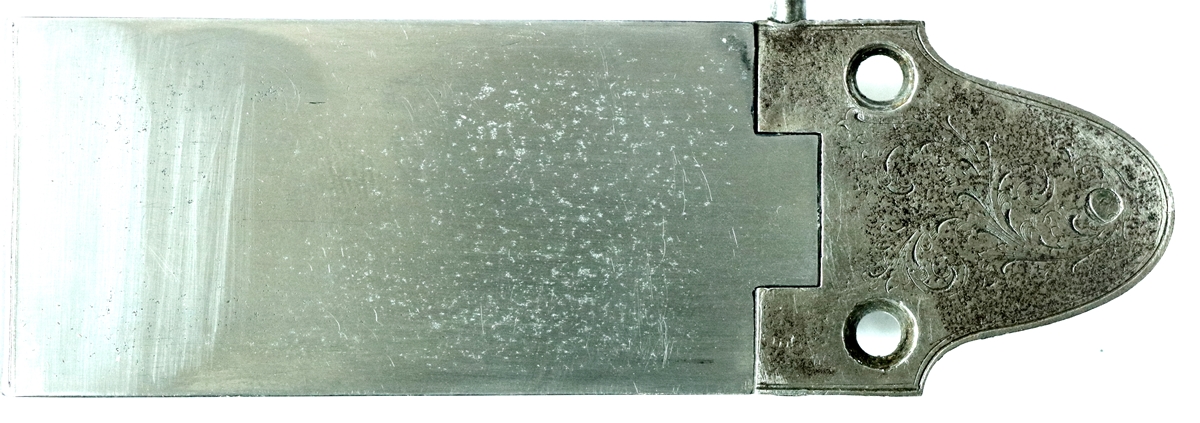

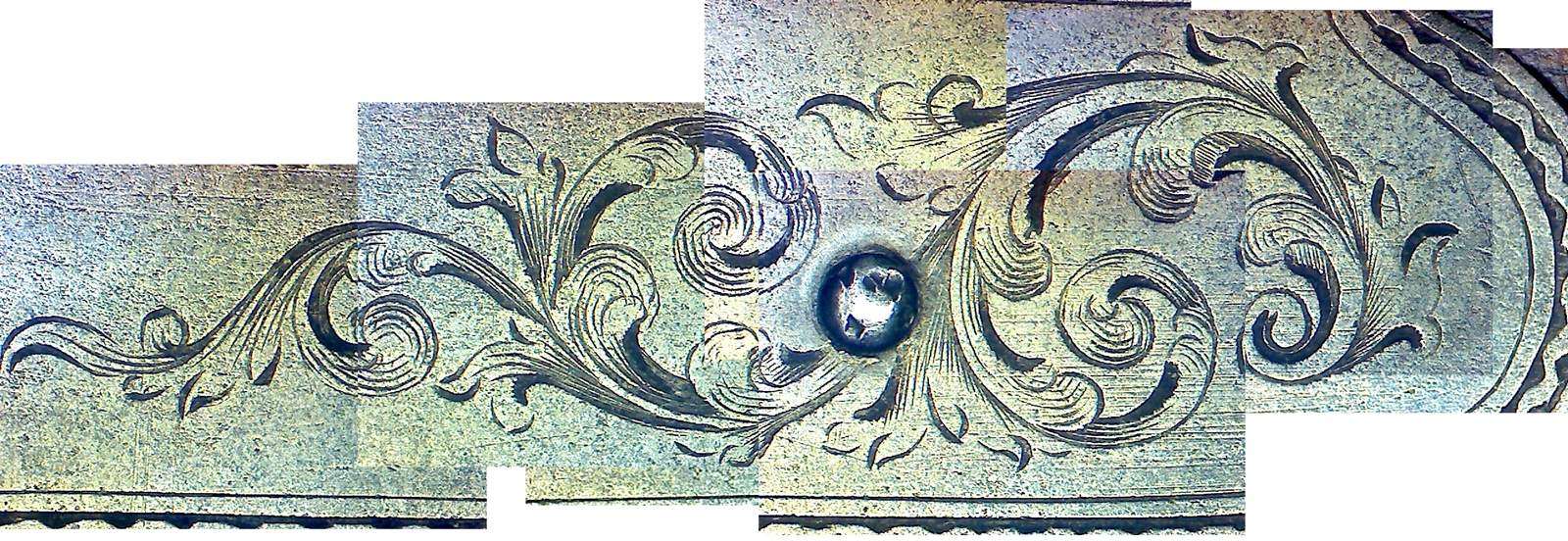

2nd June. I put the patchbox lid in the rifle and it looks good – the toning down of the colour works quite well – I coloured it lightish straw on the AGA hotplate, then rubbed it over with 7000 grit paper, then gave it a rusting with my browning solution – that went rather too well so I rubbed that partly off with 1000 grit and finished with 2500 and 7000 and polished with 0000 steel wool. It doesn’t sound like a recipe for success but it worked – I did think at one point I’d have to start again, but it came good! Photo soon! The annual trip to Leucars to shoot the Scottish National Muzzle Loading Championships is the w/e after next so I thought I’d better start loading the annual bag of black powder 12 bore cartridges – Tom shoots there too using my guns as he doesn’t have a certificate in Scotland. (He’s in St Andrews so dead handy and my B & B for the w/e) so I need double rations for the hammer gun competition. I usually take my Bacon patent antique bolt action double for him, and use my Westley Richards 1874 patent hammer gun by William Powell, of which I am very fond! Anyway 100 cartridges should do – I got a couple of bags of capped cases at the Northern Shooting Show – its as cheap to buy new capped cases as to buy the caps and use reclaimed cases, even if its not so environmentally friendly – not that shooting clays scores high on those stakes anyway… I’m getting through the restoration jobs on my list, thanks to help from Dick – I’ve now got the forend iron of the Purdey to engrave, but I’m waiting for pulls of the action body so I can line up the scrolls. After that I’ll have to find some of my own jobs to do! Things usually quieten down in the summer as I find its rather nice just to sit in the garden and read the paper………………….( weather permitting)…

1 June – I had an email from someone who had come across the post on the Land Cruiser steering lock problem on this site and had a similar problem. I was able to get out my pile of bits and work out how to remove the broken bit of the lock bar – and send him some pictures. That post gets quite a few visits – If I can be bothered I can review all the traffic to the site on a daily basis, it also tells me which are the most popular posts, and I can see where all the attempts to crack the site are coming from. I don’t look very often – I just keep an eye on the number of visitors and visits. I finished the patchbox lid and I’m just colouring it up – its not too bad considering how difficult the metal turned out to be – I couldn’t get consistent cutting, and the inclusions didn’t help, in the end I started to use the GRS gravermax air driven graver, which I don’t use often, as it ploughs through most things without discriminating and if you are not careful it goes very deep. I forgot to take a photo before browning so it will have to wait!

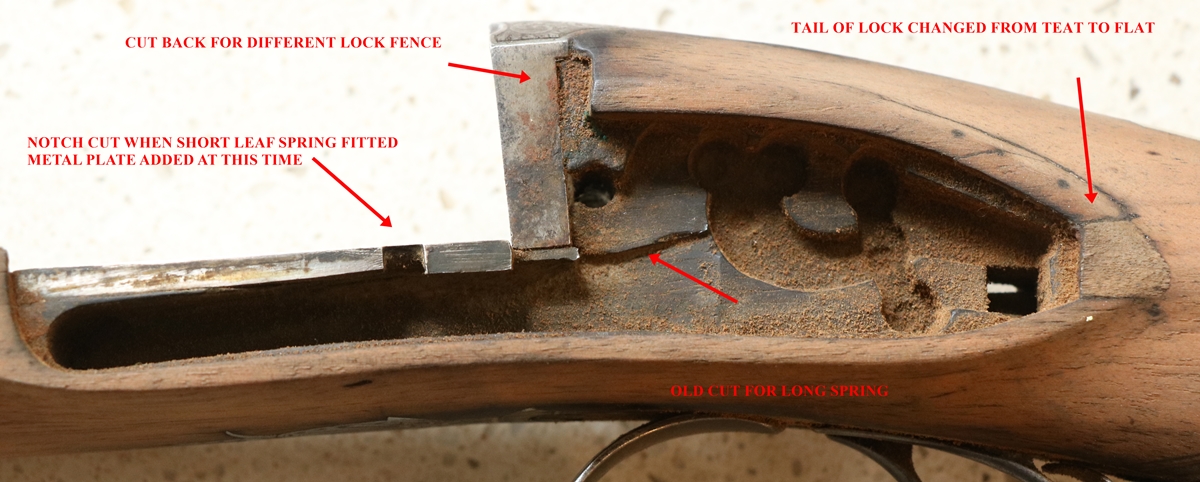

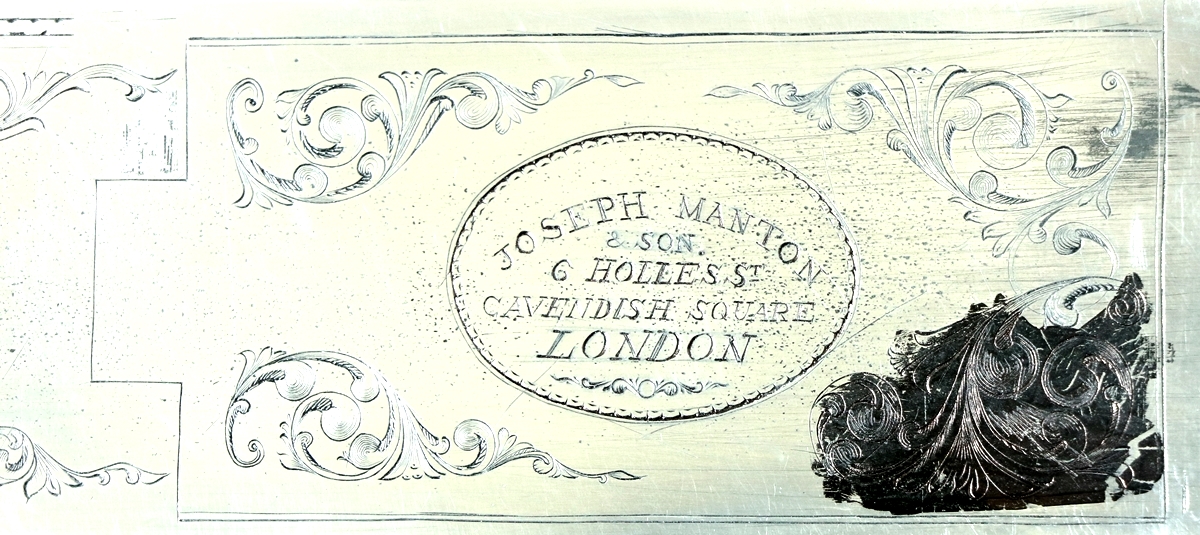

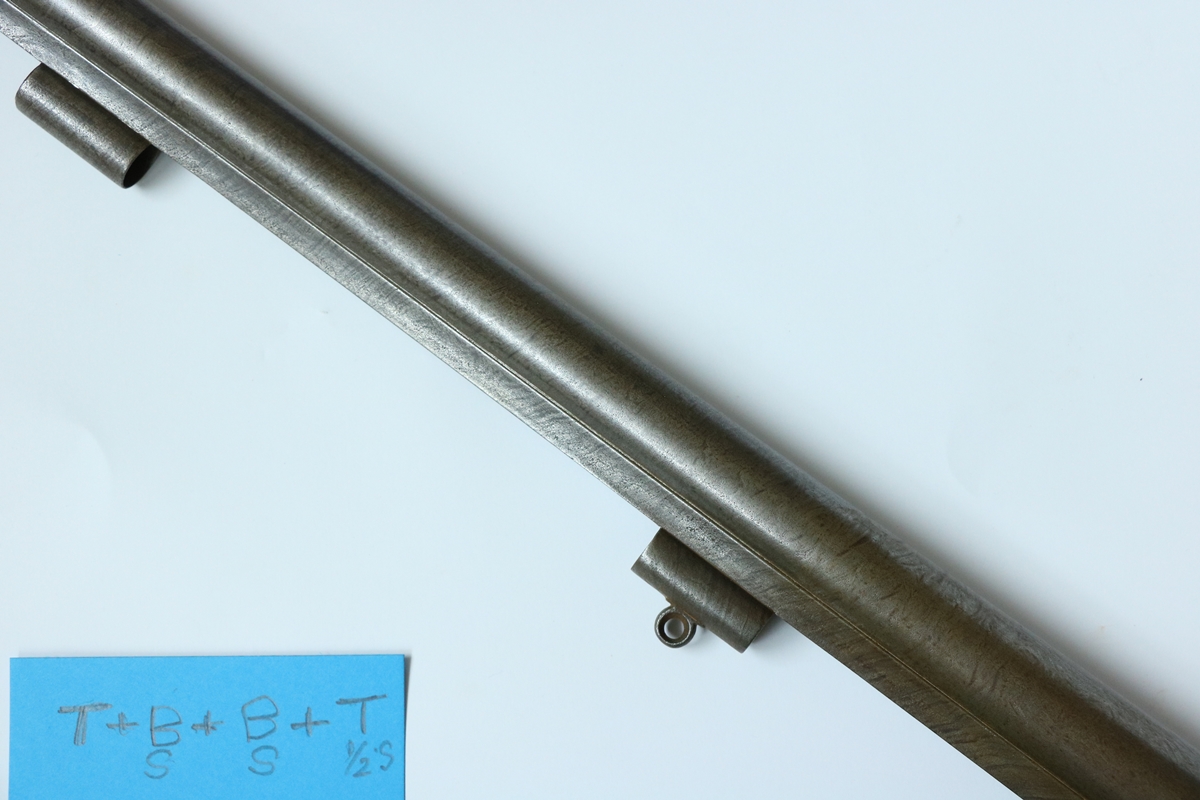

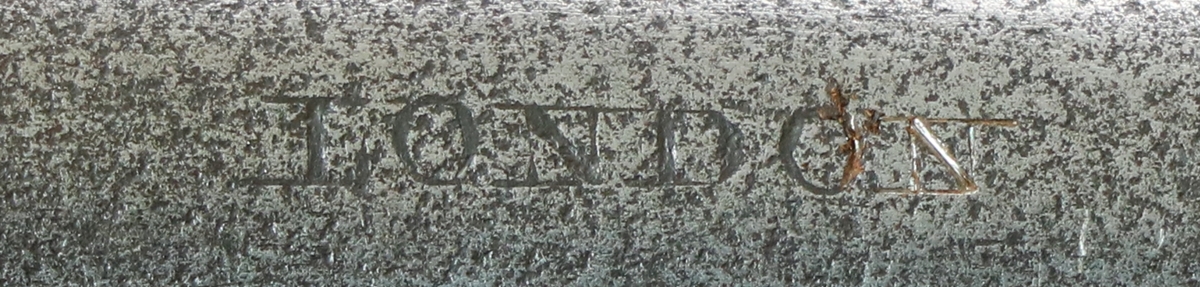

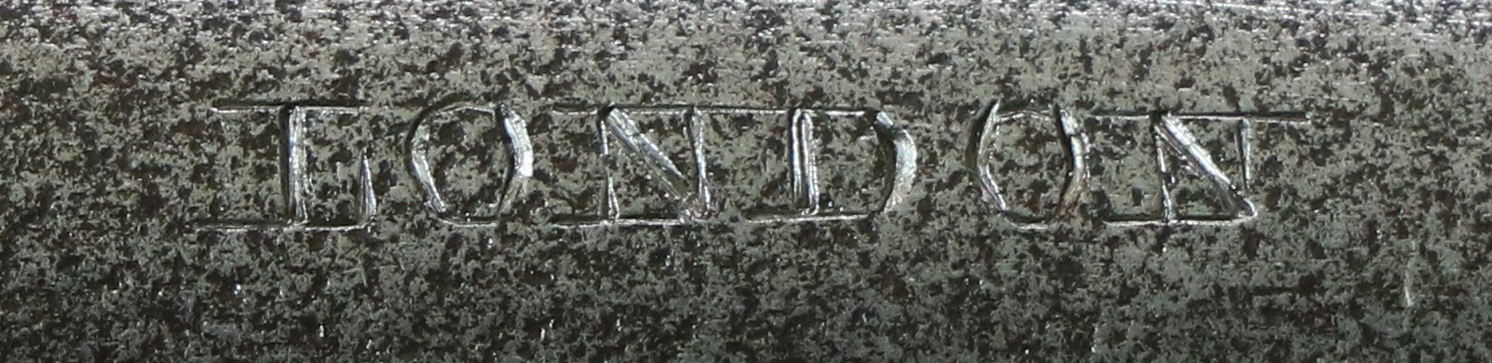

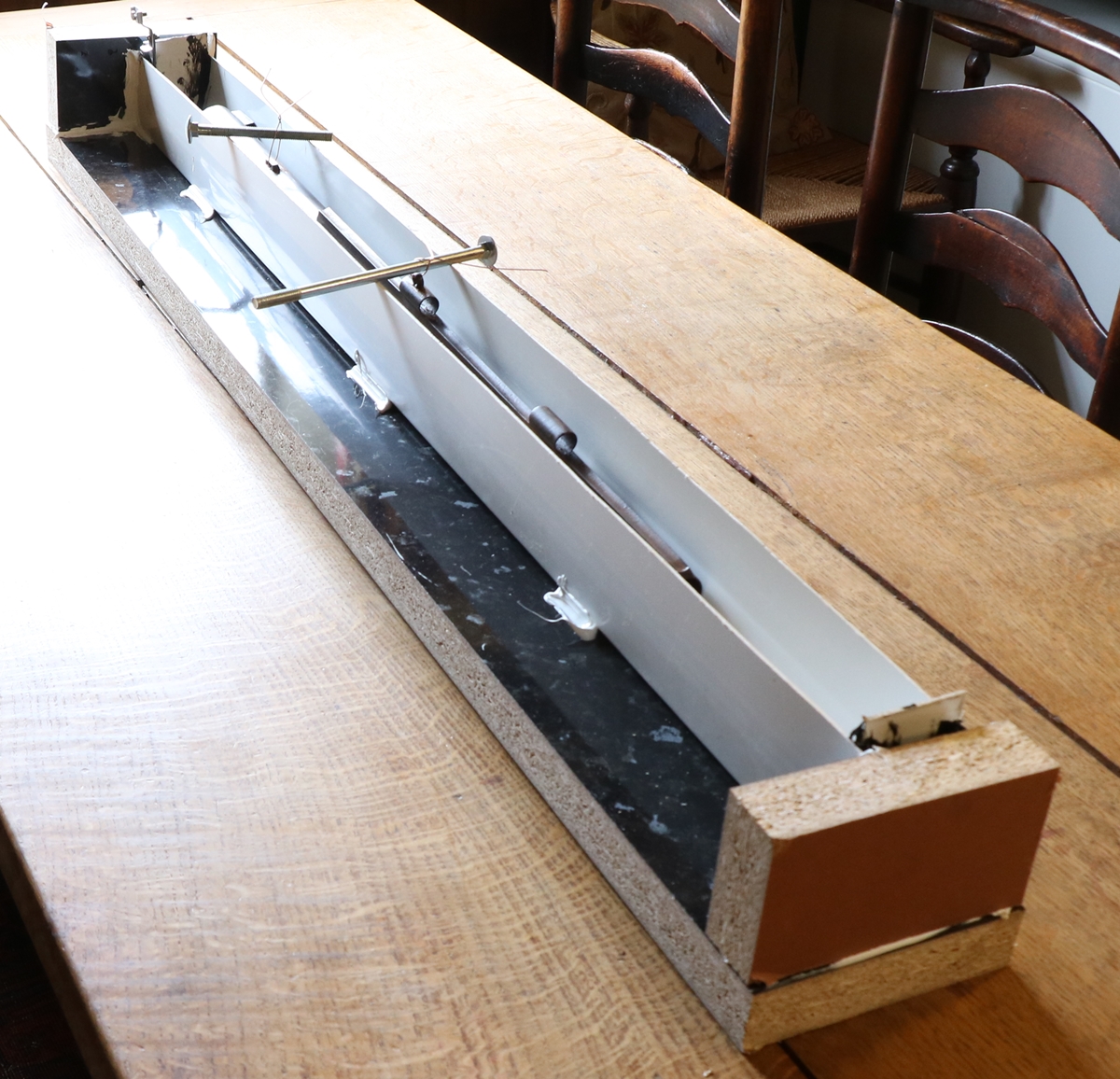

Dick got carried away with the Manton stock! He needed to sort out one or two problems, including all the cracks around the lock pockets and then decided that he would have to refinish it. In stripping it he uncovered some intriguing history – while the locks, breech plug and barrel are original Manton as far as we can tell, they have been fitted into a different stock at some point – probably a long time ago. The evidence for this comes mostly from the photo below. It looks as if the stock originally had locks with a different shaped tail (almost certainly older) and the cutout for the fence behind the false breech shows that has been changed. There is a plate (German silver?) screwed in under the breeches, presumably to reinforce that area, and it has a notch cut out for the lug to take the end of the short top arm mainspring that was fitted to the gun as found. The fixings of the plate are not symmetrical- suggesting it wasn’t done by a gunsmith.. The lock pocket of the stock has the correct cutout for a long top arm spring. Confirmation comes from the matching number engraved on the tang of the trigger guard – it is not very carefully positioned or executed and doesn’t come near the rest of the engraving in quality – it can’t be original…. The original stock was from a good quality gun, possibly even another Manton and has the original furniture and breech block, Probably percussion as there isn’t a cutout for the cock to hit the top edge of the lock – but it might be for a flintlock with a French cock….. The stock was presumably made for a long top arm mainspring, and the Manton locks will take either – I guess when the swap happened the Manton locks had had long top arm mainsprings, as had the stock, and the locks were modified by the fitting of a small lug on a peg to catch the end of the short top arm. The stock has been neatly extended and the joint covered with chequering.

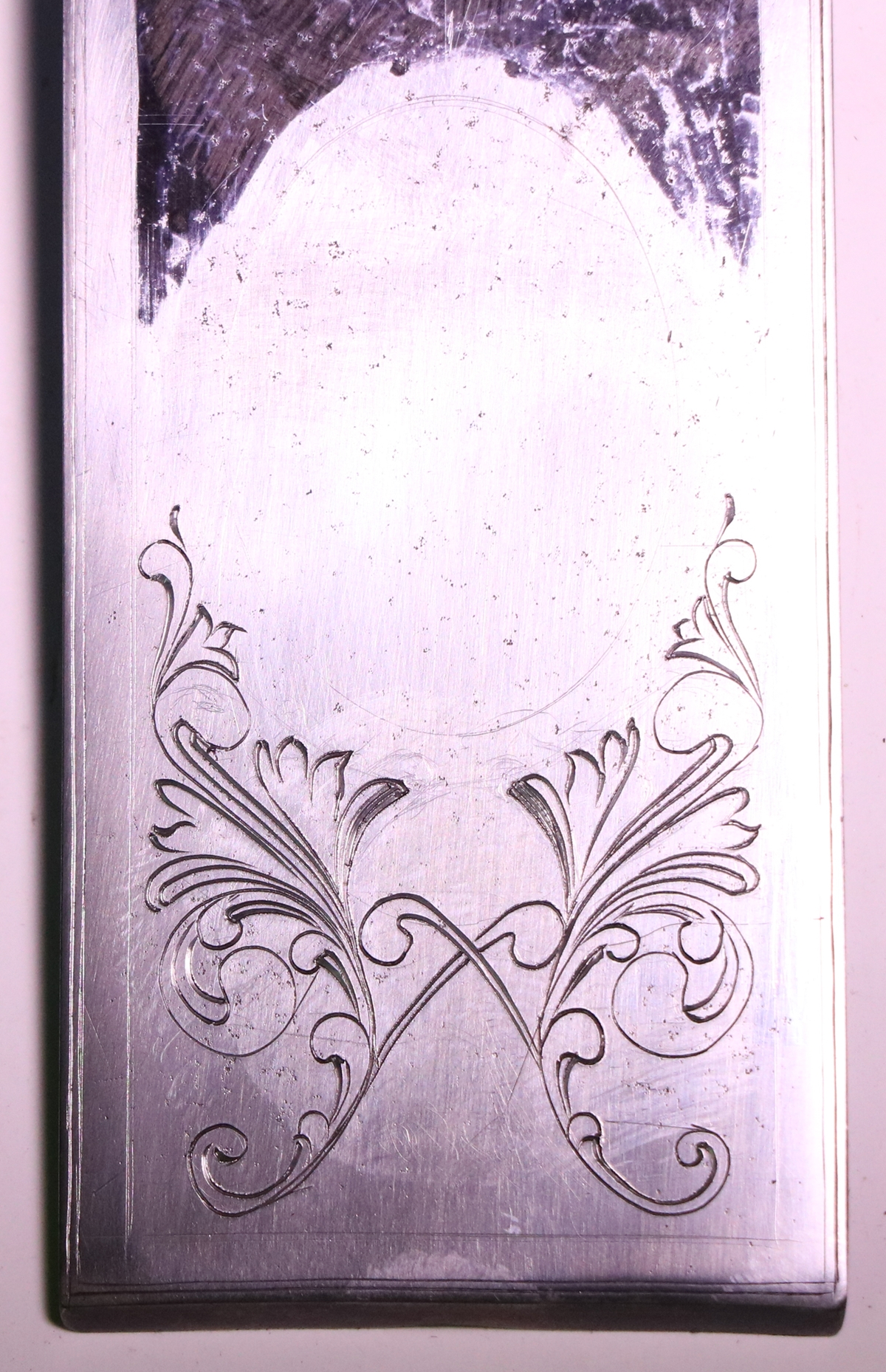

31st May Out a.m. but this afternoon I decided that it was time to bite the bullet and get on with the patchbox lid – you can walk round a job for just so long and you get nowhere. Anyway I looked at my designs and decided to go with more or less what I had already tried. The lid had lots of flecks in the surface that I thought were the orange peel marks from cold rolling, but they seemed more like little pits of corrosion – anyway it cuts OK in places but seems to have some inclusions that occasionally make it difficult to cut smoothly – anyway I’ve got most of it roughed out ready for the details and shading – I’m going to leave a space in the middle that would fit the oval, but probably not cut it. I’ll try to get it finished tomorrow with luck. I need to visit Dick and get tht Manton stock back before the weekend so I can take it back to CGC ant the muzzle loader’s shoot.

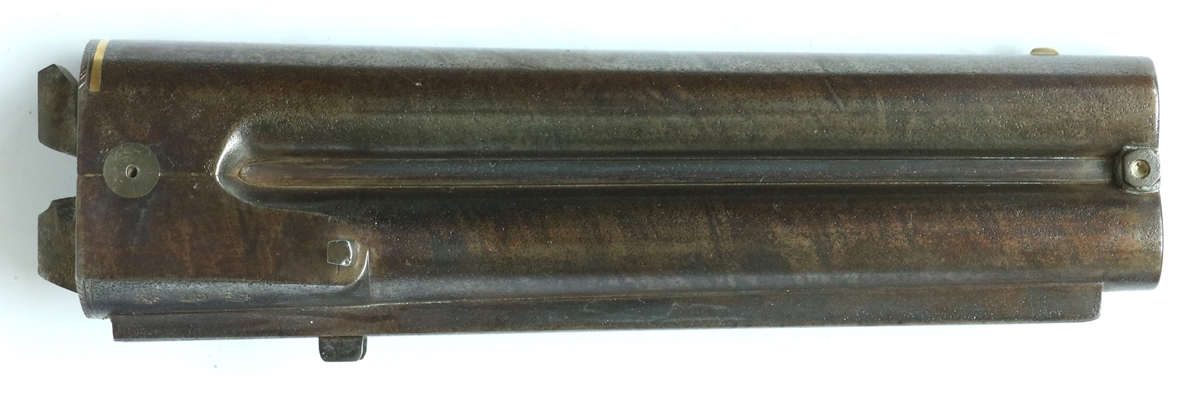

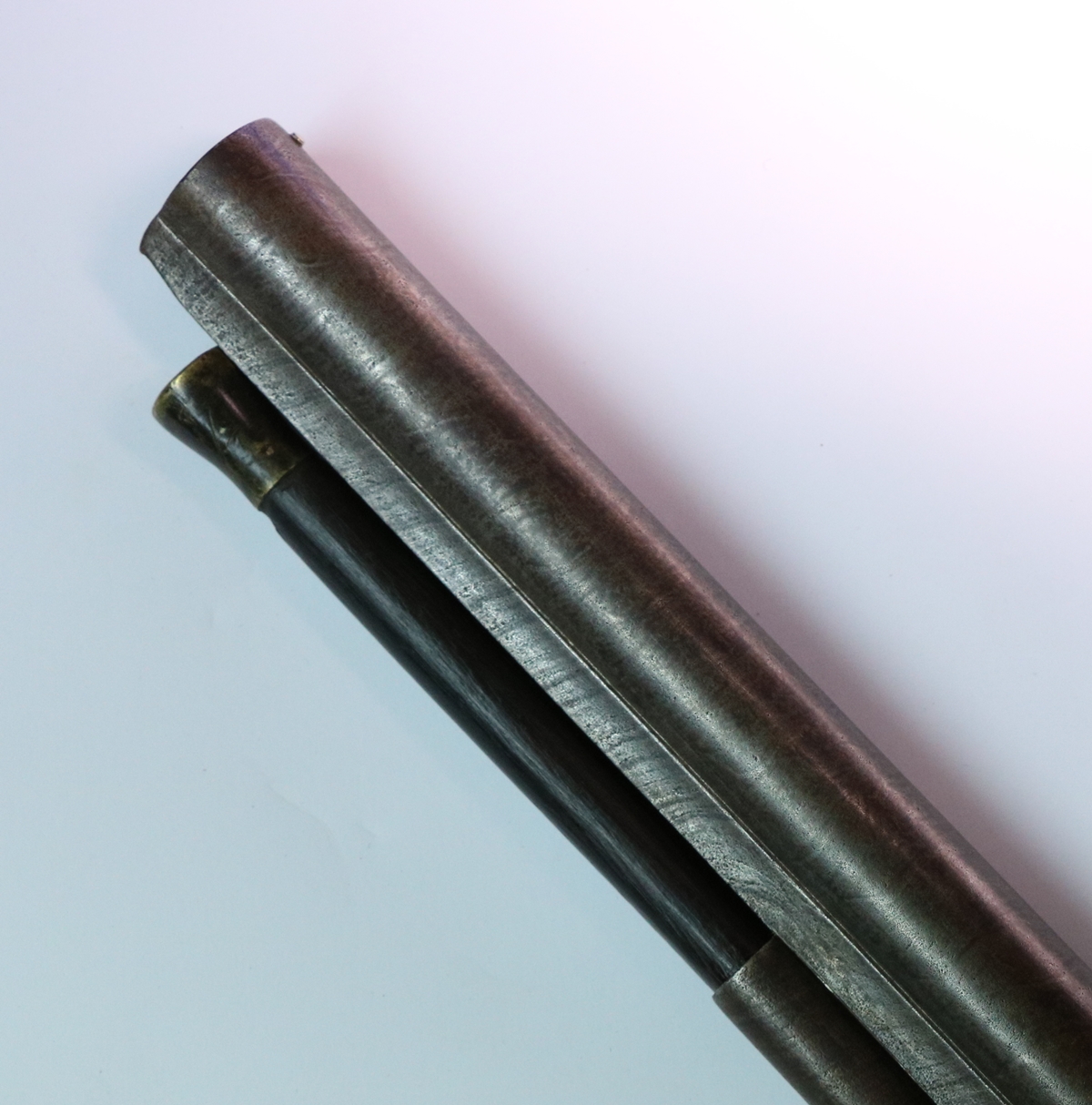

30th May – Still trialing the engraving for the patchbox lid – I needed lots of engraving practice as I’d been a bit lax recently! I finished trying my original idea for the lid, and for fun engraved the oval ( done very quickly and carelessly!). I put the lid in my furnace to ‘normalise’ it as I wanted to make sure that it was in the annealed state – an hour or so at 910 C and a very slow cool. When I looked at the existing top to the patchbox (see below) I realised I’d been copying the lock engraving – the lid is slightly different in feel and some of the cuts are different – possibly a different engraver or in different frame of mind. In particular the top isn’t symmetrical and is more open, so I am having a bit of a re-think – my efforts are not wasted as most of it is very similar. I changed my tactics with gravers today – when one got a bit blunt I sharpened it instead of changing it for a fresh one – it seemed to work better, possibly because all my gravers are different lengths and it saved continually changing my hold. Mostly I can get away with just touching up the heels. The over and under pistol barrels came good – in contrast to the Manton barrel they only needed about 5 brownings – there isn’t a lot of figure in them, the twist is a bit indistinct – I don’t think its a function of the browning process – just how the metal is, but they are a very nice chestnut brown – very discrete. It’s possible I could have brought out the figure more my etching the barrels in copper sulphate solution before browning them, but I can’t see a distinct enough twist to be worth the erosion of the metal.