A Beginners’ Guide to

Collecting and Restoration

Part 3: Muzzle Loading Fowlers.

By Tim Owen

First Published in the Spring 2015 edition of Black Powder, the magazine of the Muzzle Loading Association of Great Britain.

The preface to English Gunmakers by De Witt Bailley and Douglas A Nie makes the point that without an understanding of the social history of the time and area from which our guns came, we cannot hope to understand the guns themselves – in their words, they become merely pieces of wood with various metallic parts attached. For almost three centuries firearms were by far the most complex mechanical devices produced to a pattern in large numbers, and firearms makers pioneered almost all the early production methods that gave rise to our industrial society, so the converse is also true; we cannot hope to understand our social history without understanding the manufacture, use and abuse of firearms. In this article I have tried to show something of the context in which our sporting guns sit, and to document some of the clues to their chronology. In the interests of brevity I have concentrated on working guns rather than presentation pieces and much detail has had to be omitted – dates given are approximate and usually relate to the first introduction of features – not all makers followed changes and they often spread slowly from London outwards, and some customers would have insisted on familiar features after they had ceased to be fashionable.

The force driving firearms development was initially the requirements of the military, and one presumes that the first sporting shooting was with military muskets and pistols, and later at the turn of the 16th century, with guns made for sporting purposes along similar lines, probably using ball, at deer and ground game. Shot was known to have been used as long ago as Tudor times, so would probably have been used in s ‘birding pieces’ for sitting birds, although shooting flying birds would have been extremely difficult if not impossible with these early guns. Up to the time of the English Civil War (1656 – 66) the aristocracy held much of England in great estates and deer shooting was probably their main sporting activity. The many fens and marshes were home to vast flocks of waterfowl that provided food and employment during the winter when agriculture was dormant and country folk with a few acres probably shot whatever they could for the pot. After the Civil War the Parliamentarians dispossessed many of the landowning families and broke up many of the big estates, and rigorously controlled gunmakers. Many forests had been cut down to build ships for the navies of the two sides. Only a few parts of the country were not fought over, and the English countryside was changed by the time of the Restoration of the Monarchy in 1666. Sporting shooting began to recover and focus on wild game birds and ground game – suitable for smaller estates, while waterfowl were shot mainly as a food source.

Development in guns and powder was gradual through the beginning and middle of the 18th century, giving us the classic single barrelled Queen Anne fowler with which it was just possible to take some flying shots, but took off towards the last quarter of the 18th century spurred on by basic technical advances, an enthusiasm for science, invention and manufacturing and a cyclic market for military arms , and we see rapid change in guns, gun manufacturing and sporting shooting that didn’t begin to settle down until the end of the 19th century. Improvements in guns made it feasible to shoot flying, and also made double barrelled guns practical and by about the turn of the century the Mantons, Henry Nock and others had established London as the gunmaking capital of the world. In the second quarter of the 19th century percussion ignition made guns faster and more reliable, and reduced the cost of manufacture so that more people could have a gun for sport or for shooting for the pot. Shooting became extremely popular as a hobby – there were many volunteer rifle companies, and the forerunner of clay shooting was born; shooting at live pigeons released from traps. Initially a sport for what W. W. Greener called “the frequenters of low public houses in large towns”, it was taken up by the gentry and a number of exclusive clubs were formed around 1860. This gave rise to a characteristic type of gun – single barrelled percussion or tubelock of up to 6 bore without a ramrod, although eventually most club rules limited the bore size to 10 or 11 and the load to 1 ½ oz of No 6 shot, and competitions for double barrelled guns were introduced. Around 1856 glass balls (later filled with feathers) fired from spring traps began to be used as targets, and shortly after that clay disks were used. The shooting pressure on wild game, particularly pheasants, reduced their populations considerably, so they were no longer widely available as landowners first moved to conserve game for their own shoots, and then introduced reared game to make up the deficit as the 19th century advanced. The high cost of reared game led to pheasant shooting becoming a sport of the rich, and to a tightening of the game laws to restricted access for the less well heeled sportsman – a situation that remains to this day!

As the guns themselves evolved, so the gunmaking trade changed in response to increased demand and technical sophistication. The 17th & 18th century demand for military muskets as well as trade and ‘slave guns’ plus the market for sporting guns and private arms created a demand that the established gunmakers, up till now largely based in London, could not supply and led to a rapid growth of gun part manufacture in and around Birmingham, from more or less nothing at the beginning of the 18th century – the first Birmingham contract for military arms was in 1689 – until by the mid 19th century there were twice as many people employed in the gun ‘industry’ in Birmingham as in the whole of the rest of Scotland, England and Wales. Birmingham had few makers of ‘Best’ quality guns to compare with London, but by the end of the flintlock era many provincial gunmakers, and a number of lesser London ones, were buying in substanitally complete guns from Birmingham to resell, sometimes already engraved with their names. Birmingham provided competition to London, and they eventually settled to an ad hoc division of labour with Birmingham mostly producing Locks, furniture and barrels, and London specialising in stocking and percussioning. Despite the importance of barrel making, it is interesting that it wasn’t until 1813 that Birmingham established its own official proof house

Any provincial gunmakers that were not buying in complete guns were almost certainly buying in all or most of the metal parts ‘in the white’ so that they avoided the raw metalworking trades. The Birmingham trade was organised around individuals or small groups, often self employed, working from home or rented workshops, who specialised in just a single or very limited set of operations on one part of the gun – so that barrels for example, might be worked on by a barrel forger, borer, setter, filer, percussioner, polisher, engraver, inlayer, and browner, along with the breech forger, filer etc etc and the rib maker, pipe maker & loop maker! None of whom, with the possible exception of the engraver and of course the stocker and actioner, would normally work on more than one type of gun parts while there was enough work to keep them busy. A veritable army of boys must have been engaged in running hither and thither with parts in various stages of completion. The overall manufacture would be organised by the ‘gunmaker’ who would, in fact, not make anything! The net result was a highly diffuse but efficient almost totally manual mass production system that minimised costs, and particularly capital costs, and provided maximum flexibility in times of fluctuating market volumes. Since a Birmingham made gun might be worked on by at least 20 or 30 separate highly specialised craftsmen, it is easy to see why provincial gunmakers could not compete against Birmingham made parts and guns in the manufacture of low and middle quality guns. It is estimated that the total Birmingham output in the percussion era was as high as the equivalent of half to one million complete guns per annum. It is interesting that America never had this complex manufacturing system, so that when it came to adopting machinery there was no real competition from handwork, whereas in England it was initially difficult to justify the change economically because of the high fixed costs of machinery, and several firms based on the early use of machinery failed.

So much for the overall historical context, but what can we see in our guns to fit them into this background? A few grand people would no doubt have made sport shooting matchlocks and wheel locks, and some folk would no doubt have used old matchlocks to fill the pot, but the story really begins with the the dog lock and snaphaunch which were soon to be followed by the familiar flintlock that originated from France, around the time of the Civil War. Still looking like its military cousin, the sporting flintlocks of the mid to late 17th century would have been full stocked with a single barrel of about 46 inches to allow the coarse gunpowder time to burn fully, and with the lock mainspring bearing directly on the tumbler, the frizzen acting directly on its spring, a simple breech block with integral tang screwed in, pins through the stock holding the barrel in place and with the touchhole against the face of the breech block. The trigger pivoted on a pin through the stock, and would likely have had a small backwards curl at the end. The lock, held in by two screws, would have a convex face, coming to a point at the aft end, and the furniture of brass or steel, including a full sideplate. There were a number of gunmakers operating in London by this time and the trade was controlled by guilds and the London proof house guaranteed the quality of barrels sold, and by mid 17th century makers had started to sign their guns – up to about 1640 no guns can be positively attributed to particular makers. Any engraving would usually be simple and pretty crudely executed, unless on a richly decorated piece for status or presentation purposes. Development in the first 60 odd years of the 18th century was slow – gunpowder was still poor, lagging behind the French powder in quality, and there was only gradual change in the design of guns and locks. By this time the stock had become slimmer, often with the circular profile of the wrist carried back into stock – the ‘broomstick’ stock, and the barrel had got a bit shorter – usually around 42 inches. These barrels were often bored in a complex way to improve shooting – the breech end of the barrel tapered very slightly inwards in a ‘forcing cone’ , occasionally roughened, designed to retard the projectile while the powder got going, and then a parallel section, followed by a ‘relieving cone’ where the barrel opened out for the last 6 inches or so to ‘allow the shot to speed up’ without friction. The best barrels at this time were made in Madrid or Italy – probably because they had better ore for the iron, and also because they had perfected twist barrels rather than barrels made from a folded over strip as was common in England until the Spanish practice was copied around 1760. Early fine quality guns often had Spanish or Italian barrels mounted by English makers – gentlemen doing the ‘grand tour’ of Europe would bring back a barrel or two and get Twigg or Egg or other top maker to make a gun of it.

The gun trade jogged along , still largely in the shadow of France and the continent until the 3rd quarter of the 18th century, when London gunmakers began to turn out guns of high quality for a very active and competitive market that greatly encouraged development and innovation over the remaining 50 years before the percussion lock more or less completely replaced flintlocks, flintlocks thereafter being sold to a few diehards, or to countries where the supply of caps might be unreliable. Several changes had a marked effect on gun development around this time – the invention of drop shot by William Watts in 1769 to replace cut and tumbled sheet or cast shot which greatly reduced the cost and must have improved the patterning considerably, and the work of Major Congreve and Captain Blomfield in exposing the abysmal quality of English military gunpowder which led to a very substantial improvement in quality of both military and civil gunpowder that at last put it on a par or better than the French powder. The new powder gave much greater consistency, and was made in carefully selected grades in the Congreve Machine invented in 1779, allowing gunmakers to fine tune barrels and loads to give best results. The switch to mined black flints, primarily from Brandon, rather than field flints made ignition more reliable. Given these improvements, the main problem for shooting flying birds – probably the principal sporting shooting activity at that time – was the delay between pulling the trigger, and the discharge of the shot from the barrel. There were three factors to address beside the quality of powder, first the mechanical delay in the cock striking the frizzen and in the red hot metal arriving in the pan, second the delay in the fire travelling from pan to main charge, and thirdly the time it took for the whole main charge to explode. The first problem was tackled by putting a link between the tumbler and the mainspring, and putting a link between frizzen and spring or later substituting a roller on the frizzen or frizzen spring, both changes being made to to reduce friction and thus speed the mechnical action. Henry Nock tackled the third problem next, with his patent breech that introduced a secondary chamber to generate an intermediate explosion to ignite the main charge, which did, somewhat surprisingly, speed things up considerably. The second problem was then tackled by Joseph Manton in stages by shaping the breech block to bring the pan nearer the centreline of the barrel, and modifying the cock geometry so that the flint ended up almost dipping in the powder in the pan, and putting in a very powerful mainspring, plus changes to pan shape. The desirability of removing the barrel for cleaning had previously led to the adoption of the false breech and hooked breech-block, which facilitated these developments in breech design. Once the barrel could be removed easily, the small diameter pins that were driven through the stock to hold the barrel in place became an impediment, and were replaced by flat ‘bolts’ holding the barrel to the stock – initially without escutcheons but later with steel, silver or white metal ovals or rectangles. At around the same time pins through the stock were abandoned as a means of holding furniture, and as a pivot for the trigger. The trigger was then made as a unit with a trigger plate, and later incorporated an anti rattle spring – the subject of Joseph Manton’s first patent. The improvements in guns and powder meant that it was now possible to make a shorter barrel that would shoot as strongly as the old long barrel, and barrels of around 30 to 32 inches became common. The adoption of twist barrels – sometimes made of the stubs of worn horeseshoe nails – of welded iron and steel bars twisted round a mandrel, made it possible to fabricate lighter barrels as the construction aligned the axis of greatest strength in the wrought material with the direction of maximum stress in the barrel wall. True pattern Damascus barrels were made in England from about 1818. Combining shorter and lighter barrels made double barrelled guns a practical proposition, and led to the side by side form that dominated shotgun design for almost two hundred years. Double barrelled guns were always half stocked to save weight, this pattern was rapidly adopted for single barrelled guns as well.

Changes continued in the first decades of the 19th century, with the ‘V’ shaped and ‘waterproof’ pan designs, until the effects of Alexander Forsyth’s invention of the use of fulminates as a primer for the gunpowder, rather than as a substitute for it as had been tried, filtered through to sporting gun design. Forsyth’s patent of 1807 and his ejection from military work led to his setting up in business with James Purdy manufacturing pistols and sporting guns using loose fulminating powder – the ‘scent bottle’ lock and several variations on the pellet lock. Joseph Manton patented a pellet lock and later a tubelock in 1818 that breached Forsyth’s patent but after a legal battle an agreement was reached and the patent was anyway near to expiry The tubelock achieved limited success, but had a later revival around 1840 by Charles Lancaster and others when Manton’s patent itself expired, due to its direct and strong priming effect that resulted in very fast ignition – as I and several of my fellow muzzle loading shooters can confirm. The copper cap quickly replaced other percussion systems around 1823, and remained largely unchanged for a relatively short period before the breech loading cartridge gun became dominant after about 1856. The percussion gun had reached a high degree of perfection from its inception, and its lifetime was marked by few technical changes, limited to minor changes in barrel boring, breech design and nipple boring, progress being marked mainly by minor stylistic and decorative changes. Except for large bore mostly single barrelled guns for wildfowl or live pigeon competition, from about 1800 the most common guns built as fowling pieces, rather than conversions from flintlock, were side by side double barrelled guns with 28 to 32 inch barrels and most commonly with bores between 13 and 16 gauge.

English gun decoration was always more restrained than that commonly found on Continental firearms, and for the most part sporting guns made primarily for use were by comparison austere, particularly up to the end of the flintlock era. Style and decoration of working fowling pieces and sporting rifles was generally quite similar across all makers, and were obviously constrained by fashion and probably because many makers used the same engravers for their work – it would appear that there were far fewer engraving houses than gunmakers. The third quarter of the 18th century saw the demise of the filigree silver or brass side plate on single barrelled guns and its replacement by a flat plate, which itself was short lived, being reduced to a single washer when the front side screw was dropped. Locks from around 1750 were usually flat, with a bevelled edge and simple double line border and little or no decoration beside the maker’s name, although this gave way in the percussion era to more elaborate borders and the unnatural game scenes with the ubiquitous piece of fence, and later to more elegant sea monsters and eventually to complete scrollwork pattterns. Common engraving motives included oddly shaped hunting dogs, standing game birds amid unusual flowers, flying pheasants looking like pterodactyls or occasionally a stand of arms, or a music group. The trigger finial evolved from the early freestyle form to the standard acorn in first and second form and later to the pineapple. The false breech was usually engraved with a cutout background and the breech plug was given a single or double inlayed gold line, later replaced with platinum. English guns were almost always hand ‘push’ engraved rather than chased, carved or etched as on the Continent. Better guns were made with figured rather than straight grained walnut towards the end of the flintlock era and thereafter.

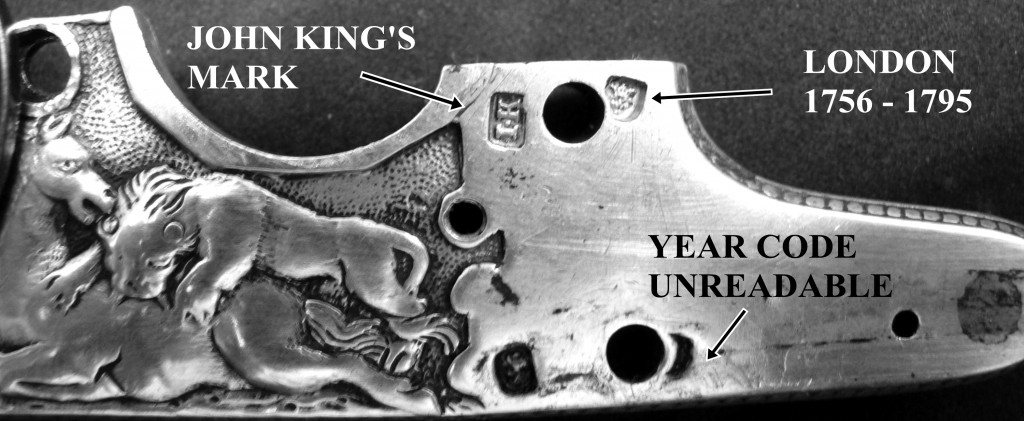

One of the most intriguing aspects of gun collecting is comparing guns made by different makers at similar times, and trying to unravel the influences that shaped the differences and the similarities. You need to recognise the type of customer and the price range the guns were aimed at, and to get to know the characteristics that were common to a number of makers, and also spot those that were restricted to a single maker, or possibly a couple of makers, perhaps linked by having worked together in the past. The Jover shown here as an exercise in dating was stripped of its silver furniture during its working life, but it contains an interesting mix of detail, some of which was probably obsolete at the time the gun was built.

Jover half stocked fowler; a dating challenge

‘Broomstick’ stock and pins securing trigger guard and trigger

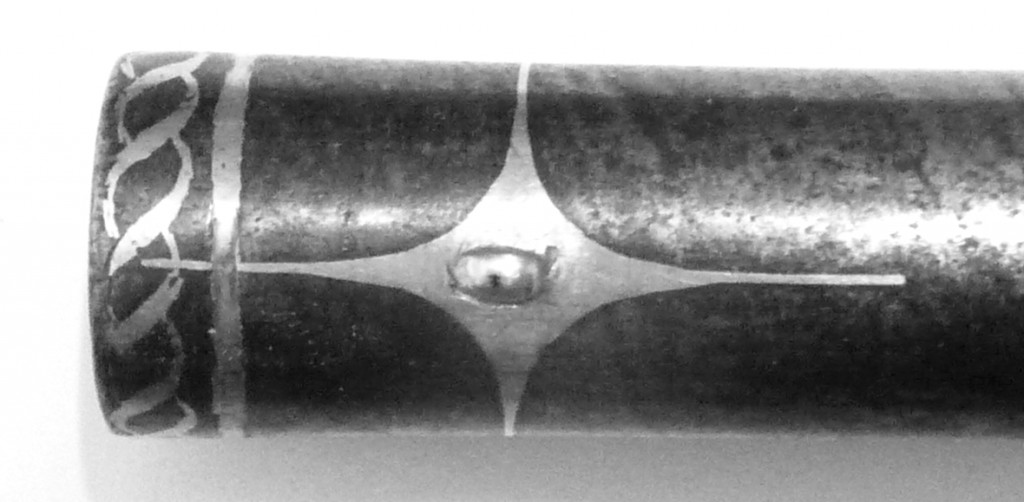

38 inch barrel, simple breech plug and hook

Muzzle – 16 bore to 14 bore over 6 inches

London Proofs and stamp of William Jover – WI

Barrel signature traded as Jover and Son from 1784 to 1810

Shell carving and chequering on wrist

Link from frizzen to spring

Interrupter scear (interceptor nose broken)

Two bolts with escutcheons hold barrel

Hallmarks for 1756 to 1795 – year stamp obliterated. Lock held by one side nail only

Dating clues:

38 inch barrel of Spanish form with distinctly flared muzzle;

Classic form of single barrelled gun but big flare is early ?

Stock with ‘broomstick’ profile; uncommon by 1775?

Simple breech plug with hook; from about 1730 to about 1787

Lock fixed by single screw; from 1777 onward

Link on frizzen; from about 1771 ( Twigg to 1775)

Link on mainspring; from 1770

Pinned furniture and pinned trigger; obsolete from 1775?

Gold touchhole; after 17xx and mostly before 1805

Spider foresight; used by Twigg in the 1770s

Shell carving around tang; Twigg stopped in 1778

Chequering on stock; 1775 or later

Intercepter scear; Twigg used in 1770 for a few years.

Lock has hook at front end but sideplate still has front nail.

Two barrel bolts with escutcheons; 1780 onward, later only one.

Barrel signature; Jover and Son from 1784 – 1796

The best guess? A lot of the features seen on this gun were dated by the time William Jover went into business with his son – he had been in a separate partnership with Nock & Green since about 1777 – so it seems likely that it was made fairly soon after the change – probably in the first few years, almost certainly before 1790. It was obviously a very finely decorated and well made gun but rather old fashioned, suggesting that it wasn’t made primarily as a working gun for a keen shot.