GRAND OPENING OF THE NEW ROOF – 13th September 2009

at 3 p.m. All welcome.

Its now finished! The last bit of slating and leading was done a couple of days

before we went on holiday in mid August.

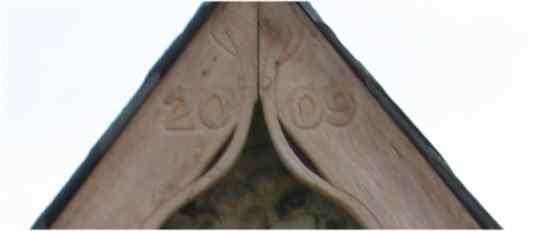

Dated Barge board with eels’ tails.

first view of completed N elevation without

scaffold on 10-9-09.

Brian looking satisfied, the last slate is

on! And one bit of lead to go!

Finished bathroom dormer

This is a diary account of the roof

renovation phase in 2009 – mostly in June, July and early August.

Newest entry is at the top.

HERE ARE THE PEOPLE AND FIRMS THAT I HAVE

USED SO FAR AND AM HAPPY WITH!

Carpentry – Richard Barker, Keeper’s

Cottage, Station Road, Dullingham – 070970 596868 – great work!

Scaffolding - Burwell Scaffold 01638 742471 Very helpful, quick and good value.

Roofing Supplies - Sudbury Roofing Supplies

- Long Melford - 01787 881398 The best

prices around for everything for roofing.

Timber - Ridgeons, Newmarket – 01638

666900 Reliable quality and service,

sometimes a bit ( or very) expensive.

Fixings etc – Screwfix 0800 056 7689 - very fast and reliable, good range and reasonable prices.

Insulation – Enigma Insulation XXXXXXX TLX Gold is unique product, prices of glass

wool etc are sharp and service good.

OAK – Duke and Brown – Wimbish 01799516084 – good source of green and seasoned oak and other hardwoods.

Reclaimed materials – Butler Bros. Duxford – the best organised yard in town!

STOP PRESS – I’m getting lots of fond references to the old

blue tarpaulin that graced the roof for may years and shed blue fibres all over the village – I miss it

too, but archeologists should have a field day in a few hundred years – the

blue tarpaulin horizon! If you want to

contact me with expressions of sympathy,

email timowen@carrack.co.uk.

DAY BY DAY ACCOUNT

Tuesday 4th

August – The weather has slowed things down a bit, but I’ve got the valley roof

sorted and yesterday I completed the rest of the ridge timberwork. Quite a tedious job as the ridge board was

original and wandered up and down and from side to side. In the end I had to get my electric planer

up on the ridge and take around 15mm

off in places – I got it acceptable in the end and put on the chamfered

2x5 and the mopstick. On the West elevation there is quite a wide gap for the

top ‘half’ slate to cover at the front, tapering out at the back to normal.

I ran out of 30mm copper nails and

thought it would be easier to buy them at Ridgeons, - I needed 4 Kg, but at

£28.50 per Kg + VAT against the £7.50 + VAT at Sudbury Roofing, I figured it was worth the 50 mile round trip to Long Melford! I don’t know if Ridgeons were charging the

5Kg price by mistake or just a rip-off - probably the latter. As luck would

have it Subury Roofing had some good secondhand Welsh slates at £1.45 + VAT so

I got another 270 which I hope will finish the roof. Their price for good new Spanish slates is 85p which is cheaper

than the rubbish on ebay! Ben and

Brian are tied up on another job and are going to try to finish my roof next

Saturday and Sunday. I’ll try to get

things ready for them, so they can finish in the 2 days – putting on the ridge

timber has already saved them a lot of time.

I got a new spring for Ben’s slating cutter and punch at Sudbury and

fitted it – so its now as good as new.

I enjoyed working on the ridge – wonderful

view of everything that is going on in the village too!

I managed to finish off the lead flashing

over the GRP joint that had been on the ‘to do’ list for some time. I got some plastic downpipe from Sudbury Roofing

to replace the rotted iron pipe that has been missing for a year – I got the

new ‘cast iron effect’ plastic as it isn’t really visible up in the valley and

its cheaper than the aluminium stuff I have ordered for the rest of the house. I suppose I ought to paint the gutters up

there while I have easy access – more jobs….

Wednesday 28th July – I’m now on my own and doing a

range of jobs so things have slowed down, but today I got up to the valley roof

and banged on a few dozen slates before it started to rain. The valley is not really visible from the

ground so I am using up my Spanish slates, which are perfectly good but a bit

bland in appearance. At least a couple

more days work on this section as I’ve got all the soakers to put in the

corners, and the joint between the 10 x20s and the 12 x 24s to sort out. Yesterday I picked up a load of slabs from

Butler Bros which I think they had mis-identified since I got around 8 sq m of

mellow natural sandstone in 22 x 44 inch slabs for just over £80, which seemed

like a bargain to me.

Slating this week is slow!

Trimming slates – a lot of 12 x 24 s ended

up as 10 x 20 - Spanish slates with small marks over the

surface - I’ve only used them in the

valley where they are not visible from the ground.

Over the weekend I stripped the dairy

window in preparation for repairing it and found, under many layers of white,

grey and beige paint, the word DAIRY painted directly on the oak frame above

the window – faint but quite definite. Its lucky that most of these very old

labels are painted in something that isn’t eaten by paint stripper! I have found several labels on different houses, our last C17 cottage had numbers

on the bedroom doors under all the paint.

Day 19 – Friday – missed putting anything

on the site yesterday. Today was fine

and a bit cloudy – a few small showers.

Ben and Brian arrived to start work at 6.30 as Ben was going on

holiday at midday. Very good progress

on the West elevation, and the valley and bathroom dormer now look superb. In the scrabble to find enough slates I bought some 20 x 11 slates as Butler Bros

had run out of 20 x 10s and I didn’t have time to do a full search. So rather than cut them down to 10 inches

wide we used them in the W valley. If

you know, you can see the difference, but very few people would notice it

unprompted – the original roof was an eclectic mix of 10 x 20s and 12 x 24s so

I think it’s a ’secret’ reference to what was there before. Ben

is now away for a week in Corfu, and may have to do another job for a

few days when he returns, so in order to finish the roof in a reasonable time, I will slate the East

elevation using the better Spanish slates where they won’t show. Ben ‘perped out’ the elevation for me and

set up the gable line, and Brian had graded the slates, so I only have to bang

them up and slip in a few soakers at the far end of the valley and work out how to run the South

part I slated ten years ago with 12 x 24 slates into the new 10 x 20s over the

top of the cross passage. It will be

interesting to see how much slower I am than the professionals. Ben kindly lent

me his special roofing hammer so no excuses about not having the right

tools. Ben and Brian will finish the W

elevation and do the leadwork in 2 or 3 days when they are free. I just have to source another 150 or so

10x20s – its getting boring, I have come to believe that the roofers are eating

them, they go so fast!

The result of today’s and yesterday’s work

– the whole thing is coming together now and you can see what it will look like

when finished. The valley looks good as

it negotiates the change in slope at

the loo outshut, and the bathroom dormer doesn’t look too squeezed up into the

corner – both details have lived up to

my design hopes.

This, and part of the W elevation is all

that remains to do!

Day 17 –Wednesday 22nd July –

Pleasant sunny day with a couple of moments when a few drops of rain might have

fallen but didn’t. Work on the Kitchen

roof continues – the slating of this bit is almost finished except for some of

the top of the valley, and most of the ridge is complete. I decided to

ridge the roofs in lead as the previous ridges were in folded over corrugated

iron or in capping tiles that were

designed for the top of a wall and were the wrong angle for the roof –

they balanced on top and looked very precarious. We cut plain scallops in the ridge lead because it adds visual

interest and makes the ridge look less heavy.

Probably the main ridge will be

plain as it can stand a heavier looking ridge as its higher. Ben did half of the chimney flashing. I went to get more 20 x 10 slates on

Tuesday, and managed to find 330 at Butler Bros in Duxford – a wonderful

reclaimed materials yard. On Wednesday

Brian sorted them and rejected around 30, so I took them back and changed them,

cleaning the yard out of 20 x 10s. We

are now a bit pushed for Welsh slates, and still have the W facing elevation around the dormers and the E

facing main valley between the Victorian and older bit. We will use the ‘cut edge’ Spanish slates in the

unseen parts of the E elevation (most of it) and probably change to the more

chamfered Spanish slates for the top courses on the W elevation. I started cutting down the 24 x 12 slates

I recovered from the previous roof

covering, which was an eclectic mix of 20 x10 and 24 x 12 – even on the same

elevations! So far I’ve cut 80 in about

2 hours, and probably have another 120 to cut down. It’s a bit of a shame to

cut down perfectly good large slates, but needs must! Butler Bros do have a load of 20 x12 and 20 x 11, so if the worst

comes to the worst I can get those and cut them down, but they are

expensive. I discovered that I’d bought code 4 instead of code 5, and

Ben wanted 450mm wide for the chimney flashing so I went back to Suffolk

Roofing and changed 10 rolls of 300mm wide code 4 lead for code 5 in 600mm wide

so the ridge is in one piece, plus some

450mm wide.

Almost complete street view

Valley in S elevation Almost complete N elevation with

chimney flashing.

Bit of a gap in the record as Ben and Brian didn’t come on Monday as they were

fixing a roof that that leaked in the torrential rain at the weekend, and I

forgot to take any photos on Tuesday until it was dark.

Day 15 – Friday 17th July –

Heavy rain in the night and very near Dullingham during the day, but no

more than a few drops here so work progressed - so far we have lost a total of

about 30 minutes work in 3 weeks due to rain.

Ben carried on slating the North elevation valley and preparing the

chimney for flashing. Brian started

slating the South elevation. I cut chamfers on some 6x2 so it would sit on top

of the ridge plate to take the top row of half slates – I burned out my old

portable circular saw in a rather spectacular fashion – it tripped the 40 Amp

cutout on the distribution board, the 32 amp trip in the shed and the 13 Amp

fuse in the plug. The 6x2 was a bit wet

and I was cutting a 40degree chamfer so I

had to take care not to trip out the radial arm saw – but I got around

10m cut – more tomorrow. I went to Long

Melford for MORE lead and copper roofing nails. The ridges will be in code 5 lead – a 300mm strip each side

doubled over the mopstick. Giles glued

and pegged his window frame together.

Brian’s slating on the S elevation –

slated ‘backward’ – i.e. left to right

so it takes a bit longer to do.

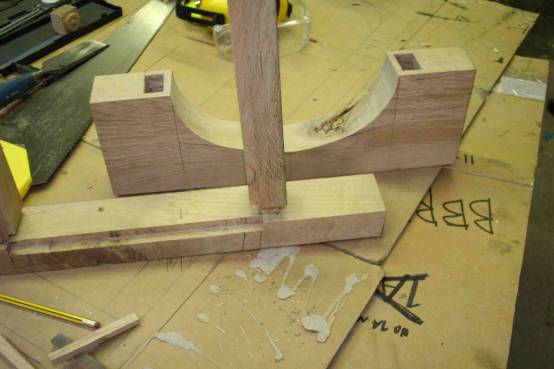

Giles’s window frame progressed !

Day 14 – Thursday 16th July –

pleasantly sunny day here.

Very industrious here today – Ben slating

the valley on the N gable, Brian busy sorting through the various piles of

slates that came from the house or that

I bought 10 years ago for £1.15p each, or the ones I got on ebay recently at

85p each, but which have rather machine cut edges and don’t look right mixed with the others. We shall soon see if I managed to collect

enough to finish the job – there are also a few 12 x 24s that can be cut down

if necessary. I cut up some old oak

for a window frame for the loo, and Giles took over cutting the mortices and

making pegs to hold the frame together.

When the scaffold is removed from over the loo window, we’ll take out

the old window and I’ll get a new opening iron casement made by Dave Gowlett at

Spring Forge, and Tom can try his hand at a stained glass window! Tom spent a couple of hours filling the

skip.

Street facing elevations in rugged slates.

Window frame for 10 inch wide window for loo out of some scraps of seasoned

oak. Giles shaping pegs for the frame.

All that is left of last year’s rubble!

Day 13 – Wednesday 15th

July - A couple of ‘almost’ showers but

otherwise pleasant

Ben continued slating the North elevation

while Brian adjusted and leaded the valley in the South elevation and sorted

slates. Tom and I started loading the

large pile of last year’s builders’ rubble into the skip. I

started to plan the guttering

and the new loo window frame.

Today’s progress – about 500 slates sorted

& fixed and the valley finished – beginning to look like a proper roof

. It must be the first time in 20 years

that there haven’t been holes in this roof!

Giles’s barge board installed.

Day 12 – Tuesday 14th July - fine, threatened showers didn’t

materialise, but it poured in Cambridge.

The whole roof is pretty well battened out

except for a couple of small areas, and Ben started slating the North elevation

while Brian leaded the valley. I went

to Suffolk Roofing Supplies in the morning to buy some Code 5 lead for the

valley and Code 4 for flashing the chimney etc. and 8 Kg of copper roofing nails.

We fitted the barge boards to the West Gable – Giles was quite

uncomplimentary about my mythical eel carving, so it was agreed that he would

carve a ‘proper’ one for the bargeboard on the loo outshut.

Battening, valley leading and some slating

– The slates are the original ones from the roof – good and solid with lovely

ragged edges so the overall effect is not too brash and modern. Note the radiused corners – a feature I am

fond of, although I gather it’s more typical of Cornish roofs than East Anglia. Never mind – we do spend time each year in

Cornwall.

Ben, Tim and Brian fixing the barge board.

Barge boards finally fixed – the joint at

the top fitted perfectly despite the two sides of the roof having different

pitches.

Giles carving his version of the Dullingham

eel for the barge board on the loo outshut.

The family seems weighed down by long hair at the moment!

Day 11 – Monday 13th July – fine

and breezy with a few clouds.

Ben and Brian started today and battened

and sorted the North elevation and the valley roof in short order. The second load of 500m of John Brash

battens arrived from Sudbury Roofing Supplies just in time (ordered Friday p.m.

delivered Monday noon!) – looking at the large pile left over from today’s

work, I think I miscalculated badly and I’ll have enough left over to reroof

the sheds, which I want to do anyway. I had a number of urgent jobs to make

sure that I didn’t hold up the slating -

I finished getting the eaves

over the loo up to the same level as the main roof, and planting a new valley board on top of the

original one, tapering to nothing where the slope changes. I also put in a 4 inch pipe for an extractor

fan and closed up the loo roof ready for battening. My main job after lunch was to make the barge boards for the W

gable end – they match the main gable but in simplified form.

North elevation ready for slates once the

barge boards are up! The original

slates from this elevation and the South side will go back on here – I think we

recovered around 80% from this elevation and a bit less from the South – so you

won’t notice anything has changed!

Most of this pile

of slates has been waiting to go on the roof for the last 9 years! - The result of my mis-ordering of battens!

I’m probably equally overstocked with slates – there are piles everywhere!

Tim carving the Bargeboards from green oak

– they will split and shrink and fade to a silver colour in time so its not a

precision carving job – These have to

go up tomorrow so that the slating can start, so I made them both in one (long)

afternoon. I will have to plane the top

edges straight so that it fits snugly against the slates – didn’t notice how

crooked they were !

The curved edge is copied from an

Elizabethan example at Baddersley Clinton Manor – but I added the mythical eel

heads and tails for a bit of fun.

Day 10 – Friday 10th July Fine

weather and not too hot.

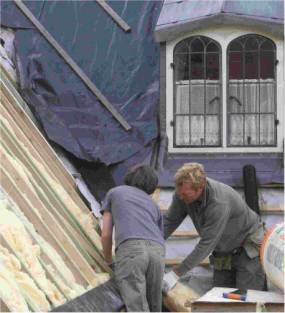

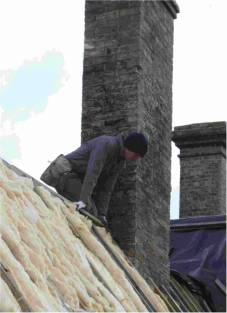

Richard and Jim finished the roof structure

and insulation today – ready for slating by Ben Blows, starting on Monday! The

work was a repeat of yesterday’s insulation, but on the North elevation. Giles took loads of photos – here are a

few;-

Richard’s final sheeting up – just to keep

the covering pristine!

Insulated and counter-battened and ready to

go!

Taping up the covering insulation– we

didn’t think the recommended Duct tape was particularly good and preferred

double sided sticky tape so we used both!

It takes a 3 man team – Richard, Jim and

Tim to get the TLX Gold on neatly.

Again the three strips reached exactly to the ridge – whoever built the

original house must have had TLX in mind.

TLX Gold section from inside : gold

foil, PET wadding, silver foil, wadding, foil, wadding, white outer layer –

total uncompressed thickness 33mm .

There has been some controversy over the effectiveness of multifoil insulation, and it is not

recommended as the sole insulation – so we used it with 100mm of glass wool,

which used up all the available space.

I will only use permeable roofing materials as old houses invariably

have quite a lot of moisture to get rid of, and TLX Gold is the first permeable

multifoil insulation. I would have used

it on the whole house if it had existed when I did the rest!

Day 9 – Thursday 9th July –

threatened to rain occasionally but only a few spots. Now on the home straight!

Giles joined the workforce for the whole

day and we all worked at insulating the South elevation.

Final stage of this part – Richard nailing

the counter battens over the TLX Gold multifoil. Due to extreme good fortune

3 strips of TLX exactly covered the roof with a perfect joint to the

ridge to give a very good breathable

warm roof.

Fitting the TLX Gold breathable multifoil

insulation over the glass wool – this is voted the product of the day – the

first breathable multifoil – we voted it excellent to use after a slight

problem when we unrolled a whole roll at once and the inner foils got displaced! We had to send Giles through the whole 10m length (on the ground!) to sort it out. Here is a rare picture of Tim with Richard – Tim is usually

behind the camera, but this time Giles was the official photographer.

At times it looked a bit dark over Bill’s

Mother’s but didn’t rain. Glass wool

installed.

Richard and Giles installing fibreglass

insulation . Jim at the ridge – this

morning’s hat is a beanie.

Day 8 – Wednesday 8th July – a

few showers but not too bad.

No

pictures today but plenty of work.

Richard and Jim re-worked the South elevation into the valley gutter as

the rafter line that we had started last year by the chimney turned out to be

wrong and we had to pack the rafters to line up with the rest. Richard sprayed the old timber with Boron

insecticide to slow down the woodworm.

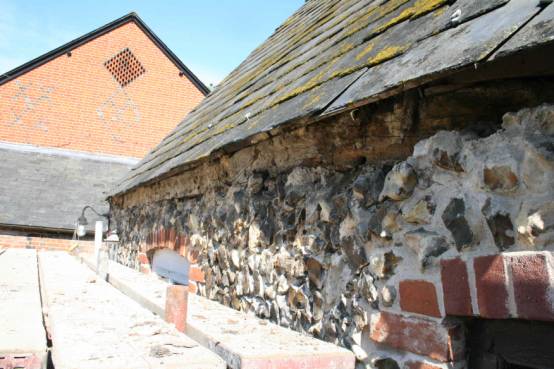

I spent part of the day repairing the flintwork at the top of the North

gable end wall, which wasn’t too difficult as I had the gable rafter to build

flints against.

Day 7 – Tuesday 7th July – more

showers, but still managed to keep on target!

The main structure is now complete with the

top collars that hang the secondary rafters and the lower collars all fixed

with wood fasteners and M10 bolts – ‘the tool of the day’ is a hex shanked socket adaptor to allow a

battery impact driver to tighten bolts using an M17 ½ inch socket. Together

with a heavy duty right-angle drill borrowed from a friendly plumber this made

fixing the collars very quick. The

new roof structure sits over the old

roof – the only connections are a few nails joining the old and new ridge plate

to aid alignment, and a few places where the old rafters were missing on the South elevation and the old collars

and purlin are strapped up to hang from the new lower collars. The new rafters sit on both the old

wallplate, where it is OK, and the added 6x3 oak facing. The secondary rafters are only held onto the

wallplates by light clips so they can settle as the I Beam takes the main load.

Rafters and collars in place with gable

ladder fitted.

Gable end flintwork on South side is now

complete

Gable end – right hand side repaired but

needing mortar cutting back and brushing.

Left hand side showing large missing area

of flintwork – tomorrow’s job if the weather permits.

Day 6 – Monday 6th July –

overcast with a few short heavy showers, but not much time lost.

Despite the weather Richard and Jim managed

to get all the rafters in place and made a start on the collars for the

principle rafters. I put in the

ironwork that supports the I Beam at the gable end.

Richard fixes twin collars to principle rafters - Ironwork I beam gable support

Day 5 – Friday 3rd July – less

hot and a couple of showers that didn’t stop work.

Richard and Jim spent the day putting in

rafters and fixing down the feet of the main loadbearing ones.

I cut and welded 75mm angle to make the I

beam support to transfer load to the

gable end wall. It is ready to be offered up on Monday.

So far there are no fixings between the old

roof and the new roof except the new ridge is nailed on to the old one.

By the end of the first week, half of the rafters are up.

The foot of one of the main75 x150 rafters

– its bolted into the iron-hard oak wallplate next to the old iron tie that

links the wallplates across the walls.

Day 4 – Thursday 2nd July 2009 –

and another very sunny day!

The bulk of the timber for the roof construction

arrived early on, just in time to start on the timber and ply I-beam that forms

the spine of the new roof and from which most of the rafters hang . Richard and Jim prefabricated top and bottom

T beams using 10mm coachscrews and then fixed them to the 18mm ply web in situ

using super strength glue and a nail gun and finished it by lunch time. Aligning it and sorting out the ridge and

rafter lines and cutting the first rafter took the rest of the day. Its now a

matter of completing the 3 principle rafter frames that are part of the

beam support and adding the 20 pairs of

dependent rafters, each with two collars, one on top of the I-beam and one

underneath it, These supplement the old rafters and take the slate load. Its interesting to see my structural design

given shape by Richard and Jim’s expert carpentry.

Loading the pre-fabricated I-beam parts

into the roof.

The giant I-beam in situ - it takes the spreading load off the

wallplates, which are only tied together at the ends and the partition in the

middle.

Jim’s latest headgear fashion – he reckons

the Arabs know a thing or two about sun.

The patch of flint wall I rebuilt yesterday looks better after going over it

with a small plastering tool and a stiff brush,

Day 3 - Wednesday 1st July – another

scorching day!

Today the North wallplate had its facing

beam of 6in x 3 in green oak applied – fitted in 3 pieces as I couldn’t get

long enough pieces (6 metres) to do it in two.

This side took longer than the South side despite not having to patch a

rotten section, because getting it level and keeping the curves gentle was

trickier. While Richard and Jim were

sorting that out, I spent most of the day crouching on the scaffolding poking

mortar and flints into gaps and holes

to give the wallplate and beam a firm seat.

It’s a tedious activity as you seldom have the ‘right’ flint for the

space, and its sometimes quite difficult to get them to stay in place. The only way I have found to do it is by

wearing gloves and applying the mortar by hand so you can push it into small

holes and gaps. The result looks a

complete mess with mortar smeared around the flints – but then when the mortar

has gone green I go back with a small plastering tool and cut the mortar back

so that it forms an angle where it touches the flints, instead of being a

rounded fillet. Then I go over it with an old washing up brush to get rid of

the loose mortar and bring out the larger sand particles. It looks reasonable, but not the same as the

old flinting, which shows virtually no mortar on the face. I don’t really understand how they did it in

the 18th and 19th century. I have been on an English Heritage courses on flintwork and

discussed it with their experts, and they don’t know either. My technique is a variation of the EH flint

re-pointing technique I learnt at West Dean.

1) Jim preparing a joint in the beam, note the stylish headgear – I won’t comment

on the use to which he is putting his

hammer!

2) The North beam in place and ready to

serve as a datum for the rafter feet.

I built up the wall to support the

wallplate in a few vital places. Once

you start trying to clean up the old wall to take a new layer you find that you

have loosened a flint or two. If you

take them out, you find that the old mortar gets in the way of where you want

to put the new flint, so you remove it – then you find that you have loosened a

flint or two…… - before you know it,

you have a large pile of flints and no wall!

So the real skill is in knowing when to stop – you can see this patch

went down quite a way before I found a base to work on. The patch looks better than this now as I’ve

cut back the mortar and brushed the wall.

When this mortar has gone hard in a few days, I’ll remove the car jack

and fill the holes, In some places on the wall someone plastered hard cement

over the flints with a trowel, presumably as a ‘repair’, so this has to be

removed, which also takes a great chunk of wall out! At about ½ to 1 hour per square foot it’s a slow business.

This is the gable end wall – you can see

the construction clearly with an inside plaster layer to the left, then clunch/chalk blocks and finally the flint

facing - total thickness around 15 inches.

On the other side of the gable the wall seems to consist of fewer clunch

blocks and more large flints.

Day 2

Tuesday 30th June 2009.

Yesterday was stripping off and destruction

day – today the wallplate on the South side was tackled . Since the top of the wall is neither

straight nor level, and the existing

wallplate ( where it still exists) is set back by variable amounts from

the flint face, there is no easy way to arrive at a datum for the feet of the

new rafters. So some time was spent head

scratching and measuring and stringing lines, until a plan emerged. I had a old 3m length of oak 150x150 that

filled the gap where the rotten wallplate had been, in the vicinity of the old

window – Richard and Jim got this perfectly tied in to the ends of the

remaining structure. Yesterday I collected enough 150x75 green oak beams to

face the wallplate out to be flush with the face of the flints, as the old

technique of sticking a thin layer of

flints on the outside face of the wallplate doesn’t last well. We are planning to bring the face of the

rafters out – probably by 75 to 100 mm

to allow us to get 150mm deep rafters above the back surface of the old laths –

we can then get in a bit more insulation.

R & J fitted the facing beam

and managed to get a very fair curve right down the roof, fixing it to the

structure with 160mm coach screws. The

new facing beam and the replacement

wallplate are now fixed to the old

structure, but for the most part are suspended in the air – the replacement wallplate is on a car jack,

so my job tomorrow is to build up some

solid support from flint and mortar.

The new facing beam is green oak, and very wet, so it will shrink 5 –10

mm in width and 3 – 6 mm in thickness

over the next 2 to 4 years, so however carefully I pack underneath it with

mortar, there will eventually be a gap.

The wall wobbles in and out a lot more than our facing beam, so the flint won’t be flush along the whole

length.

This is the end result of day 2 – facing

beam on old and replaced wallplate sections.

Jim removing deep bandsaw marks from facing

beams with planer, which you can see is very gently curved.

Another incredibly hot day, but the

occasional breeze.

The new section of wallplate wasn’t quite

long enough so left a gap to be filled with a chunk of seasoned oak.

Missing section of wallplate – and Richard

trimming up the rotten ends with a

chain saw – Richards’s new carpentry discovery!

My discovery this year is a new tarpaulin

that fits the roof and elastic cords with hooks that loop onto the scaffolding

– sheeting up now takes a few minutes – so it saves several man-hours a week

for an outlay of £60!

Day 1

Monday 29th June 2009

5.30 p.m. day 1 – stripped

roof sheeted up.

The old South wallplate is mostly the original oak with pegs where the timber

frame uprights were tenoned in

There is a joint just before the window

head, with the carpenter’s mark II on

the right hand side. All the structure above these wallplates is in softwood –

sawn larch poles or roughly squared

small trunks – and dates from the original slating of the roof – which would

have been at some time after the railways came to Dullingham (1856?) – probably

late 19 or early 20th century.

The oak is in pretty good shape – some surface softening where it has

been covered with haired mortar but still as hard as iron inside. In the foreground wallplate there

has been water ingress – there was a

window in the roof here, which had obviously been letting in water for a long

time as the wallplate had several layers added through its history. I cannot find any clue as to when the roof

was last re-slated. The slates are good

quality (Welsh?) slates but they vary along a course in thickness more than one

would see now . The nails are tapered square copper

nails. I don’t have any definite date for the original timber framed

structure, but the stops on the internal beams look mid to late 17C although

they could be re-used. The stud spacing

is 21 inches, neither narrow studding like the old Guild Hall opposite (15XX)

or square framed – probably OK for 17Century?

I think the whole timber framed house – all the current parts except the

Victorian extension, was flinted around

1800 when Repton was doing a makeover of Dullingham House grounds, at which

time the windows and doors were moved to symmetrical positions. I found one stud still embedded in the

wall, and another with the tenon cut off and left in the mortice in the beam,

so no doubt it was timber framed, almost certainly thatched like the rest of

the old house was before slate took over.

Poking away at the loose flints reveals 3

layers of wall plate here – each one rotted through then with another bit

shoved on top – plan to put in a solid piece of oak 3m long.

I fetched 28m of 150 x 75 oak beams to face

/ reinforce the wallplates today, tomorrow’s job is to fix them.

June 26th 2009 and things are

moving at last!

The work being done is a joint effort

between me (Tim Owen, joint owner of

Cables Farm) and Richard Barker and Jim – carpenters and general experts in

wood construction who are happy to work with Tim as a very effective team. Ben Blows is lined up to do the slating when

all is ready.

So it looks like no more tarpaulins and

plastic sheets after this summer – I am already suffering from withdrawal

symptoms – like loosing an old friend.

Still, there is a load more work inside, and all the shed roofs to do,

so perhaps its not over yet.

A major burst of activity is in progress

now! ( June 2009).

The main N-S roof was rebuilt last year,

along with work on the landing and bathroom and fibreglassing of a large valley

above the landing ceiling. I also replaced the two ground floor windows in the

Gable end with oak framed leaded windows I made, with iron casements made by

Dave Gowlett at Springwell Forge in Ugley.

This year so far I have leaded the two

remaining dormers that we built last year and put oak Barge Boards on the N gable and replaced the remaining window

in the first floor of the gable end. We

are now beginning to strip and rebuild the roof above the kitchen, having

partly cleared the attics for action.

These pictures below were taken on 26 June 2009 as we prepare to strip the roof.

This is the current project area!

Compare this with the picture below – there

has been some progress in the last few years – most of it under the plastic!

This picture was taken in 2005!

I rather like this state, although others

thought it was a bit too much!

After a few years like this the local

Conservation Officer kindly put us on the ‘Buildings at Risk Register’ which

meant we were eligible for a grant – although we didn’t take it up – she has

now taken us off the Register.

New Barge Boards and new bedroom window.

The Barge board design is loosely copied

from those at the Elizabethan Manor House of Baddersley Clinton at Knowle – the

National Trust kindly gave me a tracing of a sample.

Every time you go near the tops of the

flint walls at wallplates and gable ends, you end up having to sort out masses

of flintwork that comes away as you look at it – its quite absorbing crouching

on the scaffolding with a big pile of flints and a bucket of lime mortar ( St

Astier 2.5 + 2 parts sharp sand and a

bit of febmix) – its like doing a giant jigsaw puzzle upside down when you have

a pile of pieces taken at random from dozens of puzzles. You never seem to have anywhere near the

shape of flint you need – you realise that flints come in an infinite variety, which I suppose is obvious but

frustrating nevertheless! You end up

getting off the scaffold and trying to hunt down a few of the ‘right’ shaped

flints.

This

window has now been replaced – no yet pictures as its all in the scaffolding.

kitchen

was due for an upgrade! - now

re-plastered in lime plaster and painted with limewash

this

dormer has been replaced !

window

of old dairy / game larder – still to do.

back

window of old dairy / game larder still to do.

Cables Farm Home Page | Top of picture page |